SIST EN 1993-4-1:2007

(Main)Eurocode 3 - Design of steel structures - Part 4-1: Silos

Eurocode 3 - Design of steel structures - Part 4-1: Silos

Complementary to Part 1. Varied general rules and additional detailed rules for the structural design of free standing or supported steel silos of circular or rectangular plan for storing bulk granular solids.

Eurocode 3 - Bemessung und Konstruktion von Stahlbauten - Teil 4-1: Silos

Eurocode 3 - Calcul des structures en acier - Partie 4-1: Silos

Les Etats Membres de l'UE et de l'AELE reconnaissent que les Eurocodes servent de documents de référence pour les usages suivants :

comme moyen de prouver la conformité des bâtiments et des ouvrages de génie civil aux exigences essentielles de la Directive du Conseil 89/106/CEE, en particulier à l'Exigence Essentielle N°1 Stabilité et résistance mécanique et à l'Exigence Essentielle N°2 Sécurité en cas d'incendie ;

comme base de spécification des contrats pour les travaux de construction et les services techniques associés ;

comme cadre d'établissement de spécifications techniques harmonisées pour les produits de construction (EN et ATE).

Les Eurocodes, dans la mesure où ils concernent les ouvrages eux-mêmes, ont une relation directe avec les Documents Interprétatifs ) bien qu'ils soient d'une nature différente de celle des normes harmonisées de produits ). En conséquence, les aspects techniques résultant des travaux effectués pour les Eurocodes nécessitent d'être pris en considération de façon adéquate par les Comités techniques du CEN et/ou les groupes de travail de l'EOTA travaillant sur les normes de produits en vue de parvenir à une complète compatibilité de ces spécifications techniques avec les Eurocodes.

Les normes Eurocodes fournissent des règles de conception structurale communes d’usage quotidien pour le calcul des structures entières et des produits composants de nature traditionnelle ou innovatrice. Les formes de construction ou les conceptions inhabituelles ne sont pas spécifiquement couvertes, et il appartiendra en ces cas au concepteur de se procurer des bases spécialisées supplémentaires.

Evrokod 3: Projektiranje jeklenih konstrukcij - 4-1.del: Silosi

Dodatek k delu 1. Različna splošna pravila in dodatna podrobna pravila za konstrukcijsko zasnovo prosto stoječih ali podprtih jeklenih silosov z okroglim ali pravokotnim tlorisom za shranjevanje surovih razsutih snovi v zrnih.

General Information

- Status

- Published

- Publication Date

- 03-May-2007

- Technical Committee

- KON - Structures

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 12-Apr-2007

- Due Date

- 17-Jun-2007

- Completion Date

- 04-May-2007

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 01-Sep-2007

- Effective Date

- 14-Nov-2018

- Effective Date

- 01-Sep-2017

- Amended By

SIST EN 1993-4-1:2007/kFprA1:2014 - Eurocode 3 - Design of steel structures - Part 4-1: Silos - Effective Date

- 01-Nov-2014

- Corrected By

SIST EN 1993-4-1:2007/AC:2009 - Eurocode 3 - Design of steel structures - Part 4-1: Silos - Effective Date

- 01-Jun-2009

Overview - EN 1993-4-1:2007 (Eurocode 3: Silos)

EN 1993-4-1:2007 is the Eurocode part that gives principles and application rules for the structural design of steel silos. Published by CEN as part of Eurocode 3 – Design of steel structures, it supplements and, where needed, modifies the general rules in EN 1993‑1. The standard covers free‑standing or supported steel silos of circular (axisymmetric) or rectangular plan used to store bulk granular solids. It is concerned primarily with requirements for resistance and stability of silo structures.

Key topics and technical requirements

The standard addresses the following technical topics (selected from the table of contents and scope):

- Basis of design: limit states, reliability differentiation, actions and environmental effects, modelling for action effects and design assisted by testing.

- Material properties: requirements for structural and stainless steels, toughness considerations.

- Structural analysis: methods for shell silos, box structures, and equivalent properties for corrugated sheeting.

- Design rules for key components:

- Cylindrical walls (including support conditions and openings),

- Conical hoppers (membrane stress expressions included in annex),

- Circular conical roofs,

- Transition junctions and supporting ring girders,

- Rectangular and planar‑sided silos (stiffened and unstiffened walls).

- Serviceability and ultimate limit state verifications, detailing, and considerations for special support arrangements.

- Informative annexes with simplified design rules for low‑consequence silos, expressions for hopper stresses, and wind pressure distribution around circular silos.

Notable exclusions and constraints:

- Does not cover fire resistance, silos with internal subdivisions, or silos with capacity less than 10 tonnes.

- Circular planform silos are limited to axisymmetric geometry (actions may be unsymmetrical).

Practical applications and who uses it

EN 1993-4-1 is used by:

- Structural engineers and designers for verifying strength and stability of steel silos.

- Silo manufacturers and fabricators for detailed design, member sizing and connections.

- Clients, contractors and authorities as a reference for contractual specifications and regulatory compliance.

- Consultants performing structural analysis, retrofits or assessments of bulk storage facilities.

Typical applications include design and verification of: free‑standing grain silos, supported storage silos, hopper bottoms, transition rings, corrugated or plated shell walls, and junctions with supporting frameworks.

Related standards

EN 1993-4-1 is intended to be used with other Eurocodes and standards:

- EN 1990 (Basis of design)

- EN 1991‑4 (Actions in silos and tanks)

- EN 1993‑1 series (general steel rules)

- EN 1993‑1‑6 / EN 1993‑4‑2 (shell and tank-related rules)

- EN 1992, EN 1997 (foundations and geotechnical design)

- EN 1090 (execution of steel structures)

Keywords: EN 1993-4-1, Eurocode 3, steel silos, silo design, circular silos, rectangular silos, structural design, CEN, silo standards.

Frequently Asked Questions

SIST EN 1993-4-1:2007 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Eurocode 3 - Design of steel structures - Part 4-1: Silos". This standard covers: Complementary to Part 1. Varied general rules and additional detailed rules for the structural design of free standing or supported steel silos of circular or rectangular plan for storing bulk granular solids.

