SIST EN 13126-17:2019

(Main)Building hardware - Hardware for windows and door height windows - Requirements and test methods - Part 17: Hardware for Tilt and Slide windows

Building hardware - Hardware for windows and door height windows - Requirements and test methods - Part 17: Hardware for Tilt and Slide windows

This part of EN 13126 specifies requirements and test methods for durability, strength, security and function of hardware for Tilt and Slide windows and door height windows in accordance with common application as shown in Figures C.1 and C.2 in informative Annex C.

Baubeschläge - Beschläge für Fenster und Fenstertüren - Anforderungen und Prüfverfahren - Teil 17: Beschläge für Kippschiebe-Fenster und -Fenstertüren

Dieses Dokument legt die Anforderungen und Prüfverfahren für die Dauerfunktionsfähigkeit, Festigkeit, Schutzwirkung und Funktionsweise von Beschlägen für Kippschiebe Fenster und Fenstertüren entsprechend der in Bild C.1 und Bild C.2 im informativen Anhang C dargestellten üblichen Anwendung fest.

Quincaillerie pour le bâtiment - Ferrures de fenêtres et portes-fenêtres - Exigences et méthodes d'essai - Partie 17 : Ferrures pour fenêtres oscillo-coulissantes

Le présent document spécifie les exigences et les méthodes d’essai relatives à l'endurance, la résistance, la sécurité et le fonctionnement des ferrures pour fenêtres oscillo-coulissantes et fenêtres coulissantes à levage, en conformité avec l’application courante représentée dans les Figures C.1 et C.2 de l’Annexe c, informative.

Stavbno okovje - Okovje za okna in zastekljena vrata - Zahteve in preskusne metode - 17. del: Okovje za nagibno-drsna okna in vrata

Ta standard EN 13126 določa zahteve in preskusne postopke za trajnost, trdnost, varnost in delovanje okovja za nagibno-drsna okna in zastekljena vrata v skladu z običajno uporabo, kot je opisana v informativnem dodatku C.

General Information

- Status

- Published

- Public Enquiry End Date

- 19-Mar-2018

- Publication Date

- 22-May-2019

- Technical Committee

- ISTP - Doors and windows

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 25-Apr-2019

- Due Date

- 30-Jun-2019

- Completion Date

- 23-May-2019

Relations

- Effective Date

- 01-Jul-2019

Overview

EN 13126-17:2019 - Building hardware: Hardware for Tilt and Slide windows - defines requirements and reproducible test methods for the durability, strength, security and functional performance of hardware used on tilt-and-slide and door-height windows (see informative Annex C figures). Published by CEN in April 2019, this part supersedes EN 13126-17:2008 and is independent of EN 13126-1. It applies to hardware for timber, PVC‑U, aluminium and steel windows and their combinations.

Key topics and technical requirements

- Scope of testing: durability, sliding operation (crash) tests, static endurance at ambient temperature, additional loading, minimum closing device resistance and corrosion resistance.

- Classification system: four “boxes” for product classification - Box 1: Durability, Box 2: Mass, Box 3: Corrosion resistance, Box 4: Test sizes.

- Durability grades: new H‑grades introduced (H1 = 5 000 cycles, H2 = 10 000 cycles, H3 = 20 000 cycles) to quantify expected life under cyclic operation.

- Corrosion testing: references EN 1670 for corrosion resistance methods and criteria.

- Test rig and specimen preparation: standardized mounting, use of gaskets, adjustment of test mass and lubrication procedures to ensure repeatable test conditions.

- Acceptance criteria and marking: defined pass/fail criteria for each test and marking requirements to support traceability and product selection.

Practical applications

- Manufacturers and product developers use EN 13126-17:2019 to design, validate and benchmark tilt-and-slide hardware against harmonized European test methods and durability grades.

- Test laboratories and certification bodies implement the standard’s procedures to deliver consistent, reproducible performance reports and declare conformity.

