kSIST FprEN 1303:2025

(Main)Building hardware - Cylinders and Master-Key-Systems (MKS) for locks - Requirements and test methods

Building hardware - Cylinders and Master-Key-Systems (MKS) for locks - Requirements and test methods

This document applies to cylinders and their keys for such locks as are normally used in buildings and are designed to be used with cylinders, where the locks have an operational torque of maximum 1,5 Nm.

This document specifies performance and other requirements for the strength, security, durability, performance and corrosion resistance of cylinders and their original keys. It also specifies cylinders suitable for use in locking systems, Master key systems (MKS).

It establishes one category of use, three grades of durability, two grades for mechanical coding (single cylinders and MKS), three grades for fire and four grades corrosion resistance all based on performance tests as well as six grades of key related security based on design requirements and five grades on performance tests that simulate attack.

This document includes tests of satisfactory operation at a range of temperatures. It specifies test methods to be used on cylinders and their protective measures linked with these cylinders and recommended by the manufacturer.

Corrosion resistance is specified by reference to the requirements of EN 1670 on corrosion resistance of building hardware.

The suitability of cylinders for use on fire or smoke-door assemblies is determined by fire performance tests conducted in addition to the performance testing required by this document, see Annex A.

This document does not apply to the assessment of fire resistance and smoke control doors equipped with lock cylinders grade A and grade B.

Schlösser und Baubeschläge - Schließzylinder und Schließanlagen für Schlösser - Anforderungen und Prüfverfahren

Dieses Dokument ist anwendbar für Schließzylinder und ihre Schlüssel für solche Schlösser, die üblicherweise in Gebäuden verwendet werden und die für die Verwendung mit Schließzylindern vorgerichtet sind, wobei die Schlösser ein Betriebsdrehmoment von höchstens 1,5 Nm aufweisen.

Dieses Dokument enthält Festlegungen für die Leistungsfähigkeit sowie weitere Anforderungen an Festigkeit, Verschlusssicherheit, Dauerhaftigkeit, Leistung und Korrosionsbeständigkeit von Schließzylindern und ihren Originalschlüsseln. Es legt auch die Schließzylinder fest, die für die Verwendung in Schließsystemen, Hauptschlüsselsystemen (MKS), geeignet sind.

Sie legt eine Gebrauchsklasse fest, drei Klassen für Dauerhaftigkeit, zwei Klassen für die mechanische Codierung (Einzelzylinder und MKS), drei Klassen für Feuerwiderstand und vier Klassen für Korrosionsbeständigkeit, jeweils unter Zugrundelegung von Leistungsprüfungen, außerdem sechs Klassen für Verschlusssicherheit unter Zugrundelegung von Konstruktionsanforderungen und fünf Klassen von Leistungsprüfungen, die mechanischen Angriff simulieren.

Dieses Dokument beinhaltet Prüfungen über die befriedigende Funktionsfähigkeit bei verschiedenen Temperaturen. Sie legt Prüfverfahren für Schließzylinder sowie damit verbundene und vom Hersteller empfohlene Schutzeinrichtungen fest.

Die Korrosionsbeständigkeit wird durch Verweisung auf die Anforderungen von EN 1670 über die Korrosionsbeständigkeit von Schlössern und Baubeschlägen festgelegt.

Die Eignung von Schließzylindern für die Verwendung in Feuer- oder Rauchschutztüren wird durch die Prüfung der Feuerwiderstandsfähigkeit bestimmt, die zusätzlich zu den Leistungsprüfungen nach diesem Dokument gefordert wird, siehe Anhang A.

Dieses Dokument ist nicht anwendbar für die Beurteilung von Feuerschutz- und Rauchschutztüren, die mit Schließzylindern der Klasse A und der Klasse B ausgestattet sind.

Quincaillerie pour le bâtiment - Cylindres de serrures et systèmes de fermeture mécaniques - Prescriptions et méthodes d’essai

Le présent document s’applique aux cylindres et à leurs clés destinés aux serrures qui sont normalement utilisées dans le bâtiment et conçues pour fonctionner avec des cylindres, avec un couple de manœuvre maximal de 1,5 Nm.

Le présent document spécifie la performance et d’autres exigences relatives à la résistance, à la sécurité des biens, à l’endurance, à la performance et à la résistance à la corrosion des cylindres et de leurs clés d’origine. Il spécifie également les cylindres pour une utilisation dans les systèmes de verrouillage, les Systèmes d’organigrammes de clé (MKS).

Il établit : une catégorie d’utilisation ; trois grades d’endurance ; deux grades de codage mécanique (cylindres individuels et MKS) ; trois grades de résistance au feu ;et quatre grades de résistance à la corrosion, tous basés sur des essais de performance ; six grades de sécurité des biens relative à la clé, fondés sur des exigences de conception ; et cinq grades fondés sur des essais de performance simulant une attaque.

Le présent document comprend des essais de bon fonctionnement dans une certaine plage de températures. Il spécifie les méthodes d’essai pour les cylindres ainsi que les dispositifs de protection correspondants à ces cylindres et recommandés par le fabricant.

La résistance à la corrosion est spécifiée par référence aux exigences de l’EN 1670 relatives à la résistance à la corrosion de la quincaillerie pour le bâtiment.

L’aptitude à l’utilisation des cylindres sur des blocs-portes coupe-feu ou pare-fumées est déterminée par des essais de performance au feu, qui s’ajoutent aux essais de performance requis dans le présent document, voir Annexe A.

Le présent document ne s’applique pas à l’’évaluation de la résistance au feu et de l'étanchéité aux fumées des portes équipées de cylindres de serrure de grade A et grade B.

