SIST EN 14382:2019

(Main)Gas safety shut-off devices for inlet pressure up to 10 MPa (100 bar)

Gas safety shut-off devices for inlet pressure up to 10 MPa (100 bar)

This document specifies constructional, functional, testing marking and sizing requirements and documentation of gas safety shut-off devices:

- for inlet pressures up to 100 bar and nominal diameters up to DN 400;

- for an operating temperature range from -20 °C to +60 °C;

which operate with fuel gases of the 1st and 2nd family as defined in EN 437, used in the pressure regulating stations in accordance with EN 12186 or EN 12279, in transmission and distribution networks and also in commercial and industrial installations.

"Gas safety shut-off devices" will hereafter be called "SSDs" except in titles.

For standard safety shut-off devices when used in pressure regulating stations complying with EN 12186 or EN 12279, Annex ZA lists all applicable Essential Safety Requirements of Directive 2014/68/EU (PED).

This document considers the following temperature classes/types of SSDs:

- temperature class 1: operating temperature range from -10 °C to 60 °C;

- temperature class 2: operating temperature range from -20 °C to 60 °C;

- functional class A: SSDs that close when damage to the pressure detecting element occurs or when external power fails and whose re-opening, is possible only manually;

- functional class B: SSDs that do not close when damage to the pressure detecting element occurs but provide suitable and reliable protection and whose re-opening, is possible only manually;

- type IS: (integral strength type);

- type DS: (differential strength type).

SSDs complying with the requirements of this document may be declared as "in conformity with EN 14382" and bear the mark "EN 14382".

The material and functional requirements specified in this document may be applied to SSDs which use thermal energy or the effects of electrical energy to trip the operation of the closing member. For these SSDs the operational parameters are not specified in this document.

The SSD may incorporate a vent limiter, complying with the requirements in Annex J.

This standard for some paragraphs and sub clauses makes full reference to prEN 334:2016.

This document does not apply to:

- SSDs upstream from/on/in domestic gas-consuming appliances which are installed downstream of domestic gas meters;

- SSDs designed to be incorporated into pressure-regulating devices used in service lines with volumetric flow rate ≤ 200 m3/h at normal conditions and inlet pressure ≤ 5 bar.

Continued integrity of safety shut-off devices is ensured by periodic functional checks. For periodic functional checks it is common to refer to national regulations/standards where existing or users/manufacturers practices.

This document considers the reaction of the SSDs functional class A to the specified reasonable expected failures in terms of "fail close" behaviour, but it should be consider that there are other types of failures whose consequences cannot bring to the same reactions (these risks are covered via redundancy as per EN 12186) and that residual hazards should be reduced by a suitable surveillance in use / maintenance.

In this document, both safety shut-off devices that can be classified as "safety accessories" by themselves according the Pressure Equipment Directive (2014/68/EU) as well as safety shut-off devices that can be used to provide the necessary pressure protection through redundancy (e.g. shutoff device integrated in a pressure regulator, shut-off device with a second shut-off device) are considered. Addition of environmental considerations;

The provisions in this document are in line with the state of art at the moment of writing.

This document does not intend to limit the improvement of actual provisions (materials, requirements, test methods, acceptance criteria, etc.) or the developing of new provisions for SSDs where they are suitable to ensure an equivalent level of reliability.

Gas-Sicherheitsabsperreinrichtungen für Eingangsdrücke bis 10 MPa (100 bar)

Dieses Dokument legt Anforderungen an Konstruktion, Funktion, Prüfung, Kennzeichnung und Bemessung sowie die Dokumentation von Gas Sicherheitsabsperreinrichtungen fest:

- für Eingangsdrücke bis 100 bar und Nennweiten bis DN 400;

- für einen Betriebstemperaturbereich von -20 °C bis +60 °C;

soweit sie mit Brenngasen der 1. und 2. Gas Familie nach EN 437 in den Druckregelanlagen nach EN 12186 oder EN 12279 in Gastransport und Gasverteilnetzen sowie in gewerblichen und industriellen Anlagen betrieben werden.

Der Begriff Gas Sicherheitsabsperreinrichtung wird im Weiteren, außer in Überschriften, mit SAE abgekürzt.

Für Standard Sicherheitsabsperreinrichtungen, die in den Druckregelanlagen nach EN 12186 oder EN 12279 verwendet werden, schließt Anhang ZA alle maßgebenden grundlegenden Sicherheitsanforderungen der Richtlinie 2014/68/EU (PED) ein.

Dieses Dokument behandelt folgende Temperaturklassen/Ausführungen von SAE:

- Temperaturklasse 1: Betriebstemperaturbereich von -10 °C bis 60 °C;

- Temperaturklasse 2: Betriebstemperaturbereich von -20 °C bis 60 °C;

- Funktionsklasse A: SAE, die bei Beschädigung des Istwertaufnehmers oder Ausfall der externen Hilfsenergie schließen und bei denen die erneute Öffnung nur manuell möglich ist;

- Funktionsklasse B: SAE, die bei Beschädigung des Istwertaufnehmers nicht schließen, aber geeigneten und zuverlässigen Schutz bieten, und bei denen die erneute Öffnung nur manuell möglich ist.

- Ausführung IS (einheitlicher Festigkeitsbereich);

- Ausführung DS (verschiedene Festigkeitsbereiche).

SAE, die den Anforderungen dieses Dokuments entsprechen, dürfen als übereinstimmend mit EN 14382 deklariert und mit der Kennzeichnung EN 14382 versehen werden.

Die Anforderungen dieses Dokuments an Werkstoffe und Funktionsverhalten können auf SAE angewendet werden, die thermische Energie oder die Wirkung elektrischer Energie für das Auslösen des Stellglieds verwenden. Die Betriebsparameter derartiger SAE sind in diesem Dokument nicht festgelegt.

