SIST EN 13598-2:2020

(Main)Plastics piping systems for non-pressure underground drainage and sewerage - Unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP) and polyethylene (PE) - Part 2: Specifications for manholes and inspection chambers

Plastics piping systems for non-pressure underground drainage and sewerage - Unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP) and polyethylene (PE) - Part 2: Specifications for manholes and inspection chambers

This document specifies the definitions and requirements for unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP) and polyethylene (PE) manholes and inspection chambers intended for non-pressure underground drainage and sewerage systems up to a maximum depth of 6 m from ground level to the invert of the manhole or inspection chamber.

This document covers manholes and inspection chambers, with bases having a flow channel, and their joints to the piping system.

Manholes and inspection chambers are intended to be used in pedestrian or vehicular traffic areas outside the building structure.

NOTE 1 The intended use in underground installation outside the building structure is reflected in the marking of products by the application area code "U".

NOTE 2 Products complying with this document can also be used in non-traffic areas.

NOTE 3 Products complying with this standard can be installed in underground applications without additional static calculation.

NOTE 4 Shallow chambers are specified in EN 13598-1 [1].

Manholes and inspection chambers complying with EN 13598-2 are made from a prescribed set of components that are manufactured from unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP), polypropylene with mineral modifier (PP-MD) or polyethylene (PE) and assembled together.

NOTE 5 The complete manhole or inspection chamber assembly can also include items which are not covered by this document (for example near surface or surface components).

NOTE 6 Manholes and inspection chambers can be supplied with covers, frame covers and gratings complying with the relevant part of EN 124 [2].

Manholes and inspection chambers complying with EN 13598-2 may be used for storm-water systems.

Manhole and inspection chamber components can be manufactured by various methods e.g. extrusion, injection moulding, rotational moulding, low-pressure moulding or fabricated.

NOTE 7 Manholes and inspection chambers can be site assembled from different components, but can also be manufactured as a single unit.

NOTE 8 Manholes and inspection chambers can be subject to national regulations and / or local provisions.

Kunststoff-Rohrleitungssysteme für erdverlegte drucklose Abwasserkanäle und -leitungen - Weichmacherfreies Polyvinylchlorid (PVC-U), Polypropylen (PP) und Polyethylen (PE) - Teil 2: Anforderungen an Einsteigschächte und Kontrollschächte

Dieses Dokument legt die Begriffe und Anforderungen für Einsteigschächte und Kontrollschächte aus weichmacherfreiem Polyvinylchlorid (PVC U), Polypropylen (PP) und Polyethylen (PE) fest, die in erdverlegte drucklose Entwässerungs und Abwassersysteme bis zu einer Maximaltiefe von 6 m ab Geländeoberkante bis zur Sohle des Einsteigschachts oder Kontrollschachts eingebaut werden.

Dieses Dokument behandelt Einsteigschächte und Kontrollschächte, jeweils mit Schachtunterteilen mit Gerinneausbildung, und ihre Verbindungen zum Rohrleitungssystem.

Einsteigschächte und Kontrollschächte sind für die Verwendung in Bereichen mit Fußgänger und Fahrzeugverkehr außerhalb der Gebäudestruktur vorgesehen.

ANMERKUNG 1 Die vorgesehene Verwendung in Erdverlegung außerhalb der Gebäudestruktur wird durch die Kennzeichnung der Produkte mit dem Anwendungskennzeichen „U“ wiedergegeben.

ANMERKUNG 2 Produkte, die dem vorliegenden Dokument entsprechen, können auch in Bereichen ohne Verkehr verlegt werden.

ANMERKUNG 3 Produkte, die der vorliegenden Norm entsprechen, können ohne zusätzliche statische Berechnung in erdverlegte Anwendungen eingebaut werden.

ANMERKUNG 4 Schächte mit geringer Einbautiefe werden in EN 13598 1 [1] festgelegt.

Einsteigschächte und Kontrollschächte, die EN 13598 2 erfüllen, sind aus einem vorgeschriebenen Set von Bauteilen hergestellt, die aus weichmacherfreiem Polyvinylchlorid PVC U), Polypropylen (PP), Polypropylen mit mineralischen Additiven (PP MD) oder Polyethylen (PE) bestehen und zusammengebaut sind.

ANMERKUNG 5 Die komplette Bauteilkombination des Einsteigschachts oder Kontrollschachts kann auch Elemente enthalten, die nicht von dieser Norm abgedeckt werden (z. B. oberflächennahe oder Oberflächenbauteile).

ANMERKUNG 6 Einsteigschächte und Kontrollschächte können mit Abdeckungen, Rahmenabdeckungen und Gittern geliefert werden, die den entsprechenden Teil von EN 124 [2] erfüllen.