Stavbno okovje - Profilni cilindri in Master-Key sistem (MKS) za ključavnice - Zahteve in preskusne metode

General Information

- Status

- Not Published

- Public Enquiry End Date

- 14-May-2024

- Technical Committee

- ISTP - Doors and windows

- Current Stage

- 5020 - Formal vote (FV) (Adopted Project)

- Start Date

- 21-Nov-2025

- Due Date

- 09-Jan-2026

- Completion Date

- 21-Nov-2025

Relations

- Effective Date

- 23-Jun-2021

Overview

kSIST FprEN 1303:2025 is a European standard developed by CEN that specifies the requirements and test methods for building hardware cylinders and Master-Key Systems (MKS) used in locks. These locks are typically installed in building doors and are designed to operate with cylinders under a maximum torque of 1.5 Nm. The standard ensures that cylinders and original keys meet stringent criteria regarding strength, security, durability, performance, corrosion resistance, and fire suitability.

The 2024 revision of kSIST FprEN 1303:2025 extends the scope to include locking systems and MKS, introduces updated classifications, and incorporates new test procedures to evaluate manipulation resistance. This standard is essential for manufacturers, suppliers, and specifiers of high-quality locking cylinders seeking compliance with European regulatory and safety requirements.

Key Topics

Scope and Application

Applies to cylinders and keys for building locks with operational torque ≤ 1.5 Nm, including cylinders designed for Master-Key Systems (MKS).Performance Requirements

Sets benchmarks for:- Strength and durability

- Security levels, including key related and attack resistance

- Corrosion resistance per EN 1670 standards

- Operation under extreme temperatures

- Fire resistance suitability (optional, per Annex A)

Classification System

Defines grading for cylinders based on:- One category of use

- Three durability grades

- Two grades for mechanical coding (single cylinders and MKS)

- Three fire resistance grades

- Four corrosion resistance grades

- Six key-related security grades (design-based)

- Five attack resistance grades (performance-based)

Test Methods

Standardized tests cover:- Key strength and cylinder durability

- Mechanical coding accuracy

- Corrosion and temperature operation resilience

- Resistance to various attacks (drilling, chiseling, twisting, plug extraction)

- Suitability for fire and smoke control doors

Master-Key System (MKS) Requirements

Includes new definitions and additional criteria for cylinders suitable for locking systems incorporating master keys while maintaining security and functionality.

Applications

kSIST FprEN 1303:2025 applies broadly to building security hardware manufacturers, installers, and building owners who prioritize compliant, reliable, and secure locking solutions. Its practical use cases include:

Residential and Commercial Door Security

Ensuring secure yet durable locking cylinders that withstand daily use and environmental conditions.Fire and Smoke Control Doors

Cylinders tested and optionally certified for integration into fire-resistant doors, enhancing building safety compliance.Master-Key Systems Installation

Specification and evaluation of cylinders used in complex locking systems where multiple access levels are required, such as offices, hotels, and institutional buildings.Quality Assurance for Manufacturers

Use of standardized testing and classification to meet European safety norms, reduce liability, and assure end-users of product reliability.Corrosion-Prone Environments

Selection of cylinders with appropriate corrosion resistance grades for outdoor or corrosive atmosphere applications.

Related Standards

For comprehensive compliance and enhanced building security, kSIST FprEN 1303:2025 should be considered alongside the following standards:

- EN 1670 – Corrosion resistance requirements and test methods for building hardware.

- EN 1634-1, EN 1634-2, EN 1634-3 – Fire resistance and smoke control tests for door assemblies and building hardware.

- EN 1906 – Specifications and test methods for lever handles and knob furniture.

- CEN/TS 17814 – Guidelines for protection of data and sensitive information in mechanical Master Key Systems.

- EN 12164 – Standards covering copper and copper alloys relevant to key and cylinder components.

- ISO 10899 – Technical specifications for drill bits used in attack resistance testing.

Keywords: kSIST FprEN 1303:2025, building hardware standard, lock cylinders, master key systems, MKS, lock durability, mechanical coding, lock corrosion resistance, fire resistant door cylinders, key related security, lock attack resistance, European standard building locks, EN 1303, lock testing methods.

Frequently Asked Questions

kSIST FprEN 1303:2025 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Building hardware - Cylinders and Master-Key-Systems (MKS) for locks - Requirements and test methods". This standard covers: This document applies to cylinders and their keys for such locks as are normally used in buildings and are designed to be used with cylinders, where the locks have an operational torque of maximum 1,5 Nm. This document specifies performance and other requirements for the strength, security, durability, performance and corrosion resistance of cylinders and their original keys. It also specifies cylinders suitable for use in locking systems, Master key systems (MKS). It establishes one category of use, three grades of durability, two grades for mechanical coding (single cylinders and MKS), three grades for fire and four grades corrosion resistance all based on performance tests as well as six grades of key related security based on design requirements and five grades on performance tests that simulate attack. This document includes tests of satisfactory operation at a range of temperatures. It specifies test methods to be used on cylinders and their protective measures linked with these cylinders and recommended by the manufacturer. Corrosion resistance is specified by reference to the requirements of EN 1670 on corrosion resistance of building hardware. The suitability of cylinders for use on fire or smoke-door assemblies is determined by fire performance tests conducted in addition to the performance testing required by this document, see Annex A. This document does not apply to the assessment of fire resistance and smoke control doors equipped with lock cylinders grade A and grade B.

