SIST EN 14583:2022

(Main)Workplace exposure - Volumetric bioaerosol samplers - General requirements and evaluation of performance

Workplace exposure - Volumetric bioaerosol samplers - General requirements and evaluation of performance

This document specifies general requirements for the evaluation of volumetric bioaerosol samplers in order to assess workplace exposure and their physical and biological performance.

This document describes the procedures for the development of volumetric bioaerosol samplers as well as their properties and validation.

This document provides a description of a test facility and selection criteria for microbial strains that can be used to assess their biological performance.

This document addresses requirements to manufacturers and developers of volumetric bioaerosol samplers as well as to test facilities with the equipment and skills to carry out the performance measurements of these samplers (see Annex D for application guidance).

This document is not intended for operators who use volumetric bioaerosol samplers to carry out exposure measurements for workers at occupational settings.

This document is not applicable for clean room measurements other than for occupational safety.

Exposition am Arbeitsplatz - Volumetrische Sammler für Bioaerosole - Allgemeine Anforderungen und Bewertung der Leistungsfähigkeit

Dieses Dokument legt allgemeine Anforderungen an die Bewertung von volumetrischen Sammlern für Bioaerosole fest, um die Exposition am Arbeitsplatz sowie deren physikalische und biologische Leistungs-fähigkeit zu beurteilen.

Dieses Dokument beschreibt die Verfahren zur Entwicklung von volumetrischen Sammlern für Bioaerosole sowie deren Eigenschaften und Validierung.

Dieses Dokument enthält eine Beschreibung einer Prüfeinrichtung sowie Auswahlkriterien für Stämme von Mikroorganismen, die zur Bewertung von deren biologischer Leistungsfähigkeit verwendet werden können.

Dieses Dokument richtet sich an Hersteller und Entwickler von volumetrischen Sammlern für Bioaerosole sowie an Prüfeinrichtungen, die über die Ausrüstung und Befähigung verfügen, Leistungsmessungen dieser Sammler durchzuführen (siehe Anhang D für Anwendungshinweise).

Dieses Dokument ist nicht für Betreiber bestimmt, die volumetrische Sammler für Bioaerosole verwenden, um Expositionsmessungen von Arbeitnehmern an Arbeitsplätzen durchzuführen.

Exposition sur les lieux de travail - Dispositifs de prélèvement volumétrique des bioaérosols - Exigences générales et évaluation des performances

Le présent document spécifie des exigences générales relatives à l’évaluation des dispositifs de prélèvement volumétrique des bioaérosols visant à déterminer l’exposition sur les lieux de travail ainsi qu’à l’évaluation de leurs performances physiques et biologiques.

Le présent document décrit les modes opératoires pour le développement des dispositifs de prélèvement volumétrique des bioaérosols ainsi que leurs caractéristiques et le processus de validation.

Le présent document décrit une installation d’essai ainsi que les critères de sélection des souches microbiennes pouvant être utilisées pour l’évaluation des performances biologiques des dispositifs.

Le présent document couvre les exigences à l’attention des fabricants et développeurs de dispositifs de prélèvement volumétrique des bioaérosols ainsi que celles relatives aux installations d’essai disposant des équipements et des compétences pour mesurer les performances de ces dispositifs (voir l’Annexe D pour consulter les recommandations d’application).

Le présent document n’est pas destiné aux opérateurs utilisant des dispositifs de prélèvement volumétrique des bioaérosols pour mesurer l’exposition des travailleurs sur leurs lieux de travail.

Le présent document ne s’applique pas aux mesurages en salle propre, sauf dans le cadre de la sécurité au travail.

Izpostavljenost na delovnem mestu - Vzorčevalniki za volumetrijsko vzorčenje bioaerosolov - Splošne zahteve in vrednotenje lastnosti

Ta dokument določa splošne zahteve za uporabo ter vrednotenje fizičnih in bioloških lastnosti naprav za volumetrično vzorčenje, ki se uporabljajo za ocenjevanje bioaerosolov na delovnem mestu.

Ta dokument navaja merila za izbiro mikrobnih sevov, ki se lahko uporabijo za oceno bioloških lastnosti vzorčevalnikov.

Ta dokument opisuje tudi preskusno komoro za bioaerosol, primerno za ocenjevanje bioloških lastnosti naprav za vzorčenje bioaerosolov.

Dokument se ne uporablja za meritve čistih prostorov.

