SIST EN 13205-5:2014

(Main)Workplace exposure - Assessment of sampler performance for measurement of airborne particle concentrations - Part 5: Aerosol sampler performance test and sampler comparison carried out at workplaces

Workplace exposure - Assessment of sampler performance for measurement of airborne particle concentrations - Part 5: Aerosol sampler performance test and sampler comparison carried out at workplaces

This European Standard specifies a method for determining the performance of an aerosol sampler under prescribed workplace conditions in order to test whether the performance of a candidate sampler fulfils the requirements of EN 13205 1.

This part of EN 13205 specifies also a simple method to determine how, for a specific workplace aerosol, the concentration measured by the candidate sampler can be recalculated into that of a validated sampler.

This part of EN 13205 is applicable to all samplers used for the health-related sampling of particles in workplace air. Different test procedures and types of evaluation are included to enable application of this part of EN 13205 to a wide variety of instruments.

The methods specified in this part of EN 13205 are not applicable to tests where the performance of personal samplers is related to static samplers or vice versa.

Exposition am Arbeitsplatz - Bewertung der Leistungsfähigkeit von Sammlern für die Messsung der Konzentration luftgetragener Partikel - Teil 5: An Arbeitsplätzen durchgeführte Prüfungen der Leistungsfähigkeit des Aerosolsammlers

Diese Europäische Norm legt ein Verfahren zur Bestimmung der Leistungsfähigkeit eines Aerosolsammlers unter vorgeschriebenen Arbeitsplatzbedingungen fest, um zu prüfen, ob die Leistungsfähigkeit eines zu prüfenden Sammlers die Anforderungen nach EN 13205 1 erfüllt.

Dieser Teil von EN 13205 legt außerdem ein einfaches Verfahren fest, um für ein bestimmtes Arbeitsplatzaerosol zu bestimmen, wie die mit dem zu prüfenden Sammler gemessene Konzentration zu der mit einem validierten Sammler gemessenen Konzentration neuberechnet werden kann.

Dieser Teil von EN 13205 gilt für alle Sammler, die für die gesundheitsbezogene Probenahme von Partikeln aus der Luft am Arbeitsplatz eingesetzt werden. Es sind verschiedene Prüfverfahren und Typen der Beurteilung enthalten, um die Anwendung dieses Teils von EN 13205 auf ein breites Spektrum von Geräten zu ermöglichen.

Die in diesem Teil von EN 13205 festgelegten Verfahren gelten nicht für Prüfungen, bei denen die Leistungsfähigkeit personengetragener Sammler zur Leistungsfähigkeit ortsfester Sammler in Beziehung gebracht wird bzw. umgekehrt.

Exposition sur les lieux de travail - Évaluation des performances des dispositifs de prélèvement pour le mesurage des concentrations d'aérosols - Partie 5 : Essais de performances des échantillonneurs d'aérosols, réalisés sur les lieux de travail

La présente Norme européenne spécifie une méthode pour déterminer la performance d'un dispositif de prélèvement d'aérosols dans des conditions de lieu de travail prescrites, afin de vérifier si la performance d'un dispositif de prélèvement à évaluer satisfait aux exigences de l’EN 13205 1.

La présente partie de l'EN 13205 spécifie également une méthode simple afin de déterminer, pour un aérosol d'un lieu de travail spécifique, comment il est possible de convertir la concentration mesurée par le dispositif de prélèvement à évaluer en celle mesurée par un dispositif de prélèvement validé.

La présente partie de l'EN 13205 s'applique à tous les dispositifs de prélèvement utilisés pour le prélèvement, à des fins sanitaires, des particules présentes sur les lieux de travail. Elle présente différents modes opératoires d'essai et différents types d'évaluation, afin de permettre l'application de la présente partie de l'EN 13205 à un grand nombre d'instruments.

Les méthodes spécifiées dans la présente partie de l'EN 13205 ne s'appliquent pas aux essais pour lesquels la performance des dispositifs de prélèvement individuels est liée aux dispositifs de prélèvement à point fixe, et réciproquement.

