SIST EN 14250:2010

(Main)Timber structures - Product requirements for prefabricated structural members assembled with punched metal plate fasteners

Timber structures - Product requirements for prefabricated structural members assembled with punched metal plate fasteners

This European Standard specifies material, product and documentation requirements for prefabricated structural members (e.g. trusses for roofs, walls and floors, frames, composite beams and girders) for use in buildings made from solid structural timber according to EN 14081-1 with or without finger joints assembled with punched metal plate fasteners.

The standard also covers tests and/or calculation methods to carry out the evaluation of conformity and requirements for the marking of these members.

As regards resistance to biological organisms, this standard covers prefabricated structural members manufactured from either untreated timber or timber treated to improve its natural durability.

This standard does not cover prefabricated timber structural members intended to be used in constructions under predominantly dynamic loads (e.g. bridges) or for use in unprotected external conditions (i.e. use class 3 in accordance with EN 335-1).

Furthermore, it does not cover members treated to improve their fire performance.

Holzbauwerke - Produktanforderungen an vorgefertigte tragende Bauteile mit Nagelplattenverbindungen

Diese Europäische Norm legt die Werkstoff-, Produkt- und Dokumentationsanforderungen an vorgefertigte tragende Bauteile (z. B. Fachwerkträger für Dächer, Wände und Decken sowie Rahmen, Verbundbalken und Träger) fest, die aus Bauvollholz nach EN 14081-1 mit oder ohne Keilzinkenverbindungen unter Verwendung von Nagelplatten gefertigt werden und die für die Verwendung in Gebäuden bestimmt sind.

Dieses Dokument gilt für Fachwerkträger mit Längen bis 35 m und für weitere vorgefertigte tragende Bauteile mit Spannweiten bis 12 m.

Diese Norm enthält auch Prüf- und/oder Berechnungsverfahren zur Durchführung der Konformitätsbeurteilung, Kennzeichnung dieser Bauteile und zu Bedingungen im Freien (Nutzungsklasse 3 nach EN 1995-1-1 oder Gebrauchsklasse 3, 4 und 5 nach EN 335-1).

Bezüglich der Widerstandsfähigkeit gegen biologische Organismen behandelt diese Norm vorgefertigte tragende Bauteile, die entweder aus unbehandeltem Holz hergestellt sind, oder aus Holz, das behandelt wurde, um seine natürliche Haltbarkeit zu verbessern.

Diese Norm behandelt keine vorgefertigten tragenden Bauteile, die zur Verwendung in Anlagen unter vorwiegend dynamischen Belastungen (z. B. für Brücken) oder unter ungeschützten Bedingungen im Freien (d. h. Gebrauchsklasse 3 nach EN 335-1) vorgesehen sind.

Ebenso nicht enthalten sind Bauteile, die behandelt wurden, um das Verhalten im Brandfall zu verbessern.

Structure en bois - Exigences de produit relatives aux éléments de structures préfabriqués utilisant des connecteurs a plaque métallique emboutie

La présente norme spécifie les exigences de matériau, de produit et de documentation relatives aux éléments

de structure préfabriqués (par exemple, fermes pour toits, murs et planchers, cadres, poutres et poutrelles

composites) destinés à être utilisés dans des bâtiments fabriqués à partir d’éléments en bois de structure

conformément à l’EN 14081-1 avec ou sans aboutages à entures multiples, assemblés au moyen de

connecteurs à plaque métallique emboutie.

Ce document est valable pour les fermes de longueur jusqu’à 35 m et pour d’autres éléments préfabriqués de

structure avec des portées jusqu’à 12m.

Cette norme traite également des méthodes d’essai et/ou de calcul servant à l’évaluation de la conformité,

des exigences pour le marquage de ces éléments, et des conditions extérieures (classe de service 3 selon

EN 1995-1-1 ou classes d’emploi 3,4 et 5 selon EN 335-1).

En ce qui concerne la résistance vis à vis des organismes biologiques, la présente norme traite des éléments

de structure préfabriqués soit à partir de bois non traité, soit à partir de bois traité afin d’améliorer sa durabilité

naturelle.

La présente norme ne traite pas des éléments de structure préfabriqués en bois destinés à être utilisés dans

des constructions soumises de manière prédominante à des charges dynamiques (par exemple des ponts) ou

pour une utilisation dans des conditions extérieures non protégées (c’est à dire classe d’emploi 3 selon l’EN

335-1).

De plus, la norme ne couvre pas les éléments traités afin d’améliorer leur performance au feu.

