SIST EN 14363:2005

(Main)Railway applications - Testing for the acceptance of running characteristics of railway vehicles - Testing of running behaviour and stationary tests

Railway applications - Testing for the acceptance of running characteristics of railway vehicles - Testing of running behaviour and stationary tests

This document regulates the testing for acceptance of the running characteristics of railway vehicles (hereafter called vehicles). The testing of the running characteristics applies principally to all vehicles used in public transport which operate without restriction on standard gauge tracks (1 435 mm).

NOTE 1 The testing of the running characteristics of:

- railways with different track layout, e.g. tramways, metros and underground railways;

- railways with non-standard gauge tracks

can be conducted by analogy with this document.

The testing of running characteristics is part of the type testing of vehicles which

- are newly developed,

- have had relevant design modifications, or

- have changes in their operating regimes.

The testing and acceptance of running characteristics refers to the complete vehicle including the running gear. If a running gear, which has already been tested and accepted, is to be used under a vehicle body of another design, this is considered to be a design modification. The procedure as described in 5.2 is used.

NOTE 2 In addition to the testing of running characteristics for the acceptance of vehicles, the regulations can be generally applied in other technical tasks, e.g.:

- the checking for compliance against development contracts;

- the optimisation of components, vehicles or running gear;

- the testing of influences, influencing parameters and relationships of dependence;

- the monitoring of track or vehicles in operational use.

Bahnanwendungen - Fahrtechnische Prüfung für die fahrtechnische Zulassung von Eisenbahnfahrzeugen - Prüfung des Fahrverhaltens und stationäre Versuche

Diese Europäische Norm regelt die fahrtechnische Prüfung für die Zulassung von Eisenbahnfahrzeugen (nachfolgend kurz Fahrzeuge genannt). Der Anwendungsbereich ist auf Eisenbahnen des öffentlichen Verkehrs beschränkt. Die fahrtechnische Prüfung gilt grundsätzlich für Fahrzeuge, die auf Gleisen der Regelspur

(1 435 mm) freizügig betrieben werden.

ANMERKUNG 1 Die fahrtechnische Prüfung von

- Bahnen mit abweichender Gleistrassierung, beispielsweise Straßenbahnen, Stadtbahnen und Untergrundbahnen;

- Bahnen mit abweichender Spurweite

kann in Anlehnung an die Regeln dieser Europäischen Norm durchgeführt werden.

Die fahrtechnische Prüfung ist Teil einer Bauartprüfung für

- neu entwickelte Bauarten von Fahrzeugen;

- relevant geänderte Bauarten von Fahrzeugen oder

- Fahrzeuge mit relevant geänderten Betriebsbedingungen.

Die fahrtechnische Prüfung und Zulassung bezieht sich auf das vollständige Fahrzeug einschließlich Fahrwerk. Wird ein bereits geprüftes und zugelassenes Fahrwerk unter einem Fahrzeugkasten abweichender Bauart verwendet, gilt dies als konstruktive Änderung. Es ist wie in 5.2 beschrieben zu verfahren.

ANMERKUNG 2 Über die fahrtechnische Prüfung für die Zulassung hinaus können die Regeln allgemein zur Lösung fahrtechnischer Aufgabenstellungen, beispielsweise

- Prüfen der Forderungen auf Einhaltung von Entwicklungsverträgen,

- Optimieren von Bauteilen, Fahrzeugen oder Fahrwerken,

- Untersuchen von Einflüssen, Einflussgrößen und Abhängigkeiten,

- Überwachen von Fahrweg oder Fahrzeugen im Betrieb

angewendet werden.

Die fahrtechnische Prüfung besteht aus der Prüfung der Fahrfähigkeit (hauptsächlich stationäre Versuche) und der Prüfung des Fahrverhaltens (Streckenversuche).

Die vollständige Anwendung der Regeln und Grenzwerte gilt für die fahrtechnische Prüfung von Fahrzeugen des freizügigen internationalen Verkehrs.