Izpostavljenost na delovnem mestu - Ocenjevanje lastnosti merilnikov za merjenje koncentracij lebdečih delcev - 5. del: Preskušanje in primerjava vzorčevalnikov za aerosole, izvedena na delovnem mestu

Standard EN 13205-5 določa metodo za preskušanje delovanja merilnika aerosolov pod določenimi pogoji na delovnem mestu, da se preskusi, ali delovanje merilnika kandidata izpolnjuje zahteve iz standarda EN 13205-1. Ta del standarda EN 13205 prav tako določa enostavno metodo za določitev postopka, po katerem se lahko za določeni aerosol na delovnem mestu koncentracija, ki jo je izmeril merilnik kandidat, preračuna v koncentracijo validiranega merilnika. Ta del standarda EN 13205 velja za vse merilnike, ki se uporabljajo za vzorčenje delcev v zraku, ki vplivajo na zdravje na delovnem mestu. Vključeni so različni postopki preskušanja in vrste ocenjevanja, da se omogoči uporabo tega dela standarda EN 13205 za raznovrstne instrumente. Metode, določene v tem delu standarda EN 13205, ne veljajo za preskuse, kjer je delovanje osebnih merilnikov povezano s statičnimi merilniki ali obratno.

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Nov-2012

- Publication Date

- 14-Jul-2014

- Technical Committee

- KAZ - Air quality

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 10-Jul-2014

- Due Date

- 14-Sep-2014

- Completion Date

- 15-Jul-2014

Relations

- Effective Date

- 01-Sep-2014

- Effective Date

- 07-Mar-2023

- Effective Date

- 29-Jun-2011

Overview

EN 13205-5:2014 (CEN) defines a workplace-based method to assess the performance of aerosol samplers used for health-related measurement of airborne particle concentrations. The standard specifies how to test a candidate sampler under real workplace conditions to determine whether it meets the requirements of EN 13205-1 and how to derive a correction factor to convert results between a candidate sampler and a previously validated sampler for a specific workplace aerosol.

This part of EN 13205 applies to samplers for the inhalable, thoracic and respirable fractions and includes multiple test procedures and evaluation types to accommodate a wide variety of instruments. It does not cover comparisons where a personal sampler’s performance is related to a static sampler (or vice versa).

Key Topics

- Workplace performance testing: Procedures to compare concentrations measured by a candidate sampler and a validated sampler under prescribed workplace conditions.

- Correction function / factor: Simple method (see Annex A) to recalculate a candidate sampler’s measured concentration into the equivalent of a validated sampler for a specific workplace aerosol.

- Bias and uncertainty analysis: Calculation of sampler bias, individual sampler variability, combined standard uncertainty and expanded uncertainty in accordance with modern metrology practice.

- Sources of uncertainty considered: workplace aerosol concentration (via validated sampler), validated sampler performance, candidate sampler bias, individual sampler variability, excursion from nominal flow rate, and collected or internally separated mass.

- Test reporting and documentation: Required content for test reports (laboratory and field details, sampler descriptions, experimental design, data analysis, performance results and user guidance).

- Periodic validation: Guidance on re-validation intervals and conditions to maintain confidence in sampler performance.

Applications

Who uses EN 13205-5:2014 and why:

- Occupational hygienists - to verify on-site sampler performance and ensure exposure measurements are reliable for health risk assessments.

- Testing laboratories - to perform workplace comparisons, compute correction factors, and report expanded uncertainty.

- Sampler manufacturers and vendors - to support user instructions and claims about field performance when aligned with EN 13205 family requirements.

- Employers and regulators - to confirm measurement methods meet standards for compliance and worker protection. Practical outcomes include validated on-site sampling protocols, corrected concentration results between sampler types, and documented uncertainty for decision-making relative to occupational exposure limits.

Related standards

- EN 13205-1:2014 - General requirements for sampler performance assessment

- EN 13205-2:2014 & EN 13205-4:2014 - Laboratory performance tests

- EN 13205-6:2014 - Transport and handling tests

- EN 1540 - Workplace exposure terminology

- EN 481 / EN 482 - Particle size fractions and general performance requirements

EN 13205-5:2014 is intended to complement laboratory validation and provide actionable, workplace-specific evidence of sampler performance for accurate airborne particle exposure assessment.