- Architects, specifiers and façade engineers rely on the classification and test results to select appropriate hardware for building types, door‑height windows and expected service life.

- Procurement and compliance teams use the standard to create performance specifications, compare suppliers and meet regulatory or tender requirements.

Benefits and SEO keywords

Using EN 13126-17:2019 helps ensure reliable tilt and slide window hardware, predictable service life, and verified corrosion resistance and safety performance. Relevant search terms: EN 13126-17:2019, tilt and slide windows hardware, building hardware standard, durability test, corrosion resistance EN 1670, sliding crash-tests, hardware classification.

Related standards

- EN 13126 series (parts 1–19) - other window and door hardware types

- EN 1670 - Corrosion resistance - requirements and test methods

For manufacturers and specifiers working with tilt-and-slide systems, EN 13126-17:2019 is the authoritative reference for consistent testing and performance classification.

Frequently Asked Questions

SIST EN 13126-17:2019 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Building hardware - Hardware for windows and door height windows - Requirements and test methods - Part 17: Hardware for Tilt and Slide windows". This standard covers: This part of EN 13126 specifies requirements and test methods for durability, strength, security and function of hardware for Tilt and Slide windows and door height windows in accordance with common application as shown in Figures C.1 and C.2 in informative Annex C.

This part of EN 13126 specifies requirements and test methods for durability, strength, security and function of hardware for Tilt and Slide windows and door height windows in accordance with common application as shown in Figures C.1 and C.2 in informative Annex C.

SIST EN 13126-17:2019 is classified under the following ICS (International Classification for Standards) categories: 91.190 - Building accessories. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13126-17:2019 has the following relationships with other standards: It is inter standard links to SIST EN 13126-17:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13126-17:2019 is associated with the following European legislation: EU Directives/Regulations: 305/2011. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13126-17:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2019

Nadomešča:

SIST EN 13126-17:2008

Stavbno okovje - Okovje za okna in zastekljena vrata - Zahteve in preskusne

metode - 17. del: Okovje za nagibno-drsna okna in vrata

Building hardware - Hardware for windows and door height windows - Requirements and

test methods - Part 17: Hardware for Tilt and Slide windows

Baubeschläge - Beschläge für Fenster und Fenstertüren - Anforderungen und

Prüfverfahren - Teil 17: Beschläge für Kippschiebe-Fenster und -Fenstertüren

Quincaillerie pour le bâtiment - Ferrures de fenêtres et portes-fenêtres - Exigences et

méthodes d'essai - Partie 17 : Ferrures pour fenêtres oscillo-coulissantes

Ta slovenski standard je istoveten z: EN 13126-17:2019

ICS:

91.190 Stavbna oprema Building accessories

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13126-17

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2019

EUROPÄISCHE NORM

ICS 91.190 Supersedes EN 13126-17:2008

English Version

Building hardware - Hardware for windows and door

height windows - Requirements and test methods - Part

17: Hardware for Tilt and Slide windows

Quincaillerie pour le bâtiment - Ferrures de fenêtres et Baubeschläge - Beschläge für Fenster und Fenstertüren

portes-fenêtres - Exigences et méthodes d'essai - Partie - Anforderungen und Prüfverfahren - Teil 17:

17 : Ferrures pour fenêtres oscillo-coulissantes Beschläge für Kippschiebe-Fenster und -Fenstertüren

This European Standard was approved by CEN on 8 March 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13126-17:2019 E

worldwide for CEN national Members.

