SIST EN 1096-2:2012

(Main)Glass in building - Coated glass - Part 2: Requirements and test methods for class A, B and S coatings

Glass in building - Coated glass - Part 2: Requirements and test methods for class A, B and S coatings

This European Standard specifies requirements and test methods related to artificial weathering and abrasion of coatings on glass for use in buildings.

These tests are aimed at evaluating the resistance of the coating to attack by simulated natural weathering conditions as well as to abrasion. This attack can be considered as representative of that which could be found on the external and/or internal face of the glazing.

This European Standard applies to Class A, B and S coatings, as described in EN 1096-1.

Glas im Bauwesen - Beschichtetes Glas - Teil 2: Anforderungen an und Prüfverfahren für Beschichtungen der Klassen A, B und S

Diese Europäische Norm legt Anforderungen und Prüfverfahren für die Beständigkeit gegen simulierte Witterungsbedingungen und gegen Abrieb für Beschichtungen auf Glas für Anwendung im Bauwesen fest. Diese Prüfungen sind für die Beurteilung der Beständigkeit von Beschichtungen gegen Einwirkungen von simulierten natürlichen Witterungsbedingungen und gegen Abrieb vorgesehen. Diese Einwirkungen entsprechen den Einflüssen, die an der äußeren und/oder inneren Seite der Verglasung tatsächlich auftreten können. Diese Europäische Norm ist, wie in EN 1096-1 festgelegt, auf Beschichtungen der Klassen A, B und S anwendbar.

Verre dans la construction - Verre à couche - Partie 2: Exigences et méthodes d'essai pour les couches de classes A, B et S

La présente Norme européenne spécifie les exigences et méthodes d’essai de la résistance au vieillissement climatique artificiel et à l’abrasion applicables au verre à couche employé dans la construction.

Ces essais ont pour objectif d’évaluer la résistance de la couche aux attaques dans des conditions simulées de vieillissement climatique naturel ainsi que sa résistance à l’abrasion. Ces attaques peuvent être considérées comme représentatives de celles qui pourraient affecter la face extérieure et/ou intérieure du vitrage.

La présente Norme européenne s’applique aux couches de classes A, B et S telles que définies dans l’EN 1096-1.

Steklo v gradbeništvu - Steklo z nanosi - 2. del: Zahteve in preskusne metode za nanose razredov A, B in S

Ta evropski standard določa zahteve in preskusne metode v zvezi z umetno izpostavljenostjo vremenskim vplivom in abrazijo nanosov na steklu, ki se uporablja v gradbeništvu. Cilj teh preskusov je ovrednotiti odpornost nanosa na napad s simuliranimi razmerami naravne izpostavljenosti vremenskim vplivom in abrazijo. Ta napad bi lahko predstavljal to, kar je mogoče najti na zunanji in/ali notranji površini nanosa. Ta evropski standard se uporablja za nanose razredov A, B in S, kot je opisano v standardu EN 1096-1.

General Information

- Status

- Published

- Public Enquiry End Date

- 29-Sep-2011

- Publication Date

- 01-Mar-2012

- Technical Committee

- STV - Steklo, svetloba in razsvetljava v gradbeništvu

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 27-Jan-2012

- Due Date

- 02-Apr-2012

- Completion Date

- 02-Mar-2012

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 25-Jan-2012

Overview

EN 1096-2:2012 - "Glass in building - Coated glass - Part 2" - specifies requirements and test methods for Class A, B and S coated glass used in buildings. The standard focuses on evaluating the resistance of coatings to artificial weathering and abrasion, simulating natural attack on external and internal glazing faces. It defines sampling, preparation, test procedures and acceptance criteria for coated annealed, thermally treated, toughened and heat‑strengthened glass.

Key topics and technical requirements

- Scope and applicability: Applies to Class A, B and S coatings as classified in EN 1096-1; covers simulated weathering and abrasion tests representative of field exposure.

- Test methods (annexes):

- Condensation resistance (Annex B)

- Acid resistance (Annex C)

- Neutral salt spray resistance (Annex D)

- Abrasion resistance (Annex E)

- Visual inspection and spectrophotometric evaluation:

- Visual defect limits (e.g., permitted number/size categories) and procedures for reflection and transmission checks.

- Spectrophotometric limits on transmittance and reflectance (e.g., limits at 550 nm / 900 nm and emissivity at 8 μm for low‑emissivity coatings).