This document applies to cylinders and their keys for such locks as are normally used in buildings and are designed to be used with cylinders, where the locks have an operational torque of maximum 1,5 Nm. This document specifies performance and other requirements for the strength, security, durability, performance and corrosion resistance of cylinders and their original keys. It also specifies cylinders suitable for use in locking systems, Master key systems (MKS). It establishes one category of use, three grades of durability, two grades for mechanical coding (single cylinders and MKS), three grades for fire and four grades corrosion resistance all based on performance tests as well as six grades of key related security based on design requirements and five grades on performance tests that simulate attack. This document includes tests of satisfactory operation at a range of temperatures. It specifies test methods to be used on cylinders and their protective measures linked with these cylinders and recommended by the manufacturer. Corrosion resistance is specified by reference to the requirements of EN 1670 on corrosion resistance of building hardware. The suitability of cylinders for use on fire or smoke-door assemblies is determined by fire performance tests conducted in addition to the performance testing required by this document, see Annex A. This document does not apply to the assessment of fire resistance and smoke control doors equipped with lock cylinders grade A and grade B.

kSIST FprEN 1303:2025 is classified under the following ICS (International Classification for Standards) categories: 91.190 - Building accessories. The ICS classification helps identify the subject area and facilitates finding related standards.

kSIST FprEN 1303:2025 has the following relationships with other standards: It is inter standard links to SIST EN 1303:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

kSIST FprEN 1303:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

oSIST prEN 1303:2024

01-maj-2024

Stavbno okovje - Profilni cilindri in Master-Key sistem (MKS) za ključavnice -

Zahteve in preskusne metode

Building hardware - Cylinders and Master-Key-Systems (MKS) for locks - Requirements

and test methods

Schlösser und Baubeschläge - Schließzylinder und Schließanlagen für Schlösser -

Anforderungen und Prüfverfahren

Quincaillerie pour le bâtiment - Cylindres de serrures et systèmes de fermeture

mécaniques - Prescriptions et méthodes d’essai

Ta slovenski standard je istoveten z: prEN 1303

ICS:

91.190 Stavbna oprema Building accessories

oSIST prEN 1303:2024 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

oSIST prEN 1303:2024

oSIST prEN 1303:2024

DRAFT

EUROPEAN STANDARD

prEN 1303

NORME EUROPÉENNE

EUROPÄISCHE NORM

February 2024

ICS 91.190 Will supersede EN 1303:2015

English Version

Building hardware - Cylinders and Master-Key-Systems

(MKS) for locks - Requirements and test methods

Quincaillerie pour le batiment - Cylindres de serrures Baubeschläge - Schließzylinder und Schließanlagen

et systèmes de fermeture mécaniques - Prescriptions (SLA) für Schlösser - Anforderungen und

et méthodes d'essai Prüfverfahren

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 33.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 1303:2024 E

worldwide for CEN national Members.

oSIST prEN 1303:2024

prEN 1303:2024 (E)