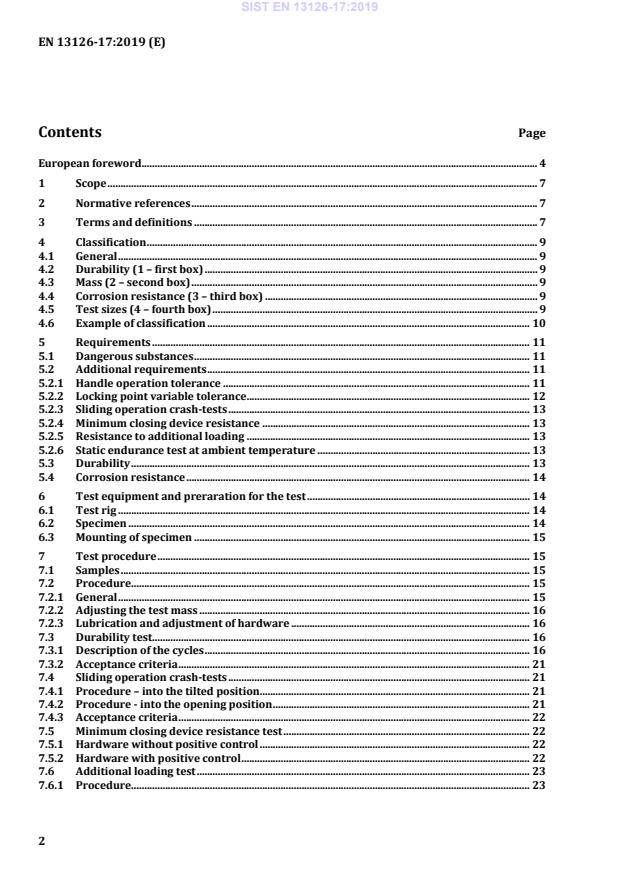

Contents Page

European foreword . 4

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Classification . 9

4.1 General . 9

4.2 Durability (1 – first box) . 9

4.3 Mass (2 – second box) . 9

4.4 Corrosion resistance (3 – third box) . 9

4.5 Test sizes (4 – fourth box) . 9

4.6 Example of classification . 10

5 Requirements . 11

5.1 Dangerous substances . 11

5.2 Additional requirements . 11

5.2.1 Handle operation tolerance . 11

5.2.2 Locking point variable tolerance . 12

5.2.3 Sliding operation crash-tests . 13

5.2.4 Minimum closing device resistance . 13

5.2.5 Resistance to additional loading . 13

5.2.6 Static endurance test at ambient temperature . 13

5.3 Durability . 13

5.4 Corrosion resistance . 14

6 Test equipment and preraration for the test . 14

6.1 Test rig . 14

6.2 Specimen . 14

6.3 Mounting of specimen . 15

7 Test procedure . 15

7.1 Samples . 15

7.2 Procedure. 15

7.2.1 General . 15

7.2.2 Adjusting the test mass . 16

7.2.3 Lubrication and adjustment of hardware . 16

7.3 Durability test. 16

7.3.1 Description of the cycles . 16

7.3.2 Acceptance criteria . 21

7.4 Sliding operation crash-tests . 21

7.4.1 Procedure – into the tilted position . 21

7.4.2 Procedure - into the opening position . 21

7.4.3 Acceptance criteria . 22

7.5 Minimum closing device resistance test . 22

7.5.1 Hardware without positive control . 22

7.5.2 Hardware with positive control . 22

7.6 Additional loading test . 23

7.6.1 Procedure. 23

7.6.2 Acceptance criteria . 23

7.7 Static endurance test at ambient temperature . 23

7.8 Corrosion resistance. 23

8 Marking . 24

Annex A (informative) Test assembly . 25

Annex B (informative) Flow chart of test procedure . 30

Annex C (informative) Window types . 31

Bibliography . 32

European foreword

This document (EN 13126-17:2019) has been prepared by Technical Committee CEN/TC 33 “Doors,

windows, shutters, building hardware and curtain walling”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2019, and conflicting national standards shall

be withdrawn at the latest by October 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13126-17:2008.

