SIST EN 16603-35-06:2022

(Main)Space engineering - Cleanliness requirements for spacecraft propulsion hardware

Space engineering - Cleanliness requirements for spacecraft propulsion hardware

EN 16603-35-06 (equivalent of ECSS-E-ST-35-06) belongs to the Propulsion field of the mechanical discipline, and concerns itself with the cleanliness of propulsion components, sub-systems and systems

The standard

- defines design requirements which allow for cleaning of propulsion components sub-systems and systems and which avoid generation or unwanted collection of contamination,

- identifies cleanliness requirements (e.g. which particle / impurity / wetness level can be tolerated),

- defines requirements on cleaning to comply with the cleanliness level requirements, and the requirements on verification,

- identifies the cleanliness approach, cleaning requirements, (e.g. what needs to be done to ensure the tolerable level is not exceeded, compatibility requirements),

- identifies, specifies and defines the requirements regarding conditions under which cleaning or cleanliness verification takes place (e.g. compatibility, check after environmental test).

The standard is applicable to the most commonly used propulsion systems and their related storable propellant combinations: Hydrazine (N2H4), Mono Methyl Hydrazine (CH3N2H3), MON (Mixed Oxides of Nitrogen), Nitrogen (N2), Helium (He), Propane (C3H8), Butane (C4H10) and Xenon (Xe).

This standard is the basis for the European spacecraft and spacecraft propulsion industry to define, achieve and verify the required cleanliness levels in spacecraft propulsion systems.

This standard is particularly applicable to spacecraft propulsion as used for satellites and (manned) spacecraft and any of such projects including its ground support equipment.

External cleanliness requirements, e.g. outside of tanks, piping and aspects such as fungus and outgassing are covered by ECSS-Q-ST-70-01.

This standard may be tailored for the specific characteristic and constraints of a space project in conformance with ECSS-S-ST-00.

Raumfahrttechnik - Sauberkeitsanforderungen für die Antriebstechnik von Raumfahrzeugen

EN 16603-35-06 (equivalent of ECSS-E-ST-35-06) belongs to the Propulsion field of the mechanical discipline, and concerns itself with the cleanliness of propulsion components, sub-systems and systems The standard

• defines design requirements which allow for cleaning of propulsion components sub-systems and systems and which avoid generation or unwanted collection of contamination,

• identifies cleanliness requirements (e.g. which particle / impurity / wetness level can be tolerated),

• defines requirements on cleaning to comply with the cleanliness level requirements, and the requirements on verification,

• identifies the cleanliness approach, cleaning requirements, (e.g. what needs to be done to ensure the tolerable level is not exceeded, compatibility requirements),

• identifies, specifies and defines the requirements regarding conditions under which cleaning or cleanliness verification takes place (e.g. compatibility, check after environmental test).

The standard is applicable to the most commonly used propulsion systems and their related storable propellant combinations: Hydrazine (N2H4), Mono Methyl Hydrazine (CH3N2H3), MON (Mixed Oxides of Nitrogen), Nitrogen (N2), Helium (He), Propane (C3H8), Butane (C4H10) and Xenon (Xe).

This standard is the basis for the European spacecraft and spacecraft propulsion industry to define, achieve and verify the required cleanliness levels in spacecraft propulsion systems.

This standard is particularly applicable to spacecraft propulsion as used for satellites and (manned) spacecraft and any of such projects including its ground support equipment.

External cleanliness requirements, e.g. outside of tanks, piping and aspects such as fungus and outgassing are covered by ECSS-Q-ST-70-01.

This standard may be tailored for the specific characteristic and constraints of a space project in conformance with ECSS-S-ST-00.

Ingénierie spatiale - Exigences de propreté du matériel de propulsion des engins spatiaux

L'ECSS-E-ST-35-06 relève du domaine de la Propulsion rattaché à la discipline mécanique, et traite de la propreté des composants, des sous-systèmes et des systèmes de propulsion.

La présente norme

• définit les exigences de conception pour permettre le nettoyage des composants, sous-systèmes et systèmes et éviter la génération ou l'accumulation indésirable de contamination,

• identifie les exigences de propreté (par exemple : niveau de particules/d'impureté/d'humidité tolérable),

• définit les exigences à observer en matière de nettoyage afin de se conformer aux exigences de niveau de propreté, ainsi qu'aux exigences de vérification,

• identifie l'approche à adopter en termes de propreté, les exigences de nettoyage (par exemple : les actions à mener pour garantir de ne pas excéder le niveau tolérable, les exigences en termes de compatibilité),

• identifie, spécifie et définit les exigences relatives aux conditions dans lesquelles les opérations de nettoyage ou de vérification de la propreté se déroulent (par exemple : compatibilité, contrôle après essai environnemental).

La présente norme s'applique aux systèmes de propulsion les plus couramment utilisés, ainsi qu'à leurs combinaisons correspondantes de propergols stockables : hydrazine (N2H4), monométhylhydrazine (CH3N2H3), MON (oxydes d'azote mélangés), azote (N2), hélium (He), propane (C3H8), butane (C4H10) et xénon (Xe).

La présente norme constitue pour l'industrie européenne des engins spatiaux et de la propulsion spatiale un cadre de référence pour définir, atteindre et vérifier les niveaux de propreté requis dans les systèmes de propulsion des engins spatiaux.

Cette norme s'applique plus particulièrement à la propulsion spatiale utilisée pour les satellites et les engins spatiaux (habités), ainsi qu'à tout projet connexe, en incluant les équipements de support au sol correspondants.

Les exigences de propreté extérieure, par exemple, extérieur des réservoirs, tuyauterie et autres aspects tels que les champignons et le dégazage, sont couvertes dans l'ECSS-Q-ST-70-01.

La présente norme peut être adaptée aux caractéristiques et contraintes spécifiques d'un projet spatial conformément à l'ECSS-S-ST-00.

Vesoljska tehnika - Zahteve za čistočo pogonske tehnike vesoljskih plovil

Standard EN 16603-35-06 (enakovreden standardu ECSS-E-ST-35-06) pripada pogonskemu področju strojne discipline in zajema zahteve za čistočo pogonskih sestavnih delov, podsistemov in sistemov.