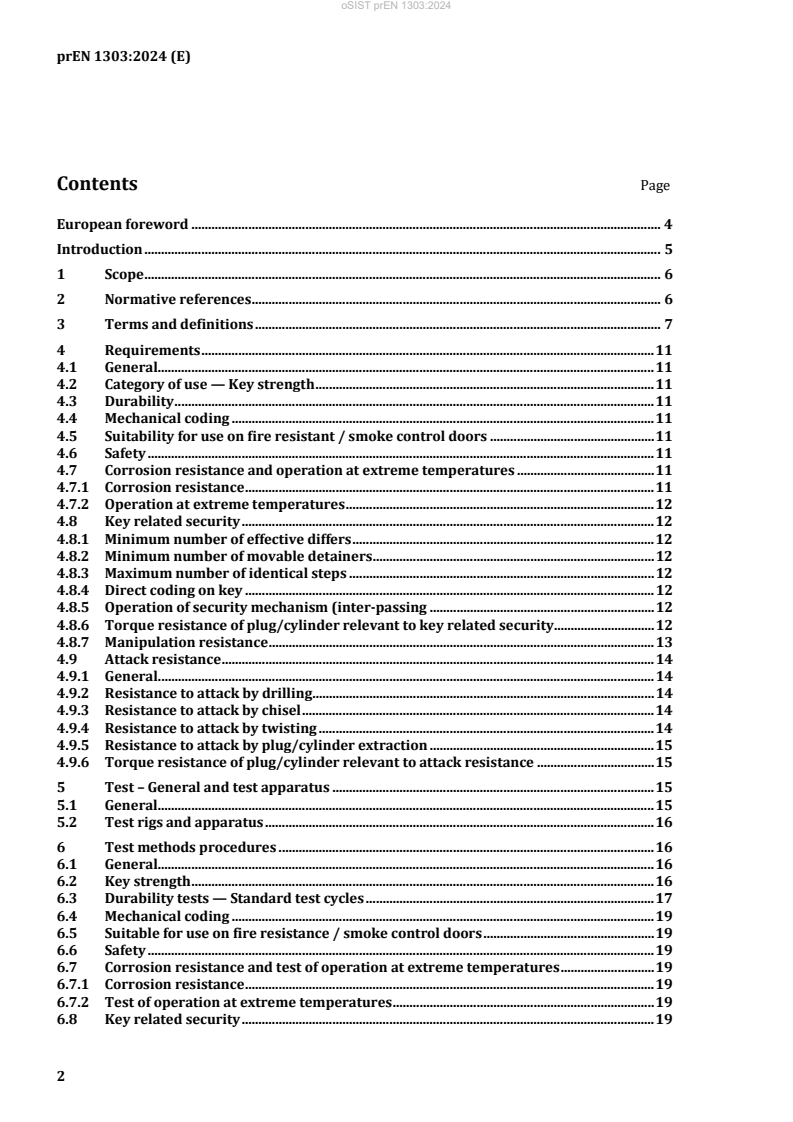

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Requirements . 11

4.1 General. 11

4.2 Category of use — Key strength . 11

4.3 Durability . 11

4.4 Mechanical coding . 11

4.5 Suitability for use on fire resistant / smoke control doors . 11

4.6 Safety . 11

4.7 Corrosion resistance and operation at extreme temperatures . 11

4.7.1 Corrosion resistance . 11

4.7.2 Operation at extreme temperatures . 12

4.8 Key related security . 12

4.8.1 Minimum number of effective differs . 12

4.8.2 Minimum number of movable detainers . 12

4.8.3 Maximum number of identical steps . 12

4.8.4 Direct coding on key . 12

4.8.5 Operation of security mechanism (inter-passing . 12

4.8.6 Torque resistance of plug/cylinder relevant to key related security . 12

4.8.7 Manipulation resistance . 13

4.9 Attack resistance . 14

4.9.1 General. 14

4.9.2 Resistance to attack by drilling . 14

4.9.3 Resistance to attack by chisel . 14

4.9.4 Resistance to attack by twisting . 14

4.9.5 Resistance to attack by plug/cylinder extraction . 15

4.9.6 Torque resistance of plug/cylinder relevant to attack resistance . 15

5 Test – General and test apparatus . 15

5.1 General. 15

5.2 Test rigs and apparatus . 16

6 Test methods procedures . 16

6.1 General. 16

6.2 Key strength . 16

6.3 Durability tests — Standard test cycles . 17

6.4 Mechanical coding . 19

6.5 Suitable for use on fire resistance / smoke control doors . 19

6.6 Safety . 19

6.7 Corrosion resistance and test of operation at extreme temperatures . 19

6.7.1 Corrosion resistance . 19

6.7.2 Test of operation at extreme temperatures . 19

6.8 Key related security . 19

oSIST prEN 1303:2024

prEN 1303:2024 (E)

6.8.1 Minimum numbers of effective differs. 19

6.8.2 Minimum number of movable detainer . 19

6.8.3 Maximum number of identical steps . 19

6.8.4 Direct coding on key . 20

6.8.5 Operation of the security mechanism . 20

6.8.6 Torque resistance of plug and/or cylinder . 20

6.8.7 Manipulation resistance . 20

6.9 Attack resistance . 21

6.9.1 Resistance to drilling . 21

6.9.2 Resistance to attack by chisel . 22

6.9.3 Resistance to attack by twisting . 23

6.9.4 Resistance to attack by plug/cylinder extraction . 23

6.9.5 Torque resistance of plug/cylinder relevant to attack resistance . 27

7 Classification . 28

7.1 General . 28

7.2 Category of use (1st digit) . 28

7.3 Durability (2nd digit) . 28

7.4 Mechanical Coding (3rd digit) . 28

7.5 Suitable for use on fire resistant/smoke control doors (4th digit) . 28

7.6 Safety (5th digit) . 28

7.7 Corrosion resistance and temperature (6th digit) . 29

7.8 Key related security (7th digit) . 29

7.9 Attack resistance (8th digit) . 29

8 Marking . 29

Annex A (normative) Cylinders suitable for use on fire resistant/smoke control doors . 30

Annex B (informative) Tables of test sequence . 31

Annex C (informative) Product information . 32

Annex D (informative) Manufacturer’s declaration of compliance . 33

Annex E (informative) Comparison tables between EN 1303:2005 - EN 1303:2015 and EN

1303:2023 . 35

Annex F (normative) Cylinders suitable for use in locking systems . 36

Annex G (informative) Pulling screws to be used in plug extraction test . 40

Bibliography . 43

oSIST prEN 1303:2024

prEN 1303:2024 (E)

European foreword

This document (prEN 1303:2024) has been prepared by Technical Committee CEN/TC 33 “Doors,

windows, shutters, building hardware and curtain walling”, the secretariat of which is held by AFNOR.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 1303:2015.

In comparison with the previous edition, the following significant changes have been made:

a) the Scope has been extended to include cylinders suitable for use in locking systems, Master key

systems (MKS);

b) a new normative Annex F, Cylinders suitable for use in locking systems, has been added;

c) definitions related to MKS have been added;

d) requirements and evaluation methods for manipulation have been added;

e) classification (digit 3) has changed from Door mass to Mechanical coding;

f) the definition of ‘pulling screws’ has changed and an informative Annex G has been added;

g) figures have been renumbered.

The European Federation of Associations of Lock and Builders Hardware Manufacturers, ARGE,

collaborated in the drafting of this document.

oSIST prEN 1303:2024

prEN 1303:2024 (E)

Introduction

This document for mechanic locking cylinders and locking systems specifies requirements and test

methods for functionality, durability, environmental and security conditions for use on doors in buildings

or related to buildings.

The aim of the test methods described in this document is to keep human influence on the test results to

a minimum, thus improving reproducibility. This document does not specify any particular design or

installation.

Suitability for use on fire resistance or smoke control doors is not essential in every situation; the

manufacturer has the option to state if the cylinder conforms to these additional requirements according

to Annex A.

Requirements and procedures to achieve and maintain protection of data and sensitive information

related to mechanical Master Key Systems is given in CEN/TS 17814.

oSIST prEN 1303:2024

prEN 1303:2024 (E)

1 Scope

This document applies to cylinders and their keys for locks that are normally used in buildings and are

designed to be used with cylinders, where the locks have an operational torque of maximum 1,5 Nm.

This document specifies performance and other requirements for the strength, security, durability,

performance and corrosion resistance of cylinders and their original keys. It also specifies cylinders

suitable for use in locking systems, Master key systems (MKS).

It establishes one category of use, three grades of durability, two grades for mechanical coding (single

cylinders and MKS), three grades for fire and four grades corrosion resistance, all based on performance

tests, as well as thirteen grades of key related security based on design requirements and five grades on

performance tests that simulate attack.

This document includes tests of satisfactory operation at a range of temperatures. It specifies test

methods to be used on cylinders and their protective measures linked with these cylinders and

recommended by the manufacturer.

Corrosion resistance is specified by reference to the requirements of EN 1670 on corrosion resistance of

building hardware.