Complementary to Part 1. Varied general rules and additional detailed rules for the structural design of free standing or supported steel silos of circular or rectangular plan for storing bulk granular solids.

SIST EN 1993-4-1:2007 is classified under the following ICS (International Classification for Standards) categories: 65.040.20 - Buildings and installations for processing and storage of agricultural produce; 91.010.30 - Technical aspects; 91.080.13 - Steel structures. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1993-4-1:2007 has the following relationships with other standards: It is inter standard links to SIST ENV 1993-4-1:2001, kSIST FprEN 1993-4-1:2025, SIST EN 1993-4-1:2007/A1:2017, SIST EN 1993-4-1:2007/kFprA1:2014, SIST EN 1993-4-1:2007/AC:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1993-4-1:2007 is associated with the following European legislation: EU Directives/Regulations: 2005-01-4408, 305/2011, 89/106/EEC; Standardization Mandates: M/265, M/BC/CEN/89/11. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1993-4-1:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Eurocode 3 - Design of steel structures - Part 4-1: SilosEvrokod 3: Projektiranje jeklenih konstrukcij - 4-1.del: SilosiEurocode 3 - Calcul des structures en acier - Partie 4-1: SilosEurocode 3 - Bemessung und Konstruktion von Stahlbauten - Teil 4-1: SilosTa slovenski standard je istoveten z:EN 1993-4-1:2007SIST EN 1993-4-1:2007en;de91.080.10Kovinske konstrukcijeMetal structures91.010.30Technical aspects65.040.20Buildings and installations for processing and storage of agricultural produceICS:SIST ENV 1993-4-1:20011DGRPHãþDSLOVENSKI

STANDARDSIST EN 1993-4-1:200701-julij-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1993-4-1February 2007ICS 65.040.20; 91.010.30; 91.080.10Supersedes ENV 1993-4-1:1999

English VersionEurocode 3 - Design of steel structures - Part 4-1: SilosEurocode 3 - Calcul des structures en acier - Partie 4-1:SilosEurocode 3 - Bemessung und Konstruktion vonStahlbauten - Teil 4-1: SilosThis European Standard was approved by CEN on 12 June 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1993-4-1:2007: E

EN 1993-4-1: 2007 (E)

Contents

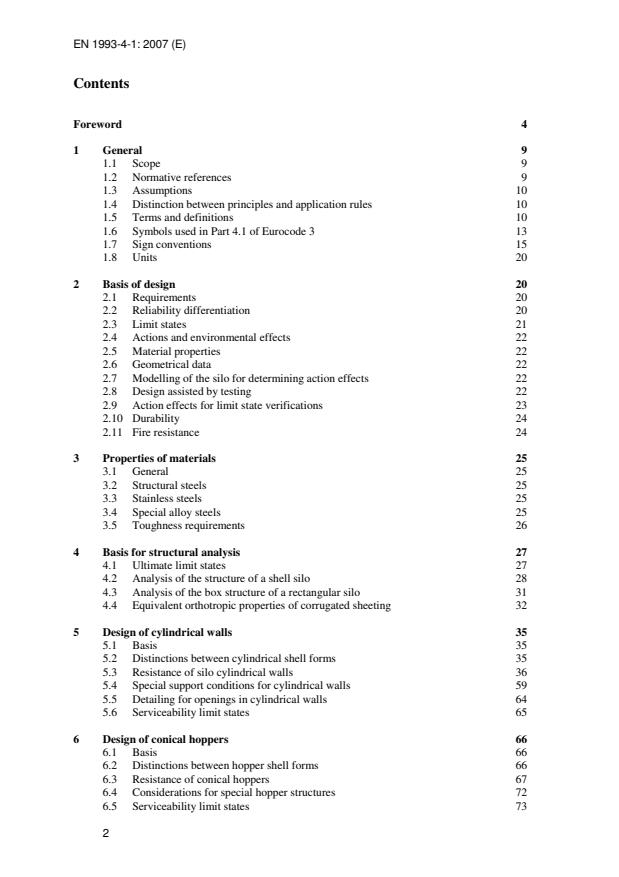

Foreword 4 1 General 9 1.1 Scope 9 1.2 Normative references 9 1.3 Assumptions 10 1.4 Distinction between principles and application rules 10 1.5 Terms and definitions 10 1.6 Symbols used in Part 4.1 of Eurocode 3 13 1.7 Sign conventions 15 1.8 Units 20 2

Basis of design 20 2.1 Requirements 20 2.2 Reliability differentiation 20 2.3 Limit states 21 2.4 Actions and environmental effects 22 2.5 Material properties 22 2.6 Geometrical data 22 2.7 Modelling of the silo for determining action effects 22 2.8 Design assisted by testing 22 2.9 Action effects for limit state verifications 23 2.10 Durability 24 2.11 Fire resistance 24 3

Properties of materials 25 3.1 General 25 3.2 Structural steels 25 3.3 Stainless steels 25 3.4 Special alloy steels 25 3.5 Toughness requirements 26 4 Basis for structural analysis 27 4.1 Ultimate limit states 27 4.2 Analysis of the structure of a shell silo 28 4.3 Analysis of the box structure of a rectangular silo 31 4.4 Equivalent orthotropic properties of corrugated sheeting 32 5 Design of cylindrical walls 35 5.1 Basis 35 5.2 Distinctions between cylindrical shell forms 35 5.3 Resistance of silo cylindrical walls 36 5.4 Special support conditions for cylindrical walls 59 5.5 Detailing for openings in cylindrical walls 64 5.6 Serviceability limit states 65 6 Design of conical hoppers 66 6.1 Basis 66 6.2 Distinctions between hopper shell forms 66 6.3 Resistance of conical hoppers 67 6.4 Considerations for special hopper structures 72 6.5 Serviceability limit states 73

EN 1993-4-1: 2007 (E)

