SIST EN 15955-1:2013

(Main)Railway applications - Track - Demountable machines and associated equipment - Part 1: Technical requirements for running and working

Railway applications - Track - Demountable machines and associated equipment - Part 1: Technical requirements for running and working

1.1 General

This European Standard specifies the technical requirements to minimise the specific railway hazards of self propelled demountable machines - henceforward referred to as machines - and associated equipment, which can arise during the commissioning, the operation and the maintenance of these machines when carried out in accordance with the specification given by the manufacturer or his authorised representative. These machines are not designed or intended to operate signalling and control systems and are only designed and intended to work and run under special operating conditions specifically designated by the infrastructure manager. Other machines are dealt with in other European Standards; see Annex D.

This part of EN 15955 deals with the technical railway requirements; Part 2 deals with the requirements for the machine to be declared conformant by the manufacturer, except in the case of machines classified in Annex 4 of the Machinery Directive (2006/42/EC) which requires conformity check in conjunction with a notified body.

These demountable machines are not intended to be vehicles as defined in the Interoperability Directive and are not permitted to run on the railway lines open to normal traffic. If this is required, they will need to be authorised or placed into service as set out in the Interoperability Directive 2008/57/EC.

Additional requirements can apply for running on infrastructures with narrow gauge or broad gauge lines, lines of tramways, railways utilising other than adhesion between the rail and rail wheels and underground infrastructures.

This European Standard is also applicable to machines and associated equipment that in working configuration are partly supported on the ballast or the formation.

This European Standard does not apply to the following:

- requirements for quality of the work or performance of the machine;

- specific requirements established by the railway infrastructure operator for the use of machines, which will be the subject of negotiation between the manufacturer and the purchaser;

- separate machines temporarily mounted on demountable machines and associated equipment.

This European Standard does not establish the additional requirements for the following:

- operation subject to special rules, e.g. potentially explosive atmospheres;

- hazards due to natural causes, e.g. earthquake, lightning, flooding;

- working methods;

- operation in severe working conditions requiring special measures, e.g. work in tunnels or in cuttings, extreme environmental conditions (below – 20 °C or above + 40 °C), corrosive environment, contaminating environments, strong magnetic fields;

- hazards due to errors in software;

- hazards occurring when used to handle suspended loads which may swing freely.

The intended use of these machines may have operational parameters specified by each infrastructure manager, e.g. the maximum speed allowed for these machines is likely to be limited by the infrastructure manager; compliance with the clauses of this standard does not confer permission for machines to travel at this speed. These machines will not be allowed on a track open to normal railway traffic.

1.2 Validity of this European Standard

This European Standard applies to all machines, which are ordered one year after the publication date by CEN of this standard.

Bahnanwendungen - Oberbau - Ausgleisbare Maschinen und zugehörige Ausstattung - Teil 1: Technische Anforderungen an das Fahren und den Arbeitseinsatz

Diese Europäische Norm legt die technischen Anforderungen zur Minimierung eisenbahnspezifischer Gefahren von selbst angetriebenen ausgleisbaren Maschinen — nachfolgend als Maschine bezeichnet — und zugehöriger Ausstattung fest, die bei der Inbetriebnahme, dem Betrieb und der Instandhaltung von diesen Maschinen, den Anweisungen des Herstellers oder seinem berechtigten Vertreter folgend, entstehen können. Diese Maschinen sind nicht für das Auslösen von Signal- und Steuerungssystemen konstruiert und vorgesehen. Sie sind nur für den Arbeitseinsatz und das Fahren bei besonderen Betriebsbedingungen, speziell vom Infrastrukturunternehmer festgelegt, konstruiert und vorgesehen. Andere Maschinen werden in anderen Europäischen Normen behandelt, siehe Anhang D.

Dieser Teil von EN 15955 behandelt die technischen Eisenbahnanforderungen; Teil 2 behandelt die Anforderungen für die Konformitätserklärung des Herstellers, mit Ausnahme von Maschinen, die nach der Maschinen-Richtlinie (2006/42/EG), Anhang 4, klassifiziert sind und eine Konformitätsprüfung durch eine notifizierte Stelle benötigen.

Diese ausgleisbaren Maschinen sind keine Fahrzeuge nach der Interoperabilitätsrichtlinie und dürfen nicht auf den Eisenbahnstrecken offen zum normalen Verkehr fahren. Wenn dies verlangt wird, benötigen sie eine Zulassung oder Inbetriebnahme nach der Interoperabilitätsrichtlinie 2008/57/EG.