The suitability of cylinders for use on fire or smoke-door assemblies is determined by fire performance

tests conducted in addition to the performance testing required by this document. Since suitability for

use on fire doors is not essential in every situation, the manufacturer has the option to state if the cylinder

conforms to these additional requirements or not. If so claimed, cylinders will comply with the

requirements in Annex A.

Assessment of fire resistance and smoke control (grade A and grade B) is beyond the scope of this

document.

On occasions there can be a need for additional functions within the design of the cylinder. Purchasers

should satisfy themselves that the products are suitable for their intended use.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 636, Plywood — Specifications

EN 1634-1, Fire resistance and smoke control tests for door and shutter assemblies, openable windows and

elements of building hardware — Part 1: Fire resistance test for door and shutter assemblies and openable

windows

EN 1634-2, Fire resistance and smoke control tests for door, shutter and openable window assemblies and

elements of building hardware — Part 2: Fire resistance characterisation test for elements of building

hardware

EN 1634-3, Fire resistance and smoke control tests for door and shutter assemblies, openable windows and

elements of building hardware — Part 3: Smoke control test for door and shutter assemblies

EN 1670, Building hardware — Corrosion resistance — Requirements and test methods

EN 1906:2012, Building hardware — Lever handles and knob furniture — Requirements and test methods

oSIST prEN 1303:2024

prEN 1303:2024 (E)

EN 12164:2016, Copper and copper alloys — Rod for free machining purposes

ISO 10899, High-speed steel two-flute twist drills — Technical specifications

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

active moveable detainer

permutable blocking element, which needs to be in the aligned or shearline position in order to unblock

the cylinder and which may stay at least in one step before and in one step after the aligned or shearline

position where the cylinder stays in the blocked condition

3.2

cylinder

device, usually distinct from its associated lock or latch, operated by a key

3.3

cam

component of the cylinder to provide the movement to effect locking

3.4

central locking cylinder

locking system is a coded cylinder where a number of different keys operates this cylinder

3.5

central locking system

locking system which has only one level of coded keys operating different cylinders whereby all keys

operate central cylinders

Note 1 to entry: See Figure 1.

oSIST prEN 1303:2024

prEN 1303:2024 (E)

Key

1 individual key

2 locking cylinder

3 central locking cylinder

Figure 1— Example for a central locking system

3.6

direct code

marking on the key where the key steps can be determined without reference to another data source

3.7

effective differ

difference between cylinders of similar design, achieved only by the movable detainer, which allows each

cylinder to be operated only by its own key

3.8

grand master key system

GMK-system

locking system which has 3 or more levels of coded keys operating different cylinders

Note 1 to entry: See Figure 2.

Note 2 to entry: The combination of grand master key system with a central locking system is possible.

Note 3 to entry: Grand master key (GMK) operates all cylinders within a GMK system.

Note 4 to entry: Sub-master key (SMK) operates a defined group of cylinders within a GMK system.

Note 5 to entry: The combination of grand master key system with a central locking system 3.5 is possible.

oSIST prEN 1303:2024

prEN 1303:2024 (E)

Key

1 grand Master key

2 sub-Master Key (level 1)

3 sub-Master Key (level n)

4 individual keys locking cylinders

Figure 2 — Example of a (structured) Grand master key system

3.9

key

separate device corresponding to the cylinder, which can mechanically operate the cylinder

3.10

keyway

aperture extending along the whole or part of the length of the plug into which the key is inserted

3.11

legitimation ID

security protocol issued by the manufacturer of a locking system that indicates to the manufacturer a

reference to allow the holder to obtain additional keys, cylinders, lock chart, or locking system data

EXAMPLES

— Security card

— Security letter (document)

— Certificate of Eligibility

— Document of ownership

— Certificate of legitimation

— Electronic Legitimation

3.12

lock chart

describes the interaction with all keys and cylinders in the locking system

oSIST prEN 1303:2024

prEN 1303:2024 (E)

3.13

locking system

combination of different coded cylinders and keys that are functionally related to each other

3.14

master key system

MK-system

locking system which has 2 levels of coded keys operating different cylinders whereby the master key

can operate all cylinders

Note 1 to entry: See Figure 3.

Note 2 to entry: The combination of master key system with a central locking system 3.5 is possible.

Key

1 master key

2 individual key

3 locking cylinder

Figure 3 — Example for a master key system

3.15

moveable detainer

permutable part of the mechanism of a cylinder which should first be moved by the key into a pre-

determined position before the key and/or plug can move

3.16

passive moveable detainer

blocking elements, which needs to be in the aligned or shearline position to unblock the cylinder and

which may stay at least in one step before or alternatively in one step after the aligned or shearline

position where the cylinder stays in the blocked condition

3.17

plug

part of a cylinder that can be moved when the proper key is used

3.18

steps

characteristics of a key which operates movable detainers

oSIST prEN 1303:2024

prEN 1303:2024 (E)

4 Requirements

4.1 General

The structure of this clause reflects the classification in accordance with Clause 7.

Additional requirements for cylinders suitable for use in locking systems are defined in Annex F.

4.2 Category of use — Key strength

Cylinders and keys shall be designed for an operational maximum torque in the application of 1,5 Nm.

The key shall not break under the applied torque of 2,5 Nm.

After the test, the key shall be capable of being removed from the cylinder and re-used to operate the

same cylinder with a torque not exceeding 1,5 Nm.

Tested in accordance with 6.2.

4.3 Durability

It shall be possible to operate the cylinders with a new original key the number of test cycles specified in

Table 1.

Tested in accordance with 6.3.

Table 1 — Number of cycles

Durability Number of cycles

Grade 4 25 000

Grade 5 50 000

Grade 6 100 000

4.4 Mechanical coding

For grade 2 locking system, see Annex F.

4.5 Suitability for use on fire resistant / smoke control doors

The cylinder shall conform to the requirements of Annex A.

