SIST EN 334:2019+A1:2025

(Main)Gas pressure regulators for inlet pressure up to 10 MPa (100 bar)

Gas pressure regulators for inlet pressure up to 10 MPa (100 bar)

This European Standard specifies constructional, functional, testing, marking, sizing and documentation requirements of gas pressure regulators:

- for inlet pressures up to 100 bar and nominal diameters up to DN 400;

- for an operating temperature range from - 20 °C to +60 °C,

which operate with fuel gases of the 1st and 2nd family as defined in EN 437:2003+A1:2009, used in the pressure regulating stations in accordance with EN 12186 or EN 12279, in transmission and distribution networks and also in commercial and industrial installations.

"Gas pressure regulators" hereafter will be called "regulators" except in the titles.

For standard regulators when used in pressure regulating stations complying with EN 12186 or EN 12279, the Annex ZA lists all applicable essential safety requirements of the European legislation on pressure equipment except external and internal corrosion resistance for applications in corrosive environment.

This document considers the following temperature classes/types of regulators:

- temperature class 1: operating temperature range from −10 °C to 60 °C;

- temperature class 2: operating temperature range from −20 °C to 60 °C;

- type IS: (integral strength type);

- type DS: (differential strength type).

This document applies to regulators which use the pipeline gas as a source of control energy unassisted by any external power source.

The regulator may incorporate a second regulator, used as monitor, complying with the requirements in this document.

The regulator may incorporate a safety shut off device (SSD) complying with the requirements of EN 14382.

The regulator may incorporate a creep (venting) relief device, complying with the requirements in Annex E and/or a vent limiter, complying with the requirements in Annex I.

This document does not apply to:

- regulators upstream from/on/in domestic gas-consuming appliances which are installed downstream of domestic gas meters;

- regulators designed to be incorporated into pressure control systems used in service lines ) with volumetric flow rate ≤ 200 m3/h at normal conditions and inlet pressure ≤ 5 bar;

- regulators for which a specific document exists (e.g. EN 88-1 and EN 88-2, etc.);

- industrial process control valves in accordance with EN 1349.

The normative Annex G of this document lists some suitable materials for pressure bearing parts, inner metallic partition walls, auxiliary devices, integral process and sensing lines, connectors and fasteners. Other materials may be used when complying with the restrictions given in Table 5.

Continued integrity of gas pressure regulators is ensured by suitable surveillance checks and maintenance. For periodic functional checks and maintenance it is common to refer to national regulations/standards where existing or users/manufacturers practices.

This document has introduced the reaction of the pressure regulators to the specified reasonable expected failures in terms of "fail close" and "fail open" pressure regulator types, but it should be considered that there are other types of failures whose consequences can bring to the same reactions (these risks are covered via redundancy as per EN 12186) and that residual hazards will be reduced by a suitable surveillance in use / maintenance.

In this document, both pressure regulators that can be classified as "safety accessories" by themselves (monitors) according to European legislation on pressure equipment as well as regulators that can be used to provide the necessary pressure protection through redundancy (e.g. pressure regulator with integrated safety shut-off device, pressure regulator + in-line monitor, pressure regulator + safety shut off device) are considered.

The provisions in this document are in line with the state of art at the moment of writing.

Gas-Druckregelgeräte für Eingangsdrücke bis 10 MPa (100 bar)

No scope available

Régulateurs de pression de gaz pour des pressions amont jusqu’à 10 MPa (100 bar)

Regulatorji tlaka plina za vstopne tlake do 10 MPa (100 bar) (vključno z dopolnilom A1)

Ta dokument določa konstrukcijske, funkcionalne in preskusne zahteve ter zahteve za označevanje, določanje velikosti in dokumentacijo regulatorjev tlaka plina:

– za vstopne tlake do 100 barov in nazivne premere do DN 400,

– za temperaturno območje delovanja od –20 °C do +60 °C,

ki delujejo z gorivnimi plini prve in druge družine, opredeljenimi v standardu EN 437:2018 [1], ki se uporabljajo v postajah za regulacijo tlaka v skladu s standardom EN 12186 ali EN 12279, v prenosnih in distribucijskih omrežjih ter tudi v komercialnih in industrijskih napravah.

»Regulatorji tlaka plina« bodo v nadaljevanju imenovani »regulatorji«, razen v naslovih.

Za standardne regulatorje, kadar se ti uporabljajo v postajah za regulacijo tlaka v skladu s standardom EN 12186 ali EN 12279, so v dodatku ZA navedene vse veljavne osnovne varnostne zahteve evropske zakonodaje o tlačni opremi, razen zunanje in notranje odpornosti proti rjavenju za uporabo v korozivnem okolju.

Ta dokument obravnava naslednje temperaturne razrede/vrste regulatorjev:

– temperaturni razred 1: temperaturno območje delovanja od −10 °C do 60 °C;

– temperaturni razred 2: temperaturno območje delovanja od −20 °C do 60 °C;

– vrsta IS: (integralna trdnost);

– vrsta DS: (diferencialna trdnost).

Ta dokument se uporablja za regulatorje, ki kot vir krmilne energije uporabljajo plin iz plinovoda brez pomoči zunanjega vira energije.

