SIST EN 50290-4-2:2015

(Main)Communication cables - Part 4-2: General considerations for the use of cables - Guide to use

Communication cables - Part 4-2: General considerations for the use of cables - Guide to use

The scope of this European Standard is to help installers and cabling designers to understand the range of communication metallic cables available. To help this choice the fundamental and practical rules on how to use these cables are established.

The related cables are specified in the documents issued by CLC/TC 46X and its sub-committees.

These cables are:

- telecom cables used in access network,

- data communication twisted pairs cables,

- coaxial cables used in CATV.

Kommunikationskabel - Teil 4-2: Allgemeine Betrachtungen für die Anwendung der Kabel - Leitfaden für die Verwendung

Câbles de communication - Partie 4-2: Considérations générales pour l'utilisation des câbles - Guide d'utilisation

Komunikacijski kabli - 4-2. del: Splošno o uporabi kablov - Vodilo za uporabo

General Information

- Status

- Published

- Publication Date

- 19-May-2015

- Technical Committee

- MOC - Mobile Communications

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 11-Feb-2015

- Due Date

- 18-Apr-2015

- Completion Date

- 20-May-2015

Relations

- Effective Date

- 07-Jun-2022

- Effective Date

- 09-Aug-2013

Overview

EN 50290-4-2:2014 - issued by CLC/CENELEC - is a practical guide for the selection and use of metallic communication cables. Its scope helps installers and cabling designers understand the range of communication cables available (telecom access cables, data communication twisted‑pair cables, and coaxial cables used in CATV) and sets out fundamental and practical rules for correct use. EN 50290-4-2:2014 supersedes the 2008 edition and should be read alongside other parts of the EN 50290 series.

Key topics

- Communication cable basics - balanced (twisted pair/twinax) vs unbalanced (coaxial) media and their roles in voice, data and CATV systems.

- Types of cables - pair constructions (pairs, quads, starquads), pair counts and identification, coaxial and variations (triax, twinax), and when each medium is preferred.

- Flexible vs rigid cables - design considerations (stranded vs solid conductors), bending radius and mechanical cycling for cord and dynamic applications.

- Regulatory and safety requirements - relationship with European directives (LVD, Construction Product Regulation), CE marking under EN 50575 and the role of Euroclasses for fire reaction.

- Electromagnetic behaviour (EMC) - considerations for screening, grounding and interference mitigation.

- Criteria for cable choice - construction, cabling topology, and transmission performance requirements.

- Installation practices - delivery, storage, pre‑installation checks, cable pulling, mechanical limits and best practices to preserve transmission characteristics.

- Installation environments - guidance for outside plant vs intrabuilding installations and selection by location.

Practical applications & who uses it

- Cabling designers and system architects - to specify appropriate metallic cables for access networks, LANs, and CATV.

- Installers and contractors - as a practical checklist for selection, handling, pulling, and storage to avoid performance degradation.

- Specifiers and procurement teams - to ensure compliance with fire performance (Euroclasses), EMC and LVD requirements.

- Manufacturers and test labs - to align product descriptions and test regimes with normative references in the standard.

- Safety and facilities engineers - when choosing cables to meet building fire regulations and CE marking obligations.

Related standards

EN 50290-4-2 is part of a wider suite and references key documents such as:

- EN 50290 (other parts), EN 50290-4-1 (environment & fire relationships)

- EN 50288 series, EN 50117 (coaxial cables), EN 50173 / EN 50174 (generic cabling & installation)

- EN 50575 (reaction to fire / Construction Product Regulation), EN 50083 (cable networks)

Use EN 50290-4-2:2014 as the practical, application‑focused complement to product and test specifications when selecting, installing and maintaining communication cables.

Frequently Asked Questions

SIST EN 50290-4-2:2015 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Communication cables - Part 4-2: General considerations for the use of cables - Guide to use". This standard covers: The scope of this European Standard is to help installers and cabling designers to understand the range of communication metallic cables available. To help this choice the fundamental and practical rules on how to use these cables are established. The related cables are specified in the documents issued by CLC/TC 46X and its sub-committees. These cables are: - telecom cables used in access network, - data communication twisted pairs cables, - coaxial cables used in CATV.