- Samples and preparation:

- Typical sample size for coated annealed glass: 300 mm × 300 mm per test.

- Special procedures for thermally treated coated glass (Annex A) since cutting can be restricted.

- Storage conditions: ~23 ± 5 °C, RH < 80 %, and maximum storage before testing (three months).

- Marking, cleaning and test sequencing: Mark test pieces on the uncoated surface; guidance on cleaning with demineralised water and soft tissue; initial and final evaluations defined.

- Equivalence criteria: Annex F provides criteria and examples to demonstrate coating equivalence for testing reduction.

Practical applications

- Ensures durability and performance of coated glazing used in facades, windows, curtain walls, solar control and low‑emissivity applications.

- Helps manufacturers validate coating robustness against weathering, condensation, chemical attack and abrasion.

- Supports product certification, quality control, and specification compliance for architectural glazing.

Who should use this standard

- Glass manufacturers and coating producers

- Facade engineers, architects and specifiers

- Testing laboratories performing durability and abrasion tests

- Product certification bodies and quality assurance teams

Related standards

- EN 1096-1 (definitions and classification for coated glass)

- EN 410 (luminous and solar characteristics)

- EN 12898 (emissivity determination)

- EN 1096-5 (self‑cleaning performance - referenced)

Keywords: EN 1096-2:2012, coated glass, glass in building, artificial weathering, abrasion resistance, Class A B S coatings, test methods, condensation resistance, neutral salt spray, spectrophotometric measurements.

Frequently Asked Questions

SIST EN 1096-2:2012 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Glass in building - Coated glass - Part 2: Requirements and test methods for class A, B and S coatings". This standard covers: This European Standard specifies requirements and test methods related to artificial weathering and abrasion of coatings on glass for use in buildings. These tests are aimed at evaluating the resistance of the coating to attack by simulated natural weathering conditions as well as to abrasion. This attack can be considered as representative of that which could be found on the external and/or internal face of the glazing. This European Standard applies to Class A, B and S coatings, as described in EN 1096-1.

This European Standard specifies requirements and test methods related to artificial weathering and abrasion of coatings on glass for use in buildings. These tests are aimed at evaluating the resistance of the coating to attack by simulated natural weathering conditions as well as to abrasion. This attack can be considered as representative of that which could be found on the external and/or internal face of the glazing. This European Standard applies to Class A, B and S coatings, as described in EN 1096-1.

SIST EN 1096-2:2012 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1096-2:2012 has the following relationships with other standards: It is inter standard links to SIST EN 1096-2:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1096-2:2012 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/135. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1096-2:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Steklo v gradbeništvu - Steklo z nanosi - 2. del: Zahteve in preskusne metode za nanose razredov A, B in SGlas im Bauwesen - Beschichtetes Glas - Teil 2: Anforderungen an und Prüfverfahren für Beschichtungen der Klassen A, B und SVerre dans la construction - Verre à couche - Partie 2: Exigences et méthodes d'essai pour les couches de classes A, B et SGlass in building - Coated glass - Part 2: Requirements and test methods for class A, B and S coatings81.040.20Steklo v gradbeništvuGlass in buildingICS:Ta slovenski standard je istoveten z:EN 1096-2:2012SIST EN 1096-2:2012en,fr,de01-april-2012SIST EN 1096-2:2012SLOVENSKI

STANDARDSIST EN 1096-2:20011DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1096-2

January 2012 ICS 81.040.20 Supersedes EN 1096-2:2001English Version

Glass in building - Coated glass - Part 2: Requirements and test methods for class A, B and S coatings

Verre dans la construction - Verre à couche - Partie 2: Exigences et méthodes d'essai pour les couches de classes A, B et S

Glas im Bauwesen - Beschichtetes Glas - Teil 2: Anforderungen an und Prüfverfahren für Beschichtungen der Klassen A, B und S This European Standard was approved by CEN on 3 December 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1096-2:2012: ESIST EN 1096-2:2012