Für das Fahren auf Infrastrukturen mit schmalen Spurweiten oder auf Breitspurstrecken, Straßenbahnlinien, von Eisenbahnen, die eine andere Haftreibung zwischen Schiene und Rad nutzen, und Infrastrukturen im Untergrund können zusätzliche Anforderungen bestehen.

Diese Europäische Norm gilt auch für Maschinen und zugehörige Ausrüstungen, die sich in Arbeitsstellung teilweise auf dem Schotter oder dem Untergrund (Planum) abstützen.

Diese Europäische Norm gilt nicht für:

Anforderungen an die Qualität von Arbeiten oder die Leistung der Maschine;

spezielle Anforderungen für die Nutzung der Maschinen, festgelegt von dem Eisenbahninfrastruktur-betreiber, die jedoch der Absprache zwischen Hersteller und Betreiber unterliegen;

gesonderte Maschinen, die vorübergehend oder dauerhaft an ausgleisbaren Maschinen angebaut sind und zugehörige Ausrüstungen.

Diese Europäische Norm legt nicht die zusätzlichen Anforderungen für Folgendes fest:

Einsätze, die besonderen Regeln unterliegen, z. B. explosionsgefährdete Umgebungen;

Gefahren aufgrund natürlicher Ursachen, z. B. Erdbeben, Blitzschlag, Überschwemmung;

Arbeitsverfahren;

Einsätze unter schweren Arbeitsbedingungen, die besondere Maßnahmen erfordern, z. B. bei Arbeiten in Tunneln oder in Streckenabschnitten mit außergewöhnlichen Bedingungen (unter −20° C oder über + 40° C), korrosiven Umgebungen, kontaminierten Umgebungen, starken Magnetfeldern;

Applications ferroviaires - Voie - Machines déraillables et éléments associés - Partie 1 : Prescriptions techniques pour la circulation et le travail

1.1 Généralités

La présente Norme européenne traite des prescriptions techniques pour minimiser les risques de danger spécifiques au domaine ferroviaire des machines déraillables (désignées ci-après comme «machines») et des équipements associés. Ces risques peuvent se produire lors des opérations de mise en service, d’exploitation et de maintenance de ces machines lorsque ces opérations sont réalisées conformément aux spécifications du fabricant ou de son mandataire. La présente Norme européenne s’applique aux machines déraillables qui ne sont pas prévues pour interagir avec les systèmes de signalisation et de commande en exploitation. Elles sont uniquement destinées à se déplacer et à travailler dans des conditions particulières d’exploitation définies par le gestionnaire d’infrastructure. D’autres Normes européennes traitent d’autres machines ; voir l’Annexe D.

Cette partie de l’EN 15955 traite des exigences ferroviaires techniques; la Partie 2 définit les prescriptions relatives à la «déclaration de conformité» d’une machine par le fabricant, à l’exception de celles classées dans l’Annexe 4 de la Directive Machine (2006/42/CE) qui exige une vérification de la conformité par un organisme autorisé.

Ces machines déraillables ne sont pas prévues pour être des véhicules tels que définis dans la Directive Interopérabilité et ne sont pas autorisées à circuler sur les lignes ferroviaires ouvertes à un trafic normal. Si nécessaire, elles devront être autorisées ou mises en service comme établi dans la directive 2008/57/CE relative à l’interopérabilité.

Des prescriptions supplémentaires peuvent s’appliquer pour la circulation sur les infrastructures ferroviaires à voies larges ou étroites, sur des lignes de tramway, sur des chemins de fer autres que ceux à adhérence rail/roue et sur des infrastructures ferroviaires souterraines.

La présente Norme européenne s’applique aussi aux machines et à leurs équipements associés qui, en configuration de travail, prennent partiellement appui sur le ballast ou sur la plate-forme.