Das SAE darf mit einem Abblasebegrenzer entsprechend den Anforderungen in Anhang J ausgerüstet sein.

Für einige Absätze und Unterabschnitte dieser Norm wird vollständig auf prEN 334:2016 verwiesen.

Dieses Dokument gilt nicht für:

- SAE vor/an/in Haushalts Gasgeräten, die hinter Hausgaszählern installiert sind;

- SAE, die für den Einbau in Druckregelgeräten in Anschlussleitungen ) mit einem Volumenstrom unter Normbedingungen Die dauerhafte Unversehrtheit von Sicherheitsabsperreinrichtungen wird durch wiederkehrende Funktions¬prüfungen sichergestellt. Für wiederkehrende Funktionsprüfungen wird im Allgemeinen auf nationale Vorschriften/Normen, sofern vorhanden, oder auf Verfahren des Anwenders/Herstellers verwiesen.

Dieses Dokument behandelt die Reaktion von SAE der Funktionsklasse A auf die festgelegten, vernünftiger-weise zu erwartenden Ausfälle in Zusammenhang mit Fail Close Verhalten, allerdings sollte beachtet werden, dass es andere Ausfallarten gibt, deren Folgen nicht zu denselben Reaktionen führen können (diese Risiken werden mittels Redundanz nach EN 12186 abgedeckt), und dass Restgefährdungen durch geeignete Überwachung während der Anwendung/Wartung gemindert werden sollten.

Dieses Dokument behandelt sowohl Sicherheitsabsperreinrichtungen, die als eigenständige Sicherheits-einrichtung nach der Druckgeräterichtlinie (2014/68/EU) klassifiziert werden können, als auch Sicherheitsabsperreinrichtungen, die für die erforderlichen Drucksicherung mittels Redundanz (z. B. in ein Regelgerät eingebaute Absperreinrichtung, Absperreinrichtung mit einer zweiten Absperreinrichtung) verwendet werden können. Umweltbezogene Betrachtungen wurden hinzugefügt.

Die Festlegungen in diesem Dokument entsprechen dem Stand der Technik zum Erarbeitungszeitpunkt.

Clapets de sécurité pour pressions amont jusqu'à 10 MPa (100 bar)

Le présent document (prEN 14382:2016) a été élaboré par le Comité technique CEN/TC 235 « Régulateurs de pression de gaz et dispositifs de sécurité associés pour le transport et la distribution de gaz », dont le secrétariat est tenu par UNI.

Ce document est actuellement soumis à l'Enquête CEN.

Le présent document est destiné à remplacer l’EN 14382:2005+A1:2009.

Le présent document a été élaboré dans le cadre d'un mandat donné au CEN par la Commission Européenne et l'Association Européenne de Libre-Échange et vient à l'appui des exigences essentielles de la (de) Directive(s) UE.

Pour la relation avec la (les) Directive(s) UE, voir l'Annexe ZA informative, qui fait partie intégrante du présent document.

Les principales modifications par rapport à l'EN 14382:2005+A1:2009, concernent :

- la mise à jour des références normatives ;

- l'ajout de termes et définitions ;

- la classification de deux CS en série en tant qu'accessoire de sécurité conformément à la DESP ;

- une référence complète à l'prEN 334:2016 pour les embouts de raccordement, les caractéristiques nominales des brides, les diamètres nominaux et les dimensions entre-brides, les matériaux (métalliques et non métalliques), la vérification de la résistance des parties sous pression ;

- l'essai de résistance réalisé sur une base statistique selon les dispositions de la DESP ;

- les caractéristiques antistatiques ;

- le limiteur d'évent en tant qu'accessoire éventuel à monter dans les CS ;

- l'intégration d'exigences relatives à l'environnement ;

- l'alignement des références normatives (Article 2), de l'Annexe G, de l'Annexe ZA et de ses articles pertinents par rapport aux règles du CEN.

La norme a fait l'objet d'une révision éditoriale.

Le présent document peut servir de ligne directrice pour les clapets de sécurité se situant en dehors des plages spécifiées dans la présente norme.

La présente édition a introduit l'application d'essais de résistance réalisés sur une base statistique pour les accessoires sous pression et les accessoires de sécurité fabriqués en série, sur la base de la Directive UE 2014/68/UE Annexe I article 3.2.2 et des Orientations 8/14. Les clapets de sécurité faisant l’objet du présent document sont des clapets de sécurité standard et, lorsqu’ils sont utilisés dans des postes de détente-régulation conformes à l’EN 12186 ou à l’EN 12279, ils sont considérés comme des équipements sous pression standard conformément au paragraphe 2 a) de l’Art. 1 de la Directive Équipements sous pression 2014/68/UE (DESP).

Pour les clapets de sécurité standard utilisés dans des postes de détente-régulation conformes à l'EN 12186 ou à l'EN 12279, le Tableau ZA.1 donné à l'Annexe ZA contient toutes les exigences essentielles applicables données à l'Annexe I de la DESP, sauf la résistance à la corrosion externe pour des applications dans des environnements corrosifs.

Plinske varnostne zaporne naprave za vstopne tlake do 10 MPa (100 bar)

Ta dokument določa konstrukcijske, funkcionalne in preskusne zahteve ter zahteve za označevanje, določanje velikosti in dokumentacijo plinskih varnostnih zapornih naprav, ki se uporabljajo v plinskih postajah za regulacijo tlaka v skladu s standardom EN 12186 ali EN 12279: – za vstopne tlake do 100 barov in nazivne premere do DN 400; – za delovno temperaturno območje od –20 °C do +60 °C, ki delujejo z gorivnimi plini 1. in 2. družine v skladu s standardom EN 437 v prenosnih in distribucijskih omrežjih ter tudi v komercialnih in industrijskih napravah.