7 Design of circular conical roof structures 75 7.1 Basis 75 7.2 Distinctions between roof structural forms 75 7.3 Resistance of circular conical silo roofs 75 8 Design of transition junctions and supporting ring girders 77 8.1 Basis 77 8.2 Analysis of the junction 80 8.3 Structural resistances 86 8.4 Limit state verifications 90 8.5 Considerations concerning support arrangements for the junction 92 9 Design of rectangular and planar-sided silos 94 9.1 Basis 94 9.2 Classification of structural forms 94 9.3 Resistance of unstiffened vertical walls 95 9.4 Resistance of silo walls composed of stiffened and corrugated plates 95 9.5 Silos with internal ties 100 9.6 Strength of pyramidal hoppers 100 9.7 Vertical stiffeners on box walls 102 9.8 Serviceability limit states 102 Annex A: [Informative] 104 Simplified rules for circular silos in Consequence Class 1 104 A.1 Action combinations for Consequence Class 1 104 A.2 Action effect assessment 104 A.3 Ultimate limit state assessment 104 Annex B: [Informative] 111 Expressions for membrane stresses in conical hoppers 111 Annex C: [Informative] 113 Distribution of wind pressure around circular silo structures 113

EN 1993-4-1: 2007 (E)

Foreword This European Standard EN 1993-4-1, “Eurocode 3: Design of steel structures – Part 4-1: Silos”, has been prepared by Technical Committee CEN/TC250 « Structural Eurocodes », the Secretariat of which is held by BSI. CEN/TC250 is responsible for all Structural Eurocodes.

This European Standard shall be given the status of a National Standard, either by publication of an identical text or by endorsement, at the latest by August 2007 and conflicting National Standards shall be withdrawn at latest by March 2010.

This Eurocode supersedes ENV 1993-4-1:1999.

According to the CEN-CENELEC Internal Regulations, the National Standard Organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Background of the Eurocode programme In 1975, the Commission of the European Community decided on an action programme in the field of construction, based on article 95 of the Treaty. The objective of the programme was the elimination of technical obstacles to trade and the harmonisation of technical specifications. Within this action programme, the Commission took the initiative to establish a set of harmonised technical rules for the design of construction works which, in a first stage, would serve as an alternative to the national rules in force in the Member States and, ultimately, would replace them.

For fifteen years, the Commission, with the help of a Steering Committee with Representatives of Member States, conducted the development of the Eurocodes programme, which led to the first generation of European codes in the 1980’s.

In 1989, the Commission and the Member States of the EU and EFTA decided, on the basis of an agreement1)

between the Commission and CEN, to transfer the preparation and the publication of the Eurocodes to the CEN through a series of Mandates, in order to provide them with a future status of European Standard (EN). This links de facto the Eurocodes with the provisions of all the Council’s Directives and/or Commission’s Decisions dealing with European standards (e.g. the Council Directive 89/106/EEC on construction products - CPD - and Council Directives 93/37/EEC, 92/50/EEC and 89/440/EEC on public works and services and equivalent EFTA Directives initiated in pursuit of setting up the internal market). The Structural Eurocode programme comprises the following standards generally consisting of a number of Parts: EN1990 Eurocode: Basis of structural design EN1991 Eurocode 1: Actions on structures EN1992 Eurocode 2: Design of concrete structures EN1993 Eurocode 3: Design of steel structures EN1994 Eurocode 4: Design of composite steel and concrete structures EN1995 Eurocode 5: Design of timber structures

1) Agreement between the Commission of the European Communities and the European Committee for Standardisation (CEN) concerning the work on EUROCODES for the design of building and civil engineering works (BC/CEN/03/89).

EN 1993-4-1: 2007 (E)

EN1996 Eurocode 6: Design of masonry structures EN1997 Eurocode 7: Geotechnical design EN1998 Eurocode 8: Design of structures for earthquake resistance EN1999 Eurocode 9: Design of aluminium structures Eurocode standards recognise the responsibility of regulatory authorities in each Member State and have safeguarded their right to determine values related to regulatory safety matters at national level where these continue to vary from State to State. Status and field of application of Eurocodes The Member States of the EU and EFTA recognise that EUROCODES serve as reference documents for the following purposes:

as a means to prove compliance of building and civil engineering works with the essential requirements of Council Directive 89/106/EEC, particularly Essential Requirement N°1 - Mechanical resistance and stability - and Essential Requirement N°2 - Safety in case of fire ; - as a basis for specifying contracts for construction works and related engineering services ; - as a framework for drawing up harmonised technical specifications for construction products (ENs and ETAs) The Eurocodes, as far as they concern the construction works themselves, have a direct relationship with the Interpretative Documents2) referred to in Article 12 of the CPD, although they are of a different nature from harmonised product standards3). Therefore, technical aspects arising from the Eurocodes work need to be adequately considered by CEN Technical Committees and/or EOTA Working Groups working on product standards with a view to achieving full compatibility of these technical specifications with the Eurocodes. The Eurocode standards provide common structural design rules for everyday use for the design of whole structures and component products of both a traditional and an innovative nature. Unusual forms of construction or design conditions are not specifically covered and additional expert consideration will be required by the designer in such cases. National Standards implementing Eurocodes The National Standards implementing Eurocodes will comprise the full text of the Eurocode (including any annexes), as published by CEN, which may be preceded by a National title page and National foreword, and may be followed by a National Annex. The National Annex may only contain information on those parameters which are left open in the Eurocode for national choice, known as Nationally Determined Parameters, to be used for the design of buildings and civil engineering works to be constructed in the country concerned, i.e. :

2) According to Art. 3.3 of the CPD, the essential requirements (ERs) shall be given concrete form in interpretative documents for the creation of the necessary links between the essential requirements and the mandates for harmonised ENs and ETAGs/ETAs. 3) According to Art. 12 of the CPD the interpretative documents shall : a) give concrete form to the essential requirements by harmonising the terminology and the technical bases and indicating classes or levels for each requirement where necessary ; b) indicate methods of correlating these classes or levels of requirement with the technical specifications, e.g. methods of calculation and of proof, technical rules for project design, etc. ; c) serve as a reference for the establishment of harmonised standards and guidelines for European technical approvals.