Standard:

– določa zahteve za projektiranje, ki omogočajo čiščenje pogonskih sestavnih delov, podsistemov in sistemov ter preprečujejo nastanek ali neželeno nabiranje onesnaženja;

– določa zahteve za čistočo (npr. kateri delec/nečistoča/raven vlažnosti je še dopusten);

– določa zahteve glede čiščenja v skladu z zahtevami ravni čistoče in zahtevami za preverjanje;

– opredeljuje pristop za čistočo, zahteve za čiščenje (npr. kaj je treba storiti, da se zagotovi, da dopustna raven ni presežena, zahteve za združljivost);

– opredeljuje, specificira in določa zahteve v zvezi s pogoji, pod katerimi poteka preverjanje čiščenja ali čistoče (npr. združljivost, preverjanje po okoljskem preskusu).

Ta standard se uporablja za večino najpogosteje uporabljenih pogonskih sistemov in njihovih povezanih kombinacij pogonskih goriv, ki jih je mogoče shraniti: hidrazin (N2H4), monometil hidrazin (CH3N2H3), MON (mešani dušikovi oksidi), dušik (N2), helij (He), propan (C3H8), butan (C4H10) in ksenon (Xe).

Ta standard je osnova za evropsko industrijo vesoljskih plovil in pogonsko industrijo za vesoljska plovila za določitev, doseganje ter preverjanje zahtevanih ravni čistoče v pogonskem sistemu vesoljskega plovila.

Ta standard se uporablja predvsem za pogon vesoljskih plovil, kot se ta uporablja za satelite in vesoljska plovila (s posadko) in katerega koli od teh projektov, vključno s podporno opremo na tleh.

Zahteve za zunanjo čistočo, npr. zunaj rezervoarjev in cevi, ter vidiki, kot so glive in razplinjevanje, so zajete v standardu ECSS-Q-ST-70-01.

Ta standard se lahko prilagodi posameznim lastnostim in omejitvam vesoljskega projekta v skladu s standardom ECSS-S-ST-00.

General Information

- Status

- Published

- Public Enquiry End Date

- 08-Sep-2021

- Publication Date

- 17-Jul-2022

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 13-Jul-2022

- Due Date

- 17-Sep-2022

- Completion Date

- 18-Jul-2022

Relations

- Effective Date

- 13-Jul-2022

- Effective Date

- 02-Dec-2020

Overview - EN 16603-35-06:2022 (Space engineering)

EN 16603-35-06:2022 (equivalent to ECSS‑E‑ST‑35‑06) is a CEN European standard that defines cleanliness requirements for spacecraft propulsion hardware. It sets design, manufacturing, cleaning and verification requirements to prevent, remove and control contamination in propulsion components, subsystems and systems. The standard is the European baseline for defining, achieving and verifying acceptable cleanliness for common storable propellant combinations and covers satellite and manned-spacecraft propulsion and related ground support equipment (GSE).

Key keywords: EN 16603-35-06:2022, cleanliness requirements, spacecraft propulsion, propulsion hardware, propellant cleanliness, ECSS‑E‑ST‑35‑06.

Key topics and technical requirements

- Design for cleanability: Requirements that components and systems be designed to enable effective cleaning and to avoid generation or trapping of contaminants.

- Cleanliness classes and limits: Definitions and classification of allowable contamination by particulates, non‑volatile residues (NVR) and liquid/wetness-including criteria and test methods.

- Cleaning processes: Requirements for pre‑cleaning, precision cleaning, drying (purge and vacuum), acceptable cleaning fluids and process controls.

- Verification and acceptance: Test and inspection methods (e.g., liquid flush, liquid flow, gas flow tests), sampling, microscopic particle counting, gravimetric NVR analysis, visual/UV inspection and dryness verification.

- Environmental and procedural controls: Controlled environments, safety, packaging, protection, labeling and maintenance of cleanliness during assembly, transport and storage.

- Scope of propellants: Applicable to Hydrazine (N2H4), MMH, MON, N2, He, Propane, Butane and Xenon.

- Supporting documentation: Normative annexes include Cleanliness Requirements Analysis (CRA), Cleaning Technique Selection (CTS), Cleanliness Certificate (CC), lists of test/cleaning liquids and pre‑cleaning sequences.

Applications - who uses this standard

- Spacecraft propulsion engineers and system designers (design-for-cleaning, material selection)

- Manufacturing and production engineers (process controls, machining, tubing/manifolds)

- Cleaning technicians and precision‑cleaning facilities (methods, fluids, drying)

- Quality assurance, verification and test teams (sampling plans, acceptance criteria)

- Ground Support Equipment (GSE) designers and operations teams

- Project managers and procurements specifying contractual cleanliness deliverables

Related standards

- ECSS‑Q‑ST‑70‑01: covers external cleanliness aspects (fungus, outgassing) outside tanks and piping.

- ECSS‑S‑ST‑00: guidance for tailoring the standard to specific project constraints.

- EN 16603‑35‑06:2022 supersedes the 2014 edition.

This standard provides practical, auditable requirements and test methods to ensure reliable propulsion performance by controlling particulate, chemical and liquid contamination across the propulsion lifecycle.