Einsteigschächte und Kontrollschächte, die EN 13598 2 entsprechen, dürfen für Regenwassersysteme verwendet werden.

Einsteigschacht und Kontrollschacht-Bauteile können in verschiedenen Verfahren hergestellt werden, z. B. Extrusion, Spritzgießen, Rotationsgießen, Niederdruckgießen oder Handfertigung.

ANMERKUNG 7 Einsteig und Kontrollschächte können vor Ort aus verschiedenen Bauteilen montiert oder als einzelne Einheit gefertigt werden.

ANMERKUNG 8 Einsteig und Kontrollschächte können nationalen Vorschriften und/oder örtlichen Regelungen unterliegen.

Systèmes de canalisations en plastique pour les branchements et les collecteurs d’assainissement enterrés sans pression - Poly(chlorure de vinyle) non plastifié (PVC-U), polypropylène (PP) et polyéthylène (PE) - Partie 2 : Spécifications relatives aux regards et aux boîtes d’inspection et de branchement

Le présent document spécifie les définitions et les exigences relatives aux regards et boîtes d’inspection et de branchement en poly(chlorure de vinyle) non plastifié (PVC-U), en polypropylène (PP) et en polyéthylène (PE), destinés aux systèmes de branchements et de collecteurs d’assainissement sans pression enterrés jusqu’à une profondeur maximale de 6 m du niveau du sol au niveau du fil d’eau du regard ou de la boîte d’inspection et de branchement.

Le présent document traite des regards et des boîtes d’inspection et de branchement avec des éléments de fond ayant une cunette, et de leurs assemblages au système de canalisation.

Les regards et les boîtes d’inspection et de branchement sont destinés à être utilisés hors ou sous charges roulantes à l’extérieur de la structure du bâtiment.

NOTE 1 L’usage prévu dans des installations enterrées à l’extérieur de la structure du bâtiment est repéré au niveau du marquage des produits par le code de zone d’application « U ».

NOTE 2 Les produits conformes au présent document peuvent également être utilisés dans des zones sans charges roulantes.

NOTE 3 Les produits conformes à la présente norme peuvent être mis en œuvre dans des applications enterrées sans calculs statiques supplémentaires.

NOTE 4 Les boîtes d’inspection et de branchement peu profondes sont spécifiées dans l’EN 13598-1 [1].

Les regards et les boîtes d’inspection et de branchement conformes à l’EN 13598-2 sont constitués d’un ensemble de composants prescrits qui sont fabriqués en poly(chlorure de vinyle) non plastifié (PVC-U), en polypropylène (PP), en polypropylène avec modificateurs minéraux (PP-MD) ou en polyéthylène (PE) et assemblés.

NOTE 5 Le montage complet du regard ou de la boîte d’inspection et de branchement peut également inclure des éléments non couverts par le présent document (par exemple, des composants supérieurs ou de surface).

NOTE 6 Les regards et les boîtes d’inspection et de branchement peuvent être fournis avec des tampons, des tampons avec cadre et des grilles conformes à la partie applicable de l’EN 124 [2].

Les regards et les boîtes d’inspection et de branchement conformes à l’EN 13598-2 peuvent être utilisés pour des systèmes d’eaux pluviales.

Les composants du regard et de la boîte d’inspection et de branchement peuvent être fabriqués selon diverses méthodes, par exemple : par extrusion, par moulage par injection, moulage par rotation, moulage à basse pression ou être façonnés.

NOTE 7 Les regards et les boîtes d’inspection et de branchement peuvent être assemblés sur site à partir de différents éléments, mais ils peuvent également être fabriqués en un seul élément.

NOTE 8 Les regards et les boîtes d’inspection et de branchement peuvent être soumis aux réglementations nationales et/ou aux dispositions locales.

Cevni sistemi iz polimernih materialov za odpadno vodo in kanalizacijo, ki delujejo po težnostnem principu in so položeni v zemljo - Nemehčan polivinilklorid (PVC-U), polipropilen (PP) in polietilen (PE) - 2. del: Specifikacije za vstopne in revizijske jaške

General Information

- Status

- Published

- Public Enquiry End Date

- 19-Feb-2019

- Publication Date

- 17-May-2020

- Technical Committee

- PCV - Plastic pipes, fittings and valves

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 12-May-2020

- Due Date

- 17-Jul-2020

- Completion Date

- 18-May-2020

Relations

- Effective Date

- 01-Jun-2020

- Effective Date

- 09-Oct-2024

Overview

EN 13598-2:2020 is the CEN European standard specifying requirements for manholes and inspection chambers made from unplasticized PVC (PVC‑U), polypropylene (PP / PP‑MD) and polyethylene (PE) for non‑pressure underground drainage and sewerage systems. It applies to assemblies with bases that include a flow channel and covers installations up to a maximum depth of 6 m from ground level to the invert. The standard targets installations in outdoor pedestrian and vehicular traffic areas and uses the application code “U” for marking.

