SIST EN 17636:2023

(Main)Railway applications - Infrastructure - Track alignment design parameters - Urban rail

Railway applications - Infrastructure - Track alignment design parameters - Urban rail

This document specifies rules and limits for track alignment design parameters, including alignments within switches and crossings. Several of these limits are functions of speed. Alternatively, for a given track alignment, it specifies rules and limits that determine permissible speed with regards to track alignment.

This document applies to urban or suburban rail networks for passenger services not integrated with the national network.

Sections of urban or suburban rail networks integrated in the national rail networks are not covered by this document. They are covered by EN 13803 (or for nominal track gauges smaller than 1 435 mm by national alignment rules).

For the purpose of this document, urban or suburban rail networks include:

- Networks designed for own right of way and segregated from general road and pedestrian traffic,

and

- Networks (partly) not segregated from general road and pedestrian traffic, with shared lanes.

This document applies to rail systems with steel wheels running on steel vignole or grooved rails. Rail systems with specific construction issues (e.g. rack railways, funicular railways and other types of cable drawn rail systems) are not covered by this document.

This document defines the parameters, rules and limits for nominal track gauges of 1 435 mm and 1 000 mm with permissible speeds up to 120 km/h. For other nominal track gauges, this document defines conversion rules which shall be used to define the limits.

Bahnanwendungen - Oberbau - Streckentrassierungsparameter für den städtischen Schienenverkehr

Diese Europäische Norm legt Regeln und Grenzwerte für die Parameter der Gleistrassierung fest, einschließlich der Trassierung in Weichen und Kreuzungen. Einige dieser Grenzwerte sind Funktionen der Geschwindigkeit. Zugleich legt das Dokument für eine vorhandene Trassierung die Regeln und Grenzwerte fest, die die zulässige Geschwindigkeit bestimmen.

Diese Norm ist anwendbar für Gleisnetze städtischer Schienenbahnen bzw. angeschlossene oder Vorort- Strecken zur Personenbeförderung, die nicht in das nationalen Vollbahnnetz integriert sind.

Abschnitte von städtischen oder Vorort-Schienennetzen, die in die nationalen Vollbahnnetze integriert sind, werden in dieser Norm nicht behandelt. Sie werden durch EN13803 abgedeckt (oder für nominale Spurweiten kleiner als 1435mm durch nationale Trassierungsregeln).

Für die Anwendung dieses Dokuments sind städtische oder Vorort- Schienennetze

- Schienennetze, die mit eigenem Wegerecht getrennt vom allgemeinen Straßen- und Fußgängerverkehr betrieben werden,

und

- Schienennetze die zumindest teilweise nicht vom allgemeinen Straßen- und Fußgängerverkehr getrennt sind und Fahrspuren mit diesem gemeinsam nutzen.

Diese Norm ist anwendbar für Schienensysteme mit Stahlrädern, die auf Vignol- oder Rillenschienen aus Stahl fahren. Schienensysteme mit besonderen baulichen Eigenheiten (z.B. Zahnradbahnen, Standseilbahnen und andere Arten von seilgezogenen Schienensystemen) werden in dieser Norm nicht behandelt.

Diese Europäische Norm nennt die Parameter, und legt Regeln und Grenzwerte für Nennspurweiten von 1435mm und 1000mm mit zulässigen Geschwindigkeiten bis zu 120km/h fest. Für andere Nennspurweiten legt diese Norm Umrechnungsregeln fest, die zur Festlegung der Grenzwerte verwendet werden müssen.

Applications ferroviaires - Infrastructure - Paramètres de conception du tracé de la voie pour le rail urbain

Le présent document spécifie les règles et limites pour les paramètres de tracé de voie, y compris dans les appareils de voie. Plusieurs de ces limites dépendent de la vitesse. En outre, le présent document spécifie les règles et limites qui déterminent la vitesse maximale autorisée pour un tracé de voie spécifique.

Le présent document s'applique aux réseaux ferroviaires urbains ou suburbains destinés au transport de voyageurs, qui ne sont pas intégrés au réseau national.

Le présent document ne couvre pas les tronçons des réseaux ferroviaires urbains ou suburbains qui sont intégrés au réseau national. Ceux-ci sont couverts par l'EN 13803 (ou par les règlements nationaux dans le cas des écartements de voie nominaux inférieurs à 1 435 mm).

Pour les besoins du présent document, les réseaux ferroviaires urbains ou suburbains incluent :

- les réseaux en site propre intégral séparés de la circulation routière et piétonne générale ;

et

- les réseaux (partiellement) en site partagé/banalisé non séparés de la circulation routière et piétonne générale.

Le présent document s'applique aux systèmes ferroviaires équipés de roues en acier circulant sur rails Vignole ou rails à gorge en acier. Les systèmes ferroviaires présentant des problématiques de construction spécifiques (trains à crémaillère, funiculaires et autres types de systèmes ferroviaires tirés par des câbles, par exemple) ne sont pas couverts par le présent document.

Le présent document définit les paramètres, règles et limites applicables aux écartements de voie nominaux de 1 435 mm et de 1 000 mm, où la vitesse maximale de circulation est limitée à 120 km/h. Pour les autres écartements de voie nominaux, le présent document définit les règles de conversion à utiliser pour définir les limites applicables.

Železniške naprave - Infrastruktura - Parametri za načrtovanje trase proge - Mestna železnica

Ta dokument določa pravila in omejitve za parametre pri načrtovanju trase proge, vključno z načrtovanjem na kretnicah in križiščih. Več teh omejitev predstavlja funkcije hitrosti. Za določene parametre pri načrtovanju trase proge pa lahko določa pravila in omejitve, ki določajo dovoljeno hitrost v zvezi z načrtovanjem trase proge.