Regulator lahko vključuje dodatni regulator, ki se uporablja kot naprava za nadzor v skladu z zahtevami v tem dokumentu.

Regulator lahko vključuje varnostno zaporno napravo (SSD) v skladu z zahtevami iz standarda EN 14382.

Regulator lahko vključuje napravo za razbremenitev pri lezenju (odzračevanje) v skladu z zahtevami iz dodatka E in/ali omejevalnik odzračevanja v skladu z zahtevami iz dodatka I.

Ta dokument se ne uporablja za:

– regulatorje, nameščene pred gospodinjskimi napravami, ki delujejo na plin, oziroma na ali v njih, ki so nameščeni za merilniki plina za gospodinjstvo;

– regulatorje, zasnovane za vgradnjo v sisteme za regulacijo tlaka, ki se uporabljajo v priključnih cevovodih2) z volumetričnim pretokom ≤ 200 m3/h ob normalnih pogojih in vstopnim tlakom ≤ 5 barov;

– regulatorje, za katere obstaja specifičen dokument (npr. EN 88-1 in EN 88-2 itd.);

– regulacijske ventile za industrijske procese v skladu s standardom EN 1349.

V informativnem dodatku G tega dokumenta je navedenih nekaj primernih materialov za tlačno obremenjene dele, notranje kovinske pregrade, pomožne naprave, vgrajene vode za obdelavo in zaznavanje ter priključke in vezne elemente. Uporabijo se lahko tudi drugi materiali, ki so v skladu z omejitvami iz preglednice 5.

Stalna celovitost regulatorjev tlaka plina je zagotovljena z ustreznimi pregledi in vzdrževanjem. V zvezi z rednim preverjanjem delovanja in vzdrževanjem je običajno sklicevanje na nacionalne predpise/standarde, če obstajajo, ali prakse uporabnikov/proizvajalcev.

Ta dokument uvaja odziv regulatorjev tlaka na navedene razumno pričakovane okvare v smislu vedenja »zaprtje ob okvari« in »odprtje ob okvari«, vendar naj se upošteva, da obstajajo tudi druge vrste okvar, katerih posledice lahko povzročijo enake odzive (ta tveganja so zajeta z redundanco v skladu s standardom EN 12186), in da se preostala tveganja zmanjšajo z ustreznim nadzorom med uporabo/vzdrževanjem.

V tem dokumentu so obravnavani tako regulatorji tlaka, ki jih je mogoče opredeliti kot »varnostne pripomočke« (naprave za nadzor) v skladu z evropsko zakonodajo o tlačni opremi, kot tudi regulatorji, s katerimi je mogoče

zagotoviti potrebno zaščito pred tlakom z redundanco (npr. regulator tlaka z vgrajeno varnostno zaporno napravo, regulator tlaka z napravo za nadzor tlaka v vodu, regulator tlaka z varnostno zaporno napravo).

Določbe v tem dokumentu so v skladu s stanjem tehnike v času njegove priprave.

Ta dokument ne namerava omejevati izboljšanja dejanskih določb (materiali, zahteve, preskusne metode, merila sprejemljivosti itd.) ali ob

General Information

- Status

- Published

- Publication Date

- 07-Jan-2025

- Technical Committee

- DPL - Gas supply

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 14-Nov-2024

- Due Date

- 19-Jan-2025

- Completion Date

- 08-Jan-2025

Relations

- Effective Date

- 01-Jan-2025

- Consolidates

SIST EN 334:2019/kFprA1:2024 - Gas pressure regulators for inlet pressure up to 10 MPa (100 bar) - Effective Date

- 01-Jan-2025

Overview

EN 334:2019+A1:2024 is the European Standard for gas pressure regulators with inlet pressures up to 10 MPa (100 bar) and nominal diameters up to DN 400. It defines constructional, functional, testing, sizing, marking and documentation requirements for regulators that operate with fuel gases of the 1st and 2nd families (per EN 437) and that are used in pressure regulating stations, transmission and distribution networks, and commercial/industrial installations. The standard covers regulators operating in the temperature range −20 °C to +60 °C and includes amendment A1 (2024).

Key topics and technical requirements

- Scope & limits

- Applies to pipeline-gas-powered regulators (no external power source).

- Covers temperature classes (Class 1: −10 °C to +60 °C; Class 2: −20 °C to +60 °C) and strength types (IS - integral strength, DS - differential strength).

- Excludes domestic appliance regulators downstream of domestic meters, certain service-line regulators (≤ 200 m3/h at inlet ≤ 5 bar), devices covered by other standards (e.g., EN 88‑1/‑2) and industrial process control valves (EN 1349).

- Design & materials

- Construction and strength requirements for bodies, flanges, inner partition walls and pressure-bearing parts.

- Material guidance in Normative Annex G and restrictions in Table 5 for alternative materials.

- Requirements for elastomers, sealing, springs and parts transmitting actuating forces.

- Functional performance

- Accuracy classes, lock-up behaviour, flow characteristics, fail‑close and fail‑open behaviour.

- Sizing equations and procedures for volumetric flow and maximum accuracy flow rates.