Lesene konstrukcije - Zahteve za proizvodnjo predhodno izdelanih konstrukcijskih elementov s kovinskimi ježastimi ploščami

Ta evropski standard določa zahteve glede materiala, proizvodov in dokumentacije za proizvodnjo predhodno izdelanih konstrukcijskih elementov (npr. nosilnih tramovov za strehe, stene in tla, okvirjev, sestavljenih gredi in tramov) za uporabo v stavbah, ki so izdelani iz trdnega konstrukcijskega lesa v skladu z EN 14081-1 z ali brez spojev z zobci, s kovinskimi ježastimi ploščami. Ta dokument se uporablja za nosilne tramove dolžin do 35 m in za druge predhodno izdelane konstrukcijske elemente z razponi do 12 m. Standard zajema tudi metode za preskušanje in/ali izračun za izvedbo ocene skladnosti, zahteve za označevanje teh elementov in zunanje pogoje (razred storitve 3 v skladu z EN 1995-1-1 ali razredi uporabe 3, 4 in 5 v skladu z EN 335-1). Glede odpornosti proti biološkim organizmom ta standard zajema predhodno izdelane konstrukcijske elemente iz bodisi neobdelanega lesa ali lesa, ki je obdelan zaradi izboljšanja njegove naravne trajnosti. Ta standard ne zajema predhodno izdelanih lesenih konstrukcijskih elementov, namenjenih za uporabo pri konstrukcijah pod pretežno dinamičnimi obtežbami (tj. mostovih) ali za uporabo v nezaščitenih zunanjih pogojih (tj. razred uporabe 3 v skladu z EN 335-1). Poleg tega ne zajema elementov, ki so obdelani zaradi izboljšanja njihove požarne odpornosti.

General Information

- Status

- Published

- Public Enquiry End Date

- 29-Nov-2007

- Publication Date

- 13-Apr-2010

- Technical Committee

- KON - Structures

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 02-Feb-2010

- Due Date

- 09-Apr-2010

- Completion Date

- 14-Apr-2010

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 01-May-2010

Overview

EN 14250:2010 - published by CEN - defines product, material and documentation requirements for prefabricated timber structural members assembled with punched metal plate fasteners (commonly used in trusses, frames, composite beams and girders). The standard applies to members made from solid structural timber (with or without finger joints) and sets out testing, conformity assessment and marking rules. Typical size limits: trusses up to 35 m and other members with spans up to 12 m.

Key exclusions:

- Not intended for structures under predominantly dynamic loads (e.g. bridges).

- Not for unprotected external use in harsh exposure (use class 3 per EN 335-1).

- Does not cover members treated specifically to improve fire performance.

Key topics and requirements

- Material requirements

- Timber must be strength-graded in accordance with EN 14081-1 (including dimensional defect limits).

- Finger-jointed timber must meet prEN 15497.

- Resistance to biological organisms: untreated timber or preservative-treated timber with declared durability per EN 350-2 / EN 15228.

- Connectors

- Punched metal plate fasteners shall comply with EN 14545; corrosion protection must be compatible with any timber preservative used.

- Performance characteristics

- Mechanical resistance (load-bearing capacity and stiffness) must be determined and declared - by testing, calculation or reference to design drawings and valid national methods.

- Reaction to fire classification according to EN 13501-1; relevant test methods (e.g. EN 13823) and CWFT provisions are referenced.

- Conformity & quality control

- Procedures for initial type testing, factory production control (FPC), initial factory inspection and ongoing surveillance are specified.

- Marking and CE‑marking requirements are addressed (see Annex ZA for links to EU Construction Products Regulation).

Practical applications and users

Who benefits from EN 14250:2010:

- Timber truss and prefabricated component manufacturers

- Structural engineers and designers specifying prefabricated timber members

- Building product certifiers and notified bodies assessing conformity and CE marking

- Contractors and specifiers wanting documented performance for load-bearing timber components

Practical uses:

- Defining manufacture and QA processes for prefabricated roof, wall and floor trusses

- Demonstrating declared load-bearing capacities and stiffness for design checks

- Ensuring connector compatibility with timber treatments and required durability

Related standards (selected)

- EN 14081-1 - Strength graded structural timber

- EN 14545 - Connectors: requirements for punched metal plate fasteners

- EN 13501-1 / EN 13823 - Reaction to fire classification and tests

- EN 350-2, EN 15228 - Durability and preservative treatment

- EN 1995 (Eurocode 5) - Design of timber structures

EN 14250:2010 is essential for compliant production and documentation of prefabricated timber members assembled with punched metal plate fasteners, ensuring safe, durable and CE‑marked timber structural products.