With regard to EN 13126-17:2008, the following significant changes were made:

— EN 13126-17 now is independent from EN 13126-1; all necessary information is included without

the need of any further information from EN 13126-1;

— several editorial changes in the wording for a better understanding;

— new terms and definitions added under 3.12 - 3.17;

— under 4.1 classification system changed completely; former digits 1 (Category of use), 4 (Fire

resistance), 5 (Safety in use), 7 (Security) and 8 (Applicable part) deleted; former digit 2 changed

into box 1 (Durability), former digit 3 changed into box 2 (Mass), former digit 6 changed into box 3

(Corrosion resistance) and former digit 9 changed into box 4 (Test sizes);

— under 4.2 new grades for the number of cycles defined; H1 (5 000), H2 (10 000) and H3 (20 000);

— under 4.6 new example of classification added in accordance with the new classification system; 2

alternative ways (table or alphanumerical) to show the classification defined;

— under Clause 6 “Test equipment and preparation for the test” additional information added for the

test rig (6.1), the specimen (6.2) and the mounting of the specimen (6.3);

— under 6.2 “Specimen” the use of gaskets added in the description instead of the prior counteracting

force of 20 N per locking point

— under 7.2 “Procedure” new subclause 7.2.1 “General”, 7.2.2 ”Adjusting the test mass” and 7.2.3

”Lubrication and adjustment of hardware” added with additional information, mainly from the

current version of part 1;

— under 7.3 “Durability test” procedure modified to ensure better correlation with the test procedure

described in EN 1191:2012;

— under 8 new clause added regarding marking with information from the current version of

EN 13126-1;

This European standard is one of a series of European standards for building hardware products for

windows and door height windows. This European standard is independent of EN 13126-1.

EN 13126 consists of the following parts:

— Building hardware — Hardware for windows and door height windows — Requirements and test

methods — Part 1: Requirements common to all types of hardware;

— Building hardware — Requirements and test methods for windows and doors height windows — Part

2: Window fastener handles;

— Building hardware — Hardware for windows and door-height windows — Requirements and test

methods — Part 3: Handles, primarily for Tilt&Turn, Tilt-First and Turn-Only hardware;

— Building hardware — Requirements and test methods for windows and doors height windows — Part

4: Espagnolettes;

— Building hardware — Hardware for windows and door height windows — Requirements and test

methods — Part 5: Devices that restrict the opening of windows and door height windows;

— Building hardware — Requirements and test methods for windows and doors height windows — Part

6: Variable geometry stay hinges (with or without a friction stay);

— Building hardware — Requirements and test methods for windows and door height windows — Part

7: Finger catches;

— Building hardware — Hardware for windows and door height windows — Part 8: Requirements and

test methods for Tilt and Turn, Tilt-First and Turn-Only hardware;

— Building hardware — Requirements and test methods for windows and door height windows — Part

9: Hardware for horizontal and vertical pivot windows;

— Building hardware — Requirements and test methods for windows and doors height windows — Part

10: Arm-balancing systems;

— Building hardware — Requirements and test methods for windows and doors height windows — Part

11: Top hung projecting reversible hardware;

— Building hardware — Requirements and test methods for windows and doors height windows — Part

12: Side hung projecting reversible hardware;

— Building hardware — Hardware for windows and balcony doors — Requirements and test methods —

Part 13: Sash balances;

— Building hardware — Hardware for windows and balcony doors — Requirements and test methods —

Part 14: Sash fasteners;

— Building hardware — Hardware for windows and doors height windows — Requirements and test

methods — Part 15: Rollers for horizontal sliding and hardware for sliding folding windows;

— Building hardware — Hardware for windows and doors height windows — Requirements and test

methods — Part 16: Hardware for Lift and Slide windows;

— Building hardware — Hardware for windows and doors height windows — Requirements and test

methods — Part 17: Hardware for Tilt and Slide windows;

— Building hardware — Requirements and test methods for windows and door height windows — Part

19: Sliding Closing Devices.

The performance tests incorporated in this European standard are considered to be reproducible and

as such will provide a consistent and objective assessment of the performance of these products

throughout CEN Member States.