Applications ferroviaires - Essais en vue de l'homologation du comportement dynamique des véhicules ferroviaires - Essais en ligne et a poste fixe

La présente Norme européenne régit les essais en vue de l’homologation des véhicules ferroviaires (appelés véhicules dans la suite du texte) du point de vue de leur comportement dynamique. Ces essais s’appliquent essentiellement à tous les véhicules de transport public circulant sans restriction sur les voies à écartement normal (1 435 mm).

NOTE 1 Les essais de comportement dynamique pour les :

chemins de fer avec un tracé de voie différent, par exemple tramways, métros ou lignes ferroviaires souterraines ;

chemins de fer avec un écartement des voies non standard ;

peuvent être réalisés par analogie avec la présente Norme européenne.

Les essais de caractérisation du comportement dynamique font partie des essais de type des véhicules :

de conception nouvelle ;

dont la conception a été modifiée de façon sensible ; ou

dont les conditions d'exploitation ont été modifiées.

Les essais en vue de l’homologation du comportement dynamique s'appliquent aux véhicules complets avec leurs organes de roulement. Si des organes de roulement déjà testés et homologués doivent être utilisés sous une caisse de type différent, ceci doit être considéré comme une modification de conception. La procédure décrite en 5.2 est appliquée.

NOTE 2 Les règles peuvent être appliquées de façon générale dans un autre contexte technique que l'essai de caractérisation du comportement dynamique en vue de l’homologation des véhicules, par exemple :

la vérification de conformité par rapport à des contrats de développement ;

l'optimisation d'éléments constructifs, de véhicules ou d'organes de roulement ;

la vérification de l’influence de la modification de paramètres et des relations de dépendance entre ces paramètres ;

la surveillance de la voie ou des véhicules en service.

Les essais du comportement dynamique consistent en des essais préliminaires d’homologation (généralement essais à poste fixe) et essais du comportement dynamique (essais en ligne).

La méthode complète et les valeurs

Železniške naprave – Preskušanje voznih karakteristik pri prevzemu železniških vozil – Preskušanje obnašanja med vožnjo in mirovanjem

General Information

- Status

- Withdrawn

- Publication Date

- 31-Oct-2005

- Withdrawal Date

- 24-Mar-2016

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 24-Mar-2016

- Due Date

- 16-Apr-2016

- Completion Date

- 25-Mar-2016

Relations

- Effective Date

- 01-May-2016

- Effective Date

- 27-Jul-2007

- Effective Date

- 27-Jul-2007

Frequently Asked Questions

SIST EN 14363:2005 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Testing for the acceptance of running characteristics of railway vehicles - Testing of running behaviour and stationary tests". This standard covers: This document regulates the testing for acceptance of the running characteristics of railway vehicles (hereafter called vehicles). The testing of the running characteristics applies principally to all vehicles used in public transport which operate without restriction on standard gauge tracks (1 435 mm). NOTE 1 The testing of the running characteristics of: - railways with different track layout, e.g. tramways, metros and underground railways; - railways with non-standard gauge tracks can be conducted by analogy with this document. The testing of running characteristics is part of the type testing of vehicles which - are newly developed, - have had relevant design modifications, or - have changes in their operating regimes. The testing and acceptance of running characteristics refers to the complete vehicle including the running gear. If a running gear, which has already been tested and accepted, is to be used under a vehicle body of another design, this is considered to be a design modification. The procedure as described in 5.2 is used. NOTE 2 In addition to the testing of running characteristics for the acceptance of vehicles, the regulations can be generally applied in other technical tasks, e.g.: - the checking for compliance against development contracts; - the optimisation of components, vehicles or running gear; - the testing of influences, influencing parameters and relationships of dependence; - the monitoring of track or vehicles in operational use.