Dokument se uporablja za mestna oziroma primestna železniška omrežja za potniški promet, ki niso del nacionalnega omrežja.

Mestna oziroma primestna železniška omrežja, ki so del nacionalnega železniškega omrežja, niso zajeta v tem dokumentu. Obravnava jih standard EN 13803 (ali za nazivno tirno širino manj kot 1435 mm v skladu z nacionalni pravili za načrtovanje).

Za namene tega dokumenta mestna oziroma primestna železniška omrežja vključujejo:

– omrežja, zasnovana za ločeno obratovanje, ki ne zajemajo cestnega prometa in peščev;

in

– omrežja, ki (delno) zajemajo cestni promet in promet peščev ter z njima souporabljajo proge.

Ta dokument se uporablja za železniške sisteme z jeklenimi kolesi, ki se premikajo po jeklenih Vignolovih tirnicah ali tirnicah z žlebom. Železniški sistemi s posebnimi težavami pri izdelavi (npr. zobate železnice, tirne vzpenjače in druge vrste železniških sistemov, ki potujejo po žičnici) v tem dokumentu niso zajeti.

Ta dokument določa parametre, pravila in omejitve za nazivno tirno širino 1435 mm in 1000 mm z dovoljeno hitrostjo največ 120 km/h. Za druge nazivne širine so v dokumentu opredeljena pravila za pretvorbo, ki jih je treba uporabiti pri določanju omejitev.

General Information

- Status

- Published

- Public Enquiry End Date

- 31-Mar-2021

- Publication Date

- 23-Oct-2023

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 19-Oct-2023

- Due Date

- 24-Dec-2023

- Completion Date

- 24-Oct-2023

Overview

EN 17636:2023 - "Railway applications - Infrastructure - Track alignment design parameters - Urban rail" (CEN) specifies rules and limits for track alignment design in urban and suburban passenger rail networks that are not integrated with the national network. The standard covers alignment elements including switches and crossings and establishes how alignment parameters relate to permissible speeds (several limits are speed-dependent). It applies to steel-wheel systems on vignole or grooved rails for nominal gauges 1 435 mm and 1 000 mm (permissible speeds up to 120 km/h) and provides conversion rules for other gauges.

Key topics and technical requirements

- Scope and applicability

- Urban/suburban networks with segregated right-of-way or shared lanes with road/pedestrian traffic.

- Excludes sections integrated in national networks (those fall under EN 13803) and special systems (rack railways, funiculars, cable-drawn systems).

- Core alignment parameters (document defines rules and limits)

- Horizontal radius and curvature

- Applied cant and cant transition lengths

- Cant deficiency and cant excess (including limits and exceptional cases)

- Lengths of transition curves (e.g., clothoids) and linear cant transitions

- Cant gradient and rate of change of cant / cant deficiency

- Abrupt changes of horizontal curvature and cant deficiency

- Track gradient, vertical radius and vertical curve lengths

- Lengths between abrupt changes and between small-radius opposite curves

- Supplementary normative annexes

- Conversion rules for gauges other than 1 435 mm (Annex A)

- Three-dimensional geometry effects on resulting cant gradients and vertical radius (Annex B)

- Sign rules, and calculation guidance for cant and gradient changes (Annex D)

- Informative relations between cant deficiency and non-compensated lateral acceleration (Annex C)

Practical applications

- Designing track alignments for urban tram, light rail and metro-type systems

- Determining permissible line speeds from a given geometry or conversely deriving geometry limits from a target speed

- Specifying alignment within switches and crossings to meet comfort, safety and maintenance constraints

- Supporting asset owners, infrastructure designers and maintenance planners to set limits that balance ride comfort, wear and lifecycle costs

- Providing conversion guidance when adapting parameter limits to alternative nominal gauges

Who should use this standard

- Railway infrastructure engineers and designers

- Urban transport authorities, system integrators and planners

- Rolling-stock engineers concerned with track/vehicle interaction

- Contractors, consultants and maintenance teams involved in alignment specification and verification

Related standards and references

- EN 13803 - alignment rules for sections integrated in national networks

- ISO/IEC terminology resources (for standard definitions referenced by EN 17636)

Keywords: EN 17636:2023, track alignment design, urban rail, cant, cant deficiency, transition curve, clothoid, permissible speed, CEN standard.

Frequently Asked Questions

SIST EN 17636:2023 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Infrastructure - Track alignment design parameters - Urban rail". This standard covers: This document specifies rules and limits for track alignment design parameters, including alignments within switches and crossings. Several of these limits are functions of speed. Alternatively, for a given track alignment, it specifies rules and limits that determine permissible speed with regards to track alignment. This document applies to urban or suburban rail networks for passenger services not integrated with the national network. Sections of urban or suburban rail networks integrated in the national rail networks are not covered by this document. They are covered by EN 13803 (or for nominal track gauges smaller than 1 435 mm by national alignment rules). For the purpose of this document, urban or suburban rail networks include: - Networks designed for own right of way and segregated from general road and pedestrian traffic, and - Networks (partly) not segregated from general road and pedestrian traffic, with shared lanes. This document applies to rail systems with steel wheels running on steel vignole or grooved rails. Rail systems with specific construction issues (e.g. rack railways, funicular railways and other types of cable drawn rail systems) are not covered by this document. This document defines the parameters, rules and limits for nominal track gauges of 1 435 mm and 1 000 mm with permissible speeds up to 120 km/h. For other nominal track gauges, this document defines conversion rules which shall be used to define the limits.