The Eurocodes, de facto, play a similar role in the field of the ER 1 and a part of ER 2.

EN 1993-4-1: 2007 (E)

- values and/or classes where alternatives are given in the Eurocode, - values to be used where a symbol only is given in the Eurocode, - country specific data (geographical, climatic, etc), e.g. snow map, - the procedure to be used where alternative procedures are given in the Eurocode. It may also contain:

decisions on the application of informative annexes, - references to non-contradictory complementary information to assist the user to apply the Eurocode. Links between Eurocodes and harmonised technical specifications (ENs and ETAs) for products There is a need for consistency between the harmonised technical specifications for construction products and the technical rules for works4). Furthermore, all the information accompanying the CE Marking of the construction products which refer to Eurocodes should clearly mention which Nationally Determined Parameters have been taken into account. Additional information specific to EN1993-4-1 EN 1993-4-1 gives design guidance for the structural design of silos. EN 1993-4-1 gives design rules that supplement the generic rules in the many parts of EN 1993-1. EN 1993-4-1 is intended for clients, designers, contractors and relevant authorities. EN 1993-4-1 is intended to be used in conjunction with EN 1990, with EN 1991-4, with the other Parts of EN 1991, with EN 1993-1-6 and EN 1993-4-2, with the other Parts of EN 1993, with EN 1992 and with the other Parts of EN 1994 to EN 1999 relevant to the design of silos.

Matters that are already covered in those documents are not repeated. Numerical values for partial factors and other reliability parameters are recommended as basic values that provide an acceptable level of reliability. They have been selected assuming that an appropriate level of workmanship and quality management applies. Safety factors for ‘product type’ silos (factory production) can be specified by the appropriate authorities.

When applied to ‘product type’ silos, the factors in 2.10 are for guidance purposes only.

They are provided to show the likely levels needed to achieve consistent reliability with other designs. National Annex for EN1993-4-1 This standard gives alternative procedures, values and recommendations for classes with notes indicating where national choices may have to be made. Therefore the National Standard implementing EN 1993-4-1 should have a National Annex containing all Nationally Determined Parameters to be used for the design of buildings and civil engineering works to be constructed in the relevant country. National choice is allowed in EN 1993-4-1 through:

2.2 (1)

- 2.2 (3)

4) see Art.3.3 and Art.12 of the CPD, as well as clauses 4.2, 4.3.1, 4.3.2 and 5.2 of ID 1.

EN 1993-4-1: 2007 (E)

- 2.9.2.2 (3) - 3.4 (1)

- 4.1.4 (2) and (4)

- 4.2.2.3 (6)

- 4.3.1 (6) and (8) - 5.3.2.3 (3)

- 5.3.2.4 (10), (12) and (15)

- 5.3.2.5 (10) and (14) - 5.3.2.6 (3) and (6) - 5.3.2.8 (2)

- 5.3.3.5 (1) and (2) - 5.3.4.3.2 (2)

- 5.3.4.3.3 (2) and (5) - 5.3.4.3.4 (5) - 5.3.4.5 (3)

- 5.4.4 (2), (3) and (4)

- 5.4.7 (3)

- 5.5.2 (3)

- 5.6.2 (1) and (2)

- 6.1.2 (4)

- 6.3.2.3 (2) and (4)

- 6.3.2.7 (3)

- 7.3.1 (4)

- 8.3.3 (4)

- 8.4.1 (6)

- 8.4.2 (5)

- 8.5.3 (3)

- 9.5.1 (3) and (4) - 9.5.2 (5)

- 9.8.2 (1) and (2)

- A.2 (1) and (2)

- A.3.2.1 (6) - A.3.2.2 (6)

- A.3.2.3 (2)

- A.3.3 (1), (2) and (3)

- A.3.4 (4)

EN 1993-4-1: 2007 (E)

1 General 1.1 Scope (1) Part 4.1 of Eurocode 3 provides principles and application rules for the structural design of steel silos of circular or rectangular plan-form, being free standing or supported. (2)

The provisions given in this Part supplement modify or supersede the equivalent provisions given in EN 1993-1. (3) This part is concerned only with the requirements for resistance and stability of steel silos.

For other requirements (such as operational safety, functional performance, fabrication and erection, quality control, details like man-holes, flanges, filling devices, outlet gates and feeders etc.), see the relevant standards. (4) Provisions relating to special requirements of seismic design are provided in EN 1998-4, which complements or adapts the provisions of Eurocode 3 specifically for this purpose. (5) The design of supporting structures for the silo are dealt with in EN 1993-1-1.

The supporting structure is deemed to consist of all structural elements beneath the bottom flange of the lowest ring of the silo, see figure 1.1. (6) Foundations in reinforced concrete for steel silos are dealt with in EN 1992 and EN 1997. (7) Numerical values of the specific actions on steel silos to be taken into account in the design are given in EN 1991-4 Actions in Silos and Tanks.

(8) This Part 4.1 does not cover: - resistance to fire; - silos with internal subdivisions and internal structures; - silos with capacity less than 10 tonnes; - cases where special measures are necessary to limit the consequences of accidents. (9) Where this standard applies to circular planform silos, the geometric form is restricted to axisymmetric structures, but the actions on them may be unsymmetrical, and their supports may induce forces in the silo that are not axisymmetrical. 1.2 Normative references This European Standard incorporates, by dated and undated reference, provisions from other standards.

These normative references are cited at the appropriate places in the text and the publications are listed hereafter. For dated references, subsequent amendments to, or revisions of, any of these publications apply to the European Standard only when incorporated in it by amendment or revision.