General Information

- Status

- Withdrawn

- Public Enquiry End Date

- 01-Jun-2016

- Publication Date

- 24-Sep-2019

- Withdrawal Date

- 07-Jan-2025

- Technical Committee

- DPL - Gas supply

- Current Stage

- 9900 - Withdrawal (Adopted Project)

- Start Date

- 14-Nov-2024

- Due Date

- 07-Dec-2024

- Completion Date

- 08-Jan-2025

Relations

- Effective Date

- 01-Nov-2019

- Effective Date

- 01-Nov-2019

- Replaced By

SIST EN 14382:2019+A1:2025 - Gas safety shut-off devices for inlet pressure up to 10 MPa (100 bar) - Effective Date

- 01-Feb-2025

- Effective Date

- 01-Oct-2022

Frequently Asked Questions

SIST EN 14382:2019 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Gas safety shut-off devices for inlet pressure up to 10 MPa (100 bar)". This standard covers: This document specifies constructional, functional, testing marking and sizing requirements and documentation of gas safety shut-off devices: - for inlet pressures up to 100 bar and nominal diameters up to DN 400; - for an operating temperature range from -20 °C to +60 °C; which operate with fuel gases of the 1st and 2nd family as defined in EN 437, used in the pressure regulating stations in accordance with EN 12186 or EN 12279, in transmission and distribution networks and also in commercial and industrial installations. "Gas safety shut-off devices" will hereafter be called "SSDs" except in titles. For standard safety shut-off devices when used in pressure regulating stations complying with EN 12186 or EN 12279, Annex ZA lists all applicable Essential Safety Requirements of Directive 2014/68/EU (PED). This document considers the following temperature classes/types of SSDs: - temperature class 1: operating temperature range from -10 °C to 60 °C; - temperature class 2: operating temperature range from -20 °C to 60 °C; - functional class A: SSDs that close when damage to the pressure detecting element occurs or when external power fails and whose re-opening, is possible only manually; - functional class B: SSDs that do not close when damage to the pressure detecting element occurs but provide suitable and reliable protection and whose re-opening, is possible only manually; - type IS: (integral strength type); - type DS: (differential strength type). SSDs complying with the requirements of this document may be declared as "in conformity with EN 14382" and bear the mark "EN 14382". The material and functional requirements specified in this document may be applied to SSDs which use thermal energy or the effects of electrical energy to trip the operation of the closing member. For these SSDs the operational parameters are not specified in this document. The SSD may incorporate a vent limiter, complying with the requirements in Annex J. This standard for some paragraphs and sub clauses makes full reference to prEN 334:2016. This document does not apply to: - SSDs upstream from/on/in domestic gas-consuming appliances which are installed downstream of domestic gas meters; - SSDs designed to be incorporated into pressure-regulating devices used in service lines with volumetric flow rate ≤ 200 m3/h at normal conditions and inlet pressure ≤ 5 bar. Continued integrity of safety shut-off devices is ensured by periodic functional checks. For periodic functional checks it is common to refer to national regulations/standards where existing or users/manufacturers practices. This document considers the reaction of the SSDs functional class A to the specified reasonable expected failures in terms of "fail close" behaviour, but it should be consider that there are other types of failures whose consequences cannot bring to the same reactions (these risks are covered via redundancy as per EN 12186) and that residual hazards should be reduced by a suitable surveillance in use / maintenance. In this document, both safety shut-off devices that can be classified as "safety accessories" by themselves according the Pressure Equipment Directive (2014/68/EU) as well as safety shut-off devices that can be used to provide the necessary pressure protection through redundancy (e.g. shutoff device integrated in a pressure regulator, shut-off device with a second shut-off device) are considered. Addition of environmental considerations; The provisions in this document are in line with the state of art at the moment of writing. This document does not intend to limit the improvement of actual provisions (materials, requirements, test methods, acceptance criteria, etc.) or the developing of new provisions for SSDs where they are suitable to ensure an equivalent level of reliability.

This document specifies constructional, functional, testing marking and sizing requirements and documentation of gas safety shut-off devices: - for inlet pressures up to 100 bar and nominal diameters up to DN 400; - for an operating temperature range from -20 °C to +60 °C; which operate with fuel gases of the 1st and 2nd family as defined in EN 437, used in the pressure regulating stations in accordance with EN 12186 or EN 12279, in transmission and distribution networks and also in commercial and industrial installations. "Gas safety shut-off devices" will hereafter be called "SSDs" except in titles. For standard safety shut-off devices when used in pressure regulating stations complying with EN 12186 or EN 12279, Annex ZA lists all applicable Essential Safety Requirements of Directive 2014/68/EU (PED). This document considers the following temperature classes/types of SSDs: - temperature class 1: operating temperature range from -10 °C to 60 °C; - temperature class 2: operating temperature range from -20 °C to 60 °C; - functional class A: SSDs that close when damage to the pressure detecting element occurs or when external power fails and whose re-opening, is possible only manually; - functional class B: SSDs that do not close when damage to the pressure detecting element occurs but provide suitable and reliable protection and whose re-opening, is possible only manually; - type IS: (integral strength type); - type DS: (differential strength type). SSDs complying with the requirements of this document may be declared as "in conformity with EN 14382" and bear the mark "EN 14382". The material and functional requirements specified in this document may be applied to SSDs which use thermal energy or the effects of electrical energy to trip the operation of the closing member. For these SSDs the operational parameters are not specified in this document. The SSD may incorporate a vent limiter, complying with the requirements in Annex J. This standard for some paragraphs and sub clauses makes full reference to prEN 334:2016. This document does not apply to: - SSDs upstream from/on/in domestic gas-consuming appliances which are installed downstream of domestic gas meters; - SSDs designed to be incorporated into pressure-regulating devices used in service lines with volumetric flow rate ≤ 200 m3/h at normal conditions and inlet pressure ≤ 5 bar. Continued integrity of safety shut-off devices is ensured by periodic functional checks. For periodic functional checks it is common to refer to national regulations/standards where existing or users/manufacturers practices. This document considers the reaction of the SSDs functional class A to the specified reasonable expected failures in terms of "fail close" behaviour, but it should be consider that there are other types of failures whose consequences cannot bring to the same reactions (these risks are covered via redundancy as per EN 12186) and that residual hazards should be reduced by a suitable surveillance in use / maintenance. In this document, both safety shut-off devices that can be classified as "safety accessories" by themselves according the Pressure Equipment Directive (2014/68/EU) as well as safety shut-off devices that can be used to provide the necessary pressure protection through redundancy (e.g. shutoff device integrated in a pressure regulator, shut-off device with a second shut-off device) are considered. Addition of environmental considerations; The provisions in this document are in line with the state of art at the moment of writing. This document does not intend to limit the improvement of actual provisions (materials, requirements, test methods, acceptance criteria, etc.) or the developing of new provisions for SSDs where they are suitable to ensure an equivalent level of reliability.