This document specifies rules and limits for track alignment design parameters, including alignments within switches and crossings. Several of these limits are functions of speed. Alternatively, for a given track alignment, it specifies rules and limits that determine permissible speed with regards to track alignment. This document applies to urban or suburban rail networks for passenger services not integrated with the national network. Sections of urban or suburban rail networks integrated in the national rail networks are not covered by this document. They are covered by EN 13803 (or for nominal track gauges smaller than 1 435 mm by national alignment rules). For the purpose of this document, urban or suburban rail networks include: - Networks designed for own right of way and segregated from general road and pedestrian traffic, and - Networks (partly) not segregated from general road and pedestrian traffic, with shared lanes. This document applies to rail systems with steel wheels running on steel vignole or grooved rails. Rail systems with specific construction issues (e.g. rack railways, funicular railways and other types of cable drawn rail systems) are not covered by this document. This document defines the parameters, rules and limits for nominal track gauges of 1 435 mm and 1 000 mm with permissible speeds up to 120 km/h. For other nominal track gauges, this document defines conversion rules which shall be used to define the limits.

SIST EN 17636:2023 is classified under the following ICS (International Classification for Standards) categories: 93.100 - Construction of railways. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17636:2023 is associated with the following European legislation: Standardization Mandates: M/486. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 17636:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2023

Železniške naprave - Infrastruktura - Parametri za načrtovanje trase proge -

Mestna železnica

Railway applications - Infrastructure - Track alignment design parameters - Urban rail

Bahnanwendungen - Oberbau - Streckentrassierungsparameter für den städtischen

Schienenverkehr

Applications ferroviaires - Infrastructure - Paramètres de conception du tracé de la voie

pour le rail urbain

Ta slovenski standard je istoveten z: EN 17636:2023

ICS:

93.100 Gradnja železnic Construction of railways

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17636

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2023

EUROPÄISCHE NORM

ICS 93.100

English Version

Railway applications - Infrastructure - Track alignment

design parameters - Urban rail

Applications ferroviaires - Infrastructure - Paramètres Bahnanwendungen - Oberbau -

de conception du tracé de la voie pour le rail urbain Streckentrassierungsparameter für den städtischen

Schienenverkehr

This European Standard was approved by CEN on 9 July 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17636:2023 E

worldwide for CEN national Members.

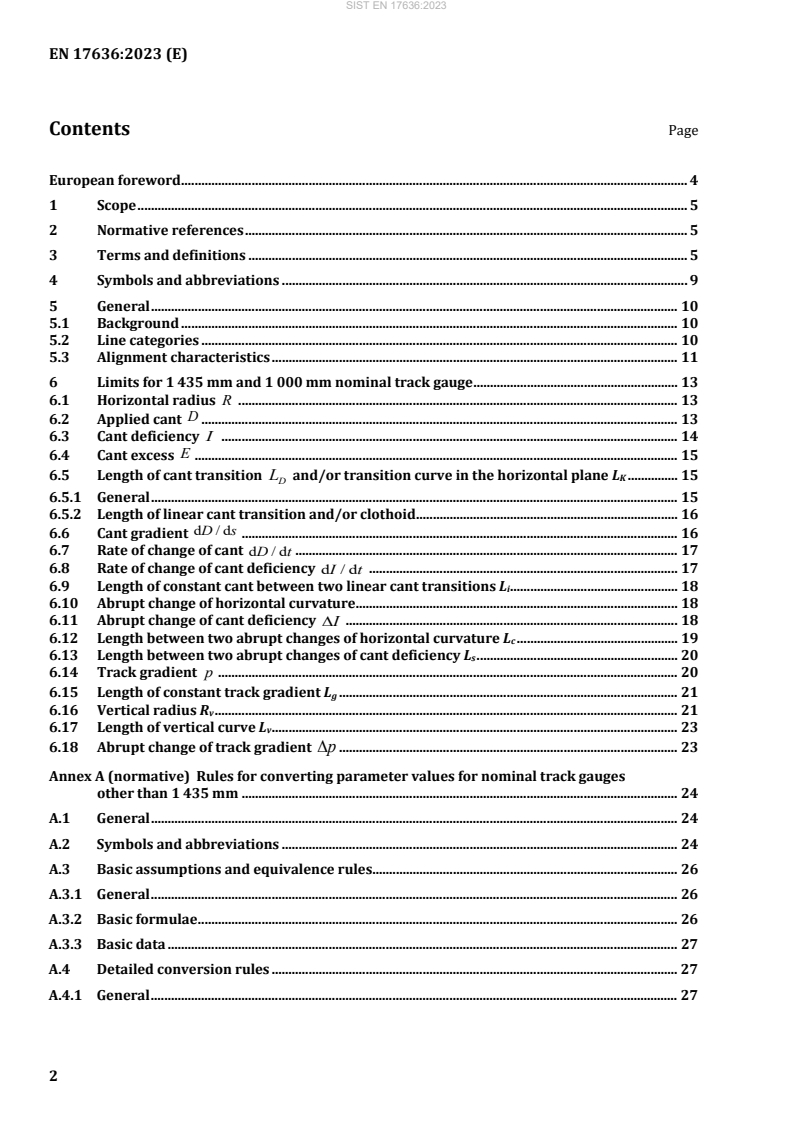

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Symbols and abbreviations . 9