For undated references the latest edition of the publication referred to applies. EN 1090 Execution of steel structures; EN 1990 Eurocode: Basis of design; EN 1991 Eurocode 1: Actions on structures; Part 1.1 Actions on structures – Densities, self-weight and imposed loads for buildings; Part 1.2:

Actions on structures – Actions on structures exposed to fire; Part 1.3:

Actions on structures – Snow loads; Part 1.4:

Actions on structures – Wind loads;

EN 1993-4-1: 2007 (E)

Part 1.5:

Actions on structures – Thermal loads; Part 1.6:

Actions on structures – Construction loads; Part 1.5:

Actions on structures – Accidental actions; Part 4:

Actions on silos and tanks; EN 1993 Eurocode 3: Design of steel structures; Part 1.1: General rules and rules for buildings; Part 1.3:

Cold formed thin gauge members and sheeting; Part 1.4:

Stainless steels; Part 1.6:

Strength and stability of shell structures; Part 1.7:

Planar plated structures loaded transversely; Part 1.8:

Design of joints; Part 1.9:

Fatigue strength of steel structures; Part 1.10:

Selection of steel for fracture toughness and through-thickness properties; Part 4.2:

Tanks; EN 1997 Eurocode 7: Geotechnical design; EN 1998 Eurocode 8: Design provisions for earthquake resistance of structures; Part 4:

Silos, tanks and pipelines; EN 10025 Hot rolled products of non-alloy structural steels - technical delivery conditions; EN 10147 Hot-rolled flat products made of high yield strength steels for cold forming; ISO 1000 SI Units; ISO 3898 Bases for design of structures - Notation - General symbols; ISO 4997 Cold reduced steel sheet of structural quality; ISO 8930 General principles on reliability for structures - List of equivalent terms.

1.3 Assumptions (1) In addition to the general assumptions of EN 1990 the following assumptions apply:

– fabrication and erection complies with EN 1090-2 1.4 Distinction between principles and application rules (1) See 1.4 in EN 1990. 1.5 Terms and definitions (1) The terms that are defined in 1.5 in EN 1990 for common use in the Structural Eurocodes and the definitions given in ISO 8930 apply to this Part 4.1 of EN 1993, unless otherwise stated, but for the purposes of this Part 4.1 the following supplementary definitions are given: 1.5.1

shell.

A structure formed from a curved thin plate.

EN 1993-4-1: 2007 (E)

1.5.2

axisymmetric shell.

A shell structure whose geometry is defined by rotation of a meridional line about a central axis.

1.5.3

box.

A structure formed from an assembly of flat plates into a three-dimensional enclosed form.

For the purposes of this Standard, the box has dimensions that are generally comparable in all directions.

1.5.4

meridional direction.

The tangent to the silo wall in a vertical plane at any point.

It varies according to the structural element being considered.

Alternatively, it is the vertical or inclined direction on the surface of the structure that a rain drop would take in sliding down the surface. 1.5.5

circumferential direction.

The horizontal tangent to the silo wall at any point.

It varies around the silo, lies in the horizontal plane and is tangential to the silo wall irrespective of whether the silo is circular or rectangular in plan. 1.5.6

middle surface.

This term is used to refer to both the stress-free middle surface when a shell is in pure bending and the middle plane of a flat plate that forms part of a box. 1.5.7

separation of stiffeners.

The centre to centre distance between the longitudinal axes of two adjacent parallel stiffeners. Supplementary to Part 1 of EN 1993 (and Part 4 of EN 1991), for the purposes of this Part 4.1, the following terminology applies, see figure 1.1: 1.5.8

silo:

A silo is a vessel for storing particulate granular solids.

In this Standard, it is assumed to have a vertical form with solids being added by gravity at the top.

The term silo includes all forms of particulate solids storage structure, that might otherwise be referred to as a bin, hopper, grain tank or bunker. 1.5.9

barrel:

The barrel is the vertical walled section of a silo. 1.5.10

hopper:

A hopper is a converging section towards the bottom of a silo.

It is used to channel solids towards a gravity discharge outlet. 1.5.11

junction:

A junction is the point at which any two or more shell segments, or two or more flat plate elements of a box meet.

It can include a stiffener or not: the point of attachment of a ring stiffener to the shell or box may be treated as a junction. 1.5.12

transition junction:

The transition junction is the junction between the barrel and hopper.

The junction can be at the base of the barrel or part way down it. 1.5.13

skirt:

The skirt is that part of the barrel which lies below the transition junction: it differs from the higher part in that it has no contact with the stored bulk solids. 1.5.14

strake:

A strake or course is a single layer of steel plates used to form one level of the cylindrical barrel of a silo. 1.5.15

stringer stiffener:

A stringer stiffener is a local stiffening member that follows the meridian of a shell, representing a generator of the shell of revolution.

It is provided to increase the stability, or to assist with the introduction of local loads or to carry axial loads.

It is not intended to provide a primary load carrying capacity for bending due to transverse loads. 1.5.16

rib:

A rib is a local member that provides a primary load carrying path for loads causing bending down the meridian of a shell or flat plate, representing a generator of the shell of revolution

EN 1993-4-1: 2007 (E)

or a vertical stiffener on a box.

It is used to distribute transverse loads on the structure by bending action. 1.5.17

ring stiffener:

A ring stiffener is a local stiffening member that passes around the circumference of the structure at a given point on the meridian.

It is assumed to have no stiffness in the meridional plane of the structure.

It is provided to increase the stability or to introduce local loads, not as a primary load-carrying element.

In a shell of revolution it is circular, but in rectangular structures is takes the rectangular form of the plan section. 1.5.18

smeared stiffeners:

Stiffeners are said to be smeared when the properties of the shell wall and the individual stiffeners are treated as a composite section using a width equal to an integer multiple of the separation of the stiffeners.

The stiffness properties of a shell wall with smeared stiffeners are orthotropic with eccentric terms leading to coupling between bending and stretching behaviour. Cylindricalshell orbarrelConical roofColumn:supportingstructureConical hopperRingSkirtTransitionSiloendshere RectangularboxPyramidalroofColumn:supportingstructurePyramidal hopperRing girderSkirtTransition a)

Circular planform silo

b)

Rectangular planform silo

Figure 1.1:

Terminology used in silo structures 1.5.19

base ring:

A base ring is a structural member that passes around the circumference of the structure at the base and provides means of attachment of the structure to a foundation or other element.