General Information

- Status

- Published

- Public Enquiry End Date

- 01-Oct-2020

- Publication Date

- 08-Feb-2022

- Technical Committee

- KAZ - Air quality

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 28-Jan-2022

- Due Date

- 04-Apr-2022

Relations

- Effective Date

- 01-Mar-2022

Overview

EN 14583:2021 (CEN) defines general requirements and test procedures for volumetric bioaerosol samplers used to assess workplace exposure to airborne microorganisms. The standard specifies how to evaluate both the physical sampling efficiency and the biological preservation efficiency of samplers, describes suitable test facilities and microbial model organisms, and gives guidance for manufacturers and test laboratories on sampler development, validation and performance reporting. EN 14583:2021 supersedes EN 14583:2004 and is intended to support the development and verification of equipment used for bioaerosol sampling in occupational environments (not for routine operator exposure measurements or clean‑room testing other than for occupational safety).

Key Topics and Requirements

- Scope and purpose: Defines performance characteristics and validation procedures for volumetric bioaerosol samplers used in workplace atmospheres.

- Design and construction: Requirements for mechanical construction, materials (to minimise moisture uptake and electrostatic bias), indicators, adjustments, battery management, and labelling.

- Airflow control and calibration: Requirements for accurate airflow measurement, calibration and maintenance of the sampler pump in accordance with related pump standards.

- Sampling performance:

- Physical sampling efficiency - the ability to capture airborne particles across relevant aerodynamic diameters.

- Biological preservation efficiency - the ability of the sampler to preserve microorganism viability during collection and handling.

- Test methods and facilities: Description of suitable test chambers and experimental conditions, concentration ranges, aerosol generation and stabilization time, and orientation and loading considerations.

- Microbial model organisms: Selection criteria and examples of microbial strains for laboratory performance tests (see Annex C).

- Documentation: Required test report content and informative application guidance (Annex D).

- Safety note: The standard warns about hazards when using test organisms and aerosols and requires appropriate safety measures.

Applications and Intended Users

- Manufacturers and developers of volumetric bioaerosol samplers seeking to design, validate and certify product performance.

- Test laboratories and research facilities performing comparative performance evaluations and biological preservation testing.

- Occupational hygiene researchers and instrument developers who require standardized methods to assess sampler performance in workplace exposure studies.

- Not intended for routine users conducting workplace exposure measurements (operators) or for clean-room process qualification (except where occupational safety applies).

Related Standards

- EN 13098 - Measurement of airborne microorganisms (general requirements)

- EN 1540 - Workplace exposure terminology

- EN ISO 13137 - Pumps for personal sampling (requirements/test methods)

- EN IEC 60079 series - Requirements for equipment in potentially explosive atmospheres

Keywords: EN 14583:2021, volumetric bioaerosol samplers, workplace exposure, bioaerosol sampling, biological preservation efficiency, physical sampling efficiency, test facility, CEN.

Frequently Asked Questions

SIST EN 14583:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Workplace exposure - Volumetric bioaerosol samplers - General requirements and evaluation of performance". This standard covers: This document specifies general requirements for the evaluation of volumetric bioaerosol samplers in order to assess workplace exposure and their physical and biological performance. This document describes the procedures for the development of volumetric bioaerosol samplers as well as their properties and validation. This document provides a description of a test facility and selection criteria for microbial strains that can be used to assess their biological performance. This document addresses requirements to manufacturers and developers of volumetric bioaerosol samplers as well as to test facilities with the equipment and skills to carry out the performance measurements of these samplers (see Annex D for application guidance). This document is not intended for operators who use volumetric bioaerosol samplers to carry out exposure measurements for workers at occupational settings. This document is not applicable for clean room measurements other than for occupational safety.

This document specifies general requirements for the evaluation of volumetric bioaerosol samplers in order to assess workplace exposure and their physical and biological performance. This document describes the procedures for the development of volumetric bioaerosol samplers as well as their properties and validation. This document provides a description of a test facility and selection criteria for microbial strains that can be used to assess their biological performance. This document addresses requirements to manufacturers and developers of volumetric bioaerosol samplers as well as to test facilities with the equipment and skills to carry out the performance measurements of these samplers (see Annex D for application guidance). This document is not intended for operators who use volumetric bioaerosol samplers to carry out exposure measurements for workers at occupational settings. This document is not applicable for clean room measurements other than for occupational safety.