Frequently Asked Questions

SIST EN 14250:2010 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Timber structures - Product requirements for prefabricated structural members assembled with punched metal plate fasteners". This standard covers: This European Standard specifies material, product and documentation requirements for prefabricated structural members (e.g. trusses for roofs, walls and floors, frames, composite beams and girders) for use in buildings made from solid structural timber according to EN 14081-1 with or without finger joints assembled with punched metal plate fasteners. The standard also covers tests and/or calculation methods to carry out the evaluation of conformity and requirements for the marking of these members. As regards resistance to biological organisms, this standard covers prefabricated structural members manufactured from either untreated timber or timber treated to improve its natural durability. This standard does not cover prefabricated timber structural members intended to be used in constructions under predominantly dynamic loads (e.g. bridges) or for use in unprotected external conditions (i.e. use class 3 in accordance with EN 335-1). Furthermore, it does not cover members treated to improve their fire performance.

This European Standard specifies material, product and documentation requirements for prefabricated structural members (e.g. trusses for roofs, walls and floors, frames, composite beams and girders) for use in buildings made from solid structural timber according to EN 14081-1 with or without finger joints assembled with punched metal plate fasteners. The standard also covers tests and/or calculation methods to carry out the evaluation of conformity and requirements for the marking of these members. As regards resistance to biological organisms, this standard covers prefabricated structural members manufactured from either untreated timber or timber treated to improve its natural durability. This standard does not cover prefabricated timber structural members intended to be used in constructions under predominantly dynamic loads (e.g. bridges) or for use in unprotected external conditions (i.e. use class 3 in accordance with EN 335-1). Furthermore, it does not cover members treated to improve their fire performance.

SIST EN 14250:2010 is classified under the following ICS (International Classification for Standards) categories: 91.080.20 - Timber structures. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14250:2010 has the following relationships with other standards: It is inter standard links to SIST EN 14250:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14250:2010 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/112. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14250:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.NRQVWUXNFLMVNLKHolzbauwerke - Produktanforderungen an vorgefertigte tragende Bauteile mit NagelplattenverbindungenStructure en bois - Exigences de produit relatives aux éléments de structures préfabriqués utilisant des connecteurs a plaque métallique emboutieTimber structures - Product requirements for prefabricated structural members assembled with punched metal plate fasteners91.080.20Lesene konstrukcijeTimber structuresICS:Ta slovenski standard je istoveten z:EN 14250:2010SIST EN 14250:2010en,fr01-maj-2010SIST EN 14250:2010SLOVENSKI

STANDARDSIST EN 14250:20051DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14250

January 2010 ICS 91.080.20 Supersedes EN 14250:2004English Version

Timber structures - Product requirements for prefabricated structural members assembled with punched metal plate fasteners

Structure en bois - Exigences de produit relatives aux éléments de structures préfabriqués utilisant des connecteurs à plaque métallique emboutie

Holzbauwerke - Produktanforderungen an vorgefertigte tragende Bauteile mit Nagelplattenverbindungen This European Standard was approved by CEN on 3 December 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14250:2010: ESIST EN 14250:2010