- Antistatic characteristics and mounting/installation considerations.

- Testing & quality

- Type tests, routine tests, production surveillance, field surveillance and documentation requirements.

- Annexes for specific devices: safety shut-off devices (SSD per EN 14382), creep (venting) relief devices (Annex E) and vent limiters (Annex I).

- Annex ZA lists essential safety requirements under EU pressure equipment legislation (except corrosion resistance in corrosive environments).

Applications and who uses it

- Intended users:

- Regulator manufacturers designing and certifying regulators to European requirements.

- Gas network operators and system designers specifying components for transmission, distribution and pressure regulating stations (EN 12186 / EN 12279).

- Testing laboratories, inspection bodies and compliance engineers performing type and routine tests.

- Commissioning, maintenance and procurement teams ensuring correct sizing, marking, documentation and surveillance.

- Typical applications:

- Pressure regulating stations, inline or integrated regulator + monitor assemblies, commercial and industrial gas installations.

Related standards

- EN 437 (gas families)

- EN 12186, EN 12279 (pressure regulating stations)

- EN 14382 (safety shut-off devices)

- EN 88‑1 / EN 88‑2 (specific regulator families)

- EN 1349 (industrial process control valves)

EN 334:2019+A1:2024 provides the harmonized technical baseline for safe, tested and correctly sized high‑pressure gas regulators used across European gas infrastructure.

Frequently Asked Questions

SIST EN 334:2019+A1:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Gas pressure regulators for inlet pressure up to 10 MPa (100 bar)". This standard covers: This European Standard specifies constructional, functional, testing, marking, sizing and documentation requirements of gas pressure regulators: - for inlet pressures up to 100 bar and nominal diameters up to DN 400; - for an operating temperature range from - 20 °C to +60 °C, which operate with fuel gases of the 1st and 2nd family as defined in EN 437:2003+A1:2009, used in the pressure regulating stations in accordance with EN 12186 or EN 12279, in transmission and distribution networks and also in commercial and industrial installations. "Gas pressure regulators" hereafter will be called "regulators" except in the titles. For standard regulators when used in pressure regulating stations complying with EN 12186 or EN 12279, the Annex ZA lists all applicable essential safety requirements of the European legislation on pressure equipment except external and internal corrosion resistance for applications in corrosive environment. This document considers the following temperature classes/types of regulators: - temperature class 1: operating temperature range from −10 °C to 60 °C; - temperature class 2: operating temperature range from −20 °C to 60 °C; - type IS: (integral strength type); - type DS: (differential strength type). This document applies to regulators which use the pipeline gas as a source of control energy unassisted by any external power source. The regulator may incorporate a second regulator, used as monitor, complying with the requirements in this document. The regulator may incorporate a safety shut off device (SSD) complying with the requirements of EN 14382. The regulator may incorporate a creep (venting) relief device, complying with the requirements in Annex E and/or a vent limiter, complying with the requirements in Annex I. This document does not apply to: - regulators upstream from/on/in domestic gas-consuming appliances which are installed downstream of domestic gas meters; - regulators designed to be incorporated into pressure control systems used in service lines ) with volumetric flow rate ≤ 200 m3/h at normal conditions and inlet pressure ≤ 5 bar; - regulators for which a specific document exists (e.g. EN 88-1 and EN 88-2, etc.); - industrial process control valves in accordance with EN 1349. The normative Annex G of this document lists some suitable materials for pressure bearing parts, inner metallic partition walls, auxiliary devices, integral process and sensing lines, connectors and fasteners. Other materials may be used when complying with the restrictions given in Table 5. Continued integrity of gas pressure regulators is ensured by suitable surveillance checks and maintenance. For periodic functional checks and maintenance it is common to refer to national regulations/standards where existing or users/manufacturers practices. This document has introduced the reaction of the pressure regulators to the specified reasonable expected failures in terms of "fail close" and "fail open" pressure regulator types, but it should be considered that there are other types of failures whose consequences can bring to the same reactions (these risks are covered via redundancy as per EN 12186) and that residual hazards will be reduced by a suitable surveillance in use / maintenance. In this document, both pressure regulators that can be classified as "safety accessories" by themselves (monitors) according to European legislation on pressure equipment as well as regulators that can be used to provide the necessary pressure protection through redundancy (e.g. pressure regulator with integrated safety shut-off device, pressure regulator + in-line monitor, pressure regulator + safety shut off device) are considered. The provisions in this document are in line with the state of art at the moment of writing.