A full contribution to the preparation of this European standard has been made by the European

manufacturers organization ‘ARGE’ and National Standards institutions.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

1 Scope

This document specifies requirements and test methods for durability, strength, security and function

of hardware for Tilt and Slide windows and door height windows in accordance with common

application as shown in Figures C.1 and C.2 in informative Annex C.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1670, Building hardware — Corrosion resistance — Requirements and test methods

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

The following terms and definitions apply to hardware for Tilt and Slide windows and door height

windows made of timber, PVC-U, aluminium or steel and their appropriate material combinations.

3.1

roller

assembly of one or more rolls in a single or multiple casing which supports Tilt and Slide windows and

door height windows which may be aligned in a straight line or rotate about an axis for Tilt and Slide

windows and door height windows (otherwise known as a bogey)

3.2

roll

singular wheel in a roller

3.3

lateral guide

hardware component that guides the lateral movement of the Tilt and Slide windows and door height

windows

3.4

guide track

track fixed on the top (top guide track) or bottom (bottom guide track) which enables a lateral guide to

run

3.5

rail

rail fixed on the top (top rail) or bottom (bottom rail) which enables the rollers to run

3.6

positive control

sash operation via the hardware which enables the sash to be moved from the closed position into the

tilted position, and from the tilted position into the closed position

Note 1 to entry: The sliding position can also be reached by means of operating the hardware.

3.7

locked closed position

situation in which the active sash rests up against the frame on all sides, the hardware is locked and the

window unit is completely closed

3.8

closed position

situation in which the active sash rests up against the frame on all sides, while the hardware is not yet

locked and in which the window unit is not completely closed

3.9

tilted position

situation in which the bottom of the active sash rests on the frame

Note 1 to entry: The top area is held in the final tilt position by means of the projecting mechanism.

3.10

sliding position

situation in which the active sash is disengaged on all sides, so that it can be moved in-line

3.11

opening position

situation in which the active sash is at the end of the sliding position (the largest possible opening

width)

3.12

sample

actual hardware components which is due to be tested

3.13

specimen

window with gaskets to accommodate hardware components (samples) for testing

3.14

test rig

testing device onto which the specimen is mounted

3.15

test equipment

series of various testing rigs, devices and machinery enabling testing to be carried out

3.16

supporting sub frame

supplementary fixing frame surrounding the specimen enabling it to be mounted on the test rig while

testing

Note 1 to entry: For example wood, steel or aluminium could be used.

3.17

rest time

time in seconds of a stationary period between the different steps

Note 1 to entry: A stationary period is between the following steps:

— between a change of direction of the moving of the sash;

— between the completion of a moving of the sash and the subsequent operating of the hardware;

— between the completion of the operation of the hardware and the subsequent moving of the sash;

— between two cycles.

4 Classification

4.1 General

Hardware for Tilt and Slide windows and door height windows shall be classified in accordance with

the four box coding system (see Table 1).

Table 1 — Classification system of hardware

Box 1 2 3 4

Durability Mass Corrosion resistance Test sizes

4.2 Durability (1 – first box)

The first box shall display the grade applied to the durability test in accordance with 5.3:

— grade H1: 5 000;

— grade H2: 10 000;

— grade H3: 20 000.

4.3 Mass (2 – second box)

The second box shall display the maximum tested sash-mass (weight).

The mass range starts from 50 kg and varies in steps of 10 kg. An unlimited number of grades are

identified, whereby 050 is the lowest (see Table 2).

Table 2 — Tested sash-mass

Grade 050 060 070 080 090 100 110 120 130 …

Mass (kg) 50 60 70 80 90 100 110 120 130 …

4.4 Corrosion resistance (3 – third box)

The third box shall display the grade regarding corrosion resistance in accordance with 5.4.

