SIST EN 1009-5:2020

(Main)Machines for mechanical processing of minerals and similar solid materials - Safety - Part 5: Specific requirements for cleaning, recycling, sorting and mud treatment machinery

Machines for mechanical processing of minerals and similar solid materials - Safety - Part 5: Specific requirements for cleaning, recycling, sorting and mud treatment machinery

This document, to be used together with EN 1009-1, specifies the safety requirements and their verification for the design and construction of machinery for cleaning, water recycling, mud treatment and sorting (other than screens) for the mechanical processing in quarrying, recycling and processing mineral and by-products. In addition, it specifies the type of information on safe working practices (including residual risks) to be provided by the manufacturer.

When requirements of this part of EN 1009 are different from those which are stated in EN 1009-1:2020, the requirements of this part of EN 1009 take precedence over the requirements of EN 1009-1:2020 for machines that have been designed and built according to the provisions of this part of EN 1009.

This document, together with EN 1009-1:2020, deals with all the significant hazards, hazardous situations and events relevant to machinery for cleaning, recycling, mud treatment when they are used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer associated with the whole lifetime of the machine (see Annex C).

This document does not cover:

- design relating to road traffic regulations;

- hazards arising from the use of the machines in potentially explosive atmospheres as well as from processing of explosive materials and risks related to electromagnetic compatibility;

- specific hazards related to mobile machinery.

NOTE 1 EN ISO 13766-1 and EN ISO 13766-2 specify test methods and acceptance criteria for evaluating the electromagnetic compatibility of all kinds of mobile construction machinery.

NOTE 2 prEN 1009-6 "Specific requirements for mobile and semi mobile equipment" is under preparation to cover specific requirements (e.g. mobility, braking, access, frequent transportation), including exceptions and additional requirements for mobile and semi mobile equipment. This means that mobile machines are not covered as long as EN 1009-6 is not published by CEN.

This document is not applicable to machinery for cleaning, recycling, mud treatment and sorting which are manufactured before the date of publication of this document by CEN.

Maschinen für die mechanische Aufbereitung von Mineralien und ähnlichen festen Stoffen - Sicherheit - Teil 5: Spezifische Anforderungen für Reinigungs-, Recycling-, Sortier- und Schlamm-Verarbeitungsmaschinen

Dieses Dokument, das zusammen mit EN 1009 1 anzuwenden ist, legt die Sicherheitsanforderungen und ihre Überprüfung für die Konstruktion und den Bau von Maschinen zur Reinigung, Wasseraufbereitung, Schlamm-Verarbeitung und Sortierung (keine Siebe) für die mechanische Aufbereitung im Sinne von Abbau, Recycling und Aufbereitung von Mineralien und Nebenprodukten fest. Zusätzlich legt es fest, welche Informationen zu sicheren Arbeitspraktiken (einschließlich Restgefahren) vom Hersteller zur Verfügung zu stellen sind.

Wenn Anforderungen dieses Teils von EN 1009 von in EN 1009 1:2020 beschriebenen abweichen, haben die Anforderungen dieses Teils von EN 1009 für Maschinen, die nach den Anforderungen dieses Teils der EN 1009 konstruiert und gebaut wurden, Vorrang vor den Anforderungen von EN 1009 1:2020.

Dieses Dokument befasst sich zusammen mit EN 1009 1:2020 mit allen signifikanten Gefährdungen, Gefährdungssituationen und -ereignissen, die für Reinigungs-, Recycling- und Schlamm-Verarbeitungsmaschinen gelten, wenn sie bestimmungsgemäß und unter Bedingungen für eine vom Hersteller in Verbindung mit der Maschinenlebensdauer vernünftigerweise vorhersehbaren Fehlanwendung verwendet werden (siehe Anhang C).

Dieses Dokument behandelt nicht:

- Konstruktion in Verbindung mit Straßenverkehrsvorschriften;

- Gefährdungen, die durch den Gebrauch der Maschinen in explosionsgefährdeter Umgebung, die Aufbereitung explosiver Materialien und durch Risiken in Bezug auf elektromagnetische Verträglichkeit entstehen;

- spezifische Gefährdungen in Verbindung mit mobilen Maschinen.

ANMERKUNG 1 EN ISO 13766 1 und EN ISO 13766 2 legen Prüfverfahren und Abnahmekriterien zur Bewertung der elektromagnetischen Verträglichkeit für alle Arten mobiler Baumaschinen fest.