Frequently Asked Questions

SIST EN 16603-35-06:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Space engineering - Cleanliness requirements for spacecraft propulsion hardware". This standard covers: EN 16603-35-06 (equivalent of ECSS-E-ST-35-06) belongs to the Propulsion field of the mechanical discipline, and concerns itself with the cleanliness of propulsion components, sub-systems and systems The standard - defines design requirements which allow for cleaning of propulsion components sub-systems and systems and which avoid generation or unwanted collection of contamination, - identifies cleanliness requirements (e.g. which particle / impurity / wetness level can be tolerated), - defines requirements on cleaning to comply with the cleanliness level requirements, and the requirements on verification, - identifies the cleanliness approach, cleaning requirements, (e.g. what needs to be done to ensure the tolerable level is not exceeded, compatibility requirements), - identifies, specifies and defines the requirements regarding conditions under which cleaning or cleanliness verification takes place (e.g. compatibility, check after environmental test). The standard is applicable to the most commonly used propulsion systems and their related storable propellant combinations: Hydrazine (N2H4), Mono Methyl Hydrazine (CH3N2H3), MON (Mixed Oxides of Nitrogen), Nitrogen (N2), Helium (He), Propane (C3H8), Butane (C4H10) and Xenon (Xe). This standard is the basis for the European spacecraft and spacecraft propulsion industry to define, achieve and verify the required cleanliness levels in spacecraft propulsion systems. This standard is particularly applicable to spacecraft propulsion as used for satellites and (manned) spacecraft and any of such projects including its ground support equipment. External cleanliness requirements, e.g. outside of tanks, piping and aspects such as fungus and outgassing are covered by ECSS-Q-ST-70-01. This standard may be tailored for the specific characteristic and constraints of a space project in conformance with ECSS-S-ST-00.

EN 16603-35-06 (equivalent of ECSS-E-ST-35-06) belongs to the Propulsion field of the mechanical discipline, and concerns itself with the cleanliness of propulsion components, sub-systems and systems The standard - defines design requirements which allow for cleaning of propulsion components sub-systems and systems and which avoid generation or unwanted collection of contamination, - identifies cleanliness requirements (e.g. which particle / impurity / wetness level can be tolerated), - defines requirements on cleaning to comply with the cleanliness level requirements, and the requirements on verification, - identifies the cleanliness approach, cleaning requirements, (e.g. what needs to be done to ensure the tolerable level is not exceeded, compatibility requirements), - identifies, specifies and defines the requirements regarding conditions under which cleaning or cleanliness verification takes place (e.g. compatibility, check after environmental test). The standard is applicable to the most commonly used propulsion systems and their related storable propellant combinations: Hydrazine (N2H4), Mono Methyl Hydrazine (CH3N2H3), MON (Mixed Oxides of Nitrogen), Nitrogen (N2), Helium (He), Propane (C3H8), Butane (C4H10) and Xenon (Xe). This standard is the basis for the European spacecraft and spacecraft propulsion industry to define, achieve and verify the required cleanliness levels in spacecraft propulsion systems. This standard is particularly applicable to spacecraft propulsion as used for satellites and (manned) spacecraft and any of such projects including its ground support equipment. External cleanliness requirements, e.g. outside of tanks, piping and aspects such as fungus and outgassing are covered by ECSS-Q-ST-70-01. This standard may be tailored for the specific characteristic and constraints of a space project in conformance with ECSS-S-ST-00.

SIST EN 16603-35-06:2022 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16603-35-06:2022 has the following relationships with other standards: It is inter standard links to SIST EN 16603-35-06:2014, SIST EN 16603-35-06:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 16603-35-06:2022 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 16603-35-06:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2022

Nadomešča:

SIST EN 16603-35-06:2014

Vesoljska tehnika - Zahteve za čistočo pogonske tehnike vesoljskih plovil

Space engineering - Cleanliness requirements for spacecraft propulsion hardware

Raumfahrttechnik - Sauberkeitsanforderungen für die Antriebstechnik von

Raumfahrzeugen

Ingénierie spatiale - Exigences de propreté du matériel de propulsion des engins

spatiaux

Ta slovenski standard je istoveten z: EN 16603-35-06:2022

ICS:

49.140 Vesoljski sistemi in operacije Space systems and

operations

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD EN 16603-35-06

NORME EUROPÉENNE

EUROPÄISCHE NORM

July 2022

ICS 49.140

Supersedes EN 16603-35-06:2014

English version

Space engineering - Cleanliness requirements for

spacecraft propulsion hardware

Ingénierie spatiale - Exigences de propreté du matériel Raumfahrttechnik - Sauberkeitsanforderungen für die

de propulsion des engins spatiaux Antriebstechnik von Raumfahrzeugen

This European Standard was approved by CEN on 20 April 2022.

CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for

giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical

references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to

any CEN and CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium,

Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy,

Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North Macedonia, Romania, Serbia,

Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

CEN-CENELEC Management Centre:

Rue de la Science 23, B-1040 Brussels

© 2022 CEN/CENELEC All rights of exploitation in any form and by any means

Ref. No. EN 16603-35-06:2022 E

reserved worldwide for CEN national Members and for

CENELEC Members.