Frequently Asked Questions

SIST EN 13205-5:2014 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Workplace exposure - Assessment of sampler performance for measurement of airborne particle concentrations - Part 5: Aerosol sampler performance test and sampler comparison carried out at workplaces". This standard covers: This European Standard specifies a method for determining the performance of an aerosol sampler under prescribed workplace conditions in order to test whether the performance of a candidate sampler fulfils the requirements of EN 13205 1. This part of EN 13205 specifies also a simple method to determine how, for a specific workplace aerosol, the concentration measured by the candidate sampler can be recalculated into that of a validated sampler. This part of EN 13205 is applicable to all samplers used for the health-related sampling of particles in workplace air. Different test procedures and types of evaluation are included to enable application of this part of EN 13205 to a wide variety of instruments. The methods specified in this part of EN 13205 are not applicable to tests where the performance of personal samplers is related to static samplers or vice versa.

This European Standard specifies a method for determining the performance of an aerosol sampler under prescribed workplace conditions in order to test whether the performance of a candidate sampler fulfils the requirements of EN 13205 1. This part of EN 13205 specifies also a simple method to determine how, for a specific workplace aerosol, the concentration measured by the candidate sampler can be recalculated into that of a validated sampler. This part of EN 13205 is applicable to all samplers used for the health-related sampling of particles in workplace air. Different test procedures and types of evaluation are included to enable application of this part of EN 13205 to a wide variety of instruments. The methods specified in this part of EN 13205 are not applicable to tests where the performance of personal samplers is related to static samplers or vice versa.

SIST EN 13205-5:2014 is classified under the following ICS (International Classification for Standards) categories: 13.040.30 - Workplace atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13205-5:2014 has the following relationships with other standards: It is inter standard links to SIST EN 13205:2002, oSIST prEN 13205:2010; is excused to oSIST prEN 13205:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13205-5:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Exposition am Arbeitsplatz - Bewertung der Leistungsfähigkeit von Sammlern für die Messsung der Konzentration luftgetragener Partikel - Teil 5: An Arbeitsplätzen durchgeführte Prüfungen der Leistungsfähigkeit des AerosolsammlersExposition sur les lieux de travail - Évaluation des performances des dispositifs de prélèvement pour le mesurage des concentrations d'aérosols - Partie 5 : Essais de performances des échantillonneurs d'aérosols, réalisés sur les lieux de travailWorkplace exposure - Assessment of sampler performance for measurement of airborne particle concentrations - Part 5: Aerosol sampler performance test and sampler comparison carried out at workplaces13.040.30Kakovost zraka na delovnem mestuWorkplace atmospheresICS:Ta slovenski standard je istoveten z:EN 13205-5:2014SIST EN 13205-5:2014en,fr,de01-september-2014SIST EN 13205-5:2014SLOVENSKI

STANDARDSIST EN 13205:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13205-5

June 2014 ICS 13.040.30 Supersedes EN 13205:2001English Version

Workplace exposure - Assessment of sampler performance for measurement of airborne particle concentrations - Part 5: Aerosol sampler performance test and sampler comparison carried out at workplaces

Exposition sur les lieux de travail - Évaluation des performances des dispositifs de prélèvement pour le mesurage des concentrations de particules en suspension dans l'air - Partie 5: Essais de performances des échantillonneurs d'aérosols, réalisés sur les lieux de travail Exposition am Arbeitsplatz - Beurteilung der Leistungsfähigkeit von Sammlern für die Messung der Konzentration luftgetragener Partikel - Teil 5: An Arbeitsplätzen durchgeführte Prüfung der Leistungsfähigkeit des Aerosolsammlers und Sammlervergleich This European Standard was approved by CEN on 7 May 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13205-5:2014 ESIST EN 13205-5:2014