La présente Norme européenne ne s’applique pas:

aux exigences relatives à la qualité du travail ou aux performances de la machine;

aux exigences spécifiques fixées par chaque exploitant d’infrastructure ferroviaire pour l’emploi des machines et qui font l’objet de négociations entre le fabricant et l’acheteur;

aux machines séparées montées pour une durée temporaire sur des machines déraillables ou équipements associés;

La présente Norme européenne ne tient pas compte des prescriptions supplémentaires suivantes:

mise en œuvre de la machine dans des conditions faisant l’objet de règles spéciales, par exemple, atmosphère potentiellement explosive;

risques dus à des causes naturelles, par exemple tremblement de terre, foudre, inondation;

méthodes de travail;

exploitation dans des conditions de travail sévères nécessitant des mesures particulières, par exemple : travail en tunnels ou en tranchées, conditions climatiques extrêmes (en dessous de - 20 °C ou au-dessus de + 40 °C), environnements corrosifs ou contaminants, champs magnétiques de forte intensité;

risques dus à des erreurs de logiciels;

risques dus aux mouvements de charges librement suspendues.

Les paramètres d’exploitation correspondant à l’utilisation prévue de ces machines peuvent être spécifiés par chaque gestionnaire d’infrastructure, par exemple la vitesse maximale autorisée pour ces machines risque d’être limitée par le gestionnaire d’infrastructure - la conformité aux dispositions de la présente norme ne signifie pas que les machines sont autorisées à se déplacer à ladite vitesse. Ces machines ne seront pas autorisées sur une voie ouverte à la circulation ferroviaire normale.

Železniške naprave - Zgornji ustroj - Motorna vozila za posebne namene in spremljajoča oprema - 1. del: Tehnične zahteve, ki se nanašajo na vožnjo in na delovanje

Ta evropski standard določa tehnične zahteve za zmanjšanje posebnih železniških nevarnosti motornih vozil za posebne namene na lastni pogon, v nadaljnjem besedilu: motorna vozila, in spremljajočo opremo, do katerih lahko pride med začetkom delovanja, delovanjem in vzdrževanjem motornih vozil, kadar to poteka v skladu s specifikacijo, ki jo zagotovi proizvajalec ali njegov pooblaščeni predstavnik. Ta motorna vozila niso oblikovana ali namenjena za upravljanje signalizacijskih in nadzornih sistemov ter so namenjena le delovanju in vožnji pod posebnimi obratovalnimi pogoji, ki jih izrecno določi upravitelj infrastrukture. Drugi stroji so obravnavani v drugih evropskih standardih; glej dodatek D.

General Information

- Status

- Published

- Publication Date

- 05-May-2013

- Technical Committee

- IŽNP - Reilway applications

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 03-May-2013

- Due Date

- 08-Jul-2013

- Completion Date

- 06-May-2013

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 16-Jun-2021

- Effective Date

- 11-Apr-2018

Frequently Asked Questions

SIST EN 15955-1:2013 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railway applications - Track - Demountable machines and associated equipment - Part 1: Technical requirements for running and working". This standard covers: 1.1 General This European Standard specifies the technical requirements to minimise the specific railway hazards of self propelled demountable machines - henceforward referred to as machines - and associated equipment, which can arise during the commissioning, the operation and the maintenance of these machines when carried out in accordance with the specification given by the manufacturer or his authorised representative. These machines are not designed or intended to operate signalling and control systems and are only designed and intended to work and run under special operating conditions specifically designated by the infrastructure manager. Other machines are dealt with in other European Standards; see Annex D. This part of EN 15955 deals with the technical railway requirements; Part 2 deals with the requirements for the machine to be declared conformant by the manufacturer, except in the case of machines classified in Annex 4 of the Machinery Directive (2006/42/EC) which requires conformity check in conjunction with a notified body. These demountable machines are not intended to be vehicles as defined in the Interoperability Directive and are not permitted to run on the railway lines open to normal traffic. If this is required, they will need to be authorised or placed into service as set out in the Interoperability Directive 2008/57/EC. Additional requirements can apply for running on infrastructures with narrow gauge or broad gauge lines, lines of tramways, railways utilising other than adhesion between the rail and rail wheels and underground infrastructures. This European Standard is also applicable to machines and associated equipment that in working configuration are partly supported on the ballast or the formation. This European Standard does not apply to the following: - requirements for quality of the work or performance of the machine; - specific requirements established by the railway infrastructure operator for the use of machines, which will be the subject of negotiation between the manufacturer and the purchaser; - separate machines temporarily mounted on demountable machines and associated equipment. This European Standard does not establish the additional requirements for the following: - operation subject to special rules, e.g. potentially explosive atmospheres; - hazards due to natural causes, e.g. earthquake, lightning, flooding; - working methods; - operation in severe working conditions requiring special measures, e.g. work in tunnels or in cuttings, extreme environmental conditions (below – 20 °C or above + 40 °C), corrosive environment, contaminating environments, strong magnetic fields; - hazards due to errors in software; - hazards occurring when used to handle suspended loads which may swing freely. The intended use of these machines may have operational parameters specified by each infrastructure manager, e.g. the maximum speed allowed for these machines is likely to be limited by the infrastructure manager; compliance with the clauses of this standard does not confer permission for machines to travel at this speed. These machines will not be allowed on a track open to normal railway traffic. 1.2 Validity of this European Standard This European Standard applies to all machines, which are ordered one year after the publication date by CEN of this standard.