SIST EN 14583:2022 is classified under the following ICS (International Classification for Standards) categories: 13.040.30 - Workplace atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14583:2022 has the following relationships with other standards: It is inter standard links to SIST EN 14583:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14583:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2022

Nadomešča:

SIST EN 14583:2004

Izpostavljenost na delovnem mestu - Vzorčevalniki za volumetrijsko vzorčenje

bioaerosolov - Splošne zahteve in vrednotenje lastnosti

Workplace exposure - Volumetric bioaerosol samplers - General requirements and

evaluation of performance

Exposition am Arbeitsplatz - Volumetrische Sammler für Bioaerosole - Allgemeine

Anforderungen und Bewertung der Leistungsfähigkeit

Exposition sur les lieux de travail - Dispositifs de prélèvement volumétrique des

bioaérosols - Exigences générales et évaluation des performances

Ta slovenski standard je istoveten z: EN 14583:2021

ICS:

13.040.30 Kakovost zraka na delovnem Workplace atmospheres

mestu

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14583

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2021

EUROPÄISCHE NORM

ICS 13.040.30 Supersedes EN 14583:2004

English Version

Workplace exposure - Volumetric bioaerosol samplers -

General requirements and evaluation of performance

Exposition sur les lieux de travail - Dispositifs de Exposition am Arbeitsplatz - Volumetrische Sammler

prélèvement volumétrique des bioaérosols - Exigences für Bioaerosole - Allgemeine Anforderungen und

générales et évaluation des performances Bewertung der Leistungsfähigkeit

This European Standard was approved by CEN on 8 November 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14583:2021 E

worldwide for CEN national Members.