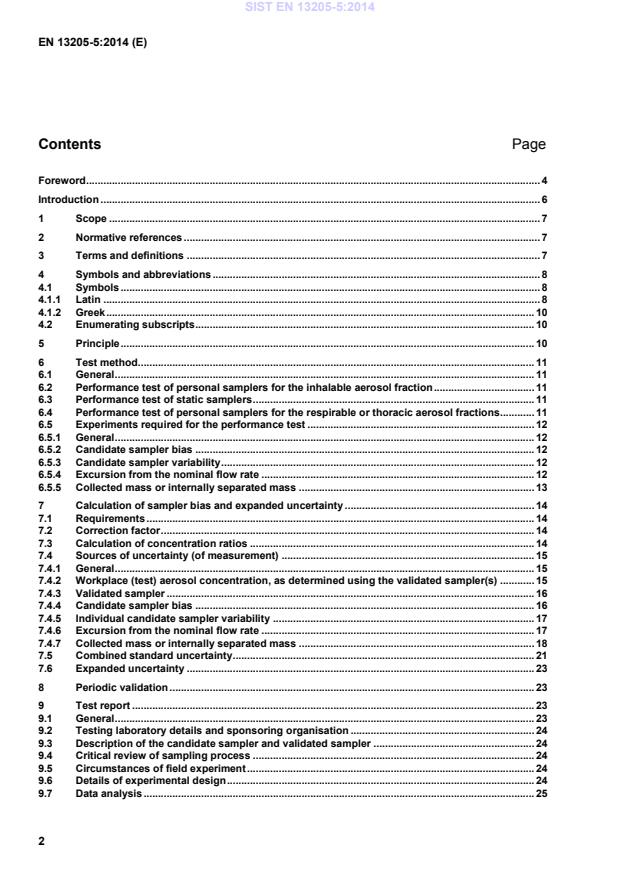

Foreword . 4

Introduction . 6 1 Scope . 7 2 Normative references . 7 3 Terms and definitions . 7 4 Symbols and abbreviations . 8 4.1 Symbols . 8 4.1.1 Latin . 8 4.1.2 Greek . 10 4.2 Enumerating subscripts . 10 5 Principle . 10 6 Test method . 11 6.1 General . 11 6.2 Performance test of personal samplers for the inhalable aerosol fraction . 11 6.3 Performance test of static samplers . 11 6.4 Performance test of personal samplers for the respirable or thoracic aerosol fractions. 11 6.5 Experiments required for the performance test . 12 6.5.1 General . 12 6.5.2 Candidate sampler bias . 12 6.5.3 Candidate sampler variability . 12 6.5.4 Excursion from the nominal flow rate . 12 6.5.5 Collected mass or internally separated mass . 13 7 Calculation of sampler bias and expanded uncertainty . 14 7.1 Requirements . 14 7.2 Correction factor . 14 7.3 Calculation of concentration ratios . 14 7.4 Sources of uncertainty (of measurement) . 15 7.4.1 General . 15 7.4.2 Workplace (test) aerosol concentration, as determined using the validated sampler(s) . 15 7.4.3 Validated sampler . 16 7.4.4 Candidate sampler bias . 16 7.4.5 Individual candidate sampler variability . 17 7.4.6 Excursion from the nominal flow rate . 17 7.4.7 Collected mass or internally separated mass . 18 7.5 Combined standard uncertainty . 21 7.6 Expanded uncertainty . 23 8 Periodic validation . 23 9 Test report . 23 9.1 General . 23 9.2 Testing laboratory details and sponsoring organisation . 24 9.3 Description of the candidate sampler and validated sampler . 24 9.4 Critical review of sampling process . 24 9.5 Circumstances of field experiment . 24 9.6 Details of experimental design . 24 9.7 Data analysis . 25 SIST EN 13205-5:2014

Procedure for a workplace comparison of a candidate sampler and a validated sampler in order to obtain a correction factor . 26 Bibliography . 31

1) The inhalable convention is undefined for particle sizes in excess of 100 µm or for wind speeds greater than 4 m/s. The tests required to assess performance are therefore limited to these conditions. Should such large particle sizes or wind speeds actually exist at the time of sampling, it is possible that different samplers meeting this part of EN 13205 give different results. SIST EN 13205-5:2014

Cambinhalertl average total airborne particle (or inhalable aerosol fraction) concentration for partial sampling period l in run r for sampling time t, [mg/m3]

COEL appropriate occupational exposure limit value (OEL) applying to the substances being measured, [mg/m3] Crtl concentration for partial sampling period l in run r, for sampling time t, [mg/m3]

twal1−l2Cr3 time-weighted concentration average for candidate sampler for run r, sampling time t = 3 extending from partial sampling period l1 to partial sampling period l2, [mg/m3] c candidate sampler correction factor for bias correction, either prescribed by sampler manufacturer or measuring procedure, or assigned the value c = 1.00, [-] mrtl average mass collected during partial sampling period l, in run r for sampling time t (where t = 1,2,3 represents sampling times texp, texp/3 and texp/9 respectively), [mg]