The scope of this European Standard is to help installers and cabling designers to understand the range of communication metallic cables available. To help this choice the fundamental and practical rules on how to use these cables are established. The related cables are specified in the documents issued by CLC/TC 46X and its sub-committees. These cables are: - telecom cables used in access network, - data communication twisted pairs cables, - coaxial cables used in CATV.

SIST EN 50290-4-2:2015 is classified under the following ICS (International Classification for Standards) categories: 33.120.10 - Coaxial cables. Waveguides. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 50290-4-2:2015 has the following relationships with other standards: It is inter standard links to SIST EN 50290-4-2:2008, SIST EN 50290-4-2:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 50290-4-2:2015 is associated with the following European legislation: EU Directives/Regulations: 2006/95/EC, 2014/35/EU; Standardization Mandates: M/117, M/212, M/443. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 50290-4-2:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Komunikacijski kabli - 4-2. del: Splošno o uporabi kablov - Vodilo za uporaboKommunikationskabel - Teil 4-2: Allgemeine Betrachtungen für die Anwendung der Kabel - Leitfaden für die VerwendungCâbles de communication - Partie 4-2: Considérations générales pour l'utilisation des câbles - Guide d'utilisationCommunication cables - Part 4-2: General considerations for the use of cables - Guide to use33.120.10Koaksialni kabli. ValovodiCoaxial cables. WaveguidesICS:Ta slovenski standard je istoveten z:EN 50290-4-2:2014SIST EN 50290-4-2:2015en01-julij-2015SIST EN 50290-4-2:2015SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 50290-4-2

December 2014 ICS 33.120.10

Supersedes

EN 50290-4-2:2008

English Version

Communication cables - Part 4-2: General considerations for the use of cables - Guide to use

Kommunikationskabel - Teil 4-2: Allgemeine Betrachtungen für die Anwendung der Kabel - Leitfaden für die Verwendung This European Standard was approved by CENELEC on 2013-09-16. CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions. CENELEC members are the national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, the Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, the Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. European Committee for Electrotechnical Standardization

Comité Européen de Normalisation Electrotechnique Europäisches Komitee für Elektrotechnische Normung CEN-CENELEC Management Centre: Avenue Marnix 17,

B-1000 Brussels © 2014 CENELEC All rights of exploitation in any form and by any means reserved worldwide for CENELEC Members.

Ref. No. EN 50290-4-2:2014 E SIST EN 50290-4-2:2015

- 3 - EN 50290-4-2:2014

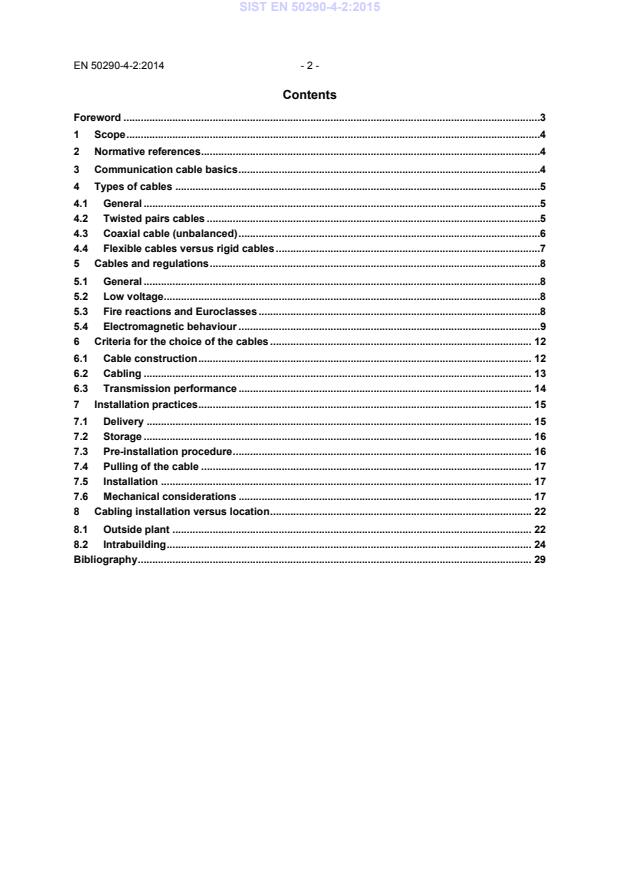

Foreword This document (EN 50290-4-2:2014) has been prepared by CLC/TC 46X "Communication cables".