5 General . 10

5.1 Background . 10

5.2 Line categories . 10

5.3 Alignment characteristics . 11

6 Limits for 1 435 mm and 1 000 mm nominal track gauge . 13

6.1 Horizontal radius R . 13

D

6.2 Applied cant . 13

6.3 Cant deficiency I . 14

E

6.4 Cant excess . 15

6.5 Length of cant transition and/or transition curve in the horizontal plane L . 15

L K

D

6.5.1 General . 15

6.5.2 Length of linear cant transition and/or clothoid . 16

dDs/d

6.6 Cant gradient . 16

6.7 Rate of change of cant . 17

dDt/d

6.8 Rate of change of cant deficiency dIt/d . 17

6.9 Length of constant cant between two linear cant transitions L . 18

i

6.10 Abrupt change of horizontal curvature . 18

6.11 Abrupt change of cant deficiency ∆I . 18

6.12 Length between two abrupt changes of horizontal curvature L . 19

c

6.13 Length between two abrupt changes of cant deficiency L . 20

s

6.14 Track gradient . 20

p

6.15 Length of constant track gradient L . 21

g

6.16 Vertical radius R . 21

v

6.17 Length of vertical curve L . 23

v

6.18 Abrupt change of track gradient ∆p . 23

Annex A (normative) Rules for converting parameter values for nominal track gauges

other than 1 435 mm . 24

A.1 General . 24

A.2 Symbols and abbreviations . 24

A.3 Basic assumptions and equivalence rules . 26

A.3.1 General . 26

A.3.2 Basic formulae . 26

A.3.3 Basic data . 27

A.4 Detailed conversion rules . 27

A.4.1 General . 27

A.4.2 Cant D (6.2) . 27

A.4.3 Cant deficiency I (6.3) . 29

A.4.4 Cant excess E (6.4) . 30

A.4.5 Length of cant transition L and transition curve in the horizontal plane L (6.5). 31

D K

A.4.6 Cant gradient dD /dt (6.6) . 31

A.4.7 Rate of change of cant dDt/d (6.7) . 32

A.4.8 Rate of change of cant deficiency dI /dt (6.8) . 33

A.4.9 Abrupt change of curvature and abrupt change of cant deficiency ∆I (6.10 and

6.11) . 34

A.4.10 Other parameters (6.1, 6.9, 6.12, 6.13, 6.14, 6.15, 6.16, 6.17 and 6.18) . 34

Annex B (normative) Three-dimensional track geometry with regards to resulting cant

gradient and resulting vertical radius . 35

B.1 General considerations regarding three-dimensional track geometry . 35

B.2 Angular twist T and resulting cant gradient (dD/ds) . 35

A r

B.2.1 Calculation of resulting cant gradient (dD/ds) where cant is applied by lifting one

r

rail D / 2 and lowering the other rail D / 2 . 35

B.2.2 Calculation of resulting cant gradient (dD/ds) when cant is applied by lifting one

r

rail D . 36

B.3 Resulting vertical radius (R ) . 36

v r

Annex C (informative) The relations between cant deficiency, non-compensated lateral

acceleration and related parameters . 38

C.1 Introduction. 38

C.2 Applied cant and roll angle . 38

C.3 Equilibrium cant . 39

C.4 Cant deficiency and non-compensated lateral acceleration . 40

C.5 Applications . 41

∆p

Annex D (normative) Sign rules for calculation of ∆D , ∆I and . 42

D.1 General regarding the sign rules . 42

D.2 Sign rules for calculation of ∆D . 42

D.3 Sign rules for calculation of ∆I . 42

D.4 Sign rules for calculation of ∆p . 43

Annex E (normative) Lengths of intermediate elements L between small radius curves in

c

opposite directions . 45

E.1 General . 45

E.2 Lengths of intermediate elements Lc for Line Category A1435 . 45

E.3 Lengths of intermediate elements L for Line Category B1435 and C1000 . 46

c

Bibliography . 48

European foreword

This document (EN 17636:2023) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2024, and conflicting national standards shall be

withdrawn at the latest by April 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document specifies rules and limits for track alignment design parameters, including alignments

within switches and crossings. Several of these limits are functions of speed. Alternatively, for a given

track alignment, it specifies rules and limits that determine permissible speed with regards to track

alignment.

This document is applicable to urban or suburban rail networks for passenger services not integrated

with the national network.

Sections of urban or suburban rail networks integrated in the national rail networks are not covered by

this document. They are covered by EN 13803 (or for nominal track gauges smaller than 1 435 mm by

national alignment rules).

For the purpose of this document, urban or suburban rail networks include:

— Networks designed for own right of way and segregated from general road and pedestrian traffic,

and

— Networks (partly) not segregated from general road and pedestrian traffic, with shared lanes.

This document is applicable to rail systems with steel wheels running on steel vignole rails or steel

grooved rails. Rail systems with specific construction issues (e.g. rack railways, funicular railways and

other types of cable drawn rail systems) are not covered by this document.

This document defines the parameters, and specifies rules and limits for nominal track gauges of

1 435 mm and 1 000 mm with permissible speeds up to 120 km/h. For other nominal track gauges, this

document defines conversion rules which are used to specify the limits.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org

3.1

track gauge

distance between the corresponding running edges of the two rails

3.2

nominal track gauge

single value which identifies the track gauge but may differ from the design track gauge

3.3

limit

restriction for design values not to be exceeded

Note 1 to entry: These values ensure that track maintenance costs and ride comfort are within a reasonable

range.

Note 2 to entry: For certain parameters, this document specifies both a normal limit and an exceptional limit.