This document regulates the testing for acceptance of the running characteristics of railway vehicles (hereafter called vehicles). The testing of the running characteristics applies principally to all vehicles used in public transport which operate without restriction on standard gauge tracks (1 435 mm). NOTE 1 The testing of the running characteristics of: - railways with different track layout, e.g. tramways, metros and underground railways; - railways with non-standard gauge tracks can be conducted by analogy with this document. The testing of running characteristics is part of the type testing of vehicles which - are newly developed, - have had relevant design modifications, or - have changes in their operating regimes. The testing and acceptance of running characteristics refers to the complete vehicle including the running gear. If a running gear, which has already been tested and accepted, is to be used under a vehicle body of another design, this is considered to be a design modification. The procedure as described in 5.2 is used. NOTE 2 In addition to the testing of running characteristics for the acceptance of vehicles, the regulations can be generally applied in other technical tasks, e.g.: - the checking for compliance against development contracts; - the optimisation of components, vehicles or running gear; - the testing of influences, influencing parameters and relationships of dependence; - the monitoring of track or vehicles in operational use.

SIST EN 14363:2005 is classified under the following ICS (International Classification for Standards) categories: 45.060.01 - Railway rolling stock in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14363:2005 has the following relationships with other standards: It is inter standard links to SIST EN 14363:2016, oSIST prEN 15686:2007, oSIST prEN 15687:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14363:2005 is associated with the following European legislation: EU Directives/Regulations: 93/38/EEC, 96/48/EC; Standardization Mandates: M/024, M/275. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14363:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Railway applications - Testing for the acceptance of running characteristics of railway vehicles - Testing of running behaviour and stationary testsŽelezniške naprave – Preskušanje voznih karakteristik pri prevzemu železniških vozil – Preskušanje obnašanja med vožnjo in mirovanjemApplications ferroviaires - Essais en vue de l'homologation du comportement dynamique des véhicules ferroviaires - Essais en ligne et a poste fixeBahnanwendungen - Fahrtechnische Prüfung für die fahrtechnische Zulassung von Eisenbahnfahrzeugen - Prüfung des Fahrverhaltens und stationäre VersucheTa slovenski standard je istoveten z:EN 14363:2005SIST EN 14363:2005en45.060.01ICS:SLOVENSKI

STANDARDSIST EN 14363:200501-november-2005

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14363June 2005ICS 45.060.01English versionRailway applications - Testing for the acceptance of runningcharacteristics of railway vehicles - Testing of running behaviourand stationary testsApplications ferroviaires - Essais en vue de l'homologationdu comportement dynamique des véhicules ferroviaires -Essais en ligne et à poste fixeBahnanwendungen - Fahrtechnische Prüfung für diefahrtechnische Zulassung von Eisenbahnfahrzeugen -Prüfung des Fahrverhaltens und stationäre VersucheThis European Standard was approved by CEN on 3 March 2005.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2005 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14363:2005: E

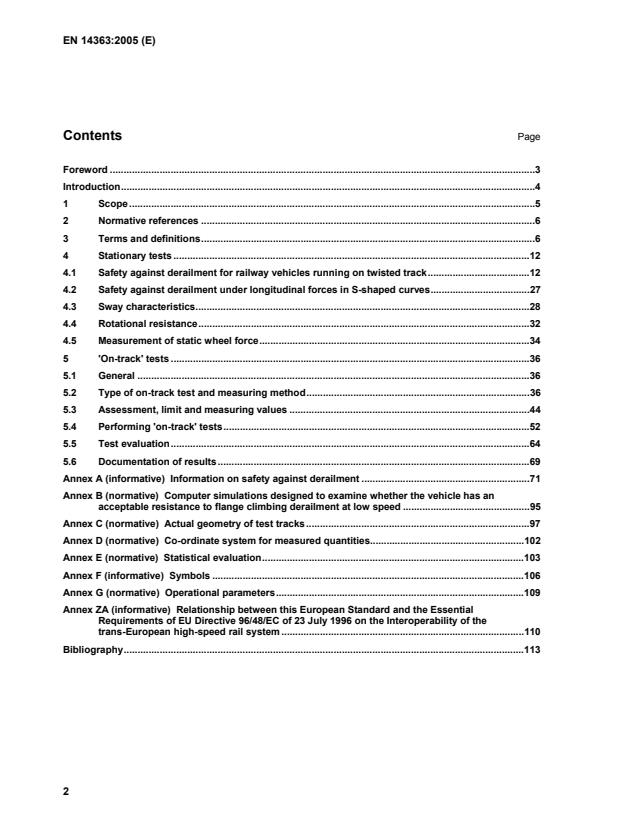

Information on safety against derailment.71 Annex B (normative)