ANMERKUNG 2 prEN 1009 6 „Spezifische Anforderungen für mobile und semi-mobile Anlagen“ ist in Vorbereitung, um spezifische Anforderungen (z. B. Beweglichkeit, Bremsen, Zugang, häufiger Transport) einschließlich Ausnahmen und zusätzliche Anforderungen an mobile und semi-mobile Anlagen abzudecken. Dies bedeutet, dass mobile Maschinen nicht behandelt werden, solange EN 1009 6 nicht von CEN veröffentlicht wurde.

Dieses Dokument gilt nicht für Reinigungs-, Recycling-, Schlammverarbeitungs- und Sortiermaschinen, die vor dem Datum der Veröffentlichung dieses Dokuments durch CEN hergestellt wurden.

Machines pour le traitement mécanique des minéraux et des matériaux solides similaires - Sécurité - Partie 5 : Prescriptions spécifiques pour machines de nettoyage, de recyclage et de traitement des boues

Le présent document, à utiliser conjointement avec l'EN 1009-1, spécifie les prescriptions de sécurité et leur vérification pour la conception et la construction de machines de nettoyage, de recyclage de l'eau, de traitement des boues et de triage (autre que criblage) pour traitement mécanique pour l'extraction, le recyclage et le traitement des minéraux et sous-produits. En outre, le présent document spécifie le type d'informations que le fabricant doit fournir sur les pratiques d'utilisation sûre (incluant les risques résiduels).

Lorsque des prescriptions de la présente partie de l'EN 1009 diffèrent de celles spécifiées dans l'EN 1009-1:2020, les prescriptions de la présente partie de l'EN 1009 prévalent sur les prescriptions de l'EN 1009-1:2020 pour les machines conçues et fabriquées conformément aux dispositions de la présente partie de l'EN 1009.

Le présent document, utilisé conjointement avec l'EN 1009-1:2020, traite de tous les phénomènes dangereux et situations et événements dangereux significatifs inhérents aux machines de nettoyage, de recyclage et de traitement des boues dans le cadre d'une utilisation normale et de mauvais usage raisonnablement prévisible par le fabricant associé à l'intégralité de la durée de vie de la machine (voir l'Annexe C).

Le présent document ne couvre pas :

- la conception relative à la réglementation de la circulation routière ;

- les risques liés à l'utilisation des machines en atmosphères explosibles ainsi qu'à la transformation de matières explosives et les risques liés à la compatibilité électromagnétique ;

- les phénomènes dangereux spécifiques liés aux machines mobiles.

NOTE 1 Les EN ISO 13766-1 et EN ISO 13766-2 spécifient des méthodes d'essai et des critères d'acceptation pour l'évaluation de la compatibilité électromagnétique de tous les types de machines mobiles pour la construction.

NOTE 2 Le prEN 1009-6 "Prescriptions spécifiques pour machines mobiles" est en préparation pour couvrir les prescriptions spécifiques (par exemple, mobilité, freinage, accès, transport fréquent), y compris les exceptions et prescriptions supplémentaires pour les équipements mobiles et semi mobiles. Cela signifie que les machines mobiles ne sont pas couvertes tant que l'EN 1009-6 ne sera pas publiée par le CEN.

Le présent document ne s'applique pas aux machines de nettoyage, de recyclage et de traitement des boues et de triage qui ont été construites avant la date de publication du présent document par le CEN.

Stroji za mehansko obdelavo mineralov in podobnih trdnih snovi - Varnost - 5. del: Posebne zahteve za stroje za čiščenje, recikliranje, sortiranje in obdelavo blata

General Information

- Status

- Published

- Public Enquiry End Date

- 17-Jan-2018

- Publication Date

- 07-Jun-2020

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 04-Jun-2020

- Due Date

- 09-Aug-2020

- Completion Date

- 08-Jun-2020

Relations

- Effective Date

- 16-Jun-2021

Overview

EN 1009-5:2020 (CEN) is the European safety standard specifying specific requirements for cleaning, recycling, sorting and mud treatment machinery used in the mechanical processing of minerals and similar solid materials. Intended to be used together with EN 1009-1:2020, this part addresses design, construction, verification and information for safe use of machines such as flotation machines, hydro‑cyclones, dewatering screws, sand units, settling tanks and presses. Where EN 1009-5 differs from EN 1009-1, the requirements of EN 1009-5 take precedence for machines built to this part.