Exceptional limits are intended for use only under special circumstances and can require an associated maintenance

regime as well as requiring to be verified against the local rolling stock.

3.4

alignment element

segment of the track with either vertical direction, horizontal direction or cant obeying a unique

mathematical description as a function of chainage

Note 1 to entry: Unless otherwise stated, the appertaining track alignment design parameters are defined for the

track centre line and the longitudinal distance for the track centre line is defined in a projection in a horizontal

plane.

3.5

chainage

longitudinal distance along the horizontal projection of the track centre line

3.6

curvature

derivative of the horizontal direction of the track centre line with respect to chainage

Note 1 to entry: In the direction of the chainage, curvature is positive in a right-hand curve and negative in a left-

hand curve. The magnitude of the curvature corresponds to the inverse of the horizontal radius.

3.7

circular curve

curved alignment element of constant curvature

3.8

transition curve

alignment element where curvature changes with respect to chainage

Note 1 to entry: The clothoid (sometimes approximated as a 3rd degree polynomial, “cubic parabola”) is

normally used for transition curves, giving a linear variation of curvature. In some cases, curvature is smoothed at

the ends of the transition. A transition can also be created by a sequence of short circular curves with radii which

change stepwise.

Note 2 to entry: It is possible to use other forms of transition curve, which show a nonlinear variation of

curvature.

Note 3 to entry: Normally, a transition curve is not used for the vertical alignment.

3.9

reverse curve

sequence of curved alignment elements, containing alignment elements which curve in opposite

directions

3.10

running plane

flat plane tangential to the running surface of both rail heads at the considered cross section

3.11

track gradient

absolute value of the derivative (with respect to chainage) of track level

3.12

cant

amount by which one running rail is raised above the other running rail, in a track cross section

Note 1 to entry: Measured over e the base measurement for cant.

3.13

applied cant

design value for cant

3.14

equilibrium cant

cant at a particular speed at which the vehicle will have a resultant force perpendicular to the running

plane

3.15

cant deficiency

difference between applied cant and a higher equilibrium cant

Note 1 to entry: When there is cant deficiency, there will be an unbalanced lateral force in the running plane. The

resultant force will move towards the outer rail of the curve.

3.16

cant excess

difference between applied cant and a lower equilibrium cant

Note 1 to entry: When there is cant excess, there will be an unbalanced lateral force in the running plane. The

resultant force will move towards the inner rail of the curve.

Note 2 to entry: Cant on a straight track results in cant excess, generating a lateral force towards the low rail.

3.17

cant transition

alignment element where cant changes with respect to chainage

Note 1 to entry: Normally, a cant transition coincides with a transition curve.

Note 2 to entry: Cant transitions giving a linear variation of cant are usually used. In some cases, cant is smoothed

at the ends of the transition.

Note 3 to entry: It is possible to use other forms of cant transition, which show a nonlinear variation of cant.

3.18

cant gradient

absolute value of the derivative (with respect to chainage) of cant

3.19

helical track

track with a track gradient combined with horizontal curvature

Note 1 to entry: This combination leads to a twisted track, even though applied cant is not changing along the

track.

3.20

resulting cant gradient

equivalent gradient of cant for a helical track situation (plus coexisting cant gradient, if present), which

results in the same angular twist as a cant gradient on a level track

3.21

angular twist

derivative of roll angle (rotation around the longitudinal axis) with respect to longitudinal distance

measured in coordinate system which has the same direction as the sloping track on a track gradient

3.22

rate of change of cant

absolute value of the time derivative of cant (resulting from vehicle speed)

3.23

rate of change of cant deficiency

absolute value of the time derivative of cant deficiency and/or cant excess (resulting from vehicle speed)

4 Symbols and abbreviations

No. Symbol Designation Unit

1 dD/ds cant gradient mm/m

2 (dD/ds)r resulting cant gradient mm/m

3 dD/dt rate of change of cant mm/s

4 dI/dt rate of change of cant deficiency (and/or cant excess) mm/s

5 D applied cant mm

6 DEQ equilibrium cant mm

7 e base measurement for cant mm

8 E cant excess mm

9 g acceleration due to gravity m/s

10 I cant deficiency mm

11 Lc length between two abrupt changes of curvature m

12 LD length of cant transition m

13 L length of constant track gradient m

g

14 L length of transition curve m

K

15 Li length of alignment elements between two linear cant transitions m

16 Ls length between two abrupt changes of cant deficiency m

17 Lv length of vertical curve m

18 p track gradient -

19 q factor for calculation of equilibrium cant mm∙m/(km/h)

E

20 qN factor for calculation of length of cant transition or transition curve with -

non-constant gradient of cant and curvature, respectively

21 qRv factor for calculation of vertical radius m/(km/h)

22 qs factor for calculation of lengths between abrupt changes of cant deficiency m/(km/h)

23 q factor for conversion of the units for vehicle speed (km/h)/(m/s)

V

24 R radius of horizontal curve m

25 Rv radius of vertical curve m

26 (Rv)r resulting vertical radius m

27 s longitudinal distance m

28 t time s

29 T angular twist rad/m

A

30 V speed km/h

31 lim limit (index) -

32 index for resulting parameters in three-dimensional calculations -

r

33 additional limit applicable at small radius curves (index) -

R, lim

5 General

5.1 Background

This document specifies rules and limits for track alignment design. These limits assume that standards

for acceptance of vehicle, track construction and maintenance are fulfilled (construction and in-service

tolerances are not specified in this document). Engineering requirements specific to the mechanical

behaviour of switch and crossing components and subsystems are to be found in the relevant standards.