Verified in accordance with 6.5.

4.6 Safety

There is no requirement on the cylinder related to safety.

4.7 Corrosion resistance and operation at extreme temperatures

4.7.1 Corrosion resistance

It shall be possible to operate the cylinder with its proper key using a maximum torque of 1,5 Nm after

testing according to grade 3 of EN 1670.

This corrosion test shall apply to the functionality only.

No distinction is made between the inside and the outside of cylinder and/or door.

Tested in accordance with 6.7.1.

oSIST prEN 1303:2024

prEN 1303:2024 (E)

4.7.2 Operation at extreme temperatures

It shall be possible to operate the cylinder with its proper key using a maximum torque of 1,5 Nm at both

− 25 °C and + 65 °C.

Tested in accordance with 6.7.2.

4.8 Key related security

4.8.1 Minimum number of effective differs

The number of effective differs is equal to the number of theoretical differs after deduction of the differs

suppressed by the manufacturer due to technical constraints and those differs suppressed in accordance

with the restraints of 4.8.3.

The minimum number of effective differs shall be as indicated in Table 2.

The number of effective differs shall be verified in accordance with 6.8.1.

4.8.2 Minimum number of movable detainers

A movable detainer shall have minimum 3 permutable characteristics (position, layer, height or other

technical distinction).

The minimum number of movable detainers shall be as indicated in Table 2.

The number of movable detainers shall be verified in accordance with 6.8.2.

4.8.3 Maximum number of identical steps

The choice of key steps for movable detainer operation which have the same operating level shall be

restricted as indicated in Table 2.

Maximum identical adjacent key steps are allowed as indicated in Table 2.

The requirements are related to one row only of movable detainers.

The number of identical steps shall be verified in accordance with 6.8.3.

4.8.4 Direct coding on key

Direct key coding shall not be permitted on keys for the key related security grades 3 to 6 as specified in

Table 2.

4.8.5 Operation of security mechanism (inter-passing

For the key related security grades 1, 2 and 3, it shall not be possible before the durability test to operate

+0,2

the cylinder with the next closest key to its own key using a torque of 1,5 Nm .

For the key related security grades 4, 5 and 6, it shall not be possible before and after the durability test

+0,2

to operate the cylinders with the next closest key to its own key using a torque of 1,5 Nm .

Tested in accordance with 6.8.5.

4.8.6 Torque resistance of plug/cylinder relevant to key related security

It shall not be possible to rotate the plug and/or cylinder in the key related security grades 1 to 6, using

the specified applied torque as indicated in Table 2.

Tested in accordance with 6.8.6.

oSIST prEN 1303:2024

prEN 1303:2024 (E)

4.8.7 Manipulation resistance

4.8.7.1 Manipulation resistance

Requirement for manipulation resistance is applicable for key related security grades 4, 5 and 6. See

Table 2.

Tested in accordance with 6.8.7.1.

4.8.7.2 Deducible coding

It shall not be possible to deduce the coding of the cylinder by bringing its detainers to their end position.

When the detainers are brought to the compressed or end position a pattern shall not be recognizable

that is representative of the actual coding.

Requirement for is applicable for key related security grades 4, 5 and 6. See Table 2.

Tested in accordance with 6.8.7.2.

4.8.7.3 Manipulation of detainers by compression

It shall not be possible to open the cylinder by bringing all its detainers to or below the shearline.

Requirement is applicable for cylinders where compression is possible, key related security grades 4, 5

and 6. See Table 2.

Tested in accordance with 6.8.7.3.

Table 2 — Summary key related security

Grades

Clause Requirement Test clause Parameter Unit

1 2 3 4 5 6

Min. number

4.8.1 of effective 6.8.1 - 100 300 15 000 30 000 30 000 100 000 No

differs

Min. number

4.8.2 of moveable 6.8.2 - 2 3 5 5 6 6 No

detainers

Max. number

of identical - 100 70 60 60 60 50 %

c

steps

4.8.3 6.8.3

Max number

of identical - - 2 2 2 2 2 No

adjacent steps

Direct coding

4.8.4 6.8.4 - - - No No No No -

on key

Operation of

security

a a a b b b

4.8.5 6.8.5 Torque 1,5 1,5 1,5 1,5 1,5 1,5 Nm

mechanism

(Interpassing)

Torque

4.8.6 resistance of 6.8.6 Torque 2,5 5 15 15 15 15 Nm

plug/cylinder

Resistance

4.8.7 against 6.8.7.1 - - - 20 20 30 Points

manipulation

oSIST prEN 1303:2024

prEN 1303:2024 (E)

Grades

Clause Requirement Test clause Parameter Unit

1 2 3 4 5 6

Deducible

coding – Not 6.8.7.2 - - - - Yes Yes Yes -

possible

Manipulation

e e e

3 3 3

of detainers

6.8.7.3 - - - - No

by f f f

1 1 1

compression

a

Tested before the durability test.

b

Tested before and after the durability test.

c

Rounded to the lower integer.

d

Only in combination with security furniture that protects the plug against pulling.

e

When it is made plausible that manipulation is impossible this requirement is fulfilled.

f

One step remaining in the plug with 1 kg load on each spring and/or detainer if applicable.

g

1 mm in the plug, springs compressed until windings are in contact if applicable.

4.9 Attack resistance

4.9.1 General

The cylinders, including any reinforcement or protection device supplied with them shall be tested as one

unit.

In case of a double cylinder, it is assumed that the grades for the attack resistance apply to the attack

side/outside of the cylinder. This side shall have a proper indication, either on the product or on the

documents with the product. If both sides are identical, it is not necessary to put an indication on the

product.

To maintain the integrity of this standard, cylinders are recommended not to protrude from the surface

of the door or security furniture more than 3 mm. See also Annex C.