Key Topics

- Scope and applicability: Safety requirements for machinery used in quarrying, recycling and mineral processing for cleaning, water recycling, mud treatment and sorting (other than screening machinery).

- Machine types covered: Examples include flotation machines, vacuum and press filters, hydro‑cyclones, sand units, fluidised bed separators, dewatering screws, log washers, rotary scrubbers, centrifuges, tube presses, magnetic separators and dewatering screens.

- Hazard identification & risk reduction: Addresses significant hazards throughout the machine lifetime (see informative Annex C), and specifies protective measures and design provisions.

- Verification and testing: Procedures to verify safety requirements and protective measures are implemented.

- Information for use: Manufacturer obligations to supply instruction handbooks, signals, warnings and safe working practice information including residual risks.

- Exclusions: Does not cover road‑traffic related design, explosive atmospheres or electromagnetic compatibility for mobile machinery, nor specific hazards of mobile machines (prEN 1009‑6 is under preparation).

Applications

- Manufacturers of cleaning, recycling and mud‑treatment machinery use EN 1009-5:2020 to design and certify safe products for mineral processing plants.

- Plant owners and operators in quarrying, construction materials production and recycling use the standard to inform procurement, risk assessment and safe operation.

- Health & safety authorities, inspection bodies and maintenance providers reference this standard for compliance, machine assessments and service procedures.

- Practical uses include guiding safe design of water recycling systems, sizing and guarding of dewatering equipment, and defining information required for safe operation and maintenance.

Related Standards

- EN 1009-1:2020 (Common requirements) - to be used together with EN 1009-5.

- EN 1009-4:2020 (Screening machinery)

- EN ISO 12100:2010 (Risk assessment and risk reduction)

- Normative references such as EN 617 and EN ISO 13857 for bulk storage safety and safety distances.

By following EN 1009-5:2020, stakeholders in mineral processing ensure machinery for cleaning, recycling and mud treatment meets recognized European safety expectations for design, verification and user information.

Frequently Asked Questions

SIST EN 1009-5:2020 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Machines for mechanical processing of minerals and similar solid materials - Safety - Part 5: Specific requirements for cleaning, recycling, sorting and mud treatment machinery". This standard covers: This document, to be used together with EN 1009-1, specifies the safety requirements and their verification for the design and construction of machinery for cleaning, water recycling, mud treatment and sorting (other than screens) for the mechanical processing in quarrying, recycling and processing mineral and by-products. In addition, it specifies the type of information on safe working practices (including residual risks) to be provided by the manufacturer. When requirements of this part of EN 1009 are different from those which are stated in EN 1009-1:2020, the requirements of this part of EN 1009 take precedence over the requirements of EN 1009-1:2020 for machines that have been designed and built according to the provisions of this part of EN 1009. This document, together with EN 1009-1:2020, deals with all the significant hazards, hazardous situations and events relevant to machinery for cleaning, recycling, mud treatment when they are used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer associated with the whole lifetime of the machine (see Annex C). This document does not cover: - design relating to road traffic regulations; - hazards arising from the use of the machines in potentially explosive atmospheres as well as from processing of explosive materials and risks related to electromagnetic compatibility; - specific hazards related to mobile machinery. NOTE 1 EN ISO 13766-1 and EN ISO 13766-2 specify test methods and acceptance criteria for evaluating the electromagnetic compatibility of all kinds of mobile construction machinery. NOTE 2 prEN 1009-6 "Specific requirements for mobile and semi mobile equipment" is under preparation to cover specific requirements (e.g. mobility, braking, access, frequent transportation), including exceptions and additional requirements for mobile and semi mobile equipment. This means that mobile machines are not covered as long as EN 1009-6 is not published by CEN. This document is not applicable to machinery for cleaning, recycling, mud treatment and sorting which are manufactured before the date of publication of this document by CEN.