This European Standard specifies constructional, functional, testing, marking, sizing and documentation requirements of gas pressure regulators: - for inlet pressures up to 100 bar and nominal diameters up to DN 400; - for an operating temperature range from - 20 °C to +60 °C, which operate with fuel gases of the 1st and 2nd family as defined in EN 437:2003+A1:2009, used in the pressure regulating stations in accordance with EN 12186 or EN 12279, in transmission and distribution networks and also in commercial and industrial installations. "Gas pressure regulators" hereafter will be called "regulators" except in the titles. For standard regulators when used in pressure regulating stations complying with EN 12186 or EN 12279, the Annex ZA lists all applicable essential safety requirements of the European legislation on pressure equipment except external and internal corrosion resistance for applications in corrosive environment. This document considers the following temperature classes/types of regulators: - temperature class 1: operating temperature range from −10 °C to 60 °C; - temperature class 2: operating temperature range from −20 °C to 60 °C; - type IS: (integral strength type); - type DS: (differential strength type). This document applies to regulators which use the pipeline gas as a source of control energy unassisted by any external power source. The regulator may incorporate a second regulator, used as monitor, complying with the requirements in this document. The regulator may incorporate a safety shut off device (SSD) complying with the requirements of EN 14382. The regulator may incorporate a creep (venting) relief device, complying with the requirements in Annex E and/or a vent limiter, complying with the requirements in Annex I. This document does not apply to: - regulators upstream from/on/in domestic gas-consuming appliances which are installed downstream of domestic gas meters; - regulators designed to be incorporated into pressure control systems used in service lines ) with volumetric flow rate ≤ 200 m3/h at normal conditions and inlet pressure ≤ 5 bar; - regulators for which a specific document exists (e.g. EN 88-1 and EN 88-2, etc.); - industrial process control valves in accordance with EN 1349. The normative Annex G of this document lists some suitable materials for pressure bearing parts, inner metallic partition walls, auxiliary devices, integral process and sensing lines, connectors and fasteners. Other materials may be used when complying with the restrictions given in Table 5. Continued integrity of gas pressure regulators is ensured by suitable surveillance checks and maintenance. For periodic functional checks and maintenance it is common to refer to national regulations/standards where existing or users/manufacturers practices. This document has introduced the reaction of the pressure regulators to the specified reasonable expected failures in terms of "fail close" and "fail open" pressure regulator types, but it should be considered that there are other types of failures whose consequences can bring to the same reactions (these risks are covered via redundancy as per EN 12186) and that residual hazards will be reduced by a suitable surveillance in use / maintenance. In this document, both pressure regulators that can be classified as "safety accessories" by themselves (monitors) according to European legislation on pressure equipment as well as regulators that can be used to provide the necessary pressure protection through redundancy (e.g. pressure regulator with integrated safety shut-off device, pressure regulator + in-line monitor, pressure regulator + safety shut off device) are considered. The provisions in this document are in line with the state of art at the moment of writing.

SIST EN 334:2019+A1:2025 is classified under the following ICS (International Classification for Standards) categories: 23.060.40 - Pressure regulators. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 334:2019+A1:2025 has the following relationships with other standards: It is inter standard links to SIST EN 334:2019, SIST EN 334:2019/kFprA1:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 334:2019+A1:2025 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU; Standardization Mandates: M/601. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 334:2019+A1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2025

Nadomešča:

SIST EN 334:2019

Regulatorji tlaka plina za vstopne tlake do 10 MPa (100 bar) (vključno z dopolnilom

A1)

Gas pressure regulators for inlet pressure up to 10 MPa (100 bar)

Gas-Druckregelgeräte für Eingangsdrücke bis 10 MPa (100 bar)

Régulateurs de pression de gaz pour des pressions amont jusqu’à 10 MPa (100 bar)

Ta slovenski standard je istoveten z: EN 334:2019+A1:2024

ICS:

23.060.40 Tlačni regulatorji Pressure regulators

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 334:2019+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

September 2024

EUROPÄISCHE NORM

ICS 23.060.40 Supersedes EN 334:2019

English Version

Gas pressure regulators for inlet pressure up to 10 MPa

(100 bar)

Régulateurs de pression de gaz pour des pressions Gas-Druckregelgeräte für Eingangsdrücke bis 10 MPa

amont jusqu'à 10 MPa (100 bar) (100 bar)

This European Standard was approved by CEN on 23 April 2019 and includes Amendment 1 approved by CEN on 21 July 2024.

This European Standard was corrected and reissued by the CEN-CENELEC Management Centre on 20 November 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATIO N

EUROPÄISCHES KOMITEE FÜR NORMUN G

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 334:2019+A1:2024 E

worldwide for CEN national Members.