Key topics and requirements

- Scope & definitions: Clarifies which manholes and inspection chambers are covered and distinguishes from shallow chambers (EN 13598‑1) and pump/valve chambers (excluded).

- Materials: Acceptable materials include PVC‑U, PP, PP‑MD and PE. Compound/formulation guidance is provided for bases, risers, cones and telescopic adaptors.

- Use of non‑virgin materials: Conditions and requirements are set out (Annex D) for recycled or reprocessed content.

- Geometrical characteristics: Requirements for dimensions of manholes/inspection chambers, base‑to‑pipe connections, steps and permanently fixed ladders.

- Mechanical & physical characteristics: Performance attributes and material durability requirements for components (including updated durability tests for risers, cones and adaptors).

- Sealing & joints: Specification of sealing ring requirements and jointing to the piping system.

- Marking & documentation: Marking of bases (including application code “U”), minimum marking for other components, and required product documentation.

- Performance & testing: Normative test methods included in annexes:

- Annex A - Durability test method

- Annex B - Structural integrity / 50‑year deflection calculation for bases

- Annex C - Impact resistance test for bases

- Annex D - Requirements for non‑virgin materials

Practical applications

- Use in non‑pressure underground drainage, sewerage and storm‑water systems in outdoor pedestrian or vehicular traffic areas.

- Suitable for site‑assembled systems or factory‑made single units; components may be manufactured by extrusion, injection, rotational or low‑pressure moulding or fabrication.

- Products compliant with EN 13598‑2 can be installed without additional static calculations for the covered applications (subject to local regulations).

Who should use this standard

- Manufacturers and fabricators of plastic manholes and inspection chambers

- Design engineers and specifiers preparing drainage/sewerage systems

- Contractors and installers selecting compliant products for site works

- Testing laboratories, conformity assessment bodies and regulators assessing compliance

Related standards

- EN 13598‑1 (shallow chambers)

- EN 1401‑1, EN 1852‑1, EN 12666‑1 (pipe/system material standards)

- EN 124 (covers, frame covers and gratings)

- EN 681 series (sealing materials)

Keywords: EN 13598‑2:2020, manholes, inspection chambers, PVC‑U, PP, PE, non‑pressure underground drainage, sewerage standard, CEN.

Frequently Asked Questions

SIST EN 13598-2:2020 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Plastics piping systems for non-pressure underground drainage and sewerage - Unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP) and polyethylene (PE) - Part 2: Specifications for manholes and inspection chambers". This standard covers: This document specifies the definitions and requirements for unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP) and polyethylene (PE) manholes and inspection chambers intended for non-pressure underground drainage and sewerage systems up to a maximum depth of 6 m from ground level to the invert of the manhole or inspection chamber. This document covers manholes and inspection chambers, with bases having a flow channel, and their joints to the piping system. Manholes and inspection chambers are intended to be used in pedestrian or vehicular traffic areas outside the building structure. NOTE 1 The intended use in underground installation outside the building structure is reflected in the marking of products by the application area code "U". NOTE 2 Products complying with this document can also be used in non-traffic areas. NOTE 3 Products complying with this standard can be installed in underground applications without additional static calculation. NOTE 4 Shallow chambers are specified in EN 13598-1 [1]. Manholes and inspection chambers complying with EN 13598-2 are made from a prescribed set of components that are manufactured from unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP), polypropylene with mineral modifier (PP-MD) or polyethylene (PE) and assembled together. NOTE 5 The complete manhole or inspection chamber assembly can also include items which are not covered by this document (for example near surface or surface components). NOTE 6 Manholes and inspection chambers can be supplied with covers, frame covers and gratings complying with the relevant part of EN 124 [2]. Manholes and inspection chambers complying with EN 13598-2 may be used for storm-water systems. Manhole and inspection chamber components can be manufactured by various methods e.g. extrusion, injection moulding, rotational moulding, low-pressure moulding or fabricated. NOTE 7 Manholes and inspection chambers can be site assembled from different components, but can also be manufactured as a single unit. NOTE 8 Manholes and inspection chambers can be subject to national regulations and / or local provisions.