The following dates are fixed: • latest date by which this document has to be implemented at national level by publication of an identical national standard or by endorsement (dop) 2015-06-05 • latest date by which the national standards conflicting with this document have to be withdrawn (dow) 2016-09-16 This document supersedes EN 50290-4-2:2008. EN 50290-4-2:2014 includes the following significant technical change with respect to

EN 50290-4-2:2008: − Subclause 5.3 was revised. This standard should be read in conjunction with EN 50290-1-1 and is completed by generic, sectional, family and detail specifications, as appropriate, to describe in a detailed manner each type of cable with its specific characteristics. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CENELEC [and/or CEN] shall not be held responsible for identifying any or all such patent rights. This document has been prepared under a mandate given to CENELEC by the European Commission and the European Free Trade Association. This standard covers the Principle Elements of the Safety Objectives for Electrical Equipment Designed for Use within Certain Voltage Limits (LVD - 2006/95/EC). EN 50290-4, Communication cables — General considerations for the use of cables, is divided into the following sub-parts: − Part 4-1: Environmental conditions and safety aspects; − Part 4-2: Guide to use [the present document]. __________

- 5 - EN 50290-4-2:2014

characteristics that will make it the ideal medium to use based on a particular set of circumstances. It is important to recognize the advantages of each and develop a system accordingly. Factors to consider when choosing communication cable include: − efficiency of transmission, − cost, − ease of installation and maintenance, − availability. 4 Types of cables 4.1 General When working with communication cables, an installer will deal with two basic types: − balanced, − unbalanced. Balanced cabling involve twisted-pair and/or twinaxial twisted cables that are composed of one or more pairs of copper wires (see Figure 1). Unbalanced cabling involves coaxial cable, that has only one centre conductor of either solid or stranded inner conductor and an outer concentric conductor. Most data and voice networks use twisted-pair cabling. Coaxial cable is now used primarily for CATV, satellite and video connections (see Figure 2).

Figure 1 Balanced cabling

Figure 2 Unbalanced cabling

4.2 Twisted pairs cables 4.2.1 Pair construction There are two different pairing constructions: − a pair made of two insulated wires twisted together (wire A and B in Figure 4); − a quad made of four insulated wires twisted together, providing two pairs from a star formation (first pair wire A and B and second pair wire D and C in Figure 3); − a pair made of two insulated wires twisted together; − a quad made of four insulated wires twisted together, providing two pairs. SIST EN 50290-4-2:2015

Figure 5 Example of pair arrangement in a telecommunication cable 4.3 Coaxial cable (unbalanced) Coaxial cable is called ‘coaxial’ because it includes one conductor surrounded by a layer of insulation, itself surrounded by a concentric conductor (a metallic foil or braid or a combination of both) and an outer sheath (see Figure 6). Coaxial cable is the primary type of communication cable used by cable TV companies for signal distribution between the community antenna (CATV, normally 75 Ω) and user’s homes and businesses. The WWW is now accessible through such communication mediums making possible all types of connections. It was once the primary medium for Ethernet and other types of local area networks because of its ability to transmit high frequencies. With the development of standards for Ethernet over twisted-pair, new installations of coaxial cable for this purpose have all but disappeared. SIST EN 50290-4-2:2015

- 7 - EN 50290-4-2:2014

Coaxial cable is still used for connecting CCTV cameras to monitors, antenna’s and video switches. Cables for radio communication (mobile telephone) antenna’s are also coaxial, these are feeder cables and are normally 50 Ω.