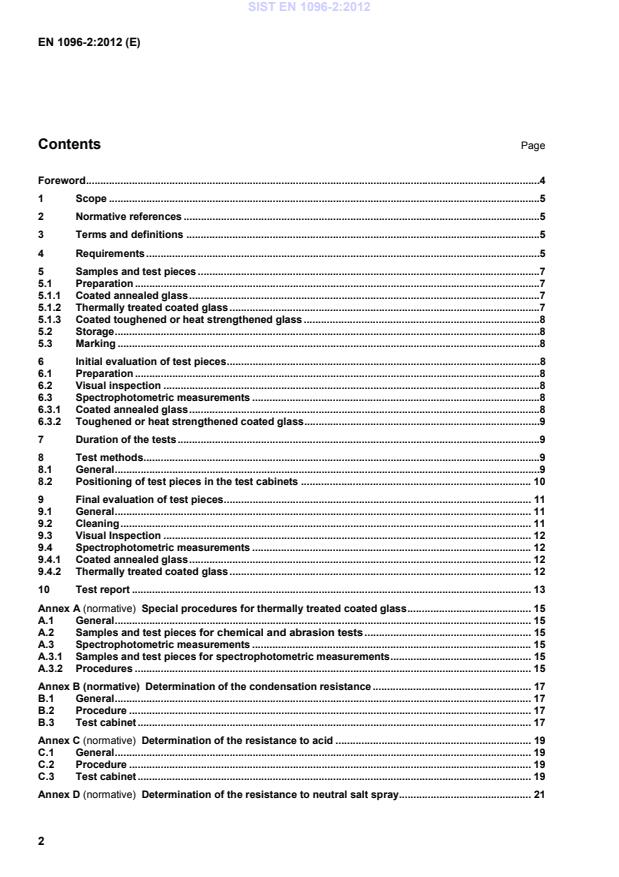

Special procedures for thermally treated coated glass . 15A.1 General . 15A.2 Samples and test pieces for chemical and abrasion tests . 15A.3 Spectrophotometric measurements . 15A.3.1 Samples and test pieces for spectrophotometric measurements . 15A.3.2 Procedures . 15Annex B (normative)

Determination of the condensation resistance . 17B.1 General . 17B.2 Procedure . 17B.3 Test cabinet . 17Annex C (normative)

Determination of the resistance to acid . 19C.1 General . 19C.2 Procedure . 19C.3 Test cabinet . 19Annex D (normative)

Determination of the resistance to neutral salt spray . 21SIST EN 1096-2:2012

Determination of resistance to abrasion

................................................................... 22E.1 General ................................................................................................................................................. 22E.2 Apparatus ............................................................................................................................................. 22E.2.1 General ................................................................................................................................................. 22E.2.2 Metal finger .......................................................................................................................................... 22E.2.3 Abrasive felt ......................................................................................................................................... 22E.3 Test piece ............................................................................................................................................. 23E.4 Test procedure ..................................................................................................................................... 23Annex F (normative)

Criteria to demonstrate equivalence of coatings . 25F.1 General . 25F.2 Composition of coatings . 25F.3 Previous test reports . 25F.4 Evaluation. 25F.5 Examples . 25Annex G (informative)

Summary of test report . 27Bibliography . 29 SIST EN 1096-2:2012

reference to the future EN 1096-5, Test method and classification for the Self-cleaning performances of coated glass surfaces;

the introduction of a method to deal with toughenable / heat strengthenable and to be toughened / to be heat strengthened coated glass, see Annex A. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

Table 1 — Requirements Characteristics Test Method Requirements Visual Inspection Spectrophotometric measurements Condensation resistance Annex B - No defect, as defined in EN 1096-1, greater than 3 mm length - Maximum one defect between 2 mm and 3 mm length - Maximum five defects between 1 mm and 2 mm length In addition, no scratches, staining of the coating or clusters of pinholes greater than 1 mm shall be allowed (see EN 1096-1). When compared with the reference test piece, in both reflection and transmission, there shall be no significant colour change. This observation shall be made within 20 sa

. The transmittance measured at 550 nm and 900 nm shall differ by no more than ± 0,03 from the corresponding measured value on the reference test piece.

For a glass claimed to have a low emissivity coating the reflectance at 8 µm shall decrease by no more than 0,02. Acid resistance Annex C No requirements Neutral salt spray resistance Annex D - No defect, as defined in EN 1096-1, greater than 3 mm length - Maximum one defect between 2 mm and 3 mm length - Maximum five defects between 1 mm and 2 mm length In addition, no scratches, staining of the coating or clusters of pinholes greater than 1 mm shall be allowed (see EN 1096-1). When compared with the reference test piece, in both reflection and transmission, there shall be no significant colour change. This observation shall be made within 20 sa

. Abrasion resistance Annex E No requirement other than to ensure that the abraded area is uniform Total (diffuse plus direct) transmittance measured at 550 nm and 900 nm shall differ by no more than ± 0,05 from the corresponding value measured for the reference test piece. a The time for observation is fixed to 20 s in order to have a reference period which can influence the visual inspection.