SIST EN 14382:2019 is classified under the following ICS (International Classification for Standards) categories: 23.060.40 - Pressure regulators. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14382:2019 has the following relationships with other standards: It is inter standard links to SIST EN 14382:2005+A1:2009, SIST EN 14382:2005+A1:2009/AC:2009, SIST EN 14382:2019+A1:2025, SIST EN 14382:2019/kFprA1:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14382:2019 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 96/86/EC, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 14382:2019 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2019

Nadomešča:

SIST EN 14382:2005+A1:2009

SIST EN 14382:2005+A1:2009/AC:2009

Plinske varnostne zaporne naprave za vstopne tlake do 10 MPa (100 bar)

Gas safety shut-off devices for inlet pressure up to 10 MPa (100 bar)

Gas-Sicherheitsabsperreinrichtungen für Eingangsdrücke bis 10 MPa (100 bar)

Clapets de sécurité pour pressions amont jusqu'à 10 MPa (100 bar)

Ta slovenski standard je istoveten z: EN 14382:2019

ICS:

23.060.40 Tlačni regulatorji Pressure regulators

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14382

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2019

EUROPÄISCHE NORM

ICS 23.060.40 Supersedes EN 14382:2005+A1:2009

English Version

Gas safety shut-off devices for inlet pressure up to 10 MPa

(100 bar)

Clapets de sécurité pour pressions amont jusqu'à 10 Gas-Sicherheitsabsperreinrichtungen für

MPa (100 bar) Eingangsdrücke bis 10 MPa (100 bar)

This European Standard was approved by CEN on 23 April 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14382:2019 E

worldwide for CEN national Members.