4.9.2 Resistance to attack by drilling

It shall not be possible to rotate the cam using a maximum torque of 5 Nm without the correct key, after

the drilling time specified in Table 3.

It is not necessary for the correct key to operate the cylinder after testing.

Testing in accordance with 6.9.1.

4.9.3 Resistance to attack by chisel

It shall not be possible to rotate the cam using a maximum torque of 5 Nm without the correct key, after

the number of blows specified in Table 3.

It is not necessary for the correct key to operate the cylinder after testing.

Testing in accordance with 6.9.2.

4.9.4 Resistance to attack by twisting

It shall not be possible to rotate the cam using a maximum torque of 5 Nm without the correct key, after

the number of twists specified in Table 3.

It is not necessary for the correct key to operate the cylinder after testing.

Testing in accordance with 6.9.3.

oSIST prEN 1303:2024

prEN 1303:2024 (E)

4.9.5 Resistance to attack by plug/cylinder extraction

It shall not be possible to extract the plug or cylinder to rotate the cam or operate the lock with the

requirements specified in Table 3.

It is not necessary for the correct key to operate the cylinder after testing.

Testing in accordance with 6.9.4.

4.9.6 Torque resistance of plug/cylinder relevant to attack resistance

It shall not be possible to rotate the plug and/or cylinder with a torque applied to the plug specified in

Table 3.

Tested in accordance with 6.9.5.

Table 3 — Summary attack resistance

Grades Unit

Test

Clause Requirement Parameter

clause

0 A B C D

Time

Resistance to

4.9.2 6.9.1 - 3/5 5/10 3/5 5/10 Min.

drilling

Net/Total

Resistance to

4.9.3 attack by 6.9.2 Blows - 30 40 30 40 No

chisel

Resistance to

4.9.4 attack by 6.9.3 Twists - 20 30 20 30 No

twisting

Resistance to

Force 10 15 kN

attack by

4.9.5 6.9.4 - - -

plug/cylinder

Net/Total 5/15 5/15 min

extraction

Torque

a

4.9.6 resistance of 6.9.5 Torque - 20 30 20 30 Nm

plug/cylinder

a

See requirement of key related security 4.8.6.

5 Test – General and test apparatus

5.1 General

To minimize the number of samples to be tested some samples may be used for several tests.

Locking cylinders of the same kind with length variations and different operating functions are

considered to be the same product. For each individual test procedure, the manufacturer and test

laboratory decide in reference to the normative requirements which cylinder variant shall be used for

testing.

In the event of a test failure, it shall not, at that point, be considered a failure to meet the standard. Two

further cylinders, with the same design, shall be tested according to the failed test and both shall pass the

test.

oSIST prEN 1303:2024

prEN 1303:2024 (E)

In case of a double cylinder, it is assumed that the grades for key related security apply to the attack

side/outside of the cylinder. This side shall have a proper indication, either on the product or on the

documents with the product. If both sides are identical, it is not necessary to put an indication on the

product.

Where a product range is submitted for evaluation the test authority shall consider each individual test

for each cylinder type. Where (by engineering judgement) it can be shown that a weaker or equivalent

cylinder type is to be evaluated then no further testing needs to be carried out.

Check the cylinders and keys conform to 4.8.1 to 4.8.6 before commencing the performance tests.

An example of a test sequence is shown in Annex B.

If additional instructions for testing are required, the manufacturer shall supply such additional

instructions. These additional instructions shall be documented in the test report.

5.2 Test rigs and apparatus

The test rigs described in this document are examples of principal unless specific design or measures are

shown in this standard.

The test apparatus shall be rigid enough to avoid influencing test measurements.

Instruments with an accuracy of ± 1,5 % of measured values, or better, shall be used for measurements

in accordance with these test methods.

All durability testing equipment shall include means of recording the number of cycles attained.

6 Test methods procedures

6.1 General

Cylinders and their original keys shall be taken at random and submitted for testing according to Annex B.

Throughout this document, the following tolerances shall apply, unless otherwise specified:

— mass in kilograms or grams (kg or g): ± 5 %,

— length in millimetres (mm): ± 2 %,

— force in kilo Newton or Newton (kN or N): ± 2 %,

— torque in Newton metres (Nm): ± 5 %,

— time in seconds or minutes (s or min): ± 5 %,

— temperature in degrees Celsius (°C): ± 2 °C.

Additional test methods for cylinders suitable for use in locking systems are defined in Annex F.

6.2 Key strength

The requirements of 4.2 shall be satisfied.

The cylinder shall be mounted, with the cam blocked against rotation, in the metal fixture illustrated in

Figure 4. The correct key shall be fully inserted in the cylinder and a torque of 2,5 Nm ± 0,1 Nm applied

+1

to it without shock for a period of 5 s.

The cam shall then be unblocked.

oSIST prEN 1303:2024

prEN 1303:2024 (E)

The key shall than be removed, reinserted and shall operate the cylinder with a torque not exceeding

1,5 Nm without torque on the cam.

Key

1 fixture

2 cylinder

3 key

Figure 4 — Metal fixture for testing key strength, operation of security mechanism and torque

resistance of plug and or cylinder

6.3 Durability tests — Standard test cycles

The cylinder shall conform to the requirements of 4.3.

The durability test shall be carried out on the cylinder using a test apparatus; see Figure 5. The apparatus

shall incorporate means for carrying out the following standard test cycle:

a) insert the key;

b) rotate it clockwise to 360° or to the maximum rotation limit of the design; during the rotation, the

+0,15

key shall overcome a torque applied to the cam of 0,15 Nm at least once to ensure that the cam

−0,05

will drive the deadbolt;

c) withdraw the key;

d) insert the key;

e) rotate it anticlockwise to 360° or to the maximum rotation limit of the design. During the rotation,

+0,15

the key shall overcome a torque applied to the cam of 0,15 Nm at least once to ensure that the

−0,05

cam will drive the deadbolt;

f) withdraw the key.

oSIST prEN 1303:2024

prEN 1303:2024 (E)

The plug shall be free from torque during insertion and withdrawal of the key. The resistive torque shall

not be applied before and after an angle of 15° from the position of the key extraction.