This document is not a design manual. The normal limits are not intended to be used as usual design

values. However, design values shall be within the limits stated in this document.

This document takes into account the usually tighter and more manifold alignment situations in urban

environments, by differentiating into line categories A, B and C (see 5.2). Due to the strong interrelation

of alignment limits and kinematic vehicle restrictions, local vehicles have often been tailored to the

respective network and vice versa. The main reason for this may be the absence of European Standards

within the urban rail sector, a situation the present document may contribute to leave in the long run.

Limits in this document are based on practical experiences of European Urban Rail networks. Limits are

applied where it is necessary to compromise between train performance (including safety) and comfort

levels, maintenance of the vehicle and track, and construction costs.

The use of design values close to normal limits should be avoided; substantial margins to them should be

provided. There are often conflicts between the desire for margins to one parameter and another; these

should be distributed over all design parameters, possibly by applying a margin with respect to speed.

For certain parameters, this document also specifies exceptional limits less restrictive than normal limits.

Such limits are intended for use only under special circumstances and can require an associated

maintenance regime as well as requiring to be verified against the local rolling stock. In particular, use of

exceptional limits (instead of normal limits) for several parameters at the same location shall be avoided.

The use of design values outside the normal limits should be documented.

Operational limits for speed and cant deficiency shall be applied to specific vehicles according to their

approval parameters. Limits for train speed shall be calculated from the speed dependent alignment

limits by solving for vehicle speed V , using 6.3, 6.4, 6.7, 6.8, 6.11, 6.13 and 6.16. As different vehicle

sections may be located on alignment sections with different speed limits, it is always the most restrictive

speed limit over the train length that applies. Speed may also be restricted for other reasons than track

alignment, for example reduced visibility and operational rules.

The limits are specified for normal service operations. If and when running trials are conducted, for

example to ascertain the vehicle dynamic behaviour (by continual monitoring of the vehicle responses),

exceeding the limits (particularly in terms of cant deficiency) should be permitted and it is up to the

responsible body to decide any appropriate arrangement.

NOTE In common with other track alignment standards and specifications, this document uses vehicle speed

expressed in km/h.

V

5.2 Line categories

Urban and suburban rail systems are local systems of different character. The requirements on the

infrastructure are related to the vehicle types to be used on the network. Three line categories are

defined, including systems for nominal track gauge 1 435 mm and 1 000 mm:

— Category A1435, lines for metro types of rail vehicles with nominal track gauge 1 435 mm

— Category B1435, lines for tram types of rail vehicles with nominal track gauge 1 435 mm

— Category C1000, lines for tram types of rail vehicles with nominal track gauge 1 000 mm

Table 1 specifies fixed parameters for Line Categories A1435, B1435 and C1000.

Table 1 — Fixed parameters for Line Categories A1435, B1435 and C1000

Parameter Line Category

A1435 B1435 C1000

nominal track gauge [mm] 1 435 1 435 1 000

e , base measurement for cant [mm] 1 500 1 500 1 060

11,8 11,8 8,3

q , factor for calculation of equilibrium cant [mm∙m/(km/h) ]

E

For other nominal track gauges, limits that depend on track gauge (6.2, 6.3, 6.4, 6.6, 6.7, 6.8 and 6.9) shall

be specified based on the limit values of A1435 and B1435 applying conversion factors (see normative

Annex A).

The conversion is done by multiplying the respective limit with the ratio W= ee/ , where e is the base

1 1

measurement for cant for the considered track gauge. However, for the cant gradient (6.6), the limit is

We⋅ +500mm/ e+500mm

obtained by multiplying with ( ) ( ) .

It is assumed that all vehicles have been assessed and approved according to the relevant standards for

the line category in question.

5.3 Alignment characteristics

The alignment defines the geometrical position of the track. It is divided into horizontal alignment and

vertical alignment.

The horizontal alignment is the projection of the track centre line on the horizontal plane. The horizontal

alignment consists of a sequence of alignment elements, each obeying a unique mathematical description

as a function of longitudinal distance along the horizontal projection (chainage). The elements for

horizontal alignment are connected at tangent points, where two connected elements have the same

coordinates and the same directions. Elements for horizontal alignment are specified in Table 2.

Table 2 — Elements for horizontal alignment

Alignment element Characteristics

Straight line No horizontal curvature

Circular curve Constant horizontal curvature

a

Transition curve, Clothoid type Horizontal curvature varies linearly with chainage

Compound transition A sequence of short circular curves where curvature

increases or decreases stepwise

a

EN 13803 gives a detailed account of certain alternative types of transition curves that may be used

in track alignment design

Most modern switches have a tangential geometry, where the diverging track starts with an alignment

that is tangential with the through track. However, switch designs may start with an abrupt change of

horizontal direction at the beginning of the switch. When a turnout is placed on a track gradient other

than zero, a vertical curve and/or cant, the horizontal geometry of the diverging track will deviate slightly

from the element types in Table 2.

The vertical alignment defines the level of the track as a function of chainage (the longitudinal position

along the horizontal projection of the track centre line). The elements for vertical alignment are

connected at tangent points where two connected elements have the same level and the same track

gradient p (with certain exceptions). Elements for vertical alignment are specified in Table 3.

Table 3 — Elements for vertical alignment

Alignment element Characteristics

Constant track gradient No vertical curvature

Vertical curve, parabola Derivative of track gradient with respect to chainage is constant

Vertical curve, circular Derivative of vertical angle with respect to sloping length along the track is

constant

NOTE A vertical curve in track that starts or ends in canted switches and crossings can be of a higher order

polynomial than a parabola.