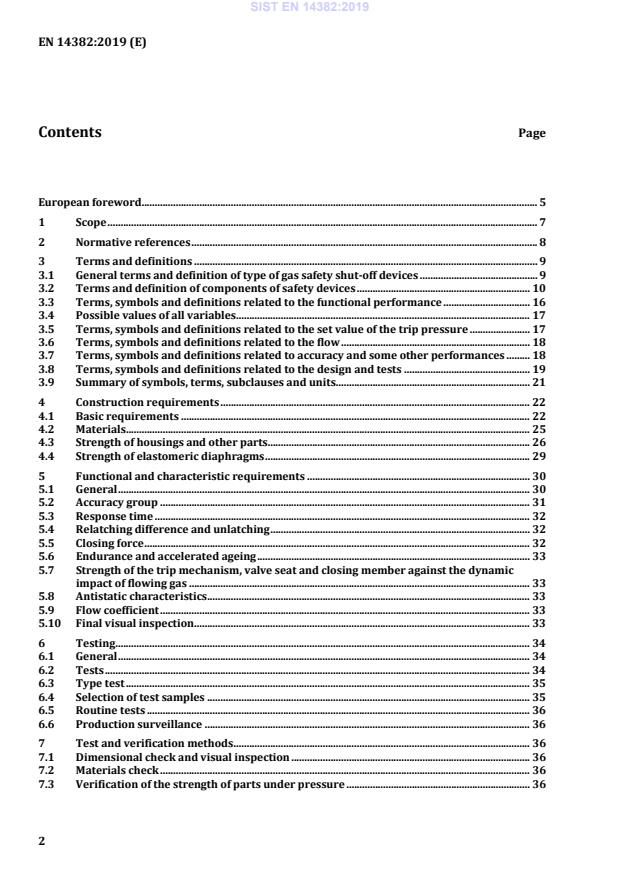

Contents Page

European foreword . 5

1 Scope . 7

2 Normative references . 8

3 Terms and definitions . 9

3.1 General terms and definition of type of gas safety shut-off devices . 9

3.2 Terms and definition of components of safety devices . 10

3.3 Terms, symbols and definitions related to the functional performance . 16

3.4 Possible values of all variables. 17

3.5 Terms, symbols and definitions related to the set value of the trip pressure . 17

3.6 Terms, symbols and definitions related to the flow . 18

3.7 Terms, symbols and definitions related to accuracy and some other performances . 18

3.8 Terms, symbols and definitions related to the design and tests . 19

3.9 Summary of symbols, terms, subclauses and units. 21

4 Construction requirements . 22

4.1 Basic requirements . 22

4.2 Materials . 25

4.3 Strength of housings and other parts. 26

4.4 Strength of elastomeric diaphragms . 29

5 Functional and characteristic requirements . 30

5.1 General . 30

5.2 Accuracy group . 31

5.3 Response time . 32

5.4 Relatching difference and unlatching . 32

5.5 Closing force . 32

5.6 Endurance and accelerated ageing . 33

5.7 Strength of the trip mechanism, valve seat and closing member against the dynamic

impact of flowing gas . 33

5.8 Antistatic characteristics . 33

5.9 Flow coefficient . 33

5.10 Final visual inspection . 33

6 Testing . 34

6.1 General . 34

6.2 Tests . 34

6.3 Type test . 35

6.4 Selection of test samples . 35

6.5 Routine tests . 36

6.6 Production surveillance . 36

7 Test and verification methods . 36

7.1 Dimensional check and visual inspection . 36

7.2 Materials check . 36

7.3 Verification of the strength of parts under pressure . 36

7.4 Verification of the strength of parts transmitting actuating forces . 36

7.5 Shell and inner metallic partition walls strength test . 37

7.6 Alternative shell and inner metallic partition walls strength test . 37

7.7 External tightness test . 37

7.8 Internal sealing test . 38

7.9 Test method and acceptance criteria to verify the antistatic characteristics . 38

7.10 Accuracy group . 38

7.11 Response time . 43

7.12 Relatching difference and unlatching . 44

7.13 Verification of closing force . 45

7.14 Endurance and accelerated ageing . 45

7.15 Resistance to gas of non-metallic parts . 45

7.16 Verification of the strength of the trip mechanism, valve seat and closing member

against dynamic impact of flowing gas . 45

7.17 Final visual inspection . 46

8 Field surveillance . 46

9 Documentation . 47

9.1 Documentation related to type test . 47

9.2 Documentation related to the routine tests . 47

9.3 Documentation related to production surveillance in accordance with 6.6 . 47

9.4 Operating instructions . 48

9.5 Information on sizing . 48

10 Marking . 49

10.1 General requirements . 49

10.2 Basic requirements . 49

10.3 Other additional requirements . 49

10.4 Markings for the various connections. 50

10.5 Identification of auxiliary devices . 50

11 Packaging and transportation of finished product . 50

Annex A (informative) Ice formation . 51

A.1 General . 51

A.2 Requirements . 51

A.3 Tests . 51

)

Annex B (informative) Compliance evaluation . 52

B.1 General . 52

B.2 Introduction. 52

B.3 Procedure . 52

B.4 Manufacturer’s compliance evaluation . 53

B.5 Issue of the certificate of compliance . 53

Annex C (informative) Pressure drop and flow coefficient . 54

C.1 Calculation method for pressure drop throughout the SSD . 54

C.2 Test method for the determination of the flow coefficients . 55

Annex D (normative) Alternative test method for verification of the strength of the trip

mechanism, valve seat and closing member . 56

D.1 Test method . 56

D.2 Test method for the determination of the dynamic factor C . 56

r

D.3 Test method for a series of SSDs . 57

Annex E (informative) Sizing equation . 59

Annex F (informative) Inspection certificate . 60

Annex G (informative) Order specification . 62

G.1 General . 62

G.2 Minimum specifications . 62

G.3 Optional specifications . 63

Annex H (informative) Acceptance test . 64

Annex I (informative) Suitability of safety shut-off device for damp operating conditions -

Test procedure, requirement and acceptance criteria. 65

Annex J (normative) Vent limiter . 66

J.1 General . 66

J.2 Scope . 66

J.3 Terms, symbols and definitions . 66

J.4 Requirements . 67

J.5 Testing and acceptance criteria . 68

J.6 Documentation . 69

J.7 Specific marking on vent limiter . 69

Annex K (informative) Glossary . 70

Annex L (informative) Environmental Provisions . 73

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of Directive 2014/68/EU aimed to be covered . 76

Bibliography . 78

European foreword

This document (EN 14382:2019) has been prepared by Technical Committee CEN/TC 235 “Gas

pressure regulators and associated safety devices for use in gas transmission and distribution”, the

secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2020, and conflicting national standards

shall be withdrawn at the latest by February 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14382:2005+A1:2009.

In comparison with the previous edition, the following technical modifications have been made:

— normative references have been updated;

— terms and definitions have been added;

— classification of two in series SSDs as safety accessory to PED;

— full reference to EN 334:2019 for end connections, flange rating, nominal and face to face

dimensions, materials (metallic and non-metallic), verification of strength of pressure bearing

parts;

— statistical strength test on the basis of PED provisions;

— antistatic characteristics;

— vent limiter as possible fixture to be assembled in the SSDs;

— integration of environmental requirements;

— alignment of normative references (Clause 2), Annex G, Annex ZA and its relevant clauses to CEN

rules.

The standard has been editorially revised.

This document can be used as a guideline for gas safety shut off devices outside the ranges specified in

this standard.

This edition has introduced the application of statistical strength testing for series produced pressure

and safety accessories on the basis of EU Directive 2014/68/EU Annex I article 3.2.2 and Guideline H-

14. Safety shut-off devices dealt with in this document are standard safety shut-off devices and, when

used in pressure regulating stations complying with EN 12186 or EN 12279, they are considered as

standard pressure equipment in accordance with Clause 2 a) of Art. 1 of Pressure Equipment Directive

2014/68/EU (PED).

For standard safety shut-off devices used in pressure regulating stations complying with EN 12186 or

EN 12279, Table ZA.1 given in Annex ZA includes all applicable Essential Requirements given in Annex I

of PED except external corrosion resistance for applications in corrosive environments.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Republic of North Macedonia, Norway,

Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document specifies constructional, functional, testing marking and sizing requirements and

documentation of gas safety shut-off devices:

— for inlet pressures up to 100 bar and nominal diameters up to DN 400;

— for an operating temperature range from –20 °C to +60 °C;

which operate with fuel gases of the 1st and 2nd family as defined in EN 437, used in the pressure

regulating stations in accordance with EN 12186 or EN 12279, in transmission and distribution

networks and also in commercial and industrial installations.