Computer simulations designed to examine whether the vehicle has an acceptable resistance to flange climbing derailment at low speed.95 Annex C (normative)

Actual geometry of test tracks.97 Annex D (normative)

Co-ordinate system for measured quantities.102 Annex E (normative)

Statistical evaluation.103 Annex F (informative)

Symbols.106 Annex G (normative)

Operational parameters.109 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 96/48/EC of 23 July 1996 on the Interoperability of the trans-European high-speed rail system.110 Bibliography.113

1) Official Journal of the European Communities No L 235/6 of 17.09.96

UIC 505-1:2003, Railway transport stock — Rolling stock construction gauge2) UIC 505-4:1977, Effects of the application of the kinematic gauges defined in the 505 series of leaflets on the positioning of structures in relation to the tracks and of the tracks in relation to each other2) UIC 505-5:1977, Basis conditions common to leaflets 505-1 to 505-4 — Notes on the preparation and provisions of these leaflets2) UIC 518:2003, Testing and approval of railway vehicles from the point of view of their dynamic behaviour — Safety — Track fatigue; Ride quality2) UIC 530-2:1997, Wagons — Running safety2) 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 testing for acceptance of running behaviour obtaining numerical values of evaluation variables which describe the running and ride characteristics. The evaluation variables together with limit values are used in the acceptance process of the vehicle The purpose of testing running characteristics is either testing of vehicles which are newly developed, or extending the scope for an already proven vehicle (e.g. relevant design modification of the vehicle or alteration of the operation conditions) 3.2 test elements related regulations for the measurement of parameters (accelerations, forces, displacements, on the vehicle) and evaluation of variables which characterise the performance of the vehicle;

2) May be purchased from: Railway Technical Publications (ETF) 16 rue Jean Rey, F-75015 Paris

Figure 1 — Structure of test elements 3.3 vehicle parameters relevant to running characteristics technical data of a vehicle relevant to running characteristics, e.g.: planned maximum permissible speed of the vehicle; planned permissible cant deficiency; smallest curve radius that shall be negotiated; wheel arrangement; wheel-base and distance between bogie centres; centre of gravity height; weight of the vehicle; wheel force and axle force distribution; unsprung mass; primary suspended mass; secondary suspended mass; moments of inertia of vehicle body (around z-axis);

simplified measuring method is used 3.7.1 'on-track' test with normal measuring method test of running behaviour for the assessment of running safety, track loading and ride characteristics of the vehicle with direct measured forces between wheel and rail and accelerations in running gear and in the vehicle body 3.7.2 'on-track' test with simplified measuring method test of running behaviour for the assessment of running safety and ride characteristics of the vehicle with measured lateral axle-box forces and/or accelerations at the bogie frame and in the vehicle body

R = 150 m. Reduction of vertical wheel force includes the following effects: twist on bogie wheel base (see 4.1.2.2.3); twist on bogie centre distance or axle distance for non bogied vehicles (see 4.1.2.2.3); torsional hysteresis during the twisting; eccentricity of centre of gravity and twist of the bogie and vehicle body as a result of tolerances; eccentricity of the centre of gravity due to cant excess or deficiency - this influence is eliminated in the test; roll torque of the lateral axle-box forces. So, the influence of cant excess is not considered. It is assumed that the reduction in the guiding forces in larger curve radii have a stronger influence on the safety against derailment than the higher offloading of the guiding wheel due to the higher allowed cant excess in these radii.

if 2a+ ≤ 4 m and 0,2a220+=++limg

if 2a+ > 4 m with 2a+ as the bogie wheel base in m and glim+ in ‰. for vehicle body test twist: 7*=limg

if 2a ≤ 4 m and 0,2220+=ag*lim

if 4 m < 2a ≤ 20 m 3*=limg

if 20 m < 2a ≤ 30 m

3)

Several measurements were made on the tracks of DB, NS, ÖBB, PKP and SNCF which lead to a limit for track twist in relation of the longitudinal basis. The analysis of the measurements was carried over a range of 1,8 m to

19,8 m.

if 2a > 30 m with 2a as the longitudinal dimension of twist in m (for single cars the longitudinal dimension of twist equals 2a*, the distance between center pivots for bogied single cars or the distance of the axles for non bogied vehicles) and g*lim in ‰. For bogied vehicles the twist due to the bogie wheel base 2a+ and the twist due to the bogie center distance 2a* shall be combined as shown in Figure 2.