The applied cant D in the track is the difference in level of two running rails. Cant can be applied by

raising one rail above the level of the vertical profile and keeping the other rail on the same level as the

vertical profile, or by a pre-defined relation raising one rail and lowering the other rail. The cant can be

considered as a sequence of elements connected at tangent points where two elements have the same

magnitude of applied cant. (At a tangent point with cant, the same rail is the high rail before and after the

tangent point.) Elements for applied cant are specified in Table 4.

Table 4 — Elements for cant

Characteristics

Alignment element

Constant cant Cant is constant along the entire element

a

Cant transition, linear Cant varies linearly with chainage

a

EN 13803 gives a detailed account of certain alternative types of cant transitions that may

be used in track alignment design.

Cant transitions should normally coincide with transition curves, but exceptions are possible.

Lateral and vertical directions in track alignment design refers to the directions of an earth-bound

coordinate system. When the alignment has a track gradient and/or applied cant, lateral and/or vertical

directions (as perceived by vehicles as well as track components) will change. The effects can be

significant for resulting vertical radius (combination of small radius curves with high value of applied

cant) and angular twist/resulting cant gradient (helical tracks with steep track gradient and small-radius

curves). Normative Annex B specifies formulae to quantify the effects.

All limits in Clause 6 apply, hence the permissible range for one parameter, for example horizontal radius

R can be further restricted due to the chosen values of other parameters. For example, at a certain

location in an alignment sequence, the permissible range for horizontal radius R can be limited due to

applied cant D , limit for cant deficiency I , track gradient , vertical radius R and/or characteristics

p

v

of adjacent elements.

6 Limits for 1 435 mm and 1 000 mm nominal track gauge

6.1 Horizontal radius R

In this document, radius is positive on both right-hand and left-hand curves.

Speed independent lower limits for horizontal radius R are specified in Table 5.

lim

Table 5 — Lower limits for horizontal radius R

lim

Line Category A1435 B1435 C1000

a

Normal limit [m] 50 25 25

a

Exceptional limit [m] 42 16 11,8

a

More restrictive lower limits for the radius along platforms may

apply, in order to minimize the gap between the vehicle floor and the

platform.

dD

Combination of horizontal radius R and track gradient p affects the resulting cant gradient , and

ds

r

combination of horizontal radius R and applied cant D affects the resulting vertical radius R , see

( )

v

r

normative Annex B.

There is no upper limit for horizontal radius in this document. However, local standards can have such

an upper limit, related to capabilities of the alignment software to handle very large numbers or to other

practical aspects. Larger horizontal radius than 99 999 m should not be used.

D

6.2 Applied cant

In this document, applied cant on a horizontal curve is positive if the outer rail is higher than the inner

rail. For Line Categories A1435 and B1435, the base measurement for cant e is 1 500 mm. For Line

e

Category C1000, the base measurement for cant is 1 060 mm.

NOTE 1 Negative cant is unavoidable at switches and crossings on a canted main line where the turnout is

curving in the opposite direction to the main line and, in certain cases, on the plain line immediately adjoining a

canted turnout. Due to camber, negative cant may be applied on street running tracks. Negative cant can also be

used on temporary tracks.

Upper limits for applied cant D , independent of horizontal radius R , are specified in Table 6.

lim

Table 6 — Upper limits for applied cant D

lim

Line Category A1435 B1435 C1000

a

Normal limit [mm] 150 150 100

a

Exceptional limit [mm] 165 165 110

a

More restrictive upper limits for cant along platforms may

apply, for the convenience for boarding and alighting passengers.

Combination of horizontal radius R and applied cant D affects the resulting vertical radius , see

R

( )

v

r

normative Annex B.

Upper limits for applied cant D , as a function of horizontal radius R , are specified in Table 7.

R , lim

Table 7 — Upper limits for applied cant D as a function of horizontal radius R

R , lim

Line Category A1435 B1435 C1000

a

Normal limit [mm]

R /1,6m (R+ 24m) /1,6m (R+ 24m) / 2,3m

Exceptional limit [mm] Same as exceptional Same as exceptional Same as exceptional

limit in Table 6 limit in Table 6 limit in Table 6

a

This limit may be increased provided that measures are taken to ensure safety, for

example installing check rails.

NOTE 2 High cant on small-radius curves (where the angles of attack for some wheels are large) increases the

risk of derailing when vehicles are running at low speed. Under these conditions, vertical wheel forces applied to

the outer rail are much reduced, especially where track twist causes additional force reductions.

6.3 Cant deficiency I

For given values of local radius R and cant D , and speed V , the cant deficiency I is defined according

to Formula (1):

V

I=D− Dq= ⋅ − D

(1)

EQ E

R

where

D is equilibrium cant [mm]

EQ

= 11,8 mm∙m/(km/h) for 1 435 mm nominal track gauge (assuming a base measurement

q

E

for cant of 1 500 mm), and

= 8,3 mm∙m/(km/h) for 1 000 mm nominal track gauge (assuming a base measurement

q

E

for cant of 1 060 mm).

NOTE 1 With negative cant D , the cant deficiency I will be higher than equilibrium cant D .

EQ

Upper limits for cant deficiency I are specified in Table 8.

lim

Table 8 — Upper limits for cant deficiency I

lim

Line Category A1435 B1435 C1000

Normal limit [mm] 100 100 70

Exceptional limit [mm] 150 150 106

Depending on the characteristics of specific features in track, such as bridges carrying direct-laid

ballastless track, tracks with jointed rails, sections of line exposed to very strong cross winds, etc., it may

be necessary to further restrict the permissible cant deficiency . Rules in respect of these restrictions

I

cannot be formulated beforehand since they will be dictated by the design of these features.