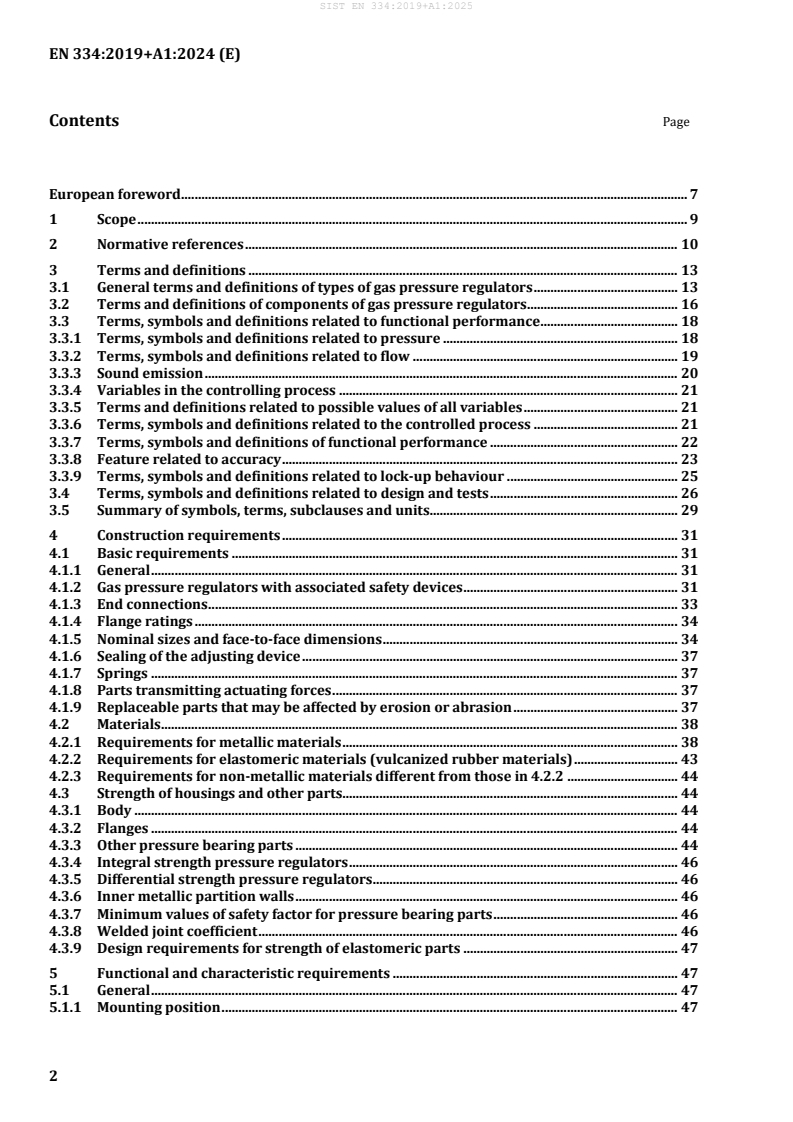

Contents Page

European foreword . 7

1 Scope . 9

2 Normative references . 10

3 Terms and definitions . 13

3.1 General terms and definitions of types of gas pressure regulators . 13

3.2 Terms and definitions of components of gas pressure regulators. 16

3.3 Terms, symbols and definitions related to functional performance . 18

3.3.1 Terms, symbols and definitions related to pressure . 18

3.3.2 Terms, symbols and definitions related to flow . 19

3.3.3 Sound emission . 20

3.3.4 Variables in the controlling process . 21

3.3.5 Terms and definitions related to possible values of all variables . 21

3.3.6 Terms, symbols and definitions related to the controlled process . 21

3.3.7 Terms, symbols and definitions of functional performance . 22

3.3.8 Feature related to accuracy . 23

3.3.9 Terms, symbols and definitions related to lock-up behaviour . 25

3.4 Terms, symbols and definitions related to design and tests . 26

3.5 Summary of symbols, terms, subclauses and units. 29

4 Construction requirements . 31

4.1 Basic requirements . 31

4.1.1 General . 31

4.1.2 Gas pressure regulators with associated safety devices . 31

4.1.3 End connections . 33

4.1.4 Flange ratings . 34

4.1.5 Nominal sizes and face-to-face dimensions . 34

4.1.6 Sealing of the adjusting device . 37

4.1.7 Springs . 37

4.1.8 Parts transmitting actuating forces . 37

4.1.9 Replaceable parts that may be affected by erosion or abrasion . 37

4.2 Materials . 38

4.2.1 Requirements for metallic materials . 38

4.2.2 Requirements for elastomeric materials (vulcanized rubber materials) . 43

4.2.3 Requirements for non-metallic materials different from those in 4.2.2 . 44

4.3 Strength of housings and other parts. 44

4.3.1 Body . 44

4.3.2 Flanges . 44

4.3.3 Other pressure bearing parts . 44

4.3.4 Integral strength pressure regulators . 46

4.3.5 Differential strength pressure regulators . 46

4.3.6 Inner metallic partition walls . 46

4.3.7 Minimum values of safety factor for pressure bearing parts . 46

4.3.8 Welded joint coefficient . 46

4.3.9 Design requirements for strength of elastomeric parts . 47

5 Functional and characteristic requirements . 47

5.1 General . 47

5.1.1 Mounting position . 47

5.2 Shell strength, external tightness and internal sealing . 47

5.2.1 Shell strength . 47

5.2.2 External tightness . 48

5.2.3 Internal sealing . 48

5.3 Control classifications . 48

5.3.1 Accuracy under stable conditions . 48

5.3.2 Lock-up behaviour . 48

5.3.3 Stable conditions. 49

5.4 Final visual inspection . 49

5.4.1 Requirements for final visual inspection after type tests . 49

5.4.2 Requirements for final visual inspection after routine tests and production

surveillance . 49

5.5 Fail close conditions . 50

5.6 Fail open conditions . 50

5.7 Closing force for monitor at full open position . 50

5.8 Antistatic characteristics . 51

6 Gas pressure regulator sizing . 51

6.1 Flow behaviour . 51

6.2 Sizing equations for the calculation of volumetric flow rates of a gas pressure

regulator with its control member in its mechanically fully open position . 52

6.2.1 Normal calculations . 52

6.2.2 Practical calculations . 52

6.2.3 Simplified calculations . 52

6.3 Calculation of the maximum accuracy flow rate . 53

6.4 Inherent flow characteristics . 53

6.5 Calculation of volumetric flow rates for partially open gas pressure regulators . 53

6.6 Flow coefficient . 53

7 Testing . 54

7.1 General . 54

7.2 Tests . 54

7.3 Type test . 55

7.4 Selection of test samples . 55

7.5 Routine tests . 56

7.6 Production surveillance . 56

7.7 Test and verification methods . 56

7.7.1 Dimensional check and visual inspection . 56

7.7.2 Materials check . 56

7.7.3 Verification of the strength of pressure bearing parts, inner metallic partition walls

and other parts . 56

7.7.4 Shell and inner metallic partition walls strength test . 58

7.7.5 Alternative shell and inner metallic partition walls strength test . 59

7.7.6 Verification of closing force for monitor in fully open position under normal

operating conditions . 59