This document, to be used together with EN 1009-1, specifies the safety requirements and their verification for the design and construction of machinery for cleaning, water recycling, mud treatment and sorting (other than screens) for the mechanical processing in quarrying, recycling and processing mineral and by-products. In addition, it specifies the type of information on safe working practices (including residual risks) to be provided by the manufacturer. When requirements of this part of EN 1009 are different from those which are stated in EN 1009-1:2020, the requirements of this part of EN 1009 take precedence over the requirements of EN 1009-1:2020 for machines that have been designed and built according to the provisions of this part of EN 1009. This document, together with EN 1009-1:2020, deals with all the significant hazards, hazardous situations and events relevant to machinery for cleaning, recycling, mud treatment when they are used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer associated with the whole lifetime of the machine (see Annex C). This document does not cover: - design relating to road traffic regulations; - hazards arising from the use of the machines in potentially explosive atmospheres as well as from processing of explosive materials and risks related to electromagnetic compatibility; - specific hazards related to mobile machinery. NOTE 1 EN ISO 13766-1 and EN ISO 13766-2 specify test methods and acceptance criteria for evaluating the electromagnetic compatibility of all kinds of mobile construction machinery. NOTE 2 prEN 1009-6 "Specific requirements for mobile and semi mobile equipment" is under preparation to cover specific requirements (e.g. mobility, braking, access, frequent transportation), including exceptions and additional requirements for mobile and semi mobile equipment. This means that mobile machines are not covered as long as EN 1009-6 is not published by CEN. This document is not applicable to machinery for cleaning, recycling, mud treatment and sorting which are manufactured before the date of publication of this document by CEN.

SIST EN 1009-5:2020 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 73.120 - Equipment for processing of minerals; 91.220 - Construction equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1009-5:2020 has the following relationships with other standards: It is inter standard links to SIST EN 1009-5:2020/oprA1:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1009-5:2020 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1009-5:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2020

Stroji za mehansko obdelavo mineralov in podobnih trdnih snovi - Varnost - 5. del:

Posebne zahteve za stroje za čiščenje, recikliranje, sortiranje in obdelavo blata

Machines for mechanical processing of minerals and similar solid materials - Safety -

Part 5: Specific requirements for cleaning, recycling, sorting and mud treatment

machinery

Maschinen für die mechanische Aufbereitung von Mineralien und ähnlichen festen

Stoffen - Sicherheit - Teil 5: Spezifische Anforderungen für Reinigungs-, Recycling-,

Sortier- und Schlamm-Verarbeitungsmaschinen

Machines pour le traitement mécanique des minéraux et des matériaux solides similaires

- Sécurité - Partie 5 : Prescriptions spécifiques pour machines de nettoyage, de

recyclage et de traitement des boues

Ta slovenski standard je istoveten z: EN 1009-5:2020

ICS:

13.110 Varnost strojev Safety of machinery

73.120 Oprema za predelavo rudnin Equipment for processing of

minerals

91.220 Gradbena oprema Construction equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1009-5

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2020

EUROPÄISCHE NORM

ICS 73.120; 91.220

English Version

Machines for mechanical processing of minerals and

similar solid materials - Safety - Part 5: Specific

requirements for cleaning, recycling, sorting and mud

treatment machinery

Machines pour le traitement mécanique des minéraux Maschinen für die mechanische Aufbereitung von

et des matières solides similaires - Sécurité - Partie 5 : Mineralien und ähnlichen festen Stoffen - Sicherheit -

Prescriptions spécifiques pour machines de nettoyage, Teil 5: Spezifische Anforderungen für Reinigungs-,

de recyclage et de traitement des boues Recycling-, Sortier- und Schlamm-

Verarbeitungsmaschinen

This European Standard was approved by CEN on 13 April 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1009-5:2020 E

worldwide for CEN national Members.