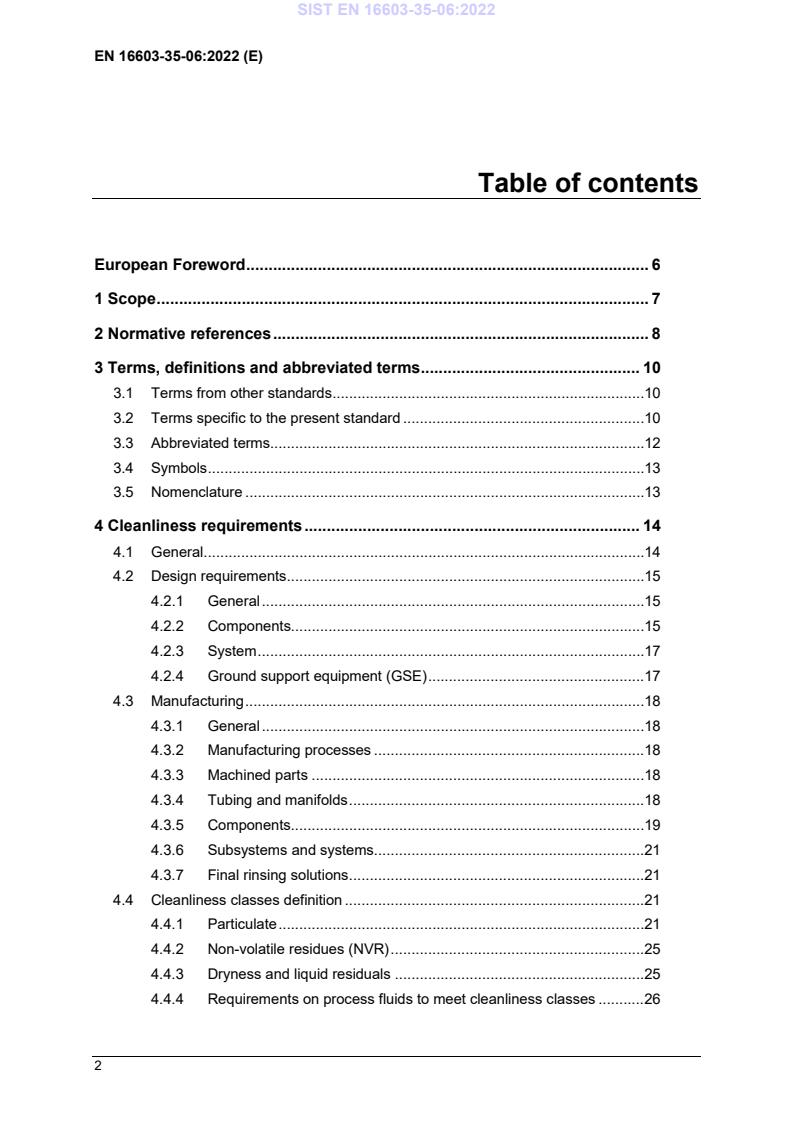

Table of contents

European Foreword . 6

1 Scope . 7

2 Normative references . 8

3 Terms, definitions and abbreviated terms . 10

3.1 Terms from other standards .10

3.2 Terms specific to the present standard .10

3.3 Abbreviated terms. 12

3.4 Symbols .13

3.5 Nomenclature .13

4 Cleanliness requirements . 14

4.1 General .14

4.2 Design requirements .15

4.2.1 General . 15

4.2.2 Components.15

4.2.3 System .17

4.2.4 Ground support equipment (GSE) . 17

4.3 Manufacturing .18

4.3.1 General . 18

4.3.2 Manufacturing processes . 18

4.3.3 Machined parts .18

4.3.4 Tubing and manifolds .18

4.3.5 Components.19

4.3.6 Subsystems and systems. 21

4.3.7 Final rinsing solutions .21

4.4 Cleanliness classes definition .21

4.4.1 Particulate .21

4.4.2 Non-volatile residues (NVR) .25

4.4.3 Dryness and liquid residuals .25

4.4.4 Requirements on process fluids to meet cleanliness classes . 26

4.5 Test methods . 27

4.6 Code usage .27

5 Cleaning techniques . 28

5.1 General .28

5.2 Environment, health and safety.29

5.2.1 General . 29

5.2.2 Hardware configuration requirements. 29

5.2.3 Cleaning process approval .30

5.3 Pre-cleaning .30

5.3.1 General . 30

5.3.2 Mechanical pre-cleaning .30

5.3.3 Chemical pre-cleaning .31

5.4 Precision cleaning.32

5.4.1 General . 32

5.4.2 Re-cleaning operational systems . 32

5.5 Drying methods .33

5.5.1 General . 33

5.5.2 Gaseous purge-drying .33

5.5.3 Drying sample .34

5.5.4 Flow rates during purging . 35

5.5.5 Vacuum drying procedure .35

5.6 Excepted components, subsystems and systems . 36

6 Cleanliness verification requirements . 37

6.1 Surface .37

6.1.1 Visual and UV inspection . 37

6.1.2 pH-test .37

6.2 Acceptance inspection of items cleaned in a controlled environment . 38

6.2.1 General . 38

6.2.2 Test fluids .38

6.2.3 Test fluid volume for analysis .38

6.2.4 Analysis of test fluid-flush sample (solvent) . 39

6.2.5 Analysis of aqueous-based, liquid-flush sample . 40

6.2.6 Drying .41

6.2.7 Vacuum drying .41

6.3 Maintaining cleanliness .42

6.3.1 Pressurant gas purge .42

6.3.2 Installation and marking of temporary hardware . 42

6.3.3 Temporary hardware replacement . 42

6.3.4 Component replacement .43

6.4 Dryness verification .43

6.4.1 General . 43

6.4.2 Purge dryness .43

6.4.3 Vacuum dryness .43

6.4.4 Sample test and qualified procedure . 44

7 Acceptance inspection of packaging materials . 45

7.1 Environmental control .45

7.2 Sampling .45

7.3 Thickness of packaging film .45

7.4 Static electricity .46

7.5 Verification of cleanliness level .46

7.5.1 General . 46

7.5.2 Minimum surface area for test .46

7.5.3 Sample preparation .46

7.5.4 Rinsing procedures .47

8 Packaging and protection . 48

8.1 Approved coverings .48

8.2 Packaging operations .48

8.3 Certification labels .48

9 Deliverables . 50

10 Test procedures . 51

10.1 Test liquid-flush procedure (solvent) .51

10.2 Gas flow test procedure .51

11 Sampling and analytical practices . 52

11.1 Cleanliness level test methods.52

11.1.1 General . 52

11.1.2 Method I “Liquid Flush Test” .52

11.1.3 Method II “Liquid Flow Test” .53

11.1.4 Method III “Gas Flow Test” .53

11.1.5 Method IV “Liquid flow test under operating conditions” . 53

12 Determination of particle population and NVR analysis . 55

12.1 Microscopic particle population .55

12.2 Gravimetric NVR analysis method . 56

Annex A (normative) Cleanliness Requirements Analysis (CRA) for

spacecraft propulsion components, subsystems and systems - DRD . 57

Annex B (normative) Cleaning Technique Selection (CTS) for spacecraft

propulsion components, subsystems and systems - DRD . 59

Annex C (normative) Cleanliness Certificate (CC) for spacecraft

propulsion components, subsystems and systems - DRD . 61

Annex D (normative) Typical test and cleaning liquids. 64

Annex E (informative) Pre-cleaning sequences . 67

Annex F (informative) Cleanliness certificate . 69

Bibliography . 71

Figures

Figure F-1 : Example of a cleanliness certificate.70

Tables

Table 4-1: Cleanliness classes .24

Table 4-2: NVR contamination levels .25

Table 4-3: Visible contamination levels .27

Table 7-1: Packaging materials .46

Table D-1 : Typical test and cleaning fluids . 64

Table E-1 : Typical pre-cleaning sequence for common materials . 67

European Foreword

This document (EN 16602-20-07:2016) has been prepared by Technical Committee CEN-CENELEC/TC 5

“Space”, the secretariat of which is held by DIN.