7.7.7 External tightness test . 59

7.7.8 Test method and acceptance criteria to verify the antistatic characteristics . 61

7.7.9 Functional tests . 61

7.7.10 Final visual inspections . 74

8 Field surveillance . 74

9 Documentation . 74

9.1 Documentation related to type test . 74

9.1.1 Documentation required prior to type test. 74

9.1.2 Test report . 75

9.2 Documentation related to the routine tests . 75

9.3 Documentation related to production surveillance in accordance with 7.6 . 75

9.3.1 Documentation for production surveillance . 75

9.3.2 Production surveillance report . 75

9.4 Operating instructions . 75

10 Marking . 76

10.1 General requirements . 76

10.2 Basic requirements . 76

10.3 Other additional requirements . 77

10.4 Marking of integrated safety devices . 77

10.5 Markings for the various connections . 77

11 Packaging of finished product . 78

Annex A (informative) Alternative methods for the determination of the accuracy class, the

lock-up pressure class, the maximum accuracy flow rate, the flow coefficients and

the verification of the hysteresis band . 79

A.1 General . 79

A.2 Test methods . 79

A.2.1 Direct acting gas pressure regulator . 79

A.2.2 Pilot controlled gas pressure regulators . 80

A.3 Determination of flow coefficients for larger capacity regulators . 81

Annex B (informative) Inspection certificate . 87

Annex C (informative) Acceptance test . 89

)

Annex D (informative) Compliance evaluation . 90

D.1 General . 90

D.2 Introduction . 90

D.3 Procedure. 90

D.4 Manufacturer’s compliance evaluation . 90

D.5 Issue of the certificate of compliance . 91

Annex E (normative) Creep (venting) relief device . 92

E.1 General . 92

E.2 Terms and definitions . 92

E.3 Requirements . 92

E.3.1 Construction . 92

E.3.2 Functional requirements. 92

E.4 Testing . 92

E.5 Type test . 93

E.6 Routine tests . 93

E.7 Documentation . 93

E.8 Marking . 93

Annex F (informative) Order specification . 94

F.1 General . 94

F.2 Minimum specifications . 94

F.2.1 Details of construction . 94

F.2.2 Dimensions . 94

F.2.3 Performance . 94

F.3 Optional specifications . 95

Annex G (informative) Materials . 97

G.1 Steel materials for pressure bearing parts and inner metallic partition walls . 97

G.2 Metallic materials different from steel materials for pressure bearing parts and

inner metallic partition walls. 114

G.3 Materials for auxiliary devices, integral process and sensing lines, threaded sealing

plug, connectors and fasteners . 119

G.4 Update to year 2017 on Metallic Material Standards used in the previous editions of

this standard . 124

Annex H (informative) Dynamic force calculation method . 126

H.1 General . 126

H.2 Test method for the determination of the dynamic factor Cr . 126

H.2.1 General . 126

H.2.2 Test method for the determination of the dynamic factor Cr for a series of monitor . 127

Annex I (normative) Vent limiter . 129

I.1 General . 129

I.2 Scope . 129

I.3 Terms, symbols and definitions . 129

I.4 Requirements . 130

I.4.1 General requirements . 130

I.4.2 Materials . 130

I.4.3 Strength . 130

I.4.4 Functional requirements . 130

I.5 Testing and acceptance criteria . 131

I.5.1 General . 131

I.5.2 Type test method . 131

I.6 Documentation . 132

I.7 Specific marking on vent limiter . 132

Annex J (normative) Elastomeric material . 133

Annex K (informative) Sound emission . 135

K.1 Sound emission requirements . 135

K.2 Methods for measuring the sound pressure level . 136

Annex L (informative) Environmental Provisions . 137

Annex M (informative) Glossary . 141

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2014/68/EU aimed to be covered . 145

Bibliography . 147

European foreword

This document (EN 334:2019+A1:2024) has been prepared by Technical Committee CEN/TC 235 “Gas

pressure regulators and associated safety devices for use in gas transmission and distribution”, the

secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by March 2025, and conflicting national standards shall

be withdrawn at the latest by March 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 21 July 2024.