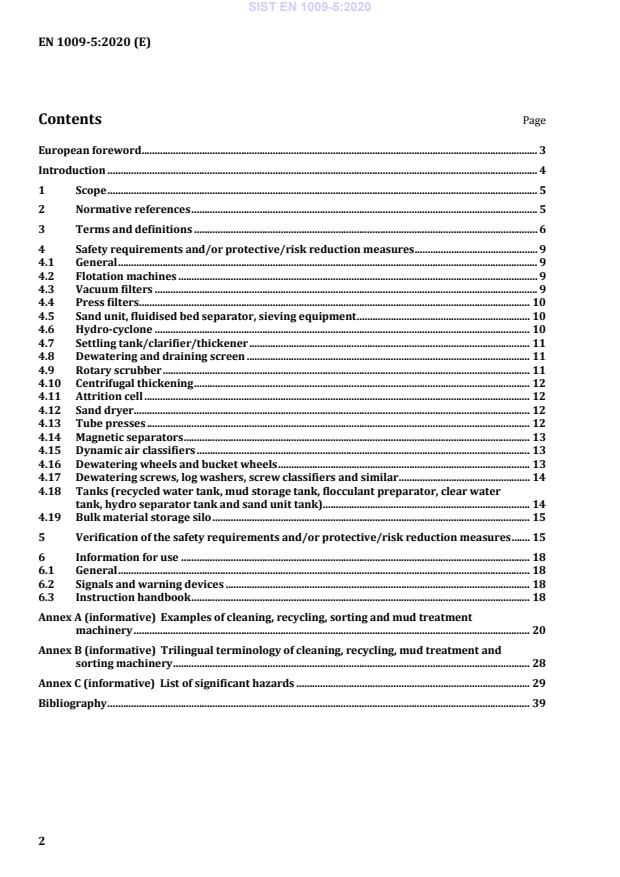

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Safety requirements and/or protective/risk reduction measures . 9

4.1 General . 9

4.2 Flotation machines . 9

4.3 Vacuum filters . 9

4.4 Press filters . 10

4.5 Sand unit, fluidised bed separator, sieving equipment . 10

4.6 Hydro-cyclone . 10

4.7 Settling tank/clarifier/thickener . 11

4.8 Dewatering and draining screen . 11

4.9 Rotary scrubber . 11

4.10 Centrifugal thickening . 12

4.11 Attrition cell . 12

4.12 Sand dryer . 12

4.13 Tube presses . 12

4.14 Magnetic separators . 13

4.15 Dynamic air classifiers . 13

4.16 Dewatering wheels and bucket wheels . 13

4.17 Dewatering screws, log washers, screw classifiers and similar . 14

4.18 Tanks (recycled water tank, mud storage tank, flocculant preparator, clear water

tank, hydro separator tank and sand unit tank). 14

4.19 Bulk material storage silo . 15

5 Verification of the safety requirements and/or protective/risk reduction measures . 15

6 Information for use . 18

6.1 General . 18

6.2 Signals and warning devices . 18

6.3 Instruction handbook . 18

Annex A (informative) Examples of cleaning, recycling, sorting and mud treatment

machinery . 20

Annex B (informative) Trilingual terminology of cleaning, recycling, mud treatment and

sorting machinery . 28

Annex C (informative) List of significant hazards . 29

Bibliography . 39

European foreword

This document (EN 1009-5:2020) has been prepared by Technical Committee CEN/TC 151 “Construction

equipment and building material machines — Safety”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2020, and conflicting national standards shall

be withdrawn at the latest by May 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a standardization request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of

EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

This part of EN 1009 is intended to be used in conjunction with EN 1009-1:2020.

EN 1009 “Machines for mechanical processing of minerals and similar solid materials — Safety”

comprises the following parts:

— Part 1: Common requirements for machinery and processing plants

— Part 2: Specific requirements for feeding machinery and continuous handling equipment

— Part 3: Specific requirements for crushing and milling machinery

— Part 4: Specific requirements for screening machinery

— Part 5: Specific requirements for cleaning, recycling and mud treatment machinery

— Part 6: Specific requirements for mobile machinery (in preparation)

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the Scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

1 Scope

This document, to be used together with EN 1009-1, specifies the safety requirements and their

verification for the design and construction of machinery for cleaning, water recycling, mud treatment

and sorting (other than screens) for the mechanical processing in quarrying, recycling and processing

mineral and by-products. In addition, it specifies the type of information on safe working practices

(including residual risks) to be provided by the manufacturer.

When requirements of this part of EN 1009 are different from those which are stated in EN 1009-1:2020,

the requirements of this part of EN 1009 take precedence over the requirements of EN 1009-1:2020 for

machines that have been designed and built according to the provisions of this part of EN 1009.

This document, together with EN 1009-1:2020, deals with all the significant hazards, hazardous

situations and events relevant to machinery for cleaning, recycling, mud treatment when they are used

as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer

associated with the whole lifetime of the machine (see Annex C).

This document does not cover:

— design relating to road traffic regulations;

— hazards arising from the use of the machines in potentially explosive atmospheres as well as from

processing of explosive materials and risks related to electromagnetic compatibility;

— specific hazards related to mobile machinery.

NOTE 1 EN ISO 13766-1 and EN ISO 13766-2 specify test methods and acceptance criteria for evaluating the

electromagnetic compatibility of all kinds of mobile construction machinery.

NOTE 2 prEN 1009-6 “Specific requirements for mobile and semi mobile equipment” is under preparation to

cover specific requirements (e.g. mobility, braking, access, frequent transportation), including exceptions and

additional requirements for mobile and semi mobile equipment. This means that mobile machines are not covered

as long as EN 1009-6 is not published by CEN.