Key 1 vertical displacement 2 bogie test twist 3 vehicle body test twist Figure 2 — Combination of bogie and vehicle body test twist The given vehicle test twist values are only valid up to a longitudinal basis 2a* of 20 m. For values of 2a* greater than 20 m a vehicle test twist value of 3*=limg ‰ will be used. Figure 3 shows the test twist values depending on length dimensions 2a+ and 2a*. The maximum vertical height difference from twist shall be

90 mm which corresponds to a twist value of 3 ‰ at 30 m. For lengths greater than 30 m the vertical height difference from twist shall be 90 mm.

Key 1 twist height h 2 twist length 2a Figure 3 — Test twist values 4.1.2.2.4 Curve radius for determination of guiding force The track shall contain a curve of R = 150 m. The evaluation considers the quasistatic guiding force of the outer leading wheel. 4.1.2.2.5 Rail conditions Tests shall be done under dry conditions in order to consider high friction forces between wheel and rail. Information used in the determination of the rail conditions shall be gathered when measuring Yi and Qi on the inner leading wheel, angle of attack αααα, and average wheel force of the leading axle and evaluated as described below. During tests the friction coefficient is to be at least 80 % of the value expected for dry rails. Therefore, the condition (Y/Q)i ≥≥≥≥ 0,8 ττττdry + γγγγ as a function of the angle of attack shall be respected. In the above formula the contact angle of the tread γγγγ shall be inserted. For example as γγγγ

= 0,025 for wheel profile S1002 according to prEN 13715.

Key 1 ratio lateral friction force – vertical force ττττdry 2 angle of attack [rad] Figure 4 — Ratio of lateral friction force to vertical force for dry friction conditions To determine friction during tests, the measurement of the angle of attack is necessary. The method is not appropriate if the angle of attack is very small (e.g. below 0,0015 rad). In the case of bogies with a low angle of attack determination of the friction conditions is to be done by measuring on a leading axle of a vehicle which generates a higher angle of attack. 4.1.2.3 Vehicle conditions 4.1.2.3.1 General Taking the vehicle design and the load distribution in the vehicle into consideration, the effects of the running direction and the direction of curvature shall be analyzed. The test conditions and the wheelsets to be tested are to be determined as a result of this analysis (for one-unit vehicles with two wheelsets or bogies, the two outer wheelsets, the leading ones, are to be analyzed). 4.1.2.3.2 Load condition The test vehicle shall be in its normal operating condition. With respect to loading, passenger or freight vehicles are to be tested in the empty condition. If the suspension is non-linear, safety against derailment shall be tested in the worst combination of load and stiffness (e.g. this will occur for a two-rate spring at the smallest loading point above the application point of

Key 1 curvature 2 cant 3 running direction Figure 5 — General layout of test track Test conditions as described 4.1.2.2.5 (dry rail conditions) shall be fulfilled. The influence of longitudinal forces in the trainset shall be minimized. The vehicle shall not be braked. The speed shall be constant and not exceed 10 km/h. Tests shall be done a minimum of 3 times. 4.1.3.2.2.2 Vehicle conditions If the vehicle test twist is greater the 3 ‰ the additional twist is included within the vehicle e.g. by packing the springs with shims in an appropriate way. A.7 contains suggestions for calculating the thickness of the shims and precise their location. The test shall be planned to ensure that the direction of running and track curvature are in such a way that the wheel with the lowest wheel load is tested in the leading position running on the outer rail of the curve (this may include additional packing of the suspensions). The influence of longitudinal forces in the train set shall be minimized. The vehicle shall not be braked. The speed shall be constant and not exceed 10 km/h. 4.1.3.2.3 Measured values, measuring positions and processing of measurements The following values shall be measured: guiding forces on the inner and outer wheel of the tested wheelset Yi, Ya ;