1.1 General This European Standard specifies the technical requirements to minimise the specific railway hazards of self propelled demountable machines - henceforward referred to as machines - and associated equipment, which can arise during the commissioning, the operation and the maintenance of these machines when carried out in accordance with the specification given by the manufacturer or his authorised representative. These machines are not designed or intended to operate signalling and control systems and are only designed and intended to work and run under special operating conditions specifically designated by the infrastructure manager. Other machines are dealt with in other European Standards; see Annex D. This part of EN 15955 deals with the technical railway requirements; Part 2 deals with the requirements for the machine to be declared conformant by the manufacturer, except in the case of machines classified in Annex 4 of the Machinery Directive (2006/42/EC) which requires conformity check in conjunction with a notified body. These demountable machines are not intended to be vehicles as defined in the Interoperability Directive and are not permitted to run on the railway lines open to normal traffic. If this is required, they will need to be authorised or placed into service as set out in the Interoperability Directive 2008/57/EC. Additional requirements can apply for running on infrastructures with narrow gauge or broad gauge lines, lines of tramways, railways utilising other than adhesion between the rail and rail wheels and underground infrastructures. This European Standard is also applicable to machines and associated equipment that in working configuration are partly supported on the ballast or the formation. This European Standard does not apply to the following: - requirements for quality of the work or performance of the machine; - specific requirements established by the railway infrastructure operator for the use of machines, which will be the subject of negotiation between the manufacturer and the purchaser; - separate machines temporarily mounted on demountable machines and associated equipment. This European Standard does not establish the additional requirements for the following: - operation subject to special rules, e.g. potentially explosive atmospheres; - hazards due to natural causes, e.g. earthquake, lightning, flooding; - working methods; - operation in severe working conditions requiring special measures, e.g. work in tunnels or in cuttings, extreme environmental conditions (below – 20 °C or above + 40 °C), corrosive environment, contaminating environments, strong magnetic fields; - hazards due to errors in software; - hazards occurring when used to handle suspended loads which may swing freely. The intended use of these machines may have operational parameters specified by each infrastructure manager, e.g. the maximum speed allowed for these machines is likely to be limited by the infrastructure manager; compliance with the clauses of this standard does not confer permission for machines to travel at this speed. These machines will not be allowed on a track open to normal railway traffic. 1.2 Validity of this European Standard This European Standard applies to all machines, which are ordered one year after the publication date by CEN of this standard.

SIST EN 15955-1:2013 is classified under the following ICS (International Classification for Standards) categories: 45.120 - Equipment for railway/cableway construction and maintenance. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15955-1:2013 has the following relationships with other standards: It is inter standard links to oSIST prEN 15955-1:2022, oSIST prEN 15955:2020, oSIST prEN 15955-1:2022, oSIST prEN 15955:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 15955-1:2013 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC; Standardization Mandates: M/024, M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 15955-1:2013 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.GHORYDQMHBahnanwendungen - Oberbau - Ausgleisbare Maschinen und zugehörige Ausstattung - Teil 1: Technische Anforderungen an das Fahren und den ArbeitseinsatzApplications ferroviaires - Voie - Machines déraillables et éléments associés - Partie 1 : Prescriptions techniques pour la circulation et le travailRailway applications - Track - Demountable machines and associated equipment - Part 1: Technical requirements for running and working45.120åLþQLFEquipment for railway/cableway construction and maintenanceICS:Ta slovenski standard je istoveten z:EN 15955-1:2013SIST EN 15955-1:2013en,fr01-junij-2013SIST EN 15955-1:2013SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15955-1

April 2013 ICS 45.060.20; 45.120 English Version

Railway applications - Track - Demountable machines and associated equipment - Part 1: Technical requirements for running and working

Applications ferroviaires - Voie - Machines déraillables et éléments associés - Partie 1 : Prescriptions techniques pour la circulation et le travail