This document specifies the definitions and requirements for unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP) and polyethylene (PE) manholes and inspection chambers intended for non-pressure underground drainage and sewerage systems up to a maximum depth of 6 m from ground level to the invert of the manhole or inspection chamber. This document covers manholes and inspection chambers, with bases having a flow channel, and their joints to the piping system. Manholes and inspection chambers are intended to be used in pedestrian or vehicular traffic areas outside the building structure. NOTE 1 The intended use in underground installation outside the building structure is reflected in the marking of products by the application area code "U". NOTE 2 Products complying with this document can also be used in non-traffic areas. NOTE 3 Products complying with this standard can be installed in underground applications without additional static calculation. NOTE 4 Shallow chambers are specified in EN 13598-1 [1]. Manholes and inspection chambers complying with EN 13598-2 are made from a prescribed set of components that are manufactured from unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP), polypropylene with mineral modifier (PP-MD) or polyethylene (PE) and assembled together. NOTE 5 The complete manhole or inspection chamber assembly can also include items which are not covered by this document (for example near surface or surface components). NOTE 6 Manholes and inspection chambers can be supplied with covers, frame covers and gratings complying with the relevant part of EN 124 [2]. Manholes and inspection chambers complying with EN 13598-2 may be used for storm-water systems. Manhole and inspection chamber components can be manufactured by various methods e.g. extrusion, injection moulding, rotational moulding, low-pressure moulding or fabricated. NOTE 7 Manholes and inspection chambers can be site assembled from different components, but can also be manufactured as a single unit. NOTE 8 Manholes and inspection chambers can be subject to national regulations and / or local provisions.

SIST EN 13598-2:2020 is classified under the following ICS (International Classification for Standards) categories: 23.040.05 - Pipeline and its parts for external sewage systems; 93.030 - External sewage systems. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13598-2:2020 has the following relationships with other standards: It is inter standard links to SIST EN 13598-2:2016, oSIST prEN 13598-2:2026. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13598-2:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2020

Nadomešča:

SIST EN 13598-2:2016

Cevni sistemi iz polimernih materialov za odpadno vodo in kanalizacijo, ki delujejo

po težnostnem principu in so položeni v zemljo - Nemehčan polivinilklorid (PVC-

U), polipropilen (PP) in polietilen (PE) - 2. del: Specifikacije za vstopne in revizijske

jaške

Plastics piping systems for non-pressure underground drainage and sewerage -

Unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP) and polyethylene (PE) -

Part 2: Specifications for manholes and inspection chambers

Kunststoff-Rohrleitungssysteme für erdverlegte drucklose Abwasserkanäle und -

leitungen - Weichmacherfreies Polyvinylchlorid (PVC-U), Polypropylen (PP) und

Polyethylen (PE) - Teil 2: Anforderungen an Einsteigschächte und Kontrollschächte

Systèmes de canalisations en plastique pour les branchements et les collecteurs

d’assainissement enterrés sans pression - Poly(chlorure de vinyle) non plastifié (PVC-U),

polypropylène (PP) et polyéthylène (PE) - Partie 2 : Spécifications relatives aux regards

et aux boîtes d’inspection et de branchement

Ta slovenski standard je istoveten z: EN 13598-2:2020

ICS:

23.040.05 Cevovodi za zunanje Pipeline and its parts for

sisteme za odpadno vodo in external sewage systems

njihovi deli

93.030 Zunanji sistemi za odpadno External sewage systems

vodo

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13598-2

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2020

EUROPÄISCHE NORM

ICS 23.040.05; 23.040.20; 93.030 Supersedes EN 13598-2:2016

English Version

Plastics piping systems for non-pressure underground

drainage and sewerage - Unplasticized poly(vinyl chloride)

(PVC-U), polypropylene (PP) and polyethylene (PE) - Part

2: Specifications for manholes and inspection chambers

Systèmes de canalisations en plastique pour les Kunststoff-Rohrleitungssysteme für erdverlegte

branchements et les collecteurs d'assainissement drucklose Abwasserkanäle und -leitungen -

enterrés sans pression - Poly(chlorure de vinyle) non Weichmacherfreies Polyvinylchlorid (PVC-U),

plastifié (PVC-U), polypropylène (PP) et polyéthylène Polypropylen (PP) und Polyethylen (PE) - Teil 2:

(PE) - Partie 2 : Spécifications relatives aux regards et Anforderungen an Einsteigschächte und

aux boîtes d'inspection et de branchement Kontrollschächte

This European Standard was approved by CEN on 14 March 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13598-2:2000 E

worldwide for CEN national Members.