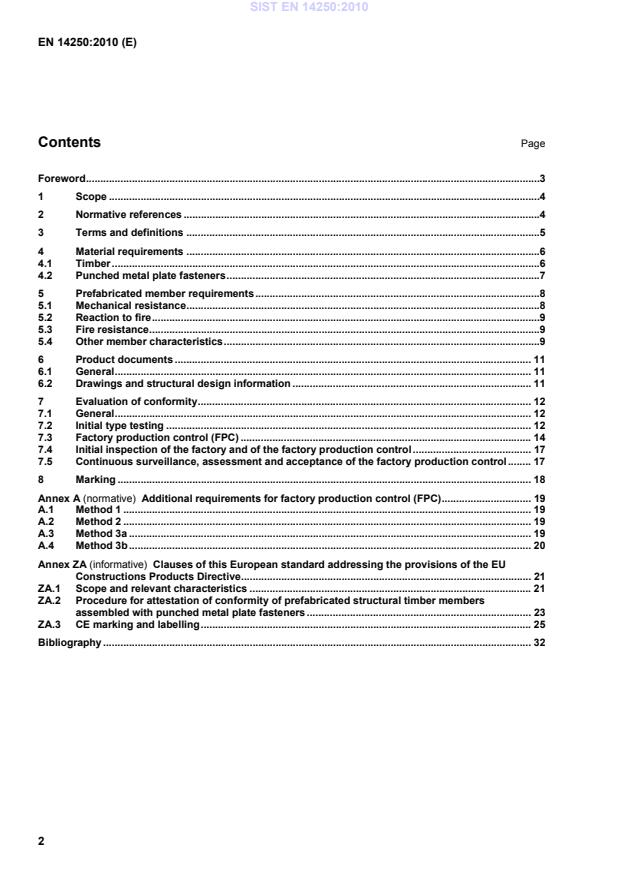

Additional requirements for factory production control (FPC) . 19A.1Method 1 . 19A.2Method 2 . 19A.3Method 3a . 19A.4Method 3b . 20Annex ZA (informative)

Clauses of this European standard addressing the provisions of the EU Constructions Products Directive . 21ZA.1Scope and relevant characteristics . 21ZA.2Procedure for attestation of conformity of prefabricated structural timber members assembled with punched metal plate fasteners . 23ZA.3CE marking and labelling . 25Bibliography . 32 SIST EN 14250:2010

Furthermore, it does not cover members treated to improve their fire performance.

2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 335-1, Durability of wood and wood-based products — Definition of use classes — Part 1: General EN 335-2, Durability of wood and wood-based products — Definition of use classes — Part 2: Application to solid wood EN 336:2003, Structural timber — Sizes, permitted deviations EN 350-2, Durability of wood and wood-based products — Natural durability of solid wood — Part 2: Guide to natural durability and treatability of selected wood species of importance in Europe EN 844-3, Round and sawn timber — Terminology — Part 3: General terms relating to sawn timber EN 844-9:1997, Round and sawn timber — Terminology — Part 9: Terms relating to features of sawn timber EN 1310, Round and sawn timber — Method of measurement of features EN 1990, Eurocode — Basis of structural design EN 1991 (all parts), Eurocode 1 — Actions on structures EN 1995-1-1, Eurocode 5: Design of timber structures — Part 1-1: General — Common rules and rules for buildings EN 1995-1-2, Eurocode 5: Design of timber structures — Part 1-2: General — Structural fire design EN 13183-2, Moisture content of a piece of sawn timber — Part 2: Estimation by electrical resistance method SIST EN 14250:2010

EN 15228, Structural timber — Structural timber preservative treated against biological attack prEN 15497, Finger jointed structural timber — Performance requirements and minimum production requirements EN ISO 9001:2008, Quality management systems — Requirements (ISO 9001:2008) 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 anchorage area surface area of timber occupied by the plate projections in any particular member 3.2 batch all the structural members produced according to the same specifications in one shift 3.3 dead knot knot that on the considered surface is intergrown with the surrounding wood for less than one quarter of the cross-sectional perimeter, as defined in EN 844-9:1997 3.4 effective thickness/width actual thickness/width as defined in EN 336:2003 minus any wane present on the edge being considered 3.5 internal bracing element to prevent lateral buckling of a compression member 3.6 live knot

intergrown knot knot that on the considered surface is intergrown with the surrounding wood for more than three quarters of the cross-sectional perimeter as defined in EN 844-9:1997 3.7 plate projection plate tooth, plate nail or burst used for the purpose of transferring forces between members SIST EN 14250:2010

Timber complying with EN 14081-1 shall be deemed to satisfy requirements for performance of this characteristic. In addition preventive structural measures suitable for the protection from biological infestation with fungi and insects should be taken into account. NOTE Dimensional stability of the member is given as the swelling and shrinkage of timber due to changes of its moisture content in perpendicular to grain and parallel to grain direction. 4.1.4 Reaction to fire The class of reaction to fire performance of the structural timber used for the prefabricated member (including the additional classification on smoke production and flaming droplets/particles, if any) shall be determined and declared according to EN 13501-1: a) either without the need for further testing (CWFT), as given in Table 11), if the timber is proved to meet the requirements of the class given therein for timber without preservative treatment as well as for preservative treated timber when the preservative treatment does not result, when dry, in an addition in the analytical zone of the treated timber of more than 2 % by mass of organic material; or

1) This table is the same as given in the Decision of the Commission 2003/43/EC of 2003-01-17 (see OJEU L 13 of 2003-01-18), as amended firstly by 2003/593/EC of 2003-08-07 (see OJEU L 201 of 2003-08-08), secondly by 2006/673/EC of 2006-10-05 (see OJEU L 276 of 2006-10-07) and thirdly by 2007/348/EC of 2007-05-15 (see OJEU L 131 of 2007-05-23), and corrected by the Corrigendum (see OJEU L 33 of 2003-02-08). SIST EN 14250:2010

c) the whole area of both wings in the SBI apparatus shall be covered with timber pieces mounted edge to edge (butt jointed), without jointing or bonding and orientated horizontally or vertically, supported by d) timber battens, minimum 40 mm × 40 mm, fixed to the test backing boards at 400 mm to 600 mm centres horizontally or vertically (perpendicular to the orientation of the timber pieces).