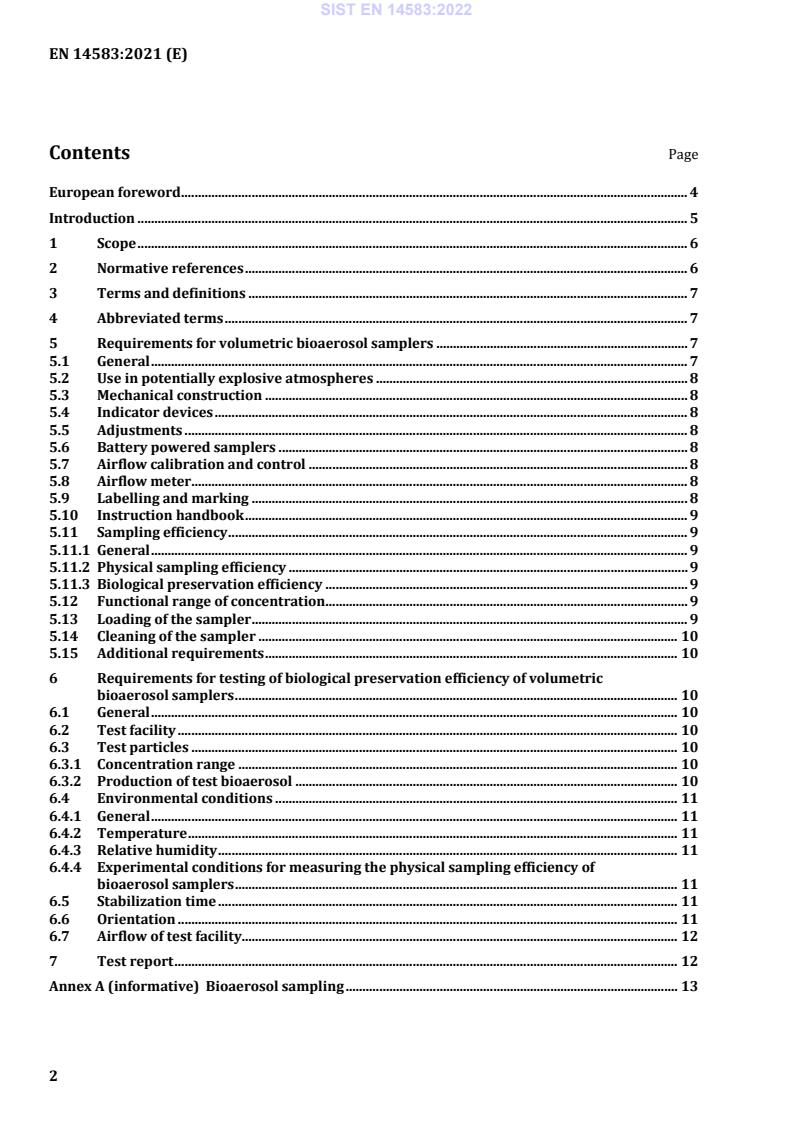

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Abbreviated terms . 7

5 Requirements for volumetric bioaerosol samplers . 7

5.1 General . 7

5.2 Use in potentially explosive atmospheres . 8

5.3 Mechanical construction . 8

5.4 Indicator devices . 8

5.5 Adjustments . 8

5.6 Battery powered samplers . 8

5.7 Airflow calibration and control . 8

5.8 Airflow meter . 8

5.9 Labelling and marking . 8

5.10 Instruction handbook . 9

5.11 Sampling efficiency . 9

5.11.1 General . 9

5.11.2 Physical sampling efficiency . 9

5.11.3 Biological preservation efficiency . 9

5.12 Functional range of concentration . 9

5.13 Loading of the sampler . 9

5.14 Cleaning of the sampler . 10

5.15 Additional requirements . 10

6 Requirements for testing of biological preservation efficiency of volumetric

bioaerosol samplers . 10

6.1 General . 10

6.2 Test facility . 10

6.3 Test particles . 10

6.3.1 Concentration range . 10

6.3.2 Production of test bioaerosol . 10

6.4 Environmental conditions . 11

6.4.1 General . 11

6.4.2 Temperature . 11

6.4.3 Relative humidity . 11

6.4.4 Experimental conditions for measuring the physical sampling efficiency of

bioaerosol samplers . 11

6.5 Stabilization time . 11

6.6 Orientation . 11

6.7 Airflow of test facility. 12

7 Test report . 12

Annex A (informative) Bioaerosol sampling . 13

Annex B (normative) Test facilities usable for assessing biological performance of

volumetric bioaerosol samplers . 15

Annex C (informative) Microbial model organisms used for bioaerosol studies . 19

Annex D (informative) Application guidance . 21

Bibliography . 22

European foreword

This document (EN 14583:2021) has been prepared by Technical Committee CEN/TC 137 “Assessment

of workplace exposure to chemical and biological agents”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2022, and conflicting national standards shall be

withdrawn at the latest by June 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14583:2004.

The major technical changes between this document and the previous edition are as follows:

a) document title changed;

b) Scope rewritten and given more detailed;

c) Terms and definitions already referred to in EN 1540 or EN 13098 deleted;

d) Annex B revised by replacing the former content by general requirements on test facilities and an

overview on different types and examples of test facilities;

e) new Annex C on microbial model organisms used for bioaerosol studies added;

f) new Annex D giving application guidance added;

g) Bibliography updated;

h) whole document restructured, editorially and technically revised.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document is needed to promote the development of new equipment for measurement of

microorganisms in the work environment. This document can also apply to existing equipment. It is

intended to specify requirements and methods to determine performance characteristics of volumetric

bioaerosol samplers used to collect bioaerosols from the workplace atmosphere. Examples of test

facilities and microbial model organisms usually used for laboratory measurements of the biological

preservation efficiency of volumetric bioaerosol samplers are provided.

WARNING — The use of this document can involve hazardous materials, operations and

equipment. This document does not purport to address all of the safety problems associated with

its use. It is the responsibility of the user of this document to take appropriate health and safety

precautions and to check which restrictive rules and regulations need to be taken into account

prior to use.

1 Scope

This document specifies general requirements for the evaluation of volumetric bioaerosol samplers in

order to assess workplace exposure and their physical and biological performance.

This document describes the procedures for the development of volumetric bioaerosol samplers as well

as their properties and validation.

This document provides a description of a test facility and selection criteria for microbial strains that can

be used to assess their biological performance.

This document addresses requirements to manufacturers and developers of volumetric bioaerosol

samplers as well as to test facilities with the equipment and skills to carry out the performance

measurements of these samplers (see Annex D for application guidance).

This document is not intended for operators who use volumetric bioaerosol samplers to carry out

exposure measurements for workers at occupational settings.