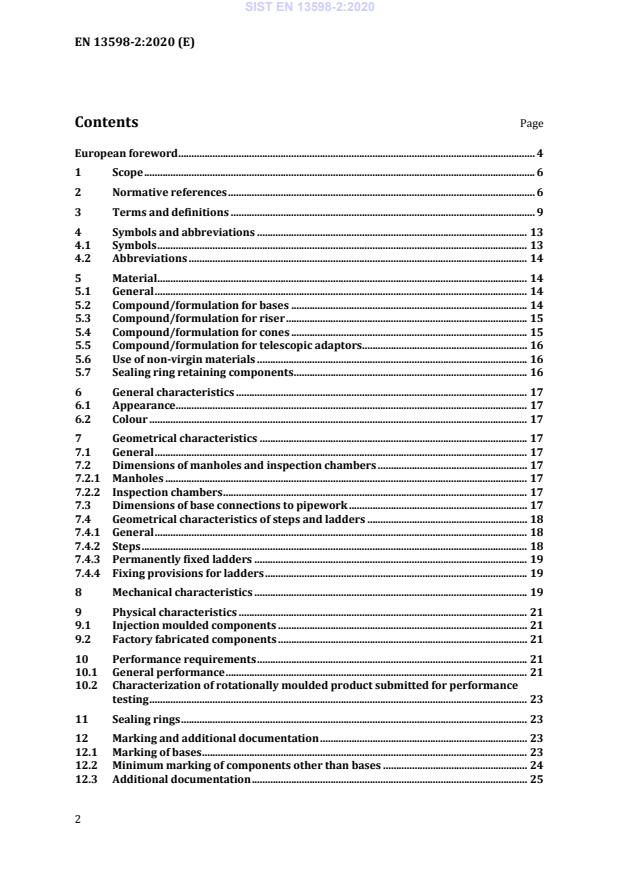

Contents Page

European foreword . 4

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 9

4 Symbols and abbreviations . 13

4.1 Symbols . 13

4.2 Abbreviations . 14

5 Material . 14

5.1 General . 14

5.2 Compound/formulation for bases . 14

5.3 Compound/formulation for riser . 15

5.4 Compound/formulation for cones . 15

5.5 Compound/formulation for telescopic adaptors . 16

5.6 Use of non-virgin materials . 16

5.7 Sealing ring retaining components . 16

6 General characteristics . 17

6.1 Appearance . 17

6.2 Colour . 17

7 Geometrical characteristics . 17

7.1 General . 17

7.2 Dimensions of manholes and inspection chambers . 17

7.2.1 Manholes . 17

7.2.2 Inspection chambers . 17

7.3 Dimensions of base connections to pipework . 17

7.4 Geometrical characteristics of steps and ladders . 18

7.4.1 General . 18

7.4.2 Steps . 18

7.4.3 Permanently fixed ladders . 19

7.4.4 Fixing provisions for ladders . 19

8 Mechanical characteristics . 19

9 Physical characteristics . 21

9.1 Injection moulded components . 21

9.2 Factory fabricated components . 21

10 Performance requirements . 21

10.1 General performance . 21

10.2 Characterization of rotationally moulded product submitted for performance

testing . 23

11 Sealing rings . 23

12 Marking and additional documentation . 23

12.1 Marking of bases . 23

12.2 Minimum marking of components other than bases . 24

12.3 Additional documentation . 25

Annex A (normative) Test method for durability . 26

A.1 General . 26

A.2 Test procedure . 26

A.3 Material characteristics . 26

Annex B (normative) Test method for structural integrity of bases . 28

B.1 Procedure . 28

B.2 Calculation of 50-year deflection. 28

Annex C (normative) Test method for impact resistance of bases . 29

C.1 Test equipment . 29

C.2 Test procedure . 29

Annex D (normative) Utilization of non-virgin materials . 30

Bibliography . 33

European foreword

This document (EN 13598-2:2020) has been prepared by Technical Committee CEN/TC 155

“Plastics piping systems and ducting systems”, the secretariat of which is held by NEN.

This European Standard shall be given the status of a national standard, either by publication of

an identical text or by endorsement, at the latest by month November 2020, and conflicting

national standards shall be withdrawn at the latest by November 2020.

Attention is drawn to the possibility that some of the elements of this document may be the

subject of patent rights. CEN shall not be held responsible for identifying any or all such patent

rights.

This document supersedes EN 13598-2:2016.

Compared to the previous version, the main changes are listed below:

1) test methods have been updated to the latest EN ISO Standards where applicable;

2) the scope has been amended to clarify the products covered in this part and avoid confusion

with the scope of part 1;

3) terms and definitions have been updated and explanatory diagrams are now included;

4) material durability test requirements have been included for riser, cone and telescopic

adaptor components. The durability test method (Annex A) has also been updated;

5) the permitted use of non-virgin materials has been clarified and a new Annex D included,

with conditions and requirements for non-virgin materials;

6) fitness for purpose testing of factory fabricated components is now included;

7) the minimum marking requirement for components other than bases has been updated.

This document is part of a System Standard for plastics piping systems of a particular material for

a specified application.

System Standards are based on the results of the work being undertaken in ISO/TC 138 “Plastics

pipes, fittings and valves for the transport of fluids”, which is a Technical Committee of the

International Organization for Standardization (ISO).