5.1 Preparation 5.1.1 Coated annealed glass A sample of 300 mm x 300 mm is needed for each test. For the three chemical durability tests, the test pieces are obtained by cutting the sample as shown in Figure 1. The abrasion test is undertaken on a

300 mm x 300 mm test piece. It is recommended that a spare sample be supplied in the event of one sample not being defect free.

Key 1. test pieces 2. reference test piece for visual inspection 3. reference test piece for spectrophotometric measurement Figure 1 — Plan for cutting a sample into test pieces 5.1.2 Thermally treated coated glass For the thermally treated coated glass, defined in EN 1096-1:2012, 3.1.8 to 3.1.11, as the test pieces cannot be cut from test samples, a special procedure has to be employed to obtain the test pieces (see Annex A). SIST EN 1096-2:2012

5.3 Marking The test pieces shall be marked on the uncoated glass surface. The following information shall be marked: manufacturers' coating reference test pieces number 1 to 4 code for test Glasses with coating on both surfaces shall be marked without damaging the coating. The two reference test pieces shall be marked as the test pieces plus "ref". 6 Initial evaluation of test pieces

6.1 Preparation All test pieces shall be cleaned with demineralised water and with a soft tissue. Drying shall also be done with a soft tissue. If necessary this cleaning procedure can be repeated. 6.2 Visual inspection The test pieces shall be subjected to a visual inspection under an artificial sky in accordance with EN 1096-1. The inspection shall take place in both transmission and reflection. The test pieces shall be observed at a distance of 600 mm. All test pieces shall be defect free. No scratches or pinholes shall be observed. If a test piece contains defects it shall be replaced. NOTE The replacement of test pieces is to avoid any misinterpretation of the testing results. 6.3 Spectrophotometric measurements 6.3.1 Coated annealed glass A measurement sample shall be cut from the centre of the reference test piece. The actual size shall be dependent on the type of equipment being used for the measurements. The transmittance of the measurement sample shall be measured with radiation of normal incidence at the following wavelengths: 550 nm (representative wavelength for light and solar transmittance); 900 nm (representative wavelength for solar transmittance). For glass claiming to have a low emissivity coating a measurement of the reflectance shall be made at 8 µm using radiation of nearly normal incidence. SIST EN 1096-2:2012

500 strokes a The neutral salt spray test is excluded for Class S coatings as they are subject to frequent cleaning in the applications for which theyare used in accordance with EN 1096-1.

8 Test methods 8.1 General The coated glass complying to this part of the European Standard shall pass the tests given in Annexes B, C, D and E which are designed to verify the chemical and mechanical characteristics of the coating. The tests are as follows: condensation resistance test (see Annex B) acid resistance test (see Annex C) neutral salt spray test (see Annex D) abrasion resistance test (see Annex E) These tests are evaluated by their effect on the visual quality of the product and its spectrophotometric properties. Whilst it would be feasible to evaluate the spectrophotometric properties across the entire spectrum, a number of representative wavelengths have been selected. These wavelengths represent transmission of light and energy, together with reflectance relating to emissivity, where appropriate. SIST EN 1096-2:2012

8.2 Positioning of test pieces in the test cabinets The test pieces shall have their coated side oriented upwards, the pieces presenting an angle of (15 ± 5)° with the vertical, and the coated side shall face away from the door. For consistent results, a certain quantity of glass shall be present. For 300 l cabinet the total weight of the glasses shall be (7,5 ± 0,5) kg. An insufficient quantity of coated glass shall be compensated with uncoated clear glasses. In the centre of the test pieces a piece of 6 mm clear glass is placed, with the reference thermocouple attached (see Figure 2). The following spacing shall be maintained: distance from the walls not less than 100 mm distance between bottom of the test pieces and water not less than 200 mm spacing between adjoining test pieces not less than 20 mm

not more than 40 mm Where there is an insufficient quantity of coated glass for testing, it is required to use uncoated clear glasses to fill up a cabinet. SIST EN 1096-2:2012

Key 1. position of the thermocouple 2. substrate holder 3. 6 mm clear glass used for temperature control inside cabinet Figure 2 — Description of the reference thermocouple position 9 Final evaluation of test pieces 9.1 General Test pieces having completed the sp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...