NOTE 2 Cant deficiency I is close to proportional to non-compensated lateral acceleration. 1 m/s non-

compensated lateral acceleration corresponds approximately to 153 mm cant deficiency for line categories A1435

and B1435, and 108 mm cant deficiency for line category C1000, see Annex C. High values of cant deficiency I are

related to passenger (dis)comfort.

E

6.4 Cant excess

On a horizontal curve where cant deficiency I (defined in Formula (1)) is negative, there is cant excess

E defined by Formula (2).

EI=− (2)

On canted turnouts, on plain tracks in close conjunction to canted switch and crossing units, and on street

tracks, there may be applied cant D on straight track. Cant may also be applied on temporary straight

tracks. On a canted straight track, there is cant excess E defined by Formula (3):

ED= (3)

Upper limits for cant excess are the same as the upper limit for cant deficiency see Table 8. The

E I

limits for cant excess apply, for a certain section of the track, for the regular speed of the slowest part

E

of a train.

NOTE High values of E reduce the quasi-static vertical wheel/rail force on the outer rail.

Requirements regarding changes in cant deficiency (6.5, 6.8, 6.11 and 6.13) apply also for changes in

I

cant excess .

E

6.5 Length of cant transition L and/or transition curve in the horizontal plane LK

D

6.5.1 General

Cant transitions should normally coincide with transition curves. However, it can be necessary to provide

cant transitions in circular curves and straights. Similarly, transition curves are preferred, in some cases

necessary, where no cant is applied or applied cant is constant.

For cant transitions and transition curves the limits are as follows:

— speed independent lower limits for lengths of transition curves are specified in Table 9;

L

K ,lim

dD

— upper limits for cant gradient are specified in 6.6;

ds

lim

dD

— upper limits for rate of change of cant are specified in 6.7; and

dt

lim

dI

— upper limits for rate of change of cant deficiency are specified in 6.8.

dt

lim

Table 9 — Lower limits for length of transition curve L

K ,lim

Line Category A1435 B1435 C1000

Normal limit [m] 10 10 10

Exceptional limit [m] 0 0 0

Very short transition curves may be necessary in turnouts or in close conjunction to turnouts.

6.5.2 Length of linear cant transition and/or clothoid

dD dD

For linear cant transition and/or clothoid, cant gradient , rate of change of cant and rate of

ds dt

dI

change of cant deficiency can be calculated according to Formulae (4), (5) and (6):

dt

dDD∆

=

(4)

dsL

D

dDV ∆D

⋅ (5)

dt qL

V D

dIV ∆I

⋅

(6)

dt qL

VK

where

ΔD is the change of applied cant over the length L , as defined in normative Annex D,

D

ΔI is the change of cant deficiency over the length LK, as defined in normative Annex D,

V is the speed in km/h and

q = 3,6 (km/h)/(m/s).

V

Formula (6) assumes that any cant transition coincides with a transition curve, LL= , and

KD

Formulae (4), (5) and (6) assume that the mathematical properties are constant over this length.

Otherwise, the transition curve and the cant transition shall be divided in parts with constant properties,

which are evaluated separately.

dDs/d

6.6 Cant gradient

dD

Upper limits for cant gradient are specified in Table 10.

ds

lim

dD

Table 10 — Upper limits for cant gradient and resulting cant gradient

ds

lim

Line Category A1435 B1435 C1000

Normal limit [mm/m] 2,5 2,5 2,0

Exceptional limit [mm/m] 3,33 3,33 3,33

dD

The resulting cant gradient depends also on combination of horizontal radius R and track

ds

r

gradient p . See normative Annex B. Limits in Table 10 apply also for (the absolute value of) the resulting

dD

cant gradient .

ds

r

=

=

6.7 Rate of change of cant dDt/d

dD

Upper limits for rate of change of cant for cant transitions are specified in Table 11.

dt

lim

dD

Table 11 — Upper limits for rate of change of cant

dt

lim

Line Category A1435 B1435 C1000

Normal limit [mm/s] 50 50 35

Exceptional limit [mm/s] 70 70 50

6.8 Rate of change of cant deficiency

dIt/d

dI

Upper limits for rate of change of cant deficiency are specified in Table 12.

dt

lim

dI

Table 12 — Upper limits for rate of change of cant deficiency

dt

lim

Line Category A1435 B1435 C1000

Normal limit [mm/s] 55 55 40

Exceptional limit [mm/s] 110 110 80

dI

Where a transition curve is of substandard length with respect to the criterion, this criterion shall be

dt

replaced with the criterion that the change of cant deficiency over its length shall be less than the upper

limit for abrupt change of cant deficiency ∆I , as specified in 6.11.

dI

NOTE Rate of change of cant deficiency is close to proportional to non-compensated lateral jerk. 1m/s

dt

non-compensated lateral jerk corresponds approximately to 153 mm/s rate of change of cant deficiency for line

categories A1435 and B1435, and 108 mm/s rate of change of cant deficiency for line category C1000, see Annex C.

dI

High values for rate of change of cant deficiency are related to passenger (dis)comfort and may also

dt

considerably increase wheel-rail forces.

6.9 Length of constant cant between two linear cant transitions Li

Lower limits for length of constant cant placed between two linear cant transitions are specified in

L

i,lim

Table 13.

Table 13 — Lower limits for length of constant cant between two linear cant transitions

L

i,lim

Line Cate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...