Table 1 – Structural timber considered as classified without the need for further testing (CWFT) Producta

Product details Minimum mean densityc

kg/m3 Minimum overall thickness mm Classb

(excluding floorings) Structural timber Visual and machine graded structural timber with rectangular cross-sections shaped by sawing, planning or other methods 350 22 D-s2, d0 a Applies to all species covered by the product standards. b Class as provided for in Table 1 of the Annex to Decision 2000/147/EC. c Conditioned according to EN 13238.

4.1.5 Resistance to biological organisms 4.1.5.1 Timber without preservative treatment The timber shall have adequate natural durability in accordance with EN 350-2 for the intended use class as defined in EN 335-1 and EN 335-2 and the durability class shall be declared. 4.1.5.2 Timber with preservative treatment If preservative treated timber is used, the durability class, type of preservative, critical retention value and penetration class in accordance with EN 15228 shall be declared.

4.2 Punched metal plate fasteners The fasteners used for prefabricated timber structural members shall comply with EN 14545. In addition, if the timber is preservative treated against biological organisms, the fasteners treatment against corrosion shall be compatible with the preservative used. NOTE When timber is treated with substances which cause corrosion (e.g. copper salts or organic substances) connectors made of austenitic stainless steel or galvanized (Z275 or Z350) can be used in use classes 1 and 2. SIST EN 14250:2010

load-bearing capacity; and

stiffness (declared normally as deflection for a specified load/unit load). Influence of preservative treatment on mechanical resistance shall be assessed according to EN 15228. 5.1.2 Determination and declaration The mechanical resistance (i.e. load-bearing capacity and stiffness) of the prefabricated structural member shall be determined and declared according to one of the following methods: a) Method 1: By reference to dated drawings of the structural member with information on the geometrical data and reference to the material properties of the structural components and punched metal plate fasteners used, necessary to calculate characteristic load-bearing capacities and stiffness according to method(s) valid in the Member State of the intended use of this structural member. NOTE 1 This method is assumed to reflect Method 1 in Guidance Paper L. By this method the characteristic mechanical resistance is indirectly declared. It may be relevant for a structural member manufactured according to the manufacturer's specification and put on the market, e.g. on the retailer shelves, without necessarily knowing the works where the member is going to be used. b) Method 2: Directly, by calculating the characteristic values or design values for the load-bearing capacities and stiffness of the structural member according to the method(s) given in EN 1995-1-1 with possibly reference to the used sets of National Determined Parameters (NDPs), if any, valid in the Member State of the intended use of the structural member. NOTE 2 This method is assumed to reflect Method 2 in Guidance Paper L. By this method the characteristic mechanical resistance is directly declared. It may be relevant for a structural member manufactured according to the manufacturer's specification and put on the market without necessarily knowing the works where the member is going to be used, e.g. for catalogue products, like trussed beams. c) Method 3a: By declaring compliance with the given production documents of the structural member, together with the information on the purchaser and the party responsible for the structural design of the member.

NOTE 3 This method is assumed to reflect Method 3a in Guidance Paper L. By this method the characteristic mechanical resistance is indirectly declared. It may be relevant for a structural member made to measure according to the purchaser’s order. d) Method 3b: By declaring compliance with a given structural design specification of the structural member produced and held by the manufacturer showing that the member is able to resist all the relevant actions affecting it in the ultimate limit state and satisfies specified serviceability requirements in a specific part of works. Structural design specification of the member is based on information (e.g. actions and deflection limits) from a specific part of works according to the design requirements in the Member State of its intended use (EN 1990, EN 1991 and EN 1995-1-1), with possibly reference to the relevant National Annexes defining the National Determined Parameters/method(s) valid in the Member State of the intended use of the structural member. NOTE 4 This method is assumed to reflect Method 3b in Guidance Paper L. By this method the characteristic mechanical resistance is indirectly declared. It may be relevant for a structural member made to measure according to the structural design specification prepared by the manufacturer when the works where the member will be used is known. SIST EN 14250:2010