Collectedavermrtl average collected mass for partial sampling period l, in run r for sampling time t (where t = 1,2,3 represents sampling times texp, texp/3 and texp/9, respectively), [mg]

InternSepavermrtl average internally separated mass for partial sampling period l, in run r for sampling time t (where t = 1,2,3 represents sampling times texp, texp/3 and texp/9, respectively), [mg]

maxmCollected maximum collected mass corresponding to maximum concentration times intended sampling time times nominal flow rate, [mg]

maxmInternSep maximum internally separated mass corresponding to difference between maximum total airborne particle (or inhalable fraction) concentration and maximum concentration expected to be sampled by candidate sampler times intended sampling time times nominal flow rate, [mg]

zeromCollected collected mass corresponding to approximately zero mass, [mg]

zeromInternSep internally separated mass corresponding to approximately zero mass, [mg]

NRun number of experimental runs, pairs of (average) validated sampler and candidate sampler concentrations

NSr number of candidate samplers used in experimental run r

NSrtl number of candidate samplers used with partial period l in run r for sampling time t

NValidr number of reference samplers (validated samplers) used in experimental run r

Q0 nominal flow rate of sampler, [l/min]

Q+ higher flow rate used for the candidate sampler in the performance test for the effect of flow excursions, [l/min]

Q- lower flow rate used for the candidate sampler in the performance test for the effect of flow excursions, [l/min]

Rg geometric mean of the Rrs values, [-] SIST EN 13205-5:2014

sR geometric standard deviation of the Rrs values, [-]

sValidConcrs uncertainty of workplace (test) aerosol concentration at position of candidate sampler(s) for experimental run r and candidate sampler individual s, [-] texp experimental sampling time for tests described in 6.5.5 based on estimated average concentration at workplace, [min] trtl actual time of partial sampling period l for set t in experiment r, [min]

UCandSampl expanded uncertainty (of measurement) of the calculated sampled concentration due to the candidate sampler, [-]

uCandSampl combined uncertainty (of measurement) of the calculated sampled concentration due to the candidate sampler, [-]

uCandSampl-Bias standard uncertainty (of measurement) due to bias (non-random errors) in relation to the sampling convention of the candidate sampler, [-]

uCandSampler-CollectedMass standard uncertainty (of measurement) of the sampled concentration (non-random errors) due to mass collected by the candidate sampler, [-]

uCandSampl-Flow standard uncertainty (of measurement) (random) due to candidate sampler flow excursion from nominal flow rate, [-]

uCandSampler-InternSepMass standard uncertainty (of measurement) due to internally separated mass (non-random errors) by the candidate sampler, [-]

uCandSampl-nR combined uncertainty (of measurement) of the sampled concentration (non-random errors) due to the candidate sampler, [-]

uCandSampl-R combined uncertainty (of measurement) of the sampled concentration (random errors) due to the candidate sampler, [-]

uCandSampl-Variability standard uncertainty (of measurement) of the sampled concentration (random errors) due to differences among candidate sampler individuals, [-]

uValidConc standard uncertainty (of measurement) of the reference concentration (random errors) at the position of candidate samplers during experiments, [-]

uValidSampl-nR standard uncertainty of the validated sampler (non-random errors), [-] Xrs measured candidate sampler concentration for candidate sampler individual s, for the run (workplace (test) aerosol concentration) r, [mg/m3] averXr average of the measured candidate sampler concentrations for the run (workplace (test) aerosol concentration) r, [mg/m3] Yrs workplace (test) aerosol concentration (measured with a validated sampler) for the reference sampler individual s, for the run (workplace (test) aerosol concentration) r, [mg/m3] Yrs* corrected concentration measured by the candidate sampler individual s, for the run experiment (workplace (test) aerosol concentration) r, [mg/m3 averYr average of the concentrations measured with validated samplers for the run (workplace (test) aerosol concentration) r, [mg/m3] SIST EN 13205-5:2014

YEst-Collected regression formula for the ratio rrtl as a function of mCollected=Collectedavermrtl, [-]