They are supported by separate standards on test methods to which references are made

throughout the System Standard.

The System Standards are consistent with general standards on functional requirements and on

recommended practice for installation.

This document does not cover sewage pump chambers, valve chambers and similar products.

Separate standard(s) for manholes, inspection chambers and road gullies for storm water

systems are currently under investigation.

EN 13598 consists of the following parts under the general title Plastics piping systems for non-

pressure underground drainage and sewerage — Unplasticized poly(vinyl chloride) (PVC-U),

polypropylene (PP) and polyethylene (PE):

— Part 1: Specification for ancillary fittings and shallow chambers (under revision);

— Part 2: Specifications for manholes and inspection chambers (this document);

— Part 3: Assessment of conformity (CEN/TS under revision).

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary,

Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland,

Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden,

Switzerland, Turkey and the United Kingdom.

1 Scope

This document specifies the definitions and requirements for unplasticized poly(vinyl chloride)

(PVC-U), polypropylene (PP) and polyethylene (PE) manholes and inspection chambers intended

for non-pressure underground drainage and sewerage systems up to a maximum depth of 6 m

from ground level to the invert of the manhole or inspection chamber.

This document covers manholes and inspection chambers, with bases having a flow channel, and

their joints to the piping system.

Manholes and inspection chambers are intended to be used in pedestrian or vehicular traffic

areas outside the building structure.

NOTE 1 The intended use in underground installation outside the building structure is reflected in the

marking of products by the application area code “U”.

NOTE 2 Products complying with this document can also be used in non-traffic areas.

NOTE 3 Products complying with this standard can be installed in underground applications without

additional static calculation.

NOTE 4 Shallow chambers are specified in EN 13598-1 [1].

Manholes and inspection chambers complying with EN 13598-2 are made from a prescribed set

of components that are manufactured from unplasticized poly(vinyl chloride) (PVC-U),

polypropylene (PP), polypropylene with mineral modifier (PP-MD) or polyethylene (PE) and

assembled together.

NOTE 5 The complete manhole or inspection chamber assembly can also include items which are not

covered by this document (for example near surface or surface components).

NOTE 6 Manholes and inspection chambers can be supplied with covers, frame covers and gratings

complying with the relevant part of EN 124 [2].

Manholes and inspection chambers complying with EN 13598-2 may be used for storm-water

systems.

Manhole and inspection chamber components can be manufactured by various methods e.g.

extrusion, injection moulding, rotational moulding, low-pressure moulding or fabricated.

NOTE 7 Manholes and inspection chambers can be site assembled from different components, but can

also be manufactured as a single unit.

NOTE 8 Manholes and inspection chambers can be subject to national regulations and / or local

provisions.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

EN 476, General requirements for components used in drains and sewers

EN 681-1, Elastomeric seals — Materials requirements for pipe joint seals used in water and

drainage applications — Part 1: Vulcanized rubber

EN 681-2, Elastomeric Seals — Materials requirements for pipe joint seals used in water and

drainage applications — Part 2: Thermoplastic elastomers

EN 681-3, Elastomeric seals — Materials requirements for pipe joint seals used in water and

drainage applications — Part 3: Cellular materials of vulcanized rubber

EN 681-4, Elastomeric seals — Materials requirements for pipe joint seals used in water and

drainage applications — Part 4: Cast polyurethane sealing elements

EN 1401-1, Plastics piping systems for non-pressure underground drainage and sewerage —

Unplasticized poly(vinyl chloride) (PVC-U) — Part 1: Specifications for pipes, fittings and the system

EN 1852-1, Plastics piping systems for non-pressure underground drainage and sewerage —

Polypropylene (PP) — Part 1: Specifications for pipes, fittings and the system

EN 1905, Plastics piping systems — Unplasticized poly(vinyl chloride) (PVC-U) pipes, fittings and

material — Method for assessment of the PVC content based on total chlorine content

EN 12099, Plastics piping systems — Polyethylene piping materials and components —

Determination of volatile content

EN 12666-1, Plastics piping systems for non-pressure underground drainage and sewerage

Polyethylene (PE) — Part 1: Specifications for pipes, fittings and the system

EN 13101:2002, Steps for underground man entry chambers — Requirements, marking, testing and

evaluation of conformity

EN 13476-2, Plastics piping systems for non-pressure underground drainage and sewerage —

Structured-wall piping systems of unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP)

and polyethylene (PE) — Part 2: Specifications for pipes and fittings with smooth internal and

external surface and the system, Type A

EN 13476-3, Plastics piping systems for non-pressure underground drainage and sewerage —

Structured-wall piping systems of unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP)

and polyethylene (PE) — Part 3: Specifications for pipes and fittings with smooth internal and

profiled external surface and the system, Type B

EN 14396, Fixed ladders for manholes

EN 14758-1, Plastics piping systems for non-pressure underground drainage and sewerage —