a) tested in end-use condition in accordance with test standards given in EN 13501-2; or b) calculated according to EN 1995-1-1 and EN 1995-1-2. 5.4 Other member characteristics 5.4.1 Timber sizes and tolerances Size tolerances of the structural member shall as a minimum be in accordance with tolerance class 2 given in EN 336:2003. Timber sizes shall be not less than:

thickness (width), all members: 35 mm;

depth, external (chord) members: 68 mm;

depth, internal (web or diagonal) members: 58 mm. The effective thickness, as defined in 3.4, of the outer face of any chord member shall not be less than 35 mm. Any damage due to handling of the structural member shall be prevented:

either by applying EN 1995-1-1; or

by using the following minimum thickness requirement "b", in millimetres (mm), for the members:

kmflb,²8,1= where l is the overall length of the member, in metres (m); fm,k is the characteristic bending strength of the member, in Newtons per square millimetre (N/mm2). NOTE Attention should be drawn on the influence of thickness of structural members on their out-of-plane behaviour. This aspect should be addressed in the design, especially when the structural members are subject to high loads. 5.4.2 Wane Wane shall not occur within the area of any jointing device or within support areas of the prefabricated timber structural member.

5.4.3 Joint gaps Within the area of the fastener, the average gap between two adjacent parts of the prefabricated timber structural members at the time of fabrication shall not exceed 1,5 mm. SIST EN 14250:2010

dimensions up to and including 10 m: ± 10 mm;

dimensions more than 10 m: ± 1 mm/m. The dimensional variation between members within the same batch shall not differ by more than 10 mm. 5.4.6 Dimensional stability If required, swelling and shrinkage of prefabricated structural members shall be calculated according to EN 1995-1-1, using the material properties given in 4.1.3. NOTE Dimensional stability of the member is given as the swelling and shrinkage of timber due to changes of its moisture content in perpendicular to grain and parallel to grain direction. 5.4.7 Camber At the time of fabrication of the timber structural member, camber shall be within a tolerance of 25 % of the camber specified in the design. 5.4.8 Live knots Live knots shall be permitted within the anchorage area of the prefabricated timber structural member, provided that the plate projections are satisfactorily embedded without visible distortion of the fasteners or splitting of the timber outside the knot.

5.4.9 Dead knots, knot holes or fissures Where a dead knot, knot hole, or fissure occurs within the anchorage area of the prefabricated timber structural member, the area of effective plate projections, disregarding those in the dead knot, knot hole or on the line of the fissure shall be in accordance with that specified in the design. Fissures which do not extend more than 50 mm from the tooth, burst or plate nail which apparently caused them, shall be disregarded. 5.4.10 Fastener positioning Fasteners used for the prefabricated timber structural member shall not be misplaced by more than the amount considered in the structural design and not more than 10 mm in any direction in relation to the design position.

5.4.11 Fastener embedment The plate projections of the fastener shall be inserted perpendicular to the embedment surface of the timber and the plate surface shall be free of distortion. Any gap between the timber surface and the underside of a punched metal plate fastener shall not exceed 1 mm and shall not occur over more than 25 % of the anchorage area in any prefabricated timber structural member in any joint. SIST EN 14250:2010

NOTE It is important that consideration is given to masking of protruding corners of fasteners, particularly those that protrude into walk spaces or other areas permitting access. 6 Product documents 6.1 General Adequate drawings and written instructions shall be provided with the prefabricated members relating to their transport, handling, storage, erection, positioning and internal bracing, together with any fixing details necessary to construct compound or multi-part structures. 6.2 Drawings and structural design information 6.2.1 Drawings

The drawings of the prefabricated timber structural member shall as a minimum contain:

the main dimensions and tolerance classes;

the cross section sizes and strength grades of the timber components;

the punched metal plate type, size, orientation and position on each joint;

the punched metal plate fastener assembly tolerance;

precamber, if any;

connections to be done on the building site including other fastener types and sizes;

position of supports and minimum support lengths;

the requirements on bracing of compressed components;

notation of points suitable for hanging to crane;

spacing of members;

treatment with timber preservatives against biological attack and durability class. 6.2.2 Structural design documentation When the structural design of the prefabricated member is covered (i.e. Method 2 or 3b) the following information shall be provided in addition to the drawing of the member: a) Method 2: 1) the design codes that have been used to verify the design (EN 1995-1-1); 2) the design software used, if any, unambiguously identified; 3) designer responsible for the structural design of the member; SIST EN 14250:2010

2) the place of use of the member; 3)

the design software used, if any, unambiguously identified; 4) designer responsible for the structural design of the member; 5) all the actions (loads) imposed on the member;