“Gas safety shut-off devices” will hereafter be called “SSDs” except in titles.

For standard safety shut-off devices when used in pressure regulating stations complying with

EN 12186 or EN 12279, Annex ZA lists all applicable Essential Safety Requirements of Directive

2014/68/EU (PED).

This document considers the following temperature classes/types of SSDs:

— temperature class 1: operating temperature range from –10 °C to 60 °C;

— temperature class 2: operating temperature range from –20 °C to 60 °C;

— functional class A: SSDs that close when damage to the pressure detecting element occurs or when

external power fails and whose re-opening, is possible only manually;

— functional class B: SSDs that do not close when damage to the pressure detecting element occurs

but provide suitable and reliable protection and whose re-opening, is possible only manually;

— type IS: (integral strength type);

— type DS: (differential strength type).

SSDs complying with the requirements of this document may be declared as “in conformity with

EN 14382“ and bear the mark “EN 14382”.

The material and functional requirements specified in this document may be applied to SSDs which use

thermal energy or the effects of electrical energy to trip the operation of the closing member. For these

SSDs the operational parameters are not specified in this document.

The SSD may incorporate a vent limiter, complying with the requirements in Annex J.

This standard for some paragraphs and sub clauses makes full reference to EN 334:2019.

This document does not apply to:

— SSDs upstream from/on/in domestic gas-consuming appliances which are installed downstream of

domestic gas meters;

— SSDs designed to be incorporated into pressure-regulating devices used in service lines with

volumetric flow rate ≤ 200 m /h at normal conditions and inlet pressure ≤ 5 bar.

The service lines are those defined in EN 12279

Continued integrity of safety shut-off devices is ensured by periodic functional checks. For periodic

functional checks it is common to refer to national regulations/standards where existing or

users/manufacturers practices.

This document considers the reaction of the SSDs functional class A to the specified reasonable

expected failures in terms of “fail close” behaviour, but it should be consider that there are other types

of failures whose consequences cannot bring to the same reactions (these risks are covered via

redundancy as per EN 12186) and that residual hazards should be reduced by a suitable surveillance in

use / maintenance.

In this document, both safety shut-off devices that can be classified as “safety accessories” by

themselves according the Pressure Equipment Directive (2014/68/EU) as well as safety shut-off

devices that can be used to provide the necessary pressure protection through redundancy (e.g. shutoff

device integrated in a pressure regulator, shut-off device with a second shut-off device) are considered.

Addition of environmental considerations;

The provisions in this document are in line with the state of art at the moment of writing.

This document does not intend to limit the improvement of actual provisions (materials, requirements,

test methods, acceptance criteria, etc.) or the developing of new provisions for SSDs where they are

suitable to ensure an equivalent level of reliability.

Some clauses of this standard should be re-considered at the time when characteristics for non-

conventional gases will be available.

Gas safety shut-off devices according to this European standard do not have their own source of ignition

and therefore are not within the scope of European Directive 2014/34/EU. Any additional component

(e.g. proximity switch, travel transducer etc.) should be independently considered in the framework of

assemblies per ATEX Guideline to the application of Directive 2014/34/EU of the European Parliament

and of the Council of 26nd February 2014, edition December 2017, §§42 and 43.

The document includes also environmental considerations.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 334:2019, Gas pressure regulators for inlet pressures up to 100 bar

EN 1092-1:2007+A1:2013, Flanges and their joints - Circular flanges for pipes, valves, fittings and

accessories, PN designated - Part 1: Steel flanges

EN 1092-2:1997, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 2: Cast iron flanges

EN 1092-3:2003, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 3: Copper alloy flanges

EN 1092-4:2002, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 4: Aluminium alloy flanges

EN 1349:2009, Industrial process control valves

EN 1759-1:2004, Flanges and their joint - Circular flanges for pipes, valves, fittings and accessories, Class

designated - Part 1: Steel flanges, NPS 1/2 to 24

EN 1759-3:2003, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, Class

designated - Part 3: Copper alloy flanges

EN 1759-4:2003, Flanges and their joint - Circular flanges for pipes, valves, fittings and accessories, class

designated - Part 4: Aluminium alloy flanges

EN 10204:2004, Metallic products - Types of inspection documents

EN 12186:2014, Gas infrastructure - Gas pressure regulating stations for transmission and distribution -

Functional requirements

EN 12279:2000, Gas supply systems - Gas pressure regulating installations on service lines - Functional

requirements

EN 13906-1:2013, Cylindrical helical springs made from round wire and bar - Calculation and design -

Part 1 : Compression springs

EN 13906-2:2013, Cylindrical helical springs made from round wire and bar - Calculation and design -

Part 2: Extension springs

EN 13906-3:2014, Cylindrical helical springs made from round wire and bar - Calculation and design -

Part 3: Torsion springs

EN 60534-1:2005, Industrial-process control valves - Part 1: Control valve terminology and general

considerations

ISO 7005-2:1998, Metallic flanges — Part 2: Cast iron flanges

3 Terms and definitions

For the purposes of this document, the following terms, definitions and symbols apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

NOTE Annex K lists all definitions and terms in alphabetic order for the English language, the relevant

translation in French and German language and the relevant sub clause of this clause.

3.1 General terms and definition of type of gas safety shut-off devices

3.1.1

gas safety shut-off device

device whose function is to stay in the open position under normal operating conditions and to shut-off

the gas flow automatically and completely when the monitored pressure exceeds the pre-set values

(over-pressure monitoring and/or under-pressure monitoring)

3.1.2

direct acting gas shut-off device

SSD in which the pressure detecting element is directly connected to the trip mechanism

Note 1 to entry: See Figure 1.