This document supersedes !EN 334:2019".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

!Deleted paragraph"

This document can be used as a guideline for gas pressure regulators outside the ranges specified in this

standard. This edition has introduced the application of statistical strength testing for series produced

pressure and safety accessories on the basis of EU Directive 2014/68/EU, Annex I, Article 3.2.2 and

Guideline H-14. Gas pressure regulators dealt with in this document are considered as standard

pressure equipment in accordance with Clause 2 a) of Art. 1 of Pressure Equipment Directive

2014/68/EU (PED).

Gas pressure regulators according to this European Standard do not have their own source of ignition.

However, the manufacturer is responsible to identify any potential ignition sources of his product

1)

which could be effective during the intended use .

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

1) Therefore gas pressure regulators are usually not within the scope of ATEX European legislation on equipment

and protective systems intended for use in potentially explosive atmospheres. Any additional component (e.g.

proximity switch, travel transducer etc.) should be independently considered in the framework of assemblies as

per ATEX 2014/34/EU Guidelines – 2nd Edition - December2017 clauses § 44 “Combined equipment

(assemblies)”, § 46 “Components” and § 94 “Written attestation of conformity for components”.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document specifies constructional, functional, testing, marking, sizing and documentation

requirements of gas pressure regulators:

— for inlet pressures up to 100 bar and nominal diameters up to DN 400;

— for an operating temperature range from – 20 °C to +60 °C,

which operate with fuel gases of the 1st and 2nd family as defined in EN 437:2018 [1], used in the

pressure control stations in accordance with EN 12186 or EN 12279, in transmission and distribution

networks and also in commercial and industrial installations.

“Gas pressure regulators” hereafter will be called “regulators” except in the titles.

For standard regulators when used in pressure control stations complying with EN 12186 or EN 12279,

the Annex ZA lists all applicable essential safety requirements of the European legislation on pressure

equipment except external and internal corrosion resistance for applications in corrosive environment.

This document considers the following temperature classes/types of regulators:

— temperature class 1: operating temperature range from −10 °C to 60 °C;

— temperature class 2: operating temperature range from −20 °C to 60 °C;

— type IS: (integral strength type);

— type DS: (differential strength type).

This document applies to regulators which use the pipeline gas as a source of control energy unassisted

by any external power source.

The regulator may incorporate a second regulator, used as monitor, complying with the requirements

in this document.

The regulator may incorporate a safety shut off device (SSD) complying with the requirements of

EN 14382.

The regulator may incorporate a creep (venting) relief device, complying with the requirements in

Annex E and/or a vent limiter, complying with the requirements in Annex I.

This document does not apply to:

— regulators upstream from/on/in domestic gas-consuming appliances which are installed

downstream of domestic gas meters;

2)

— regulators designed to be incorporated into pressure control systems used in service lines with

volumetric flow rate ≤ 200 m /h at normal conditions and inlet pressure ≤ 5 bar;

— regulators for which a specific document exists (e.g. EN 88-1 and EN 88-2, etc.);

— industrial process control valves in accordance with EN 1349.

2) The services lines are those defined in EN 12279.

The informative Annex G of this document lists some suitable materials for pressure bearing parts,

inner metallic partition walls, auxiliary devices, integral process and sensing lines, connectors and

fasteners. Other materials may be used when complying with the restrictions given in Table 5.

Continued integrity of gas pressure regulators is ensured by suitable surveillance checks and

maintenance. For periodic functional checks and maintenance it is common to refer to national

regulations/standards where existing or users/manufacturers practices.

This document has introduced the reaction of the pressure regulators to the specified reasonable

expected failures in terms of “fail close” and “fail open” pressure regulator types, but it should be

considered that there are other types of failures whose consequences can bring to the same reactions

(these risks are covered via redundancy as per EN 12186) and that residual hazards will be reduced by

a suitable surveillance in use / maintenance.

In this document, both pressure regulators that can be classified as “safety accessories” by themselves

(monitors) according to European legislation on pressure equipment as well as regulators that can be

used to provide the necessary pressure protection through redundancy (e.g. pressure regulator with

integrated safety shut-off device, pressure regulator + in-line monitor, pressure regulator + safety shut

off device) are considered.

The provisions in this document are in line with the state of art at the moment of writing.

This document does not intend to limit the improvement of actual provisions (materials, requirements,

test methods, acceptance criteria, etc.) or the developing of new provisions for gas pressure regulators

where they are suitable to ensure an equivalent level of reliability.