6) requirements for the serviceability limit states (i.e. deflection limits); 7) material values necessary as input for calculation; 8) safety factors and other NDPs, if any, used in the calculation; 9) calculation results. 7 Evaluation of conformity 7.1 General The conformity of a prefabricated timber structural member with the requirements of this European Standard and with the stated values shall be demonstrated by: a) initial type testing; b) factory production control by the manufacturer, including member assessment. For the purposes of testing, the manufacturer's members may be grouped into families, where it is considered that the results for one or more characteristics from any one member within the family are representative for the same characteristics for all the members within that same family. 7.2 Initial type testing

7.2.1 General An initial type test is the complete set of tests or other procedures, in respect of the characteristics to be assessed, determining the performance of samples of member representative (see Notes 1 and 2 hereafter) of the product type. NOTE 1 For prefabricated structural members assembled with punched metal plate fasteners a product range may be introduced to simplify the ITT (ITC) and FPC. The product range may cover similar members with different cross sections and spans (e.g. trusses for saddle roof or trusses with constant height).

NOTE 2 Typical products are controlled for made-to-measure prefabricated structural members assembled with punched metal plate fasteners. Typical products represent the members produced and designed using the same methods. If these methods are changed, then additional typical product is needed. SIST EN 14250:2010

at the beginning of the production of a prefabricated structural members design;

at the beginning of a new or modified method of production or when the raw materials or the supplier of components are changed. In case of the initial type testing of prefabricated structural members for which type testing in accordance with this standard was already performed, the initial type testing may be reduced, if:

it has been established that the performance characteristics compared with the already tested prefabricated structural members have not been affected; or

it is in accordance with the rules for families and/or direct or extended application of test results. Where components are used, whose characteristics have already been determined, by the component manufacturer, on the basis of conformity with other technical specifications, these characteristics need not be reassessed provided that the components' performance or method of assessment remain the same, that the characteristics of the component are suitable for the intended end use of the prefabricated structural member, and insofar as the manufacturing process does not have a detrimental affect on the determined characteristics. Products or components CE marked in accordance with appropriate harmonised European specifications, used in the production of the structural member, may be presumed to have the performances stated with the CE marking, although this does not replace the responsibility of the manufacturer of the prefabricated structural member to ensure that the member complies with the additional requirements given in this standard and its components have the necessary performance values to meet the design. All characteristics in Clauses 4 and 5 shall be subject to initial type testing of the member where relevant.

7.2.2 Use of previously existing data Tests previously performed on the same members in accordance with the provisions of this standard (i.e. same characteristic(s), test method, sampling procedure, system of attestation of conformity, etc.) may be taken into account for the purpose of ITT. 7.2.3 "Deemed to satisfy" provisions and use of reference tabulated data In those cases where conformity with this standard is based on classified without the need for further testing (CWFT) the initial type testing shall be limited to the verification of whether the members meet the requirements to use those values, classes or levels, unless better values, classes or levels are being claimed. 7.2.4 ITT reports The results of the ITT (including ITC) shall be recorded in a "report". The report shall at least include the following information: a) manufacturer and manufacturing plant; b) identification of the member in accordance with this European Standard; c) information about: 1) sampling; 2) date of verification; 3) involved personnel; SIST EN 14250:2010

d) identification of the organisation and personnel executing the verification; e) place and date; f) the results of the verification, including analysis of these, when relevant; g) place and date of the delivery of the report. The ITT report shall comply with the relevant clauses of this European Standard.

7.3 Factory production control (FPC)

7.3.1 General The manufacturer shall establish, document and maintain an FPC system to ensure that the members placed on the market conform to the declared performance characteristics. The FPC system shall consist of written procedures (works' manual), regular inspections and tests and/or assessments and the use of the results to control raw and other incoming materials or components, equipment, the production process and the member. Records shall remain legible, readily identifiable and retrievable. An FPC system conforming with the requirements of EN ISO 9001:2008 and made specific to the requirements of this standard shall be considered to satisfy the above requirements. The results of inspections, tests or assessments requiring action shall be recorded, as shall any action taken. The action to be taken, when control values or criteria are not met, shall be recorded and retained for the period specified in the manufacturer’s FPC procedures. 7.3.2 FPC requirements for all manufacturers The manufacturer shall establish procedures to ensure that the production tolerances allow for the prefabricated structural member's performances to be in conformity with the declared values, derived from initial type testing. The manufacturer shall record the results of the tests specified above. These records shall at least include the following information:

identification of the member tested;

the date of sampling and testing;

the test methods performed;

the test results. 7.3.3 Manufacturer-specific FPC system requirements 7.3.3.1 Personnel The responsibility, authority and the relationship between personnel that manages, performs or verifies work affecting member conformity, shall be defined. This applies in particular to personnel that need to initiate actions preventing product non-conformities from occurring, actions in case of non-conformities and to identify and register member conformity problems. Personnel performing work affecting member conformity shall be competent on the basis of appropriate education, training, skills and experience for which records shall be maintained. SIST EN 14250:2010