It is required to ensure that the assumed boundary conditions are achieved in practice. 1.5.20

ring girder or ring beam:

A ring girder or ring beam is a circumferential stiffener which has bending stiffness and strength both in the plane of the circular section of a shell or the plan section of a rectangular structure and also normal to that plane.

It is a primary load-carrying element, used to distribute local loads into the shell or box structure. 1.5.21 continuous support:

A continuously supported silo is one in which all positions around the circumference are supported in an identical manner.

Minor departures from this condition (e.g. a small opening) need not affect the applicability of the definition. 1.5.22

discrete support:

A discrete support is a position in which a silo is supported using a local bracket or column, giving a limited number of narrow supports around the silo circumference.

Four or six discrete supports are commonly used, but three or more than six are also found.

EN 1993-4-1: 2007 (E)

1.5.23

pyramidal hopper:

A pyramidal hopper is used for the hopper section of a rectangular silo, in the form of an inverted pyramid.

In this Standard, it is assumed that the geometry is simple, consisting of only four planar elements of trapezoidal shape. 1.6 Symbols used in Part 4.1 of Eurocode 3 The symbols used are based on ISO 3898: 1987.

1.6.1 Roman upper case letters A

area of cross-section; C

membrane stretching stiffness; C buckling coefficient; D

bending flexural rigidity; E

Young’s modulus; F

force; G

shear modulus; H

height of structure; I

second moment of area of cross-section; It

uniform torsion constant; K

flexural stiffness of wall panel; L

height of shell segment or stiffener; M

bending moment; N

axial force; Q

fabrication tolerance quality of construction of a shell susceptible to buckling; Rf

local radius at the crest or trough of a corrugation. 1.6.2 Roman lower case letters a

coefficient; b

width of plate or stiffener; d

crest to crest dimension of a corrugation; e

eccentricity of force or stiffener; fy

yield strength of steel; fu

ultimate strength of steel; h

separation of flanges of ring girder; j

joint efficiency factor for welded lap joints assessed using membrane stresses; j

equivalent harmonic of the design stress variation;

effective length of shell in linear stress analysis;

wavelength of a corrugation in corrugated sheeting;

half wavelength of a potential buckle (height to be considered in calculation); m

bending moment per unit width; mx

meridional bending moment per unit circumference; my circumferential bending moment per unit height of box; mq circumferential bending moment per unit height of shell; mxy

twisting shear moment per unit width of plate; mxq

twisting shear moment per unit width of shell; n

membrane stress resultant; n number of discrete supports around silo circumference; nx meridional membrane stress resultant per unit circumference; ny circumferential membrane stress resultant per unit height of box; nq circumferential membrane stress resultant per unit height of shell; nxy membrane shear stress resultant per unit width of plate; nxq

membrane shear stress resultant per unit width of shell;

EN 1993-4-1: 2007 (E)

p

pressure distributed loading; pn

pressure normal to shell (outward); px

meridional surface loading parallel to shell (downward); pq

circumferential surface loading parallel to shell (anticlockwise in plan); q

transverse force per unit length acting on a tie; r

radial coordinate in a circular plan-form silo; r

radius of shell middle surface; s

circumferential separation of stiffeners; t

wall thickness; tx,

ty

equivalent wall thickness of corrugated sheet for stretching in the x, y directions; w

imperfection amplitude; w radial deflection; x

local meridional coordinate; y

local circumferential coordinate; z

global axial coordinate; z

coordinate along the vertical axis of an axisymmetric silo (shell of revolution). 1.6.3 Greek letters a

elastic buckling imperfection factor (knock-down factor); a coefficient of thermal expansion; b

hopper apex half angle; gF

partial factor for actions; gM

partial factor for resistance; d

limiting deflection; D

increment; c

reduction factor for flexural column buckling; c

shell buckling stress reduction factor; l

shell meridional bending half-wavelength; l-

relative slenderness of a shell; m

wall friction coefficient; n

Poisson’s ratio; q

circumferential coordinate around shell; s

direct stress; sbx

meridional bending stress; sby

circumferential bending stress in box; sbq

circumferential bending stress in curved shell; tbxy

twisting shear stress in box; tbxq

twisting shear stress in curved shell; smx

meridional membrane stress; smy

circumferential membrane stress in box; smq

circumferential membrane stress in curved shell; tmxy

membrane shear stress in box; tmxq

membrane shear stress in curved shell; ssox

meridional outer surface stress; ssoy

circumferential outer surface stress in box; ssoq

circumferential outer surface stress in curved shell; tsoxy

outer surface shear stress in box; tsoxq

outer surface shear stress in curved shell; t

shear stress; w

dimensionless parameter in buckling calculation;

EN 1993-4-1: 2007 (E)

w inclination to vertical of a hopper whose axis is not vertical; y

stress non-uniformity parameter. 1.6.4 Subscripts E value of stress or displacement (arising from design actions);

F actions;

M material;

R resistance; S value of stress resultant (arising from design actions); b

bending; c cylinder; cr critical buckling value; d design value; eff

effective;

h hopper; m

membrane, midspan; min minimum allowed value; n

normal to the wall; p

pressure; r

radial; s

skirt, support; s

surface stress (o… outer surface, i… inner surface) u

ultimate; w

meridionally parallel to the wall (wall friction); x

meridional; y

circumferential (box structures), yield; z

axial direction; q

circumferential (shells of revolution). 1.7 Sign conventions 1.7.1 Conventions for global silo structure axis system for circular silos (1) The sign convention given here is for the complete silo structure, and recognises that the silo is not a structural member.

a)

general coordinate system b)

silo shell coordinates and loading: section

Figure 1.2:

Coordinate systems for a circular silo

EN 1993-4-1: 2007 (E)

(2) In general, the convention for the global silo structure axis system is in cylindrical coordinates (see figure 1.2) as follows: Coordinate system Coordinate along the central axis of a shell of revolution z

Radial coordinate r Circumferential coordinate

q (3) The convention for positive directions is: Outward direction positive (internal pressure positive, outward displacements positive)

Tensile stresses positive (except in buckling expressions where compression is positive)

(4) The convention for distributed actions on the silo wall surface is: Pressure normal to shell (outward positive) pn

Meridional surface loading parallel to shell (downward positive) px

Circumferential surface loading parallel to shell (anticlockwise positive in plan) pq

1.7.2 Conventions for global silo structure axis system for rectangular silos (1) The sign convention given here is for the complete silo structure, and recognises that the silo is not a structural member.