Repeat the sequence at a speed of five to 12 cycles per minute.

During the cycle test, the key may remain partly inserted in the cylinder but shall have cleared all movable

detainers.

The keys used for the durability test can be cleaned and the cylinder shall be lubricated according to

instructions of the manufacturer at the start of the test and after each 5 000 cycles or with a lower

frequency agreed between the manufacturer and the test lab, using a lubricant recommended by the

manufacturer.

In cases where it is not possible to use the standard cycle sequence, the manufacturer shall, if so desired,

specify an alternative sequence that conforms as closely as possible to the standard procedure. Subject

to the approval of the testing authority the modified sequence shall then be used. The test report shall

include a description of the special cycle used and the approval of the test authority.

If the cylinder should jam and cease to operate during the test, then providing the cylinder continues to

operate in the proper manner when released, the test shall be allowed to continue.

After completion of the appropriate number of cycles the operation of the cylinders shall be tested using

a new original key. The rotation shall be obtained with a maximum torque of 1,5 Nm without any load on

the cam.

Where a cylinder is uniquely suitable for use with a particular lock unit, or where a cylinder is sold with

and intended for use with a particular lock unit, then the cylinder shall be tested with the lock without

applying the 0,15 Nm resistive torque in the test.

Insert the key to its correct position for operating the cylinder plug. Forces caused by misalignment

should not result in the cylinder being damaged during the test.

Key

1 fixture

2 cylinder

3 key

4 flexible key guide

Figure 5 — Fixture for durability

oSIST prEN 1303:2024

prEN 1303:2024 (E)

6.4 Mechanical coding

Check in accordance with manufacturer’s information.

6.5 Suitable for use on fire resistance / smoke control doors

Test methods reference is made to Annex A.

6.6 Safety

No tests.

6.7 Corrosion resistance and test of operation at extreme temperatures

6.7.1 Corrosion resistance

The cylinder shall be tested with a neutral salt spray in accordance with EN 1670 grade 3.

For this test the cylinder shall be mounted in a block in accordance with the manufacturer's instructions

and placed in the cabinet that the cylinder is oriented in the manner that it would assume in use.

After the salt spray procedure, it shall be possible to operate the cylinder with the proper key using a

maximum torque of 1,5 Nm within 5 min where the key may be inserted several times and/or moved in

a rotating way.

This operational test shall be started within one min after completion of the salt spray test.

The cylinder may be lubricated before and/or during the operational test in accordance with the

manufacturer’s instructions.

6.7.2 Test of operation at extreme temperatures

The cylinder and key shall be stabilized at room temperature (20 ± 5) °C for at least 24 h before the test.

The key shall be kept separately at the temperature mentioned above during the following tests.

Stabilize the cylinder in +20 °C and 50 % RH for 1 h before lowering the temperature. The cylinder shall

be cooled gradually by decreasing the temperature at a rate of (20 ± 1) °C per hour until a temperature

of (-25 ± 2) °C is attained. The test temperature shall be maintained for a minimum of 10 min and a

maximum of 20 min, after which period the cylinder shall be operated with its correct key in the

laboratory at ambient temperature at least once within 5 attempts within 5 min.

Stabilize the cylinder in +20°C and 50 % RH for 1 h before rising the temperature. The cylinder shall be

heated gradually at a rate of (20 ± 1) °C per hour until a temperature of (65 ± 2) °C is attained. The test

temperature shall be maintained for a minimum of 10 min and a maximum of 20 min after which period

the cylinder shall be operated with its correct key in the laboratory at ambient temperature at least once

within 5 attempts within 5 min.

6.8 Key related security

6.8.1 Minimum numbers of effective differs

Check in accordance with manufacturer’s information.

6.8.2 Minimum number of movable detainer

Check in accordance with manufacturer’s information.

6.8.3 Maximum number of identical steps

Check in accordance with manufacturer’s information.

oSIST prEN 1303:2024

prEN 1303:2024 (E)

6.8.4 Direct coding on key

Check in accordance with manufacturer’s information.

6.8.5 Operation of the security mechanism

The cylinders shall be fitted in a metal fixture as illustrated in Figure 4.

After verification of the function using the correct key, attempts shall be made to operate the cylinder in

both directions by the next closest keys, according to the required security grade.

+0,2

A torque of 1,5 Nm shall be applied with a gentle increase of the torque and without shock to the bow

of a fully and correctly inserted next closest key (one step up and one step down) taken from the

manufacturer’s chart which shall differ from the correct key by one-step at one position only.

During the test, the fixing in the test apparatus shall keep the next closest key fully inserted and

maintained in that position. Clearances and tolerances between the key and cylinder shall be used in

attempt to operate the cylinder with the torque above.

For security grades 1, 2 and 3, the tests shall be performed on new cylinders.

For security grades 4, 5 and 6, the tests shall be performed on cylinders that have first been subjected to

the appropriate cycles for durability specified in 4.3.

The choice of the code and the position shall be agreed between the lab and the manufacturer.

6.8.6 Torque resistance of plug and/or cylinder

All requirements of 4.8.6 shall be fulfilled.

The cylinders shall be mounted in the metal fixture illustrated in Figure 4. A torque specified in Table 2

shall be applied to the plug by an appropriate tool. If the torque required cannot be applied, the cylinder

shall be deemed to have passed the test.

6.8.7 Manipulation resistance

6.8.7.1 Resistance against manipulation

Points calculat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...