This document is not applicable for clean room measurements other than for occupational safety.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1540, Workplace exposure - Terminology

EN 13098:2019, Workplace exposure - Measurement of airborne microorganisms and microbial

compounds - General requirements

EN 60079-1, Explosive atmospheres - Part 1: Equipment protection by flameproof enclosures "d"

EN 60079-2, Explosive atmospheres - Part 2: Equipment protection by pressurized enclosure "p"

EN 60079-5, Explosive atmospheres - Part 5: Equipment protection by powder filling "q"

EN 60079-6, Explosive atmospheres - Part 6: Equipment protection by liquid immersion "o"

EN 60079-7, Explosive atmospheres - Part 7: Equipment protection by increased safety "e"

EN 60079-11, Explosive atmospheres - Part 11: Equipment protection by intrinsic safety “i”

EN 60079-18, Explosive atmospheres - Part 18: Equipment protection by encapsulation "m"

EN 60079-25, Explosive atmospheres - Part 25: Intrinsically safe electrical systems

EN IEC 60079-0, Explosive atmospheres - Part 0: Equipment - General requirements (IEC 60079-0)

EN ISO 13137, Workplace atmospheres - Pumps for personal sampling of chemical and biological agents -

Requirements and test methods (ISO 13137)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 1540, EN 13098 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

personal sampler

sampler, attached to a person, that collects gases, vapours or airborne particles in the breathing zone for

the purpose of measuring exposure to chemical agents and/or biological agents

Note 1 to entry: Some samplers have integral pumps, and some do not. Where the personal sampler requires the

use of an external pump, the pump is not subject to the requirements of this document.

[SOURCE: ISO 18158:2016, 2.2.2.2, modified – Note 1 to entry has been added.]

3.2

particle aerodynamic diameter

diameter of a sphere of 1 g/cm density with the same terminal settling velocity in calm air as the particle,

under the prevailing conditions of temperature, pressure and relative humidity

[SOURCE: ISO 18158:2016, 2.1.4.8, [21]]

4 Abbreviated terms

ATCC American Type Culture Collection

CBS Centraalbureau voor Schimmelcultures

CCUG Culture Collection University of Göteborg

DSMZ Deutsche Stammsammlung für Mikroorganismen und Zellkulturen

HEPA High Efficiency Particulate Air-(filter)

NCTC National Collection of Type Cultures

OPC Optical Particle Counter

5 Requirements for volumetric bioaerosol samplers

5.1 General

The pumps used for personal sampling shall fulfil the requirements specified in EN ISO 13137.

NOTE EN 13205 can be used to assess the sampler performance for measurement of airborne particle

concentrations. However, at present no practical experience is reported on the application of EN 13205 for

volumetric bioaerosol samplers.

5.2 Use in potentially explosive atmospheres

When the sampler covered by this document is to be used in potentially explosive atmospheres, it shall

comply with EN IEC 60079-0, EN 60079-1, EN 60079-2, EN 60079-5, EN 60079-6, EN 60079-7,

EN 60079-11, EN 60079-18 and EN 60079-25.

5.3 Mechanical construction

Every sampler shall be constructed in such a manner that it is easily accessible for regular function checks

and that airflow can easily be measured and calibrated. The sampling pump shall maintain the required

airflow rate throughout the sampling period.

Material used in the sampling head should be chosen to avoid moisture uptake and electrostatic charges.

5.4 Indicator devices

An indicator device shall be provided to show that the sampler is switched on. If the sampler has more

than one measuring range, the selected range shall be clearly identified.

NOTE It is an advantage if elapsed time indicators, low flow rate indicators, flow interrupted indicators are

given.

5.5 Adjustments

Any equipment (switch, knob, etc.) used for modifying the operating parameters (sampling time, flow

rate, etc.) of the sampler shall be protected against inadvertent or purposeful adjustment during

sampling. The operational settings should be displayed.

5.6 Battery powered samplers

Samplers powered with integrated batteries shall be provided with an early indication of low battery

condition.

5.7 Airflow calibration and control

During sampling the deviation from the required airflow should not exceed ± 5 %.

The manufacturer shall state the following:

a) the way in which the calibration of the air flow rate of the sampler can be checked and re-calibration

can be done, if necessary;

b) the parameters that should be calibrated, the frequency required and whether the calibration can be

carried out by the operator.

5.8 Airflow meter

A device to measure the airflow through the sampler before and after sampling in the field should be

supplied if required.

NOTE This device can be different from that used for calibration.

Samplers with integral airflow meters shall be calibrated against a traceable external airflow meter

before use.

5.9 Labelling and marking

The manufacturer of the sampler shall be clearly identified to ensure traceability to specified

performance characteristics.