This document is not applicable to machinery for cleaning, recycling, mud treatment and sorting which

are manufactured before the date of publication of this document by CEN.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 617:2001+A1:2010, Continuous handling equipment and systems — Safety and EMC requirements for

the equipment for the storage of bulk materials in silos, bunkers, bins and hoppers

EN 1009-1:2020, Machines for mechanical processing of minerals and similar solid materials — Safety —

Part 1: Common requirements for machinery and processing plants

EN 1009-4:2020, Machines for mechanical processing of minerals and similar solid — Safety — Part 4:

Specific requirements for screening machinery

EN 61496-1:2013, Safety of machinery — Electro-sensitive protective equipment — Part 1: General

requirements and tests (IEC 61496-1:2012)

EN 61496-2:2013, Safety of machinery — Electro-sensitive protective equipment — Part 2: Particular

requirements for equipment using active opto-electronic protective devices (AOPDs) (IEC 61496-2:2013)

EN ISO 7010:2020, Graphical symbols — Safety colours and safety signs — Registered safety signs (ISO

7010:2019)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13732-1:2008, Ergonomics of the thermal environment — Methods for the assessment of human

responses to contact with surfaces — Part 1: Hot surfaces (ISO 13732-1:2006)

EN ISO 13857:2019, Safety of machinery — Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2019)

EN ISO 14119:2013, Safety of machinery — Interlocking devices associated with guards — Principles for

design and selection (ISO 14119:2013)

EN ISO 14122-3:2016, Safety of machinery — Permanent means of access to machinery — Part 3: Stairs,

stepladders and guard-rails (ISO 14122-3:2016)

ISO 14123-1:2015, Safety of machinery — Reduction of risks to health resulting from hazardous substances

emitted by machinery — Part 1: Principles and specifications for machinery manufacturers

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010,

EN 1009-1:2020, EN 617:2001+A1:2010 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/ui

— IEC Electropedia: available at http://www.electropedia.org/

NOTE Annex A shows examples of cleaning, recycling, sorting and mud treatment machinery.

3.1

sand unit

sand treatment plant with hydro-cyclone system, a tank, a pump and a drying system, allowing the

washing and drying of sands

3.2

settling tank

clarifier

thickener

plant containing a decantation pool with a scraper, pumps and a flocculation plant with the aim to clarify

washing water through a mud thickening, for their recycling

3.3

dewatering screw

screw classifier

plant containing a screw rotating within a tank or sump to separate sand from fines

3.4

hydro-cyclone

classifying (or concentrating) separator into which pulp is fed, so as to take a circular path

Note 1 to entry: Coarser and heavier fractions of solids report at apex of long cone while finer particles overflow

from central vortex.

3.5

sieving equipment

static or vibrating equipment with a single level, ensuring a sand classification

3.6

dewatering and draining screen

equipment decreasing the moisture of sands and aggregates

3.7

fluidised bed separator

equipment realizing a cut size between 100 μm and 800 μm, through density control and water injection

3.8

hydro-separator

equipment realizing a cut size less than 100 μm, by water injection

3.9

log washer

slurry tank in which one or two shafts equipped with paddles acting against each other in order to break

various types of materials like clay, sands, aggregates agglomerates, impurities (e.g. wood) in order to

produce a clean aggregate outlet and a dirty water outlet with impurities and fines

3.10

blender

equipment with a tank in which an agitator is turning in order to mix a liquid product with a solid product

3.11

press filter

multiple plate filters in which the mud is injected under pressure to produce mud cakes on one side and

collect filtrates on the other side

3.12

rotary scrubber

rotary device in which coarse and sticky ore is mixed with water to wash and disintegrate material and

achieve a free rock from one side and slurry from the other side

3.13

centrifugal thickening

equipment used for fine separation, using centrifugal forces fed by concentrated slurry to be separated

in a pasty sludge and centrates (e.g. water)

3.14

vacuum filter

filtering device where the pulp is drawn into contact with a porous media by means of a moderately high

vacuum, solids being filtrated drawn through from one side and filtrates collected from the other side

Note 1 to entry: A vacuum filter can be a belt filter, a drum filter or a disc filter.

Note 2 to entry: In the drum and disc types, filtration is continuous.

Note 3 to entry: Vacuum is produced by means of a pump.