(2) In general, the convention for the global silo structure axis system is in Cartesian coordinates

x, y, z, where the vertical direction is taken as

z,

see figure 1.3. (3) The convention for positive directions is: Outward direction positive (internal pressure positive, outward displacements positive)

Tensile stresses positive (except in buckling expressions where compression is positive)

(4) The convention for distributed actions on the silo wall surface is:

Pressure normal to box (outward positive) pn Meridional surface loading parallel to box surface (downward positive) px

Circumferential surface loading in the plane of the box plan cross-section (anticlockwise positive)

py

EN 1993-4-1: 2007 (E)

a)

general coordinate system b)

silo box coordinates and loading: section

Figure 1.3:

Coordinate systems for a rectangular silo

1.7.3 Conventions for structural element axes in both circular and rectangular silos (1) The convention for structural elements attached to the silo wall

(see figures 1.4 and 1.5) is different for meridional and circumferential members. (2) The convention for meridional straight structural elements (see figure 1.4a) attached to the silo wall (shells and boxes) is: Meridional coordinate for barrel, hopper and roof attachment x Strong bending axis (parallel to flanges: axis for meridional bending) y Weak bending axis (perpendicular to flanges) z NOTE:

A meridional stiffener bending in a manner that is compatible with meridional bending

(mx) in the cylinder bends about the

y

axis of the stiffener.

EN 1993-4-1: 2007 (E)

a)

stiffener and axes of bending b)

local axes in different segments

Figure 1.4:

Local coordinate systems for meridional stiffeners on a shell or box

a)

stiffener and axes of bending b)

local axes in different segments

Figure 1.5:

Local coordinate systems for circumferential stiffeners on a shell or box (3) The convention for circumferential curved structural elements (see figure 1.5a) attached to a shell wall is: Circumferential coordinate axis (curved) q Radial axis

(axis for bending in the vertical plane) r Vertical axis

(axis for circumferential bending) z NOTE: A circumferential stiffener or ring is subject to bending about its vertical axis z when the bending is compatible with circumferential bending in the cylinder (mq).

It is subject to bending moments about its radial axis r when either acting as a ring girder, or when subject to radial forces acting at a point eccentric to the ring centroid.

EN 1993-4-1: 2007 (E)

(4) The convention for circumferential straight structural elements attached to a box is: Circumferential axis

x Horizontal axis

y Vertical axis

z NOTE: A circumferential straight stiffener on a box is subject to bending about its vertical axis

z

when the bending is out of the plane of the box wall, which is the normal condition.

1.7.4 Conventions for stress resultants for circular silos and rectangular silos (1) The convention used for subscripts indicating membrane forces is: "The subscript derives from the direction in which direct stress is induced by the force" Membrane stress resultants: nx meridional membrane stress resultant nq circumferential membrane stress resultant in shells ny circumferential membrane stress resultant in rectangular boxes nxy or nxq membrane shear stress resultant Membrane stresses:

smx meridional membrane stress smq circumferential membrane stress in shells smy circumferential membrane stress in rectangular boxes tmxy or tmxq membrane shear stress (2) The convention used for subscripts indicating moments is: "The subscript derives from the direction in which direct stress is induced by the moment" NOTE: This plate and shell convention differs from that for beams and columns as used in Eurocode 3 Parts 1.1 and 1.3.

Care must be exercised when using Parts 1.1 and 1.3 in conjunction with these rules. Bending stress resultants: mx meridional bending moment per unit width mq circumferential bending moment per unit width in shells my circumferential bending stress resultant in rectangular boxes mxy or mxq twisting shear moment per unit width

Bending stresses: sbx meridional bending stress sbq circumferential bending stress in shells sby circumferential bending stress in rectangular boxes tbxy or tbxq twisting shear stress

EN 1993-4-1: 2007 (E)

Inner and outer surface stresses:

ssix, ssox

meridional inner, outer surface stress for boxes and shells ssiq, ssoq

circumferential inner, outer surface stress in shells tsixq, tsoxq

inner, outer surface shear stress in shells ssiy, ssoy

circumferential inner, outer surface stress in rectangular boxes tsixy, tsoxy

inner, outer surface shear stress in rectangular boxes

a)

Membrane stress resultants

b)

Bending stress resultants

Figure 1.6:

Stress resultants in the silo wall

(shells and boxes)

1.8 Units (1)P S.I. units shall be used in accordance with ISO 1000.

(2) For calculations, the following consistent units are recommended: - dimensions and thicknesses : m mm - unit weight

: kN/m3 N/mm3 - forces and loads : kN N - line forces and line loads

: kN/m N/mm - pressures and area distributed actions : kPa MPa - unit mass

: kg/m3 kg/mm3 - acceleration

: km/s2 m/s2 - membrane stress resultants : kN/m N/mm - bending stress resultants : kNm/m Nmm/mm - stresses and elastic moduli : kPa MPa (=N/mm2)

EN 1993-4-1: 2007 (E)

Basis of design 2.1 Requirements (1)P A silo shall be designed, constructed and maintained to meet the requirements of section 2 of EN 1990 as supplemented by the following. (2) The silo structure should include all shell and plated sections of the structure, including stiffeners, ribs, rings and attachments.

(3) The supporting structure should not be treated as part of the silo structure.

The boundary between the silo and its supports should be taken as indicated in figure 1.1.

Similarly, other structures supported by the silo should be treated as beginning where the silo wall or attachment ends.

(4) Silos should be designed to be damage-tolerant where appropriate, considering the use of the silo. (5) Particular requirements for special applications may be agreed between the designer, the client and the relevant authority. 2.2 Reliability differentiation (1) For reliability differentiation, see EN 1990. NOTE:

The national annex may define consequence classes for silos as a function of the location, type of infill and loading, the structural type, size and type of operation.