Bahnanwendungen - Oberbau - Ausgleisbare Maschinen und zugehörige Ausstattung - Teil 1: Technische Anforderungen an das Fahren und den Arbeitseinsatz This European Standard was approved by CEN on 3 August 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15955-1:2013: ESIST EN 15955-1:2013

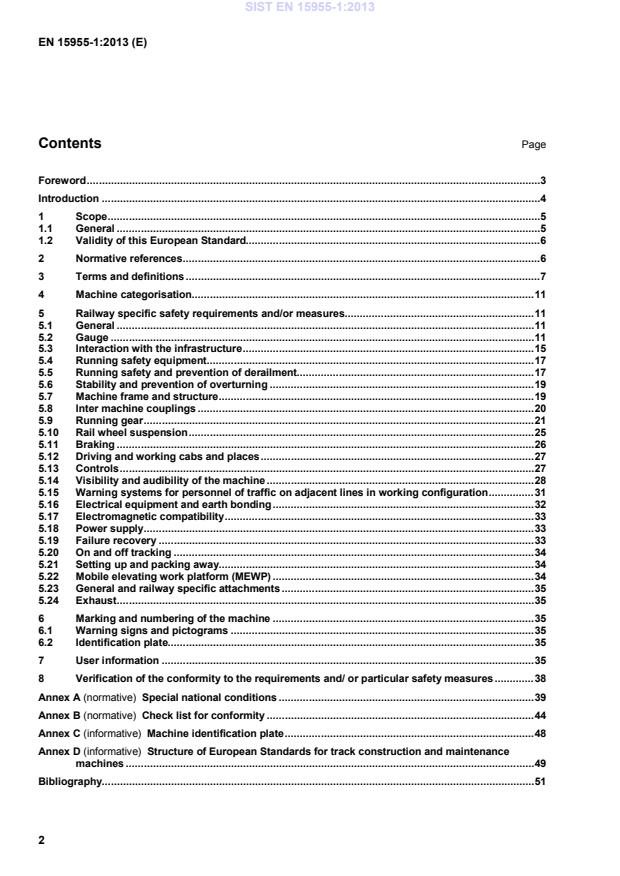

Special national conditions . 39 Annex B (normative)

Check list for conformity . 44 Annex C (informative)

Machine identification plate . 48 Annex D (informative)

Structure of European Standards for track construction and maintenance machines . 49 Bibliography. 51

The machinery concerned and the extent to which hazards, hazardous situations and events are covered are indicated in the scope of this European Standard. This European Standard was prepared to meet the basic requirements of EU Directives to facilitate an open market for goods and services. Demountable machines as specified in 3.1 form the object of this standard. This standard deals with railway specific risks of the demountable machines defined in Clause 4 when running and working on railway infrastructures. The safety requirements in relation to the Machinery Directive 2006/42/EC are dealt with in EN 15955-2 of this series of standards. Deviations or special national conditions are dealt with in Annex A. The risks which exist in all mechanical, electrical, hydraulic, pneumatic and other components of machines and which are dealt with in the relevant European Standards are not within the scope of this European Standard. If necessary, references are made to appropriate standards of this type. SIST EN 15955-1:2013

1) May be purchased from: Union Internationale de Chemins de fer (UIC), 14 rue Jean Rey, F-75015 Paris. SIST EN 15955-1:2013

Note 1 to entry: The driver and operator can be the same person. 3.20 train self-propelled vehicle/machine or assembly of vehicles/machines attached by couplings conforming to the relevant regulations of the authorised body and/or infrastructure manager 3.21 working limit contour limit in which a machine can work without interfering with the kinematic gauge of trains on adjacent tracks Note 1 to entry: For the kinematic gauge, see EN 14033-2:2008+A1:2011, Annex D. 3.22 rated load maximum load that the lifting equipment has been designed for normal operation and the manufacturer states can be lifted in any specified position 3.23 authorised body body in a state that, in accordance with the laws and prescriptions in force in that state, is competent to approve rail vehicles for the use on the rail network SIST EN 15955-1:2013