3.15

attrition cell

device to liberate sand from clay coating in wet process by friction of grains using a screw or paddles to

move the material past each other (attrition)

3.16

sand dryer

rotating equipment fitted with filtrating grids decreasing the amount of moisture in the sand after drying

through vacuum and/or heating

3.17

bucket wheel

rotating system with bucket wheel for separation of sand from water within a tank, combined or not with

dewatering screen (e.g. bucket wheel or sand trap)

3.18

dynamic/static air classifier

dry classification device that separates sand and ultra-fine particles

3.19

mixer

machine with a hopper where are mainly introduced two solids which are mixed with one or several

screws with the possibility or not to add water and an operation at ambient temperature or heated

atmosphere

3.20

tank

storage equipment containing a liquid or a pulp

3.21

tube press

membrane type filter press, which performs filtration and separation during its press operation, designed

in cylindrical format and capable of operating at high filtration

3.22

magnetic separator

mechanism for removing ferrous contaminates from the material being processed, e.g. permanent or

electric, conveyors or drums

4 Safety requirements and/or protective/risk reduction measures

4.1 General

Cleaning, recycling and mud treatment machinery shall comply with the requirements of

EN 1009-1:2020, as far as not modified or replaced by the requirements of this part.

Machines designed with several decks/levels shall comply with EN 1009-4:2020, 4.2.

4.2 Flotation machines

If there is a hazard of crushing, cutting and severing between the dart valve and its seat located in the

outlet of the tank, this outlet shall be protected by guards as specified in EN 1009-1:2020, 4.11 from the

inside of the tank.

If there is a hazard of inhalation or contact with hazardous substances, the machine shall be equipped

with a vacuum system in accordance with the principles of EN ISO 14123-1:2015.

Cleaning of internal parts should be possible from the outside and provision of the procedure for safe

cleaning shall be provided in the information for use (see 6.3).

The same principles apply to the area of impeller and diffuser.

4.3 Vacuum filters

If there is a hazard of crushing, cutting and severing

— between the drum and the tank;

— between the drum and the agitator arms;

— between the tank and the agitator arms;

— at the nip points between the belt and tracking rollers in belt drum filter (BDF);

— at the nip point between the belt and the feed box in top feed filter (TFF);

— between the maintenance opening in the tank and the agitator;

— between the maintenance opening in the drum and the tank during its operation;

this area shall be protected by guards as specified in EN 1009-1:2020, 4.11.

These guards shall be of a fixed or movable type.

If there is a hazard of shearing related to the drum edge of the vacuum filter during its operation, the area

which can be reached by the operator shall be protected by guards.

4.4 Press filters

Due to the serious hazard of crushing

— between the plates;

— between spray bars;

— between the fixed head and the first plate;

— between wheels or pads of the moving head and the rails in its normal operating conditions;

— between the trap door/drip tray and the frame;

these areas shall be protected either by electro sensitive protective equipment of category II type in

accordance to EN 61496-1:2013 and EN 61496-2:2013 or by guards as specified in EN 1009-1:2020,

4.11.

An emergency stop according to EN 1009-1:2020, 4.10.4 shall be fitted at least at each side.

Cleaning of internal parts should be possible from the outside and provision of the procedure for safe

cleaning shall be provided in the information for use (see 6.3).

4.5 Sand unit, fluidised bed separator, sieving equipment

For maintenance purpose, means of access complying with EN 1009-1:2020, 4.4 shall be provided:

— at the discharge of the cyclone;

— dewatering screen.

Between a fixed part of the frame and the dewatering screen, there shall have a foot guard complying

with EN ISO 14122-3:2016.

NOTE For changing the deck and the grids of the dewatering screen and the underflow nozzles of the cyclone,

the operator can use the dewatering screen as means of access to the maintenance point.

For fluidised bed separator, in case a heating system is fitted, this area shall be protected by guards as

specified in EN 1009-1:2020, 4.11 where burning hazard it is determined according to

EN ISO 13732-1:2008. In addition, an overheating system shall be provided to stop the combustion

material in order to prevent fire conditions.

4.6 Hydro-cyclone

When hydro-cyclone is not part of the sand unit, the design shall allow the use of mobile access means

(e.g. mobile elevating working platform fulfilling EN 280:2013+A1:2015).

4.7 Settling tank/clarifier/thickener

4.7.1 General

EN 1009-1:2020, 4.7.1 to 4.7.3 do not apply. In addition, the following requirements apply:

Tanks of settling tank/clarifier/thickener shall be designed to avoid any overflow.