Some clauses of this standard should be re-considered at the time when characteristics for non-

conventional gases will be available.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 549:1994, Rubber materials for seals and diaphragms for gas appliances and gas equipment

EN 1092-1:2018, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 1: Steel flanges

EN 1092-2:1997, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 2: Cast iron flanges

EN 1092-3:2003, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 3: Copper alloy flanges

EN 1092-4:2002, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 4: Aluminium alloy flanges

EN 1349:2009, Industrial process control valves

EN 1759-1:2004, Flanges and their joint - Circular flanges for pipes, valves, fittings and accessories, Class

designated - Part 1: Steel flanges, NPS 1/2 to 24

EN 1759-3:2003, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, Class

designated - Part 3: Copper alloy flanges

EN 1759-4:2003, Flanges and their joint - Circular flanges for pipes, valves, fittings and accessories, class

designated - Part 4: Aluminium alloy flanges

EN 10204:2004, Metallic products - Types of inspection documents

EN 10226-1:2004, Pipe threads where pressure tight joints are made on the threads - Part 1: Taper

external threads and parallel internal threads - Dimensions, tolerances and designation

EN 10226-2:2005, Pipe threads where pressure tight joints are made on the threads - Part 2: Taper

external threads and taper internal threads - Dimensions, tolerances and designation

EN 12186:2014, Gas infrastructure - Gas pressure regulating stations for transmission and distribution -

Functional requirements

EN 12279:2000/A1:2005, Gas supply systems - Gas pressure regulating installations on service lines -

Functional requirements

EN 12516-1:2014+A1:2018, Industrial valves - Shell design strength - Part 1: Tabulation method for steel

valve shells

EN 12516-2:2014, Industrial valves - Shell design strength - Part 2: Calculation method for steel valve

shells

EN 12516-4:2014+A1:2018, Industrial valves - Shell design strength - Part 4: Calculation method for valve

shells manufactured in metallic materials other than steel

!EN 13445-4:2021+A1:2023, Unfired pressure vessels - Part 4: Fabrication"

EN 13906-1:2013, Cylindrical helical springs made from round wire and bar - Calculation and design -

Part 1 : Compression springs

EN 13906-2:2013, Cylindrical helical springs made from round wire and bar - Calculation and design -

Part 2: Extension springs

EN 13906-3:2014, Cylindrical helical springs made from round wire and bar - Calculation and design -

Part 3: Torsion springs

EN 14382:2019, Safety devices for gas pressure regulating stations and installations – Gas safety shut-off

devices for inlet pressures up to 10 MPa (100 bar)

EN 60534-2-1:2011, Industrial-process control valves - Part 2-1: Flow capacity - Sizing equations for fluid

flow under installed conditions

EN 60534-2-3:2016, Industrial-process control valves - Part 2-3: Flow capacity - Test procedures

(IEC 60534-2-3:2016)

EN 60534-3-1:2000, Industrial-process control valves - Part 3-1: Dimensions - Face-to-face dimensions for

flanged, two-way, globe-type, straight pattern and centre-to-face dimensions for flanged, two-way, globe-

type, angle pattern control valves

EN ISO 148-1:2016, Metallic materials - Charpy pendulum impact test - Part 1: Test method (ISO 148-

1:2016)

EN ISO 175:2010, Plastics - Methods of test for the determination of the effects of immersion in liquid

chemicals (ISO 175:2010)

EN ISO 9606-1:2017, Qualification testing of welders - Fusion welding - Part 1: Steels (ISO 9606-1:2012

including Cor 1:2012 and Cor 2:2013)

EN ISO 9606-2:2004, Qualification test of welders - Fusion welding - Part 2: Aluminium and aluminium

alloys (ISO 9606-2:2004)

EN ISO 9606-3:1999, Approval testing of welders - Fusion welding - Part 3: Copper and copper alloys (ISO

9606-3:1999)

EN ISO 9606-4:1999, Approval testing of welders - Fusion welding - Part 4: Nickel and nickel alloys (ISO

9606-4:1999)

!EN ISO 9712:2022, Non-destructive testing - Qualification and certification of NDT personnel (ISO

9712:2012)"

EN ISO 12156-1:2018, Diesel fuel - Assessment of lubricity using the high-frequency reciprocating rig

(HFRR) - Part 1: Test method (ISO 12156-1:2018)

EN ISO 14732:2013, Welding personnel - Qualification testing of welding operators and weld setters for

mechanized and automatic welding of metallic materials (ISO 14732:2013)

!EN ISO 15607:2019, Specification and qualification of welding procedures for metallic materials -

General rules (ISO 15607:2019)

EN ISO 15609-1:2019, Specification and qualification of welding procedures for metallic materials -

Welding procedure specification - Part 1: Arc welding (ISO 15609-1:2019)"

EN ISO 15610:2003, Specification and qualification of welding procedures for metallic materials -

Qualification based on tested welding consumables (ISO 15610:2003)

EN ISO 15611:2003, Specification and qualification of welding procedures for metallic materials -

Qualification based on previous welding experience (ISO 15611:2003)

EN ISO 15612:2018, Specification and qualification of welding procedures for metallic materials -

Qualification by adoption of a standard welding procedure (ISO 15612:2018)

EN ISO 15613:2004, Specification and qualification of welding procedures for metallic materials -

Qualification based on pre-production welding test (ISO 15613:2004)

EN ISO 15614-1:2017, Specification and qualification of welding procedures for metallic materials -

Welding procedure test - Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys

(ISO 15614-1:2017, Corrected version 2017-10-01)

EN ISO 15614-2:2005/AC:2009, Specification and qualification of welding procedures for metallic

materials - Welding procedure test - Part 2: Arc welding of aluminium and its alloys (ISO 15614-

2:2005/Cor 2:2009)

EN ISO 17637:201

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...