examination of the conformity of each machine to the all the safety requirements of this standard before delivery of the machine 3.26 type examination certificate document issued after the checking of documents and/or testing of machines in which the agreement of the use of the machine in the railway infrastructure is confirmed 3.27 type conformance certificate document which states that the machine conforms to the design of the first machine of the type that has been approved 3.28 railway undertaking private or public undertaking whose main business is to provide rail transport services for goods and/or passengers 3.29 infrastructure manager public body or undertaking responsible for establishing and maintaining railway infrastructure as well as for operating the railway control and safety systems 3.30 working authorisation authorisation given by an infrastructure manager which permits a machine to work on that railway infrastructure 3.31 methods of examination visual checks, measurements, functional tests, load test(s), specific verification/measurements and other controls Note 1 to entry: For methods of examination, see Table B.1. 3.32 visual check check that establishes whether all elements on the machine, system or component, e.g. protective devices, visual warning device, marking, are present and that documents and drawings correspond to the requirements 3.33 measurement test test that establishes whether the stated measurable parameters have met the requirements of this standard

Note 1 to entry: Measureable parameters include geometric dimensions, safety distances, insulation resistance of electric circuits, noise and vibration.

3.34 functional test test that establishes whether, in unloaded working condition the machine, including all safety devices, works as intended and all functions comply with the requirements and with the technical documentation SIST EN 15955-1:2013

5 Railway specific safety requirements and/or measures 5.1 General Machines shall comply with the safety requirements and/or protective measures in accordance with Clauses 5 and 6, and supplied with information in accordance with Clause 7. Machines shall be designed to work on working track within the geometric limits, see EN 14033-2:2008+A1:2011, Annex F, and shall be designed to work on operating track. Machines that can only work on operating tracks shall display in each driving cab and on the identification plate an indication of that restriction. 5.2 Gauge 5.2.1 Running gauge 5.2.1.1 General Except as shown in 5.2.1.2, machines in running configuration shall meet the dimensional requirements of EN 15273-2. The critical points near the limits of the permissible kinematic gauge, see EN 14033-1:2011, Annex C, shall be recorded in the technical documentation detailed in Clause 7. 5.2.1.2 Special case for restrictive gauges Machines intended to travel on infrastructures with more restrictive gauges shall conform to the specific rules of those infrastructures and the corresponding restrictions shall be indicated on their operating permits. SIST EN 15955-1:2013

This distance shall be taken with the worst case wheel wear and suspension condition. Machines are permitted to move over live conductor rails providing that they meet the requirements of the minimum safety distance given in Table 2. Machines not meeting these clearances are not permitted to move over live conductor rail and the type examination certificate shall indicate this restriction. 5.2.6 Working limit in the upper area 5.2.6.1 General All metallic parts of the machine shall be equipotential bonded to rail according to EN 15955-2:2013, 5.16.7. 5.2.6.2 Protection for the operator All work positions at a height greater than that shown in Annex A (line 9 of table) shall be protected such that it is not possible to make contact with live electric traction equipment. This requirement shall be achieved by either: a) the provision of an earthed metallic roof without open holes: where open holes in a metallic roof are necessary they shall be a maximum 25 mm aperture and covered by a conducting structure. It is SIST EN 15955-1:2013

or b) the machine shall be accepted for use with the restriction that it may only be operated under isolated and earthed catenaries (this means the electrical power switched off and the contact cable connected to ground potential). This restriction shall be written in the instruction handbook, see Clause 7, list entry a) 3) i), and a notice provided on the side of the machine. A warning notice shall be placed on MEWPs which do not have a roof, which states that use under live overhead wires is prohibited; see EN 50122-1. All places on the machine which allow access to either platforms or working areas without roofs in accordance with a) above shall be marked with a warning pictogram; see EN 14033-2:2008+A1:2011, Figure G.1. 5.2.6.3 Prevention of machine contact with the catenary Requirements for prevention of machine contact with the catenary are given in EN 15955-2:2013, 5.16.6. 5.3 Interaction with the infrastructure 5.3.1 General The wheels, supports and working tools shall not generate harmful stresses in the infrastructure components, e.g. rail, fastenings, sleepers, ballast and formation. Furthermore, it is required to take into consideration the maximum rail load, the permissible bending of the rail, the transverse forces on the sleeper fastenings, the surface pressure on the ballast as well as the load carrying ability of the formation. The manufacturer shall state the line category according to EN 15528 of the machine and record in the instruction handbook; see Clause 7. For the parameters of calculations, see EN 14033-2:2008+A1:2011, Annex K. If the machine contains devices for levelling and/or lining of the track, the maximum stresses generated by these devices in the rail shall be stated in the instruction handbook; see Clause 7. 5.3.2 Main wheels The wheels referred to in this clause are the wheels used for the running configuration of the machine. If the configuration of these wheels in working configuration of the machine is different from the running configuration, then the changes shall not cause derailment over the full range of the machine’s operational conditions. The load from the main wheels in working configuration shall not generate stresses in the rail higher than the values shown in Table 3. SIST EN 15955-1:2013