In case supplied components are used, the attestation of conformity level of the component shall be at least that given in the appropriate harmonised technical specification for that component. If this is not the case, the inspection scheme shall be adequate to demonstrate their suitability. When following the reaction to fire CWFT-procedure the minimum requirements for timber are ensured by prescribing timber density and measuring timber sizes. Minimum density and size requirements shall be fulfilled in addition to ITT also during FPC. 7.3.3.5 In-process control The manufacturer shall plan and carry out production under controlled conditions. Compliance with EN ISO 9001:2008, 7.5.1 and 7.5.2, shall be deemed to satisfy the requirements of this subclause. 7.3.3.6 Traceability and marking Individual members, member batches or packages shall be identifiable and traceable with regard to their production origin. The manufacturer shall have written procedures ensuring that processes related to affixing traceability codes and/or markings are inspected regularly. Compliance with EN ISO 9001:2008, 7.5.3, shall be deemed to satisfy the requirements of this subclause. 7.3.3.7 Non-conforming members The manufacturer shall have written procedures which specify how non-conforming members shall be dealt with. Any such events shall be recorded as they occur and these records shall be kept for the period defined in the manufacturer's written procedures. Compliance with EN ISO 9001:2008, 8.3, shall be deemed to satisfy the requirements of this subclause. 7.3.3.8 Corrective action The manufacturer shall have documented procedures that instigate action to eliminate the cause of non-conformities in order to prevent recurrence. Compliance with EN ISO 9001:2008, 8.5.2, shall be deemed to satisfy the requirements of this subclause. SIST EN 14250:2010

4) geometrical defects (see 4.1.1, b)); 5) moisture content (see 5.4.4); 6) resistance to biological organisms, if any (see 4.1.5); b) at beginning of assembly: 1) fastener type, thickness and size (see 4.2); 2) fastener positioning, orientation and installation (see 5.4.10, 5.4.11 and 5.4.12); 3) joint gap (see 5.4.3); 4) wane and knots within the anchorage zone (see 5.4.2 and 5.4.8); 5) dimensional accuracy (see 5.4.5 and 5.4.7). 7.3.5 Medium-term control In addition to the items mentioned in 7.3.4, the following shall be regularly controlled once per week for one batch (chosen at random) per production line:

the dimensional variations (see 5.4.5);

the availability of drawings and other documents (see Clause 6). 7.3.6 Control of measuring and testing equipment All measuring and testing equipment shall be calibrated and inspected according to documented procedures, frequencies and criteria. 7.3.7 Records The following records shall be kept at least ten years: a) for each batch:

1) job number and purchaser's name; 2) production date and shift; SIST EN 14250:2010

7.4.2 Initial inspection

In the case of a new factory an initial inspection of the factory and of the factory production control shall be carried out. The initial inspection shall: a) confirm that the factory production control manual complies with the requirements of 7.3; a) assess that the production equipment is in accordance with the factory production control manual and in relation to providing the ability to meet the requirements of this European Standard; b) assess that the laboratory equipment is in accordance with the factory production control manual and is suitable for factory production control; c) confirm that the production is performed under the supervision of an adequate organisation. 7.4.3 Reports In the event that an initial inspection is carried out, a report as specified in 7.5.3 shall be prepared. 7.5 Continuous surveillance, assessment and acceptance of the factory production control 7.5.1 Inspection tasks The tasks of the inspections are the surveillance, assessment and acceptance of the factory production control. Any major change in the factory production control manual shall be reported by the manufacturer within one month of its implementation. It shall be verified that factory production control complies with the requirements of 7.3. 7.5.2 Frequency of inspections Inspections shall be carried out at least once per year. 7.5.3 Reports Following each inspection a report shall be prepared and sent to the manufacturer. The manufacturer shall, if appropriate, make corrective actions following the receipt of the report. SIST EN 14250:2010

Where ZA.3 covers the same information as this clause, the requirements of this clause are met. SIST EN 14250:2010

Additional requirements for factory production control (FPC)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...