YEst-InternSep regression formula for the ratio rrtl as a function of mInternSep=InternSepavermrtl, [-] y = f(x)

correction function that relates the concentration measured with the candidate sampler to those measured with the (average of) validated sampler(s), [ln(mg/m3)] 4.1.2 Greek

δPump maximum relative change in flow rate allowed by pump flow rate stability, [-] 4.2 Enumerating subscripts l for partial sampling periods l1 for first partial sampling period in summation l2 for last partial sampling period in summation r for runs s for candidate sampler individual t for sampling time (where t = 1,2,3 represents sampling times texp, texp/3 and texp/9 respectively) 5 Principle The test method described in this part of EN 13205 is based on concentrations measured at a specific workplace by the candidate sampler, whether all aspirated particles are part of the sample (as for most inhalable samplers) or if a particle size-dependent penetration occurs between the inlet and the collection substrate (as for thoracic and respirable samplers). The purpose of determining the performance of a candidate sampler at a workplace is to enable the user of the samplers to carry out measurements of dust concentration with samplers that have not been evaluated in laboratory tests according to this part of EN 13205. The validated sampler and candidate sampler shall both be either personal or static samplers. The bias versus the sampling convention is determined by comparing the concentrations determined with the candidate sampler and a validated sampler. Other sampling errors due to non-random and random sources of error are also determined, for example, individual sampler variability, excursion from nominal flow rate and experimental errors. Analysis of the field data is carried out to determine the performance of the candidate sampler. The performance will be specific to the workplace activities included in the performance test and cannot be assumed to apply to different circumstances. The criteria for accepting the performance of the sampler is identical to those for a laboratory test for performance evaluation. If the performance is poor, this will probably be due to either that the inherent variability at the workplace is exceedingly large, or by including too wide a range of workplace activities in the test, rather than too poor performance by the sampler. In the first case the large variability can only be reduced by averaging over several sampler individuals, which can be difficult with personal samplers. In the second case the performance test shall be repeated for a more narrowly-defined group of exposed persons or workplace activities, until an adequate degree of equivalence is established. In some workplaces the nature or organisation of the work can make this impossible. NOTE The variability of the concentration at many workplaces can prove to be so large that it becomes impossible to determine a performance (expanded uncertainty) within the bounds specified by EN 482. To try to determine the (hopefully low) combined standard uncertainty of the sampler in the midst of an inherently large variability at the workplace can, SIST EN 13205-5:2014

2) See Bibliography, references [1] to [3]. SIST EN 13205-5:2014

maxmCollected, by multiplying the maximum concentration with the nominal flow rate of the candidate sampler and the intended sampling time when using the candidate sampler at the workplace. Determine the maximum internally separated mass,

maxmInternSep, by multiplying the difference between the maximum total airborne particle (or inhalable aerosol fraction) concentration and the maximum concentration expected to be sampled by candidate sampler, with the nominal flow rate of the candidate sampler and the intended sampling time when using the candidate sampler at the workplace, respectively. When the tests are performed the concentrations are presumably lower than the estimated maximum concentration. Calculate from the maximum collected mass an experimental sampling time, texp, based on an expected average concentration at the workplace. This experimental sampling time can extend over more than one working shift. The pumps used have to be selected in accordance with this test condition, or the sampling period split up into parts, with fresh pumps for each part. This experiment requires three sets of (at least two) candidate sampler individuals: — the first set is operated throughout the experimental sampling time, texp. — the second set consists of three subsets of candidate sampler individuals. Each subset is only operated for approximately one third of the experimental sampling time, texp /3 (in order to collect approximately one third of the mass collected of the first set), and is then replaced with a fresh subset of candidate sampler individuals (i.e. cleaned, and dried, sampler individuals loaded with unused collection substrates) for the next third of the experimental sampling time. — the third set consists of nine subsets of candidate sampler individuals. Each subset is only operated for approximately one ninth of the experimental sampling time, texp /9 (in order to collect approximately one ninth of the mass collected of the first set), and then replaced with a fresh subset of candidate samplers individuals (i.e. cleaned, and dried, sampler individuals loaded with unused collection substrates) for the next ninth of the experimental sampling time. The calculated sampling times are only indicative. When sampling occurs at the workplace it is expected that the concentration will vary considerably. It is important to try to obtain similar sampled/internally separated mass for each collection substrate in the same set per run r. Therefore the actual sampling times during sampling may be increased during times of lower aerosol concentrations and decreased during higher aerosol concentrations in order to obtain similar sampled/internally separated masses. The actual experimental sampling times for all candidate samplers shall be noted for use in the calculations. SIST EN 13205-5:2014