Bending stress Measure points Ultimate tensile strength of the rail % a) Maximum permissible tensile

bending stress Centre line of the top of the head and bottom of the foot of the rail 45 At the corner of the head of the rail 50 At the foot of the rail 60 b) Maximum permissible

compressive bending stress Head and foot of the rail 65

The values above allow for safety in particular conditions, e.g. track joints, non-standard sleeper spacing, residual stresses in the rails. 5.3.3 Auxiliary wheels, auxiliary guides and working parts The auxiliary wheels and guides according to this clause are for the support and guidance of assemblies associated with on and off tracking and/or the working configuration of the machine. The construction and positioning of any auxiliary wheels and/ or guides shall provide satisfactory guidance on rails and shall not cause damage to the rail or any associated part of the railway infrastructure. The limits a) and b) given in Table 3 shall be followed for any tool associated with the working configuration but may be exceeded when guiding or placing rails. If the rail is subject to other external stresses, for example thermal stress, this shall be taken into consideration. The limits a) and b) given in Table 3 can be exceeded in machines specifically designed for straightening or bending rails. Any additional supporting elements necessary to ensure stability or assist the work process shall also comply with the above requirements. 5.3.4 Loads applied to the ballast Where the surface pressure applied directly to the ballast by any part of the machine exceeds 0,3 MN/m2, the manufacturer shall state the maximum value in each working configuration in the instruction handbook. Machines that apply loads to the ballast by means of a tracked device shall have the surface pressure calculated according to the requirements of EN 791. 5.3.5 Loads applied to the formation Where the surface pressure applied directly to the formation by any part of the machine exceeds 0,1 MN/m2, the manufacturer shall state the maximum value in each working configuration in the instruction handbook. NOTE The value of 0,1 MN/m2 can be too high for some areas. It is expected that the infrastructure manager will be aware of these areas and specially control machines in these areas. Machines that apply loads to the formation by means of a tracked device shall have the surface pressure calculated according to the requirements of EN 791. SIST EN 15955-1:2013

Key 1 no limitation Figure 1 — Load model The loading situations to be taken into consideration for each working condition are to be indicated in technical documentation; see Clause 7, list entry b) 6) v). 5.4 Running safety equipment The infrastructure manager mandates special fixed and/ or portable equipment specific for running safety on their infrastructure. Machines shall be fitted with the equipment detailed in Annex A before access on the specified infrastructure. Where required, the controls for this equipment shall be located in each driving position. 5.5 Running safety and prevention of derailment 5.5.1 General The aim of the following requirements is to provide the same level of confidence for safety against derailment on the operating track as given by the acceptance procedures defined in EN 14363:2005, 4.1 and Clause 5. In addition, the operating conditions on the working track are covered by 5.5.3. 5.5.2 Running safety for demountable machines running at a speed of 60 km/h < v ≤ 100 km/h First of class machines shall follow the acceptance procedure according to EN 14363:2005: 4.1: the most adversely loaded condition when moving along the track in running configuration and where applicable in working condition shall be investigated; Clause 5 in running configuration: when using EN 14363:2005, the machine is described as a "special vehicle" due to the low numbers of these machines. In some cases, EN 14363 does not have specific requirements for "special vehicles"; in such cases the machines shall be assigned to a vehicle type most applicable to their design. SIST EN 15955-1:2013

A "similar type approved machine" is a machine with similar configuration and running under similar conditions, which can be used as a reference for the test exemption of a new machine, according to the requirements of EN 14363 and the corresponding Table 1, Annex B of EN 14363:2005. Where machines are designed for use on working track, they shall additionally comply, in the most adversely loaded condition when moving along the track in working configuration, with 5.5.3. Where a machine is not designed for use on working track, the limitation shall be detailed in the instruction handbook; see Clause 7. 5.5.3 Running safety for demountable machines running at a speed of < 60 km/ h First of class machines that have single axles, or freely rotating bogie (where wheels are a maximum 600 mm diameter and spaced a maximum 1 800 mm apart) at either end of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...