This standard (EN 16602-20-07:2016) originates from ECSS-Q-ST-20-07C.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2023, and conflicting national standards shall

be withdrawn at the latest by January 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 16603-35-06:2014.

The main changes with respect to EN 16603-35-06:2014 are listed below:

• Implementation of Change Requests received to the ECSS equivalent standard

• Addition of the Nomenclature in clause 3.5

• Definition of “accuracy” deleted in 3.2 and reference to ECSS-S-ST-00-01 made in 3.1

• Definition “condensable hydrocarbon” and “dewar” deleted in clause 3.2 as they were not used in

the standard

• Added requirements 6.4.3d.

• Modifed requirements: 4.1h Note 2 (reference to Figure of other ECSS Standard corrected); 6.2.6.2a;

6.4.3a; 6.4.3c; 12.1a; 12.2c Note to item 10 moved to the end of the requirement.

• Interleaved Notes in requirement 12.1a move to the end of the requirement

• Cross-reference in Annex B.1.1 to added requirement 6.4.3d created

• Caption of Table in Annex D corrected from “Table A-1” to “Table D-1”.

This document has been prepared under a standardization request given to CEN by the European

Commission and the European Free Trade Association.

This document has been developed to cover specifically space systems and has therefore precedence

over any EN covering the same scope but with a wider domain of applicability (e.g. : aerospace).

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden,

Switzerland, Turkey and the United Kingdom.

Scope

ECSS-E-ST-35-06 belongs to the Propulsion field of the mechanical discipline, and

concerns itself with the cleanliness of propulsion components, sub-systems and

systems

The standard

• defines design requirements which allow for cleaning of propulsion

components sub-systems and systems and which avoid generation or

unwanted collection of contamination,

• identifies cleanliness requirements (e.g. which particle / impurity / wetness

level can be tolerated),

• defines requirements on cleaning to comply with the cleanliness level

requirements, and the requirements on verification,

• identifies the cleanliness approach, cleaning requirements, (e.g. what

needs to be done to ensure the tolerable level is not exceeded, compatibility

requirements),

• identifies, specifies and defines the requirements regarding conditions

under which cleaning or cleanliness verification takes place (e.g.

compatibility, check after environmental test).

The standard is applicable to the most commonly used propulsion systems and

their related storable propellant combinations: Hydrazine (N2H4), Mono Methyl

Hydrazine (CH3N2H3), MON (Mixed Oxides of Nitrogen), Nitrogen (N2), Helium

(He), Propane (C3H8), Butane (C4H10) and Xenon (Xe).

This standard is the basis for the European spacecraft and spacecraft propulsion

industry to define, achieve and verify the required cleanliness levels in spacecraft

propulsion systems.

This standard is particularly applicable to spacecraft propulsion as used for

satellites and (manned) spacecraft and any of such projects including its ground

support equipment.

External cleanliness requirements, e.g. outside of tanks, piping and aspects such

as fungus and outgassing are covered by ECSS-Q-ST-70-01.

This standard may be tailored for the specific characteristic and constraints of a

space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through

reference in this text, constitute provisions of this ECSS Standard. For dated

references, subsequent amendments to, or revisions of any of these publications,

do not apply. However, parties to agreements based on this ECSS Standard are

encouraged to investigate the possibility of applying the most recent editions of

the normative documents indicated below. For undated references the latest

edition of the publication referred to applies.

EN reference Reference in text Title

EN 16601-00 ECSS-S-ST-00-01 ECSS system — Glossary of terms

EN 16603-35 ECSS-E-ST-35 Space engineering — Propulsion general

requirements

EN 16602-40 ECSS-Q-ST-40 Space product assurance — Safety

EN 16602-70-01 ECSS-Q-ST-70-01 Space product assurance — Cleanliness and

contamination control.

EN 16602-70 ECSS-Q-ST-70 Space product assurance — Materials, mechanical

parts and processes

ISO 2210:1972 Liquid halogenated hydrocarbons for industrial use-

Determination of residue on evaporation

ISO 5789:1979 Fluorinated hydrocarbons for industrial use —

Determination of non-volatile residue

ISO 5884:1987 Aerospace — Fluid systems and components —

Methods for system sampling and measuring the

solid particle contamination of hydraulic fluids

ISO 14951-3:2000 Space systems —Fluid characteristics —Part 3:

Nitrogen

ISO 14951-4:2000 Space systems — Fluid characteristics —Part 4:

Helium

ISO 14951-10:2000 Space systems — Fluid characteristics —Part 10:

Water

ISO 14952-3:2003 Space systems — Surface cleanliness of fluid systems

— Part 3: Analytical procedures for the

determination of non-volatile residues and

particulate contamination

ASTM D257(99) 2005 Standard Test Method for DC Resistance or

Conductance of Insulating Materials

ASTM D329 10 Dec Standard specification for Acetone

EN reference Reference in text Title

ASTM D740 Standard specification for Methyl Ethyl Ketone

15 May 2005

ASTM D770-05 Standard specification for Isopropyl Alcohol

15 May 2005

ASTM D1152 Standard specification for Methanol (Methyl

1 Apr 2006 Alcohol)

ASTM D1293 10 Dec Standard test methods for pH of water

ASTM D4376 Standard specification for vapor-degreasing grade

Perchloroethylene

MIL-PRF-27415B Performance specification, propellant pressurizing

8 Feb 2007 agent, Argon

O-E-760D Federal specification

28 May 1987

SEMI C47-0699 Guideline for Trans 1,2 Dichloroethylene

May 1999

Terms, definitions and abbreviated terms

3.1 Terms from other standards

a. For the purpose of this Standard, the terms and definitions from ECSS-S-

ST-00-01 apply, in particular for the following term:

1. accuracy

b. For the purpose of this Standard, the terms and definitions from ECSS-E-

ST-35 apply.