3.1.3

indirect acting gas shut-off device

SSD without mechanical connection between the pressure detector element and the trip mechanism

and where (pressure) energy from an internal or external source is used for activating the trip

mechanism and moving the closing element

Note 1 to entry: See Figures 2, 3 and 4.

3.1.4

gas cut-off device

SSD designed to shut-off the gas flow, which responds slower dynamically than a slam shut device when

the monitored pressure exceeds the pre-set values

EXAMPLE SSD using actuator driven by pipeline gas or external power.

3.1.5

gas slam shut device

SSD designed to quickly shut-off the gas flow when the monitored pressure exceeds the pre-set values

EXAMPLE Spring or weight loaded SSD.

3.1.6

sensing point

point from which the monitored variable is fed to the SSD

3.1.7

SSD size

nominal size DN of the inlet connection in accordance with EN ISO 6708 [5]

3.1.8

series of safety shut-off devices

SSDs with the same design concept but differing only in size

3.1.9

auxiliary energy

energy coming from pressure of the system (internal energy) or from any external source (compressed

air or gas)

3.2 Terms and definition of components of safety devices

3.2.1

main components

parts including normally: a controller, a trip mechanism, an actuator, a closing member and a relatching

device permitting the manual opening of the SSD. All these parts are functionally connected

Note 1 to entry: See Figures 1 to 5.

3.2.2

closing member

part which shuts off the gas flow completely

3.2.3

trip mechanism

mechanism which releases the closing member when activated by the controller

3.2.4

actuator

device activated by the trip mechanism which shuts the closing member

3.2.5

relatching device

device which enables the complete opening of the SSD

3.2.6

body

main pressure bearing envelope which provides the fluid flow passageway and the pipe end

connections

3.2.7

valve seat

corresponding sealing surfaces within an SSD which make full contact only when the closing member is

in the closed position

3.2.8

seat ring

part assembled in a component of the SSD to provide a removable seat

3.2.9

controller

device which includes:

— a setting element to adjust the set value of the trip pressure;

— a pressure detecting element which has the function to detect the feedback of the monitored

pressure (e.g. a diaphragm);

— a unit which compares the set value of the trip pressure with the monitored pressure;

— a system which gives the energy to operate the trip mechanism

3.2.10

bypass

device permitting manual equalization of pressure across a closed SSD

3.2.11

diaphragm

diaphragm used as pressure detecting element and diaphragm used to separate one chamber subjected

to pressure into two parts with different pressure (e.g.: balancing diaphragm)

Note 1 to entry: Diaphragms used as a closing member are not part of this group.

3.2.12

auxiliary devices

any device functionally connected to the main components of the SSD

Note 1 to entry: Examples are controller, vent limiter, etc.

Key

1 bypass 6 controller

2 relatching device 7 sensing line

3 trip mechanism 8 actuator

4 breather line 9 sensing point

5 setting element 10 closing member

11 SSD Body

Figure 1 — Example of direct acting gas safety shut-off devices

Key

1 bypass 8 loading pressure line (from internal power

source)

2 actuator 9 loading pressure line (from external power

source)

3 relatching device 10 breather/exhaust line

4 exhaust line 11 sensing point

5 trip mechanism 12 closing member

6 controller 13 SSD Body

7 sensing line

Figure 2 — Example N. 1 of an indirect acting gas shut-off device

Key

1 bypass 9 sensing point

2 actuator 10 closing member

3 relatching device 11 isolating valve

4 safety relief valve 12 pressure regulator

5 trip mechanism (directional control valve) 13 exhaust line

6 controller 14 breather line

7 sensing line 15 SSD Body

8 loading pressure line (from internal power source)

Figure 3 — Example N. 2 of an indirect acting gas shut-off device

Key

1 bypass 7 sensing line

2 actuator 8 loading pressure line (from external power source)

3 relatching device 9 loading pressure line (from internal power source)

4 exhaust line 10 breather/exhaust line

5 trip mechanism 11 sensing point

6 controller 12 closing member

13 pressure reducer (if applicable)

Figure 4 — Example N. 3 of an indirect acting gas shut-off device

3.2.13

loading pressure line

line connecting the controller and/or actuator to the internal or external power source

3.2.14

pressure bearing parts

parts whose failure to function would result in a release of the retained fuel gas to the atmosphere

Note 1 to entry: These include bodies, closing member, controllers, bonnets, blind flanges and pipes for process

and sensing lines but exclude compression fittings, diaphragms, bolts and other fasteners.

3.2.15

inner metallic partition wall

metallic wall that separates a chamber into two individual pressure-containing chambers at different

pressures under normal operating conditions

3.2.16

sensing line

line connecting the sensing point and the controller

3.2.17

exhaust line

line connecting the controller and/or actuator of the SSD to atmosphere for the safe exhausting of fuel

gas in the event of closing and/or failure of any part

3.2.18

breather line

line connecting the atmospheric side of the pressure detecting element to atmosphere

Note 1 to entry: In the event of a fault in the pressure detecting element this line can become an exhaust line.

3.3 Terms, symbols and definitions related to the functional performance

3.3.1 Terms related to types of pressure

3.3.1.1

inlet pressure

pu

gas pressure at the inlet of the SSD

3.3.1.2

pressure

all pressures specified in this standard are static gauge pressures except the ambient atmospheric

pressure

(2)

Note 1 to entry: Pressure is expressed in bar .