(2) Different levels of rigour should be used in the design of silo structures, depending on the consequence class chosen, the structural arrangement and the susceptibility to different failure modes. (3) For this standard, 3 consequence classes are used, with requirements which produce designs with essentially equal risk in the design assessment and considering the expense and procedures necessary to reduce the risk of failure for different structures: Consequence Classes 1, 2 and 3. NOTE 1:

The national annex may provide information one the consequence classes. Table 2.1 gives an example for the classification of two parameters, the size and the type of operation into consequence classes when all other parameters result in medium consequences, see EN 1990, B.3.1.

EN 1993-4-1: 2007 (E)

Table 2.1: Consequence classes depending on size and operation Consequence Class Design situations

Consequence Class 3

Ground supported silos or silos supported on a complete skirt extending to the ground with capacity in excess of

W3a tonnes

Discretely supported silos with capacity in excess of

W3b

tonnes

Silos with capacity in excess of

W3c tonnes in which any of the following design situations occur: a) eccentric discharge b) local patch loading c) unsymmetrical filling Consequence Class 2 All silos covered by this Standard and not placed in another class

Consequence Class 1 Silos with capacity between W1a

tonnes† and

W1b

tonnes

† Silos with capacity less than W1a tonnes are not covered by this standard.

The recommended values for class boundaries are as follows: Class boundary Recommended value (tonnes) W3a 5000 W3b 1000 W3c 200 W1b 100 W1a 10 NOTE 2:

For the classification into action assessment classes, see

EN 1991-4 (4) A higher Consequence Class may always be adopted than that required. (5)P The choice of relevant Consequence Class shall be agreed between the designer, the client and the relevant authority. (6) Consequence Class 3 should be used for local patch loading, which refers to a stored solids loading case causing a patch load which extends round less than half the circumference of the silo, as defined in EN 1991-4. (7) For Consequence Class 1, simplified provisions may be adopted. NOTE: Appropriate provisions for silos in Consequence Class 1 are set out in Annex A. 2.3 Limit states (1) The limit states defined in EN 1993-1-6 should be adopted for this Part.

EN 1993-4-1: 2007 (E)

2.4 Actions and environmental effects 2.4.1 General (1)P The general requirements set out in section 4 of EN 1990 shall be satisfied. 2.4.2 Wind action (1) For specifications of wind actions not set down in EN 1991-1-4 for the design of silos in isolation and in groups, appropriate additional information should be agreed. (2) Because these large light structures are sensitive to the detailed wind pressure distribution on the wall, both with respect to the buckling resistance when empty and the holding down details required at the foundation, additional information may be used to augment the basic wind data provided in EN 1991-1-4 for the specific needs of individual constructions. NOTE: Appropriate additional information on wind pressure distributions is set out in Annex C. 2.4.3 Combination of solids pressures with other actions (1)P The partial factors on actions in silos set out in 2.9.2 shall be used. 2.5 Material properties (1) The general requirements for material properties set out in EN 1993-1-1 should be followed.

(2) The specific properties of materials for silos given in section 3 of this Part should be used. 2.6 Geometrical data (1)P The provisions concerning geometrical data given in section 6 of EN 1990 shall be followed.

(2) The additional information specific to shell structures given in EN 1993-1-6 should also be applied. (3) The shell plate thickness should be taken as the nominal thickness.

In the case of hot-dipped metal coated steel sheet conforming with EN 10147, the nominal thickness should be taken as the nominal core thickness, obtained as the nominal external thickness less the total thickness of zinc coating on both surfaces. (4) The effects of corrosion and abrasion on the thickness of silo wall plates should be included in the design, in accordance with 4.1.4. 2.7 Modelling of the silo for determining action effects (1)P The general requirements set out in section 7 of EN 1990 shall be followed.

(2) The specific requirements for structural analysis in relation to serviceability, set out in sections 4 to 9 of this Part for each structural segment, should be followed. (3) The specific requirements for structural analysis in relation to ultimate limit states, set out in sections 4 to 9 of this Part and in more detail in EN 1993-1-6 and EN 1993-1-7, should be followed. 2.8 Design assisted by testing (1) The general requirements set out in Annex D of EN 1990 should be followed.

EN 1993-4-1: 2007 (E)

(2) For 'product type' silos (factory production), which are subject to full scale testing, 'deemed-to-satisfy' criteria may be adopted for design purposes. 2.9 Action effects for limit state verifications 2.9.1 General (1)P The general requirements set out in section 9 of EN 1990 shall be satisfied.

2.9.2 Partial factors for ultimate limit states 2.9.2.1 Partial factors for actions on silos (1)P For persistent, transient and accidental design situations, the partial factors gF shall be taken from EN 1990 and EN 1991-4. (2) Partial factors for ‘product type’ silos (factory production) may be specified by the appropriate authorities.

NOTE: When applied to ‘product type’ silos, the factors in (1) are for guidance purposes only.

They are provided to show the likely levels needed to achieve consistent reliability with other designs. 2.9.2.2 Partial factors for resistances (1) Where structural properties are determined by testing, the requirements and procedures of EN 1990 should be adopted. (2) Fatigue verifications should satisfy section 9 of EN 1993-1-6. (3)P The partial factors gMi

for different limit states shall be taken from table 2.2.

Table 2.2: Partial factors for resistance Resistance to failure mode Relevant g Resistance of welded or bolted shell wall to plastic limit state gM0

Resistance of shell wall to stability gM1

Resistance of welded or bolted shell wall to rupture

gM2

Resistance of shell wall to cyclic plasticity

gM4

Resistance of connections

gM5

Resistance of shell wall to fatigue

gM6

NOTE: Partial factors gMi for silos may be defined in the National Annex. For values of gM5, further information may be found in EN 1993-1-8.

For values of gM6, further information may be found in EN 1993-1-9.

The following numerical values are recommended for silos:

gM0

= 1,00 gM1

= 1,10 gM2

= 1,25 gM4

= 1,00 gM5

= 1,25 gM6

= 1,10 For further differ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...