3.2 Terms specific to the present standard

3.2.1 blank

result for an analytical sample of the virgin test fluid prior to use in performing

a cleanliness verification test

3.2.2 cleanliness verification

activity intended to verify that the actual cleanliness conditions of an item are in

conformance with the applicable specification

3.2.3 crazing

creating microvoids in glassy thermoplastic polymers preceding the formation of

cracks

3.2.4 critical surface

any surface of an item that contacts the service medium

NOTE Examples of service media are propellants and

pressurants.

3.2.5 dew point

temperature at which condensation of water vapour takes place at prevailing

pressure

NOTE The prevailing pressure is usually atmospheric

pressure.

3.2.6 fibre

flexible structure having a length-to-width ratio of 10 to 1 or greater

NOTE 1 A fibre is considered to be a particle, see clause

3.2.11.

NOTE 2 The size of a fibre is its maximum length.

3.2.7 field cleaning

processes of pre-cleaning and precision cleaning of components, subsystems and

systems which cannot be processed in a controlled environment such as a clean

room

3.2.8 generally clean

free from manufacturing residue, dirt, oil, grease, processing debris, or other

extraneous contamination based on visual examination

3.2.9 high-efficiency particulate air filter

filter that is at least 99,97 % efficient by volume on 0,3 μm particles

3.2.10 non-volatile residue

soluble or suspended material and insoluble particulate matter remaining after

temperature-controlled evaporation of a volatile liquid

NOTE See also clause 6.2.4.3

3.2.11 particle

unit of solid matter with observable size

NOTE 1 Various methods for defining its size may be

used and are dependant upon the measurement

technique.

NOTE 2 For the manual method the apparent maximum

linear dimension of a particle in the plane of

observation as observed with instruments such

as optical, electron, or atomic force microscopes

is the particle size.

NOTE 3 For the automatic method, the equivalent

diameter of a particle detected by automatic

instrumentation is the particle size.

NOTE 4 The equivalent diameter is the diameter of a

reference sphere having known properties and

producing the same response in the sensing

instrument as the particle being measured.

NOTE 5 A fibre is considered a particle, see clause 3.2.6.

3.2.12 passivation

process by which a corrosion-resistant layer is formed on a metal surface by

submersing the surface in an acid solution

3.2.13 pickling

chemical or electrochemical process by which surface oxides are removed from

metals

3.2.14 precision cleaning

cleaning process used to achieve cleanliness levels more stringent than visibly

clean

3.2.15 pre-cleaning

cleaning process normally used to achieve the visibly clean cleanliness level

3.2.16 reversion

decrease in viscosity, strength, or in rubber modulus due to heating or

overworking, resulting in a tacky and soft material

3.2.17 silting

accumulation of particles of sufficient quantity to cause a haze or obscuring of

any portion of a filter membrane when viewed visually or under 40-power

maximum magnification

3.2.18 test fluid

specified fluid that is utilized to determine the fluid system wetted-surface

cleanliness level

3.2.19 threshold limit value

maximum average daily dosage, based on an 8-h day, 5-day week, to which an

average worker may be exposed to hazardous chemicals without harmful effect

NOTE 1 The TLV is a time-weighted average

concentration.

NOTE 2 The TLV is normally expressed in parts of the

gas or vapour in micro litres per litre.

3.2.20 visibly clean

absence of surface contamination when examined with a specific light source,

angle of incidence, and viewing distance using normal or magnified vision up to

×20

3.2.21 visibly clean plus ultraviolet

cleaning level that is visibly clean and also meets the requirements for inspection

with the aid of an ultraviolet light of wavelength 250 nm to 395 nm

3.2.22 volatile hydrocarbon

hydrocarbon capable of going from liquid or solid to a gaseous state at ambient

temperature and pressure

3.3 Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSS-S-ST-00-01

and the following apply:

Abbreviation Meaning

CC cleanliness certificate

CRA cleaning requirement analysis

CTS cleaning technique selection

GC generally clean

HEPA high-efficiency particulate air filter

HFE hydro fluor ether (Per fluoro-n-butyl methyl ether)

IPA isopropanol

MAIT manufacturing, assembly, integration and test

MEK methyl ethyl keton

MS mass spectroscopy

NVR non-volatile residue

ppmv parts per million, volumetric

TLV threshold limit value

US ultra sonic

VC visibly clean

VC + UV visibly clean plus ultraviolet

3.4 Symbols

Symbol

Meaning

dp mean pore diameter of a filter

3.5 Nomenclature

The following nomenclature applies throughout this document:

c. The word “shall” is used in this Standard to express requirements. All the

requirements are expressed with the word “shall”.

d. The word “should” is used in this Standard to express recommendations.

All the recommendations are expressed with the word “should”.

NOTE It is expected that, during tailoring,

recommendations in this document are either

converted into requirements or tailored out.

e. The words “may” and “need not” are used in this Standard to express

positive and negative permissions, respectively. All the positive

permissions are expressed with the word “may”. All the negative

permissions are expressed with the words “need not”.

f. The word “can” is used in this Standard to express capabilities or

possibilities, and therefore, if not accompanied by one of the previous

words, it implies descriptive text.

NOTE In ECSS “may” and “can” have completely

different meanings: “may” is normative

(permission), and “can” is descriptive.

g. The present and past tenses are used in this Standard to express statements

of fact, and therefore they imply descriptive text.

Cleanliness requirements

4.1 General

a. This standard shall only apply to propulsion systems using Hydrazines,

MON, Propane, Butane, Nitrogen, Helium, Xenon as propellants.

b. Cleanliness assurance precautions and features shall be specified and

incorporated in the hardware at the design phase.

NOTE In propulsion systems cleanliness is a major

requirement to avoid loss of function and

performance.

c. Cleanliness verification shall be applied at progressive MAIT stages in the

process.

d. The hardware shall be designed to enable post-build cleaning and

cleanliness verification.

e. Operation and use shall not generate or release contamination.

f. A cleanliness verification should be performed successively at component,

sub-system and system level prior to a blind-end close-out.

g. Cleanliness Particle Count levels shall be to a lower required class or

subclass at the early hardware build and verification stages, than the final

product.