Permanent means of access, especially platform at the top part of settling tank/clarifier/thickener shall

be fitted and designed in accordance with to EN 1009-1:2020, 4.4.

For mounting/dismounting phase and in case of exceptional interventions, tanks of settling

tank/clarifier/thickener shall be fitted with a passage opening, according to EN 1009-1:2020, 4.2.1, d) at

the bottom of the tank.

4.7.2 Clarifiers

In case of clarifier with tunnel, the following requirements apply:

— by exception to EN 1009-1:2020, 4.2.1, d) the minimum dimensions of tunnels shall be 1,2 m height

as a minimum and 0,8 m width as a minimum;

— by design, there shall not have any structural parts in the passageway of the tunnel;

— the emergency stop according to EN 1009-1:2020, 4.10.4 shall be fitted at least at the entry and at

the exit or end of the tunnel.

In case of clarifier with rotating walkway, the access to this walkway shall be locked by a guard as

specified in EN 1009-1:2020, 4.11 during normal working conditions. The unlocking system shall be

designed in such a way that the access to the rotating walkway is possible only when it is aligned with

the permanent mean of access.

Minimum clearance between rotating walkway and fixed parts of the plant, when aligned, shall be 80 mm.

If there is a hazard of contact with hazardous substances, the machine shall be designed in such a way to

limit exposure to these substances, e.g. floculants, in accordance with the principles of ISO 14123-1:2015.

Cleaning of internal parts should be possible from the outside and provision of the procedure for safe

cleaning shall be provided in the information for use (see 6.3).

4.8 Dewatering and draining screen

When dewatering screen is not part of sand unit, the design shall allow the use of mobile access means

(e.g. mobile elevating working platform fulfilling EN 280:2013+A1:2015).

NOTE For changing the deck and the grids of the dewatering screen, the operator can use the dewatering

screen as a means of access to the maintenance point.

4.9 Rotary scrubber

If there is a hazard of crushing, cutting and severing between

— the drum and the wheels,

— the drum and the feed chute,

— the drum and the discharge chute,

the hazard area shall be protected by guards.

If an access door to this area is necessary for inspection, the access shall be controlled with an interlocking

guard with guard locking as specified in EN 1009-1:2020, 4.11.3, e.g. trapped key system according to

EN ISO 14119:2013, B.2.

The feed chute and the discharge chute arrangements shall be constructed in a way that prevents the user

from touching the materials through chutes or inspection doors in the chute arrangements.

A temporary working platform shall be provided to give access inside the drum for lining maintenance.

The supports of this temporary working platform shall be designed in order to avoid damages or wear

due to material flow.

The minimum operating loads of temporary working platform shall be 1,5 kN/m under distributed load

for the structure.

In case of adjustable temporary working platform fitted with a locking mechanism, it shall hold twice the

minimum operating loads of temporary working platform.

If there is a risk of falling during maintenance operation, anchorage points shall be provided in

accordance with tests of EN 795:2012.

For maintenance work in the drum, isolation and energy dissipation shall be provided for the drum as

well as for upstream and downstream sub-assemblies. See EN 1009-1:2020, 4.10.1.

Permanents means of access shall be provided for the feed chute visual inspection and the discharge

chute access and comply with EN 1009-1:2020, 4.4. A lifting accessory shall be provided for the wheels

dismantling and designed in such way to ensure the stability during the maintenance phase.

4.10 Centrifugal thickening

A visual inspection opening as specified in EN 1009-1:2020, 4.2.3 shall be fitted.

4.11 Attrition cell

Visual inspection openings as specified in EN 1009-1:2020, 4.2.3 shall be fitted with fixed guards

complying with EN 1009-1:2020, 4.11 and fulfilling the requirements of EN ISO 13857:2019, 4.2.4.1,

Table 4.

Permanent means of access shall be provided at maintenance and visual inspection access points and

comply with EN 1009-1:2020, 4.4.

For maintenance purpose (e.g. blades replacement), lifting points shall be provided to lift the attrition

sub-assemblies. These lifting points shall fulfil the requirements of EN 1009-1:2020, 4.17.5.

4.12 Sand dryer

At the top part of the sand dryer, a permanent means of access, including a platform shall be fitted and

designed in accordance with EN 1009-1:2020, 4.4.

In case a heating system is fitted, this area shall be protected by guards as specified in EN 1009-1:2020,

4.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...