5.10 Instruction handbook

The instruction handbook shall be written in a language, which is understandable in the country of the

operator. It shall be easily understood and every function explained.

The instruction handbook shall illustrate all components and their handling by figures.

The instruction handbook shall give the environmental conditions and other conditions under which the

sampler shall be operated including limitations to its use. It shall give exact calibration instructions and

recommended equipment (e.g. flow meters) to be used. The instruction handbook shall also give

instructions for troubleshooting and maintenance of the sampler.

5.11 Sampling efficiency

5.11.1 General

The sampling efficiency of samplers collecting biological agents comprises of a physical part, the physical

sampling efficiency (see 5.11.2) and the biological preservation efficiency (see 5.11.3).

The sampler should be able to collect a representative sample of the required health-related fraction of

the bioaerosol according to EN 481.

The health-related fraction to be used shall be specified by the manufacturer.

5.11.2 Physical sampling efficiency

The physical sampling efficiency can be measured as a function of particle aerodynamic diameter and

other influent parameters. For bioaerosol samplers the physical sampling efficiency which corresponds

to the (size-selective) sampling efficiency should comply with EN 13205, where applicable.

When assessing the performance of any bioaerosol sampler, the overall sampling efficiency (see A.2,

item c)) shall be determined.

The performance of a personal sampler is affected by the proximity of the operator's body when worn

within the breathing zone. This needs to be taken into account when assessing that performance. See A.2.

NOTE Annex A gives some information about the physical behaviour of a sampler and the experimental

assessment of its physical sampling efficiency in the laboratory.

5.11.3 Biological preservation efficiency

To determine the culturable number of microorganisms, the sampler shall be tested with relevant

microorganisms to establish the biological preservation efficiency. The ability of the sampling medium to

maintain the integrity of the sampled microorganisms shall be known.

5.12 Functional range of concentration

The manufacturer shall give the upper and lower functional range for the concentration of collected

culturable microorganisms and/or the total number of microorganisms.

The manufacturer shall specify the maximum sampling time or the sampling volume that can be sampled

without recharging battery-operated samplers or replacing the collection substrate.

NOTE The sampling time can vary from a few minutes up to an 8 h workshift.

5.13 Loading of the sampler

The sampler shall be loaded, emptied and reloaded easily with aseptic collection substrates at the

workplace with a minimum loss of collected bioaerosol.

5.14 Cleaning of the sampler

The sampler shall be constructed in such a way that cleaning and decontamination in the field can be

done easily and disinfection in the laboratory is possible.

If required for biosecurity or contamination control purposes, samplers shall be resistant to

decontamination by surface disinfection or fumigation, e.g. by using hydrogen peroxide vapour.

5.15 Additional requirements

When possible, battery-operated samplers should have a short recharge time.

All samplers should be light-weighted and have low noise levels.

6 Requirements for testing of biological preservation efficiency of volumetric

bioaerosol samplers

6.1 General

The test conditions applied shall be within the operational range of the sampler as specified by the

manufacturer.

The risk class to which the microbial model organisms belong to shall be compatible with the level of

safety of the test facility and the training of the operators so that microbial model organisms are handled

under optimum safety and health protection conditions.

For the purpose of testing the performance of samplers, the tests shall be carried out on at least two

replicate samplers and compared to the performance of a reference sampler.

The biological preservation efficiency itself cannot be determined as the actual concentration cannot be

measured without any bias. In practise, bioaerosol samplers are compared to each other to show

differences with regard to their biological preservation efficiency.

6.2 Test facility

The biological performance of the bioaerosol samplers shall be studied in a test facility into which specific

aerosols of microorganisms can be generated in suitable conditions (see Annex B). The ratio between the

concentration of microorganisms measured by the sampler to be tested and the concentration assessed

by the reference sampler shall be calculated by using representative microorganisms (see Annex C).

The reference sampler shall comply with the requirements given in EN 13098:2019, 6.2.2.

6.3 Test particles

6.3.1 Concentration range

The test environment shall consist of single particles as well as aggregates of particles in an atmosphere

with controllable relative humidity and temperature. The concentration range of particles within which

the sampler is evaluated shall be given. The temperature and relative humidity of the test environment

shall be stated.

Restrictions on the usability of the sampler in terms of temperature and relative humidity shall be

specified by the manufacturer.

6.3.2 Production of test bioaerosol

Microbial cell suspensions shall be controllably aeroso

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...