texp3. 7 Calculation of sampler bias and expanded uncertainty 7.1 Requirements The requirements for the expanded standard uncertainty of candidate sampler tested with a type C test are given in EN 13205-1:2014, 5.2 c). 7.2 Correction factor A correction factor, c [-], stated either in the manufacturer’s instructions for use or in the relevant measuring procedure shall be applied to the sampled concentrations. No other correction factor may be applied to the sampled concentrations. If no correction factor is stated, c, is assigned a value of 1,00. The value chosen for c shall be clearly stated in the sampler test report. 7.3 Calculation of concentration ratios Designate the concentrations measured with the candidate sampler in experimental run r using candidate sampler individual s as Xrs. Designate the concentrations measured with the validated sampler in experimental run r using validated sampler individual s as Yrs. Calculate the concentration ratio for each candidate sampler individual from Formula (1):

Rrs=XrsYr (1) where

Rrs is the concentration ratio for candidate sampler s in run r;

Xrs is the concentration measured with candidate sampler individual s in run r;

Yr is the (average of the

NValidr) concentration measured with the validated sampler(s) in run r;

NValidr is the number of validated samplers in run r. Exclude pairs (of averages) for which ratios

Rrs>10 or

Rrs<0.1 from further analysis, provided a) no more than one pair of results is excluded for every 10 pairs of data points; and b) there are at least 10 un-excluded ratios for 5 different experimental runs r. Calculate the average concentration ratio for each experimental run r from Formula (2): SIST EN 13205-5:2014

averRr=1NSrRrss=1NSr∑ (2) where

NSr is the number of tested candidate samplers in run r;

Rrs is the concentration ratio for candidate sampler s in run r;

averRr is the average concentration ratio for run r. 7.4 Sources of uncertainty (of measurement) 7.4.1 General The expanded uncertainty as determined in a workplace experiment can be analysed according to a modified version of EN 13205-4:2014, 8.3. The following sources of uncertainty (of measurement) shall be evaluated: — reference concentration, as determined using the validated sampler(s) (see 7.4.2); — reference sampler (see 7.4.3); — candidate sampler bias (see 7.4.4); — individual candidate sampler variability (see 7.4.5); — excursion from the nominal flow rate (see 7.4.6); and — collected mass or internally separated mass (see 7.4.7). 7.4.2 Workplace (test) aerosol concentration, as determined using the validated sampler(s) Any possible inhomogeneity of the workplace (test) aerosol concentration in the test system shall be evaluated separately. The calculation of the uncertainty describing the inhomogeneity depends on how it was evaluated. NOTE 1 Such methods can be found in text books on statistical methods. Calculate the standard uncertainty (of measurement) for the validated concentration weighted over all runs r from Formula (3):

uValidConc2=1NRun1NValidrsValidConcrs2s=1NValidr∑r=1NRun∑ (3) where

NRun is the number of experimental runs;

NValidr is the number of validated samplers used in run r; SIST EN 13205-5:2014

sValidConcrs is the relative uncertainty of workplace (test) aerosol concentration at the position of the candidate sampler(s) for experimental run r and candidate sampler individual s; and

uValidConc is the standard uncertainty (of measurement) of the validated concentration at the position of candidate samplers during experiments. NOTE 2 If the workplace (test) aerosol concentration is averaged from

NValidr validated samplers, the random uncertainty components of the workplace (test) aerosol concentrations is reduced by a factor of

1NValidr. 7.4.3 Validated sampler The random uncertainties due to the experiment and the measured workplace (test) aerosol concentration, as determined by the validated sampler, will incorporate the random uncertainties of the validated sampler. Only the non-random uncertainty components of the validated sampler uncertainty,

uValidSampl-nR, are needed. This component consists of the sources termed “calibration of sampler test system”, “bias relative to the sampling convention” and “excursion from the nominal flow rate”. When the performance of the validated sampler was determined, these three entities would have been determined according to EN 13205-2:2014, 8.4.2, 8.4.4 and 8.4.6, resp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...