NOTE 1 This allows final system-level cleanliness to be

achieved.

NOTE 2 See Table 4-1 for cleanliness classes and

subclasses.

h. During the design phase the necessity of cleanliness verification shall be

assessed.

NOTE 1 This applies from components to the design of

systems, and to operations as not to generate

contamination and to enable cleaning.

NOTE 2 Figure C-1 of ECSS-Q-ST-70-01 gives an

overview of space system cleanliness

requirements organized in a cleanliness control

flow chart.

i. Compatibility of cleaning fluids with the propulsion system materials and

propellants shall be established in conformance with Annex A.

NOTE 1 For efficient cleaning chemical compounds like

alkaline and acid cleaners are required.

NOTE 2 Related requirements are specified in ECSS-E-

ST-35-10, ‘Known incompatibilities’ concerning

compatibility testing for liquid propulsion

components, subsystems and systems.

j. All components, subsystems, systems or related equipment for use in

ground support equipment and spacecraft requiring cleaning shall be

1. cleaned to the specified cleanliness level, in conformance with the

CRA produced in conformance with Annex A,

2. inspected in conformance with Annex B.

k. The results of 4.1j shall be reported in conformance with Annex C.

l. Any component, subsystem or system that can be damaged during

cleaning shall be:

1. protected or removed before cleaning;

2. cleaned as a separate item in conformance with the CTS produced

in conformance with Annex B.

m. Cleaning or disassembly operations on precision components shall be

performed only by personnel who have been trained and certified to

perform these functions.

4.2 Design requirements

4.2.1 General

a. Designs shall be such that the product

1. avoids contamination and

2. allows for cleaning and drying.

b. Cleanliness classes shall be established in conformance with Annex A, to

apply to propulsion components, subsystems and systems.

4.2.2 Components

4.2.2.1 Tanks

a. Tank internal structures shall not shed particles during operation.

b. Tank internal structures shall allow for draining and cleaning.

NOTE Examples of such structures are diaphragms,

bladders, baffles, and surface tension screens.

4.2.2.2 Tubing and manifolds

a. Tubings and manifolds should avoid stepped diameter transitions that

create turbulence or flow separation.

NOTE Turbulent flows and wakes can cause particle

deposition.

b. Tubings and manifolds should avoid blind holes and dead ends,

c. Tubings and manifolds shall avoid internal threads.

NOTE The risk of contamination is increased with the

number of screw joints.

4.2.2.3 Valves and regulators

a. Solenoid valves should use flexure guided armatures.

NOTE Sliding surfaces can jam or generate particles.

b. Valve or regulator function and performance shall be independent from

lubrication on critical surfaces.

c. Fluid paths should be smooth, avoiding stepped transitions.

NOTE This is to avoid entrapment of contamination.

d. Valve or regulator parts and assembled parts should allow for ultrasonic

cleaning, in conformance with the CTS produced in conformance with

Annex B.

e. Protective filters shall be dimensioned in conformance with the CRA

produced in conformance with Annex A, such that the selected filtration

rate does not allow particles exceeding a specified size, to pass, thereby

degrading function and performance.

f. Reference ports on regulators shall be protected by filters.

g. In conformance with the CRA produced in conformance with Annex A,

protective filters shall be dimensioned such that the specified accumulated

contamination causes no pressure drop exceeding the requirement.

h. Valve- or regulator-poppet design shall avoid entrapment of

contamination.

i. A valve or regulator assembly should allow for the integration of

protective filters after the final cleaning of the unit has been performed and

verified in conformance with the CTS produced in conformance with

Annex B.

j. Valves and regulators subject to reverse flow shall incorporate an outlet

filter.

k. Valves and regulators shall avoid cavities, if not functionally required.

l. Valves and regulators shall not generate contamination, exceeding the

specified level, when exposed to the specified environmental and

functional tests.

NOTE 1 E.g. during dry cycles.

NOTE 2 Sliding armatures can generate contamination.

NOTE 3 Sliding armatures are susceptible to jamming

and wear.

4.2.2.4 Filters

a. Filters shall not shed particles, exceeding the specified level, during

operation and environmental testing.

4.2.2.5 Instrumentation

a. Sensors introducing cavities shall allow for cleaning by a flushing lance.

NOTE See Annex B.

b. Cavities or dead end tubing shall allow for thermal and vacuum drying.

NOTE See Annex B.

4.2.2.6 Injectors

a. The deposition of NVR in capillary tubes and injector bores during

operation shall be analysed and reported.

NOTE 1 E.g. during pulse mode.

NOTE 2 See Annex A.

4.2.2.7 Thrust chambers

a. The deposition of NVR on catalyst beds shall be analysed and reported.

NOTE See Annex A.

4.2.3 System

a. The system shall allow for ground draining of simulation fluids and of

propellants.

b. Systems requiring cleaning and cleanliness verification shall have no

protective filters at fill and drain valves or test ports.

c. Filtration rate and capacity requirements shall include the flight operation

and the contamination introduced by integration and testing at higher

build level.

NOTE See Annex A.

d. The integration of filters should be performed after final cleaning and

verification of the related subsystems.

NOTE See Annex B.

e. Line replaceable components shall be protected by built-in filters.

f. The system design should enable flow-down cleanliness verification (see clause

4.1g).

4.2.4 Ground support equipment (GSE)

a. Connect/disconnect interfaces shall be protected from contamination by

filters or by procedures

NOTE E.g. purge flow during connection / disconnection.

b. GSE protective filters shall be at the interfacing point to the flight

hardware.

c. The GSE shall provide for draining and drying interfaces

NOTE E.g. back flush.

d. The GSE shall provide sampling interfaces and sampling equipment to

verify cleanliness.

e. Filtration of simulation fluids or propellants shall be performed to a

cleanliness class equal or better than the propulsion system requirements.