Polypropylene with mineral modifiers (PP-MD) — Part 1: Specifications for pipes, fittings and the

system

EN ISO 1043-1, Plastics — Symbols and abbreviated terms — Part 1: Basic polymers and their

special characteristics (ISO 1043-1)

EN ISO 1133-1, Plastics — Determination of the melt mass-flow rate (MFR) and melt volume-flow

rate (MVR) of thermoplastics — Part 1: Standard method (ISO 1133-1)

EN ISO 1183-1, Plastics — Methods for determining the density of non-cellular plastics — Part 1:

Immersion method, liquid pyknometer method and titration method (ISO 1183-1)

EN ISO 1183-2, Plastics — Methods for determining the density of non-cellular plastics — Part 2:

Density gradient column method (ISO 1183-2)

EN ISO 2507-1, Thermoplastics pipes and fittings — Vicat softening temperature — Part 1: General

test method (ISO 2507-1)

EN ISO 3126, Plastics piping systems — Plastics components — Determination of dimensions

(ISO 3126)

EN ISO 3127, Thermoplastics pipes — Determination of resistance to external blows — Round-the-

clock method (ISO 3127)

EN ISO 3451-1, Plastics — Determination of ash — Part 1: General methods (ISO 3451-1)

EN ISO 3451-5, Plastics — Determination of ash — Part 5: Poly(vinyl chloride) (ISO 3451-5)

EN ISO 9967:2016, Thermoplastics pipes — Determination of creep ratio (ISO 9967:2016)

EN ISO 11357-6, Plastics — Differential scanning calorimetry (DSC) — Part 6: Determination of

oxidation induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT)

(ISO 11357-6)

EN ISO 13229, Thermoplastics piping systems for non-pressure applications — Unplasticized

poly(vinyl chloride) (PVC-U) pipes and fittings — Determination of the viscosity number and K-value

(ISO 13229)

EN ISO 13254, Thermoplastics piping systems for non-pressure applications — Test method for

watertightness (ISO 13254)

EN ISO 13259, Thermoplastics piping systems for underground non-pressure applications — Test

method for leaktightness of elastomeric sealing ring type joints (ISO 13259)

EN ISO 13263, Thermoplastics piping systems for non-pressure underground drainage and

sewerage — Thermoplastics fittings — Test method for impact strength (ISO 13263)

ISO 13266:2010, Thermoplastics piping systems for non-pressure underground drainage and

sewerage — Thermoplastics shafts or risers for inspection chambers and manholes —

Determination of resistance against surface and traffic loading (ISO 13266)

ISO 13267, Thermoplastics piping systems for non-pressure underground drainage and

sewerage — Thermoplastics inspection chamber and manhole bases — Test methods for buckling

resistance (ISO 13267)

ISO 13268, Thermoplastics piping systems for non-pressure underground drainage and

sewerage — Thermoplastics shafts or risers for inspection chambers and manholes —

Determination of ring stiffness

3 Terms and definitions

For the purposes of this document, the terms, definitions and abbreviations given in EN ISO 1043-

1 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

manhole

chamber with a removable cover constructed in a drain or sewer to permit entry by personnel,

with a riser of 800 mm minimum inner diameter

Note 1 to entry: Figure 1 shows typical manholes.

Note 2 to entry: See EN 476 for dimensions of non-circular manholes.

Note 3 to entry: Manholes are subject to national safety regulations and / or local provisions regarding

man-entry limitations.

3.2

inspection chamber

chamber with a removable cover constructed in a drain or sewer that permits the introduction of

cleaning and inspection equipment from surface level, but does not provide access for personnel,

with a riser of 200 mm minimum outer diameter and an inner diameter of less than 800 mm

Note 1 to entry: Figure 2 shows typical inspection chambers.

Note 2 to entry: See EN 476 for non-circular chambers.

3.3

base

bottom part of a manhole or inspection chamber, allowing direct connection to buried drain or

sewer pipes and including integrally formed channels with benching as appropriate

Note 1 to entry: In case of a one-piece manhole or inspection chamber, for testing purposes the base

component ends at a distance of minimum 300 mm measured from the top of the main channel. Above

300 mm the section should be considered as a riser and tested accordingly.

Note 2 to entry: Bases having a spherical design may be used. National regulations can apply.

3.4

flow channel

open and accessible continuation of the sewer network in a manhole or inspection chamber to

allow directional changes maintaining the hydraulic performance of a sewer system

Note 1 to entry: The term flow profile is also used.

3.5

benching

sloped surface adjacent to the channel in a manhole or inspection chamber

3.6

riser

component which is connected onto a base and which defines the nominal size of the manhole or

inspection chamber

Note 1 to entry: The riser can be supplied either as one or more separate items, for site jointing to the

base, or integrated with the base.