Figure 6 Coaxial cable illustration There are several variations. Triaxial (Triax) is a form of cable that uses a single centre conductor with two shields (one could be tape and one braid). This is important when considering EMC (electromagnetic compatibility). This composition affords a greater transmission distance with less loss due to interference from outside electrical signals. Twinaxial (Twinax) is two coaxial systems packaged within a single concentric outer conductor and jacket to form the cable. 4.4 Flexible cables versus rigid cables Communication infrastructure includes different sections. Some sections are installed, indoor or outdoor, permanently (i.e. fixed) so the cables are static (once installed, do not move) for their lifetime. Some other sections are subjected to continuous movement and different mechanical behaviour is required for the cable (see 7.6). Copper is inherently rigid and leads to build cables with a certain degree of stiffness suitable for permanent installations. However, copper is one of the most malleable of the rigid metals and so cannot be unsupported. Nonetheless, cable construction includes design to allow appropriate bending radius to be performed without degradation of mechanical and transmission properties. For some applications there is a need for smaller bending radius, multiple bending, or less stiffness while keeping requested transmission properties (i.e. work area cables or cables used in lift machinery). Specific designs to achieve this target use stranded conductors instead of one-solid-conductor; also with insulation material having specific mechanical properties are used. These cables, named “flexible cables”, are often used in cord assemblies and are specified for a given number of mechanical cycles.

In order to provide more flexibility to cables used in cords, stranded conductors are used instead of solid conductors. Not only does this improve flexibility but also allows the cable to be repeatedly flexed many times; this can be useful in robotic systems. The relevant cable standards identifies whether the cable is either flexible or rigid, depending on how the cable will be used in its life cycle i.e. look for properties such as simulated installation, torsion and twisting or flexing performance tests. These basic principles, along with avoiding already known stresses and misuses of installations, will ensure the cable does not irreversibly degrade below the performance criteria. There are many situations already known that will change the performance criteria below that of the specified limits. Inner conductor SIST EN 50290-4-2:2015

When constructed in accordance with EN 50290-2-1 and submitted to spark testing, communication cables may be installed together with Low Voltage cable. Moreover the tests are performed after environmental and ageing tests. In addition the raw materials of these cables are defined in the EN 50290 series. This ensures sufficient stability of the cable related to this characteristic for its life cycle. Thus these cables are considered safe when: − they are used for their intended purpose and applications; − they are used under voltages and currents that do not exceed the limits given in the relevant specification.

Figure 7 5.3 Fire reactions and Euroclasses Cables that are installed in construction works are governed by the “Construction Product Regulation”; thus they shall be “CE” marked according to EN 50575.

- 9 - EN 50290-4-2:2014

Moreover, in each country, regulations may exist that explain the use of cables according to a given Euroclass versus the type of building that is considered. Regulations as well as standards give only the minimum requirement and it is therefore always recommended to choose cable that fulfill or better exceed these requirements. This is particularly true when the requirement is safety related. The designer/installer is invited to consider the relevant regulation related to safety in case of fire. A choice of cables that strictly comply to the requirements will give greater safety margin (especially in the case where the public or individuals are involved). The EN 50288, EN 50441 and EN 50117 product standards series refer to the EN 50290 series to describe how a cable behaves in fire. This is achieved through EN 50290-4-1 that gives the relationship between the Euroclasses and the related test methods and limits. Some local regulations/customer-requirements are stricter than the Euroclassification tables and therefore can and should be designed by discussions between the producer and customer. During a building fire, a cable that runs in a wall, up an elevator shaft, or through an air-handling plenum could become a wick that carries the flame from one floor, or one part of the building, to the next. The standards, among other things, enable engineers to calculate the time that it will take for a cable to become a hazard once it is exposed. Evacuation times and building safety management can now be engineered to ensure complete safety for the occupants. Additionally, because the outer coverings of cables and wires are typically plastic, they can create smoke when they burn. They also describe the amount of smoke and the type of gasses a burning cable can generate. This is important because cables often run in ventilation system return spaces above ceilings or below floors.