NOTE See Annex A.

4.3 Manufacturing

4.3.1 General

a. Manufacturing aspects that affect the selection of cleaning techniques shall

be reported in conformance with Annex B.

4.3.2 Manufacturing processes

a. ECSS-Q-ST-70-01 requirements for ‘Manufacturing’ and ‘Assembly and

integration’ shall apply.

b. The required proof pressure testing shall be performed after cleaning

processes that affect material properties

NOTE E.g. after acid treatment.

4.3.3 Machined parts

a. Machined parts shall be cleaned as specified for the subsequent

manufacturing operations.

NOTE This is also to achieve the final cleanliness level.

b. Machined parts shall be free of burrs.

NOTE For large items such as diaphragms and

bladders, special cleaning procedures can be

necessary.

4.3.4 Tubing and manifolds

a. Tubing, manifolds and transition joints shall be free of burrs, maintaining

sharp edges for welding.

b. Tubing, manifolds and transition joints shall have passed all

contaminating handling steps before final cleaning, e.g. bending, flaring,

cutting to length and contaminating inspections.

c. Light oxide films, shall be removed by validated processes, e.g. brushing

with a clean stainless steel wire brush, glass blasting (except for flow

paths), draw filing, acid pickling.

d. Grinding shall not be performed on tube end interface surfaces that are

subject to welding.

NOTE Debris from the grinding wheel can get

embedded in the metal surface. This has been

known to cause weld problems due to

contamination embedded at the interface during

welding.

e. The area to be treated by acid pickling shall be degreased with non-

halogenated solvents.

f. Component interiors shall be protected by internally plugging the tubing

stud in case of acid pickling.

NOTE For example, valves.

g. Water flushing shall be used to neutralize the pickling solution.

h. Tubing and manifolds shall be dried by gas purging.

i. Tubing shall be protected from contamination by oxidation during

welding.

j. Welding shall avoid generating weld sputter in components, subsystems

and system.

k. To protect stainless steel against external corrosion (e.g. after welding)

pickling and passivation shall be performed.

NOTE Titanium tubing and manifolds can be pickled in

a suitable acid and flushed with de-mineralised

water to allow surface natural re-passivation.

l. Installation of a seal shall not introduce contamination into the system.

NOTE E.g. installation of O-rings.

m. Abrasion and surface damage of a seal during integration shall be avoided.

NOTE E.g. by using application compatible lubricants,

masking of sharp edges.

n. The lubricant of mechanical joints shall not be introduced into the critical

surface area or come into contact with propellants, pressurants or simulation

fluids.

o. The joining process shall not introduce contamination into the critical

surface area or bring contaminants into contact with propellants,

pressurants or simulation fluids.

p. For repair and trimming-to-length clause 6.3.4 shall apply

4.3.5 Components

a. Components with liquid retaining cavities or capillary structures used for

gas applications shall be

1. flushed with liquids only at component level,

2. verified to be dry.

NOTE E.g. pressure regulators, non return and relief

valves.

b. Joining components to cleaning facilities shall not cause damage to

interfaces.

c. Assembly of components (e.g. orifices, valve seats) shall be performed under

a controlled environment in conformance with the requirements for

“Cleanrooms” in ECSS-Q-ST-70-01F, and the cleanliness requirements of the

component.

d. Hardware shall not be exposed to environments causing chemical

contamination.

NOTE This can give rise to corrosion or chemical

reactions in a later stage of life.

e. If not protected by specific means to avoid internal contamination,

assembled components shall be tested in a controlled environment in

conformance with the requirements for cleanrooms in ECSS-Q-ST-70-01

and the cleanliness requirements of the component.

f. It shall be determined which environmental classes apply to 4.3.5c and

4.3.5e.

NOTE See Annex A.

g. Procedures shall ensure that components that can be damaged or

contaminated by reverse flow are not flushed or purged in opposite

direction, neither during component operation, nor during subsystem or

system operation.

h. For filters, procedures shall ensure that the last flushing operation at

component level is performed in the nominal direction.

i. Tanks with built in propellant management devices shall have undergone

all individually required precision cleaning processes and verification

prior to final welding.

j. No introduction or formation of contaminants during subsequent

assembly and operations shall take place.

NOTE E.g. introduction or formation of weld sputter.

k. Valves and regulators that cannot be dried after liquid flushing shall be

cleaned with either:

1. Nitrogen in conformance with ISO 14951-3 Type A, filtered through

a filter with dp ≤ 2 μm, or

2. Helium in conformance with ISO 14951-4 Type A, filtered through

a filter with dp ≤ 2 μm, or

3. Argon in conformance with MIL-PRF-27415B grade B, filtered

through a filter with dp ≤ 2 μm.

l. For the purpose of cleaning, the non-single-use valve or regulator shall be

operated during flushing or purging.

m. Purging or flushing of thrusters shall take the thrusters characteristics into

account.

NOTE 1 Monopropellant thrusters with catalytic beds

have limitations regarding flushing liquids, gas

flow rates and pressure differentials.

NOTE 2 Actuation of a flow control valve with gas flow

is subject to limitations to avoid overheating of

the valve.

4.3.6 Subsystems and systems

a. Subsystems incorporating components that constrain flushing or purging

shall be built up allowing for in-process cleaning in accordance with clause

4.1c.

b. Subsystems with limited access and requiring flushing or purging shall be

fitted with test ports.

c. Closed or protected subsystems and systems shall be handled in

conformance with the ECSS-Q-ST-70-01, class M6.5 environment.

d. Open subsystems and systems shall be handled in a specified environment

equal to or better than ECSS-Q-ST-70-01 class M6.5.

e. It shall be determined which environmental class applies to requirement

4.3.6d.

NOTE See Annex A.

f. Procedures shall be established to avoid contamination of the subsystem

or system in case of component exchange.

4.3.7 Final rinsing solutions

a. The final rinsing solution shall meet or exceed the cleanliness requirements

for which they are intended.

b. The rinsing liquid shall meet the requirements of clauses 4.4.4a, 4.4.4b,

4.4.4c, and 4.4

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...