4.5 Test sizes (4 – fourth box)

The fourth box shall display the test sizes (active sash) which were used for testing the hardware for

Tilt and Slide windows and door height windows as follows:

SRW (= sash rebate width) in mm / SRH (= sash rebate height) in mm – tolerance ± 10 mm.

— 1 200 mm SRW / 2 000 mm SRH

The stated sizes are test sizes only. They do not relate to the maximum or minimum sizes to which a

window may be fabricated.

The manufacturer shall ensure, that with the application of the tested hardware in window sizes

deviating from the test sizes (smaller or larger), the forces on the hardware do not exceed those during

the durability test. This shall be reflected in the appropriate product documentation.

In the case of not being capable of manufacturing the specified test size due to the fact that the

hardware field of application is smaller than these specified test sizes, smaller test sizes shall be used. In

this case the window shall be tested in accordance with the largest possible SRW (or SRH) as specified

by the hardware manufacturers appropriate documentation and a SRH (or SRW) in a ratio of

2 000/1 200 (factor approximately 1,67).

This means that if the specified test sizes are larger than those which can be manufactured, the test

specimens shall be tested using the largest possible SRW or SRH in accordance with the manufacturer's

documentation and using a SRH to SRW ratio of 2 000/1 200 (factor approximately 1,67).

EXAMPLE 1 largest possible SRH = 800 mm = SRH of the test specimen

SRH = 800 mm × 2 000/1 200 = 1 333 mm = SRH of the test specimen

EXAMPLE 2 largest possible SRW = 1 600 mm = SRW of the test specimen

SRW = 1 600 mm × 1 200/2 000 = 960 mm = SRW of the test specimen

The missing dimensions in each case (SRH or SRW) should be calculated in accordance with example 1

or example 2 with the objective of establishing the maximum test-format, which lies within the

hardware manufacturers application range.

4.6 Example of classification

a) Alternative 1: Table with boxes

1 2 3 4

EN 13126-17:YYYY H2 120 3 1 200/2 000

In accordance with Clause 8 the information regarding the classification by using a table with boxes

shall always be shown together with the number of this standard EN 13126-17.

b) Alternative 2: Alphanumerical

EN 13126-17:YYYY H2-120-3-1 200/2 000

This denotes hardware for Tilt and Slide windows and door height windows, which have:

box 1 durability grade H2 (10 000 cycles)

box 2 mass 120 kg

box 3 corrosion resistance grade 3

box 4 test sizes SW = 1 200 mm / SH = 2 000 mm

5 Requirements

5.1 Dangerous substances

Materials in products should not release any dangerous substances in excess of the maximum levels

specified in the European material standards and any National regulations.

5.2 Additional requirements

5.2.1 Handle operation tolerance

The maximum torque T which is the result of a force of 100 N applied at a distance of 20 mm from the

,

h

end point of the handle, shall not be exceeded during the normal operation of the hardware.

The length of the handle used during the test or the length of the handle intended for the hardware set

shown in the hardware manufacturer’s documentation shall be recorded in the test report.

The torque Th resulting from the operative length of the used handle (key l2 in Figure 1) and the force of

100 N shall be calculated and recorded in the test report.

EXAMPLE length of the handle = 220 mm

operative length (key l in Figure 1) = 220 mm – 20 mm = 200 mm

torque T = operative length × force F = 200 mm × 100 N = 20 Nm

h

Dimensions in millimetres

Key

1 location for the force

l length of the handle

l operative length

2 force F = 100 N

Figure 1 — Handle length

5.2.2 Locking point variable tolerance

Before and after the durability test in accordance with 7.3, the distance “X” between the frame surface

and the sash-overlap-begin shall be measured. The results shall not differ by more than 1 mm (see

Figure 2).

Key

1 frame

2 sash

x measurement

Figure 2 — Measurement of locking point variable tolerance

5.2.3 Sliding operation crash-tests

After the sliding operation crash test in accordance with 7.4.1 and 7.4.2:

— active sash shall not drop and shall still be constrained by its fixings;

— active sash shall function correctly.