5.4 Electromagnetic behaviour 5.4.1 General A cable's path may pass through many stray electric fields. Some of these may come from motors used in heating, ventilation, and air conditioning (HVAC). Florescent lights, radio transmitters, and power transformers may generate others. These stray fields are called ‘electromagnetic interference’ (EMI) if they originate from electrical sources and ‘radio frequency interference’ (RFI) if they come from radios, mobile phones, radars, or microwave ovens. There are electrical environments in which EMI and RFI are so strong that induced voltage in the cable affects the integrity of the transmitted signals thus additional shielding is a requirement to make communication possible. An expensive way to supply this shielding might be to route the cabling through small pipes, called conduit, and then to make sure that the conduits are grounded (to make sure that any stray fields picked up by the conduits are passed to ground and do not induce interference into the data cables). However, conduit is expensive and difficult to work with. 5.4.2 Coaxial cables The EN 50117 series that describes coaxial cables defines two classes of shielding effectiveness. The EN 50117 series that describes coaxial cables defines multiple classes of shielding effectiveness. The most commonly used, Class A, implies the use of a “foil+braid” outer conductor that would provide a sufficient immunity to the cable. The use of Class A cables gives assurance that the cabling system will work satisfactorily under normal conditions. Other shielding methods such as foil-braid-foil or foil-braid-foil-braid may also be used and higher shielding classifications may also be considered. 5.4.3 Twisted pairs cables The coupling attenuation and/or the transfer impedance that is given in the relevant cable specification describe electromagnetic behaviour of twisted pairs cables. The coupling attenuation is the resultant of twist effect and screening effect. The actual signal on the twisted pair version is applied to both the ‘a’ leg and ‘b’ leg simultaneously. However, the actual signal voltage level in each leg is opposite, 180’ out of phase, and therefore any SIST EN 50290-4-2:2015

- 11 - EN 50290-4-2:2014

Figure 8 Twisted pairs cables Screen description SIST EN 50290-4-2:2015

6 Criteria for the choice of the cables 6.1 Cable construction 6.1.1 General Regardless of the construction, all cables contain certain common elements that are detailed in EN 50290-2-1: - insulation to prevent short circuits between the individual conductors; - spacers (dielectric) to preserve the electrical properties of the cable; - a sheath for protection. A copper conductor in a cable can be composed of a single solid copper core or a bundle of thin strands. The advantages and disadvantages of each been discussed next. Some parts of the EN 50288 and EN 50117 series describe flexible cables manufactured with “stranded conductors”.

EN 50290-2-1 gives tools to get the cable attenuation depending upon the size of conductors and their nature (stranded or not). 6.1.2 Cable insulation/spacers Insulation is used as a high resistance material that is extruded onto the conductor to resist the flow of current between conductors. This is sometimes referred to as the dielectric/insulation. This material also impinges on the transmission properties of the cable (especially in high frequencies as detailed in EN 50290-2-1). There are several types of materials used for insulation, each having its advantages and disadvantages. Insulation materials are characterized using their loss angle (High Frequency) and their relative permitivity. For a suitable cable behaviour both of them should be low and stable. There are several primary categories of insulators: Table 1 Polyvinylchloride (PVC) PVC easy to strip Flame retardant Low frequency High loss angle and high permitivity Polyethylene Flammable Halogen free High frequency Good loss angle and low permitivity Fluoropolymers High temperature applications, Flame retardant High frequency Low loss angle and low permitivity The type of insulation used depends on the intended application of the cable: - EN 50290-2-23 describes suitable polyethylene; - EN 50290-2-30 describes suitable fluoropolymers; - for low frequency cables, PVC according to EN 50290-2-21 may be used. 6.1.3 Cable sheath There are several types of materials used for sheathing, each having its advantages and disadvantages: SIST EN 50290-4-2:2015

- 13 - EN 50290-4-2:2014

Table 2 Polyvinylchloride (PVC) PVC easy to strip Flame retardant PVC allows for bright colors. Can be made flexible Depending upon the detail specification resists to UV, ozone, oil and solvents Polyethylene Flammable (Outdoor applications) Water proofed Depending upon the detail specification resists to UV, ozone, oil and solvents Halogen free sheathing compound Flame retardant Low smoke emission Halogen free

Depending upon the detail specification resists to UV, ozone, oil and solvents Fluoropolymers High temperature applications Flame retardant Water proofed Resists to UV, ozone, oil and solvents, acid, contaminating fluids The type of sheathing used depends on the intended application of the cable: - EN 50290-2-22 describes suitable polyvinylchloride; - EN 50290-2-24 describes suitable polyethylene; - EN 50290-2-27 describes suitable halogen free sheathing compound; - EN 50290-2-30 describes suitable fluoropolymers. 6.1.4 Armouring/additional protections Some cables are manufactured with a metallic (or non-metallic) armour to provide added strength and protection against rodents and mechanical damage, usually required when burying direct. Cable that is used in outside plant or undergrou

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...