(see 4.1.2.2.5); wheel lift of the guiding wheel of the tested wheelset ∆∆∆∆z in the whole curve. Forces may be measured by appropriate devices on the rails, or appropriate devices on the vehicles. In the case of rail measurements the measuring positions have to fulfill the following conditions as shown in

Figure 6: measuring positions shall be within the twisted part of the track; in zone 2 where the track twist first influences the whole vehicle the distance between two measuring sections shall not be greater than 1,5 m; in the other areas of the twisted track the distance between two measuring sections shall not be greater than 3 m.

Key

1 running direction 4 zone 1 2 cant 5 zone 3 3 measuring positions

Figure 6 — Track based measuring positions to be used in method 1 For each measuring section the value of (Y/Q)a of the leading wheelset shall be recorded. Wheel lift of the outer wheel of the leading wheelset ∆∆∆∆z shall be recorded continuously.

4)

The investigations are documented in several reports of ERRI B55, see [4] in the Bibliography.

5 mm is permissible according to 4.1.3.2.5. Consequently, the effective twist for the vehicle is reduced. Following values shall be used on the twist test rig: for bogie test twist: ++−=a257limg if 2a+ < 4 m

0,2a215+=++limg if 2a+ ≥ 4 m with 2a+ as the bogie wheel base in m and g+lim in ‰. for vehicle body test twist **a257−=limg if 2a* < 4 m and 0,2a215**+=limg if

4 m ≤ 2a* ≤ 20 m **lima253−=g if 20 m < 2a* ≤ 30 m **a285=limg if 2a* > 30 m. with 2a* as the longitudinal dimension of the vehicle (distance between centre pivots for bogied single vehicles or axles for non bogied vehicles) in m and g*lim in ‰. For bogied vehicles the twist on the bogie wheel base 2a+ and the twist on the bogie center distance 2a* shall be combined as shown in Figure 2. An appropriate test rig shall be used on which at least the supports of the two wheelset of one bogie may be lifted and lowered. With this the twist of the track on bogie wheel base as well as on bogie center distance can be simulated.

4.1.3.3.2 Measured values, measuring positions and processing of measurements for minimum vertical wheel force on twist test rig The displacements ∆∆∆∆zjk of the wheels shall be measured continuously during the twist test. Additionally the wheel forces Qjk of all wheels shall be measured by suitable devices. By testing the vehicle on the test rig the following vehicle parameters are evaluated: Q0,j average wheel force for each wheelset for level track (twist g = 0); ∆∆∆∆Qjk deviation of wheel force from Q0 due to the combined bogie and body twist and eccentricity of center of gravity including friction and tolerances;

Key 1 curvature 2 measuring positions 3 zone 1 4 zone 2 Figure 7 — Track based measuring positions for determination of Y and Q For each measuring position the values of Ya and Yi of the tested wheelset shall be recorded. Assessment is done with the mean value Ya,med and Yi,med of the measuring positions separately for zone 1 and zone 2. For the evaluation of Yi the direction of forces shall be noted (in most cases opposite to Ya). To determine the friction conditions (Y/Q)i and αααα shall be evaluated as mean values of all measuring positions or of a continuous recorded signal. If vehicle based measurement is used the results shall be analyzed equivalently to the above conditions. 4.1.3.3.5 Assessment values Analysis of safety against derailment shall be done for the tested wheelsets of the vehicle. The following formula shall be evaluated for each tested wheelset: jHmin,jkmeda,jja)(QQYQYû+= where Yja,med

is the quasistatic guiding force evaluated by the tests described in 4.1.3.3.5; Qjk,min is the smallest wheel force evaluated by twist test described in 4.1.3.3.3; ∆∆∆∆QjH

is the change of wheel force due to the moment of the sum of guiding forces:

is the effective height above rail of the primary lateral suspension; 2bA is the lateral distance of wheel/rail contact points (normally 1 500 mm). A vehicle is considered to be safe against derailment if

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...