Note 2 to entry: In case of a one-piece manhole or inspection chamber, for testing purposes the riser

component starts at a distance of minimum 300 mm measured from the top of the main channel. Below

300 mm the section should be considered as a base and tested accordingly.

3.7

telescopic adaptor

part of the assembly on top of the riser or cone that allows adjustment of the surface component

or near surface component

Note 1 to entry: Telescopic adaptors allow accommodation of settlement during lifetime and eliminate

the transmission of vehicular loading down the riser.

3.8

cone

adapter allowing change in diameter, close to ground level

3.9

near-surface component

component intended to spread vehicular loading directly to the soil and/or provide a seating for

the cover and its frame

3.10

assembly

items collectively forming a manhole or inspection chamber

Note 1 to entry: See typical examples in Figures 1 and 2.

3.11

invert

lowest point of the internal surface of the barrel of a pipe or channel at any cross section

3.12

maximum height of groundwater above invert

H

w

height of water column above the invert that the manhole or inspection chamber can withstand

during use

3.13

virgin material

material in a form such as granules or powder that has not been subjected to use or processing

other than that required for its manufacture and to which no reprocessed or recycled material

has been added

3.14

own reprocessed material

material prepared from unused products, including trimmings from the production, that will be

reprocessed in a manufacturer’s plant after having been previously processed by the same

manufacturer

3.15

recycled material

material prepared from used thermoplastic products which have been cleaned and crushed or

ground

3.16

agreed specification

specification of the relevant material characteristics agreed between the supplier of the non-

virgin material and the manufacturer

Key

a cover (not covered by this document) 1 inlet

b near surface component (not covered by this 2 outlet

document)

c telescopic adaptor 3 invert

d cone 4 inner diameter

e riser 5 benching

e considered as riser 6 channel

f base

f considered as base

g connection

Figure 1 — Typical manholes

Key

a cover (not covered by this document) 1 inlet

b near surface component (not covered by this 2 outlet

document)

c telescopic adaptor 3 invert

e1 riser 4 inner diameter

e2 considered as riser 5 benching

f base 6 channel

f2 considered as base

g connection

Figure 2 — Typical inspection chambers

4 Symbols and abbreviations

4.1 Symbols

For the purposes of this document, the following symbols apply.

A length of engagement

d nominal outside diameter

n

d mean outside diameter

em

d mean inside diameter of socket

sm

H maximum height of groundwater above invert

w

L length of spigot

4.2 Abbreviations

For the purposes of this document, the following abbreviations apply.

MFR melt mass-flow rate

OIT oxidation induction time

PE polyethylene

PP polypropylene

PP-MD polypropylene modified with minerals

PVC-U unplasticized poly(vinyl chloride)

5 Material

5.1 General

Components of manholes and inspection chambers may be manufactured from different

compounds/formulations.

The compound/formulation shall be PVC-U resin, PP or PE polymer, additives and if applicable

non-virgin material that shall allow the final component to comply with the requirements of this

document.

5.2 Compound/formulation for bases

The base shall be tested according to Table 1.

Table 1 — Durability requirements for bases

Test parameters

Test

Characteristic Requirement

method

Parameter Value

Durability No cracks or crazes Test pressure, P e c

−0,1 × Hw/R bar Annex A

Maximum height of groundwater b

2 m ≤ Hw ≤ 5 m

a

above invert, H

w

Rating factor, R Shall conform to

Table A.1

Duration, t d

3 000 h

Test temperature, T Shall conform to

Table A.1

a

Test in accordance with the manufacturer's declared maximum height of groundwater.

b

The minimum value of 2 m of groundwater above invert is based on the need to safeguard durability where

there is no groundwater present.

c

When testing for the durability of materials rubber ring joints can be replaced by welding.

d

Materials complying with material requirement of the standards in Table 2, duration may be reduced to

1 000 h.

e 5 2

1 bar = 10 N/m = 0,1 MPa.

Table 2 — Materials and corresponding European standards

Material Corresponding European standard

Unplasticized poly(vinyl chloride) (PVC-U) EN 1401-1, EN 13476-2 type A2, EN 13476-3

Polypropylene (PP) EN 1852-1, EN 13476-2 type A2, EN 13476-3

Polyethylene (PE) EN 12666-1, EN 13476-2 type A2, EN 13476-3

Polypropylene with mineral modifiers (PP-MD) EN 14758-1

5.3 Compound/formulation for riser

The riser shall be tested according to Table 3.

Components manufactured from compound/formulation complying with Table 1 or Table 2 are

deemed to comply with this requirement without further testing.

Table 3 — Durability requirements for riser

Test par

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...