3.3.1.3

differential pressure

Δp

pressure drop across the SSD in mbar

3.3.1.4

loading pressure

pressure of the gas from the upstream or downstream pipeline or of the air from an external source

used as an energy source for the controller and/or actuator

3.3.1.5

trip pressure

p (for over-pressure monitoring)

do

p (for under-pressure monitoring)

du

pressure value at which the closing member moves to closed position

3.3.2 Other terms related to pressure

3.3.2.1

monitored pressure

pressure monitored and safeguarded by the SSD, normally the outlet pressure of the pressure

regulating station/installation

3.3.2.2

ambient atmospheric pressure

p

b

local static atmospheric pressure in bar (absolute pressure)

2 5

-1 5 2

1 bar = 10 Pascal = 1 000 mbar = 10 MPa = 10 N/m .

3.4 Possible values of all variables

3.4.1

actual value of the trip pressure

p (for over-pressure monitoring)

dio

p (for under-pressure monitoring)

diu

pressure value at which the closing member of an SSD starts to move

3.4.2

maximum value

highest value, which is specified by the index “max” added to the symbol of the variable:

— to which any variable can be adjusted or to which it is limited;

— any variable may reach during a series of measurements, or during a certain time period

3.4.3

minimum value

lowest value, which is specified by the index “min“ added to the symbol of the variable:

— to which any variable can be adjusted or to which it is limited;

— any variable may reach during a series of measurements or during a certain time period

3.4.4

disturbance variables

variables affecting the functioning of the SSD

EXAMPLES

— changes in flow rate;

— temperature changes;

— mechanical impacts;

— influence of moisture;

— influence of gas conditioning agents;

— dust, condensation or other foreign material;

— dynamic force on closing member created by gas flow

3.5 Terms, symbols and definitions related to the set value of the trip pressure

3.5.1

set point

p (for over-pressure monitoring)

dso

p (for under-pressure monitoring)

dsu

nominal trip pressure value under specified conditions

3.5.2

set range

W (for over-pressure monitoring)

do

W (for under-pressure monitoring)

du

whole range of set points which can be obtained with a SSD by adjustment and/or the replacement of

some components (e.g. replacement of the setting mean, or pressure detecting element)

3.5.3

specific set range

W (for over-pressure monitoring)

dso

W (for under-pressure monitoring)

dsu

whole range of set points which can be obtained with a SSD by adjustment and without replacement of

any component

3.6 Terms, symbols and definitions related to the flow

3.6.1

normal conditions

absolute pressure p of 1,01325 bar and temperature T of 273,15 K (0 °C)

n n

3.6.2

gas volume

volume of gas at normal conditions

Note 1 to entry: Gas volume is expressed in m .

3.6.3

volumetric flow rate

Q

n

volume of fluid at operating conditions which flows through the SSD per unit time, recalculated at

normal conditions

Note 1 to entry: Volumetric flow rate is expressed in m /h at normal conditions.

3.7 Terms, symbols and definitions related to accuracy and some other performances

3.7.1

trip pressure deviation

difference between the actual value of the trip pressure and the set point as a percentage of the set

value

Note 1 to entry: See Figure 5.

3.7.2

accuracy group

AG

maximum permissible absolute value of trip pressure deviation

Note 1 to entry: See Figure 5.

3.7.3

inlet operating pressure range

b

pu

range of inlet operating pressure for which the SSD ensures a given accuracy group

3.7.4

response time

t

a

time interval between attaining the permissible limit value of the trip pressure at the sensing point and

complete closure of the closing member

3.7.5

relatching pressure difference

Δp

w

minimum difference between the set value of the trip pressure and the monitored pressure which is

required for the correct resetting of the SSD

Key

1 Set value of trip pressure (pdso)

2 Actual value of trip pressure (pdio)

3 Trip pressure deviation

4 Accuracy group (AG)

5 Relatching difference (Δpw)

Figure 5 — Monitored pressure and trip pressure

3.7.6

pressure drop

drop in pressure, at specified operating conditions, of gas passing through the SSD

3.8 Terms, symbols and definitions related to the design and tests

3.8.1

component operating pressure

p

gas pressure occurring in any part of a SSD during operation

3.8.2

maximum component operating pressure

p

max

highest operating pressure at which a component of an SSD will continuously operate within specified

conditions

3.8.3

maximum inlet pressure

p

umax

highest inlet pressure at which the SSD can continuously operate within specified conditions

3.8.4

maximum allowable pressure

PS

maximum pressure for which the body, its inner metallic partition walls and some other pressure

bearing parts are designed in accordance with the strength requirements in this document

3.8.5

maximum/minimum allowable temperature

TS

maximum/minimum temperatures for which the body, its inner metallic partition walls and some other

pressure bearing parts are designed in accordance with the strength requirements in this document

3.8.6

specific maximum allowable pressure

PSD

pressure for which some pressure bearing parts of differential strength SSDs are designed where

PSD < PS

3.8.7

test pressure

pressure applied to a section of the SSD for a limited period of time in order to prove certain

characteristics

3.8.8

limit pressure

p

l

pressure at which yielding becomes apparent in any component of the SSD or its auxiliary devices

3.8.9

nominal pressure

PN

alphanumeric designation used for reference purposes related to a combination of mechanical and

dimensional characteristics of flanges in accordance with the relevant parts of EN 1092 series and

ISO 7005-2, which comprises the letters PN followed by a dimensionless whole number

3.8.10

safety factor

ratio of the limit pressure p to the maximum allowable pressure PS or to specific maximum allowable

l

pressure PSD applied to:

— SSD body: Sb (only PS);

— other pressure bearing part of the SSD: S (PS or PSD)

3.8.11

operating temperature range

temperature range at which the SSD components and auxiliary devices are capable of operating

continuously

3.8.12

closing force

F

S

force created by a spring, by a weight-piece or by pressure to operate the clo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...