After the sliding operation crash-test all adjustment possibilities may be used to operate the sash.

5.2.4 Minimum closing device resistance

5.2.4.1 Hardware without positive control

The closing device shall withstand a torque T of 25 Nm.

hr

Upon completion of the test in accordance with 7.5.1, the closing device shall operate.

5.2.4.2 Hardware with positive control

The hardware shall withstand a torque T , which is the threefold torque T as calculated and recorded

hr h

in accordance with 5.2.1.

EXAMPLE length of the handle (key l in Figure 1) = 220 mm

operative length (key l in Figure 1) = 220 mm – 20 mm = 200 mm

torque T = operative length × force F = 200 mm × 100 N = 20 Nm

h

torque T = 3 × T = 3 × 20 Nm = 60 Nm

hr h

The closing device shall operate upon completion of the test in accordance with 7.5.2.1 and 7.5.2.2.

5.2.5 Resistance to additional loading

After the additional loading test in accordance with 7.6 the active sash shall not drop and shall still be

constrained by its fixings.

It is not necessary for the sash to operate during and after the additional loading test.

5.2.6 Static endurance test at ambient temperature

An additional endurance test at ambient temperature in accordance with 7.7 is required.

Before and upon completion of the endurance test in accordance with 7.7, no roll shall deviate by more

than 0,5 % of its initial diameter.

5.3 Durability

The manufacturer specifies one of the following 3 grades for the number of cycles, with which the

durability test shall be carried out:

— grade H1: 5 000 cycles (+ 1 %);

— grade H2: 10 000 cycles (+ 1 %);

— grade H3: 20 000 cycles (+ 1 %).

5.4 Corrosion resistance

Hardware shall conform to the grades listed in EN 1670.

Unless already stated with a test report by the manufacturer, relevant components which are

representative for the hardware shall be tested in accordance with EN 1670. The hardware components

shall not be mounted on a window profile for the corrosion test.

NOTE The evaluation of the corrosion resistance is limited to the essential areas (as a rule, the visible

surfaces of the installed hardware).

Exempt from the corrosion resistance evaluation are:

— rivet locations;

— locations of later processing (for example: cleaved surfaces that result from cropping the hardware

components, millings etc.);

— non surface-treated parts/surfaces, provided they are not in the visible vicinity of the hardware

(for example: screw guide-holes made of zinc die-cast, etc.);

— welding joints and their immediate surroundings;

— areas of corrosion as a result of contact corrosion.

6 Test equipment and preraration for the test

6.1 Test rig

The test rig shall be so rigid that any deformation during the tests shall have no influence on the results.

The test shall be conducted on a test rig which corresponds in function and shape to the sash for which

the hardware is intended. The dimensions of the test rig shall conform to 4.5.

See informative Annex A / Figure A.1.

6.2 Specimen

Hardware sets for Tilt and Slide windows and door height windows shall be mounted in a specimen in

accordance with the manufacturer’s instructions. Gaskets shall be used. The hardware tested shall

conform to the manufacturer's recommendations for size and mass of the specimen. The tolerance for

the specimen (test sizes) is ± 10 mm.

The specimen to be tested shall correspond in function, shape and material for which the hardware is

intended. The specimen shall be infilled with an adequately rigid timber-based panel, PVC, steel or

timber-composite material; this substitutes the glazing.

The specimen shall be installed in a supporting sub-frame using common-practice building procedures.

The circumferential clearance between the frame member and the sub-frame shall be 5 mm to 10 mm,

with the exception of the bottom part of the specimen; the area at the fasteners should be compression

resistant packed. As a rule, fixings should be spaced (150 ± 50) mm from the corners; additional fixings

shall be with a distance of 400 mm to 600 mm.

The general tolerance in this standard is +5 % unless otherwise specified.

The hardware manufacturer should provide complete test specimens for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...