SIST EN 1303:2015

(Main)Building hardware - Cylinders for locks - Requirements and test methods

Building hardware - Cylinders for locks - Requirements and test methods

This European Standard applies to cylinders and their keys for such locks as are normally used in buildings and are designed to be used with cylinders, where the locks have an operational torque of maximum 1,2 Nm.

This European Standard specifies performance and other requirements for the strength, security, durability, performance and corrosion resistance of cylinders and their original keys. It establishes one category of use, three grades of durability, three grades for fire and four grades corrosion resistance all based on performance tests as well as six grades of key related security based on design requirements and five grades on performance tests that simulate attack.

This European Standard includes tests of satisfactory operation at a range of temperatures. It specifies test methods to be used on cylinders and their protective measures linked with these cylinders and recommended by the manufacturer.

Corrosion resistance is specified by reference to the requirements of EN 1670 on corrosion resistance of building hardware.

The suitability of cylinders for use on fire or smoke-door assemblies is determined by fire performance tests conducted in addition to the performance testing required by this standard. Since suitability for use on fire doors is not essential in every situation the manufacturer has the option to state if the cylinder conforms to these additional requirements or not. If so claimed, cylinders will comply with the requirements in Annex A.

Assessment of fire resistance of grade 1 doors is beyond the scope of this document.

On occasions there may be a need for additional functions within the design of the cylinder. Purchasers should satisfy themselves that the products are suitable for their intended use.

Baubeschläge - Schließzylinder für Schlösser - Anforderungen und Prüfverfahren

Diese Europäische Norm gilt für Schließzylinder und ihre Schlüssel für solche Schlösser, die üblicherweise in Gebäuden verwendet werden und die für die Verwendung mit Schließzylindern vorgerichtet sind, wobei die Schlösser ein Betätigungsmoment von höchstens 1,2 Nm aufweisen.

Die vorliegende Europäische Norm enthält Festlegungen für die Leistungsfähigkeit sowie weitere Anforderungen an Festigkeit, Verschlusssicherheit, Dauerhaftigkeit, Leistung und Korrosionsbeständigkeit von Schließzylindern und ihren Originalschlüsseln. Sie legt eine Gebrauchsklasse fest, drei Klassen für Dauerhaftigkeit, drei Klassen für Feuerwiderstand und vier Klassen für Korrosionsbeständigkeit unter Zugrundelegung von Leistungsprüfungen, außerdem sechs Klassen für Verschlusssicherheit unter Zugrundelegung von Konstruktionsanforderungen und fünf Klassen von Leistungsprüfungen, die mechanischen Angriff simulieren.

Die vorliegende Europäische Norm beinhaltet Prüfungen über die befriedigende Funktionsfähigkeit bei verschiedenen Temperaturen. Sie legt Prüfverfahren für Schließzylinder sowie damit verbundene und vom Hersteller empfohlene Schutzeinrichtungen fest.

Die Korrosionsbeständigkeit wird durch Verweisung auf die Anforderungen von EN 1670 über die Korrosionsbeständigkeit von Schlössern und Baubeschlägen festgelegt.

Die Eignung von Schließzylindern für die Verwendung in Feuer- oder Rauchschutztüren wird durch die Prüfung der Feuerwiderstandsfähigkeit bestimmt, die zusätzlich zu den Leistungsprüfungen nach dieser Norm gefordert wird. Da die Gebrauchseignung an Feuerschutztüren nicht in jeder Situation erforderlich ist, hat der Hersteller die Wahl, anzugeben, ob der Schließzylinder diese zusätzlichen Anforderungen erfüllt oder nicht. Wenn dies verlangt wird, werden Schließzylinder mit den in Anhang A beschriebenen Anforderungen übereinstimmen.

Die Bewertung des Feuerwiderstandes von Türen der Klasse 1 ist nicht Bestandteil dieses Dokumentes.

Gelegentlich können zusätzliche Funktionen für eine Schließzylinderausführung erforderlich sein. Käufer sollten sich vergewissern, dass die Produkte für ihren beabsichtigten Gebrauch geeignet sind.

Quincaillerie pour le bâtiment - Cylindres de serrures - Exigences et méthodes d'essai

La présente Norme européenne s’applique aux cylindres et à leurs clés destinés aux serrures normalement utilisées dans le bâtiment et conçues pour fonctionner avec des cylindres, avec un couple de manœuvre maximal de 1,2 Nm.

La présente Norme européenne spécifie la performance et d’autres exigences relatives à la résistance, à la sécurité des biens, à l’endurance, à la performance et à la résistance à la corrosion des cylindres et de leurs clés d’origine. Elle établit une catégorie d’utilisation, trois grades d’endurance, trois grades de résistance au feu et quatre grades de résistance à la corrosion, tous basés sur des essais de performance, ainsi que six grades de sécurité des biens relative à la clé fondés sur des exigences de conception et cinq grades fondés sur des essais de performance simulant une attaque.

La présente Norme européenne comprend des essais de bon fonctionnement dans une certaine plage de températures. Elle spécifie les méthodes d’essai pour les cylindres et les dispositifs de protection correspondants recommandés par le fabricant.

La résistance à la corrosion est spécifiée par référence aux exigences de l’EN 1670 relative à la résistance à la corrosion de la quincaillerie pour le bâtiment.

L’aptitude des cylindres à l’utilisation sur des blocs-portes coupe-feu et/ou étanches aux fumées est déterminée par des essais de performance au feu, qui s’ajoutent aux essais de performance requis dans la présente norme. Lorsque l’aptitude à l’utilisation sur des portes coupe-feu n’est pas primordiale dans chaque situation, le fabricant a le choix de déclarer si le cylindre est conforme à ces exigences additionnelles ou non. Dans l’affirmative, les cylindres sont conformes aux exigences spécifiées dans l’Annexe A.

L’évaluation de la résistance au feu des portes de grade 1 ne relève pas du domaine d’application du présent document.

Il se peut que parfois une exigence nécessite des fonctions supplémentaires dans la conception du cylindre. Il convient que les acheteurs s’assurent que les produits sont compatibles avec l’usage prévu.

Stavbno okovje - Profilni cilindri za ključavnice - Zahteve in preskusne metode

Ta evropski standard se uporablja za profilne cilindre za take ključavnice, kot se običajno uporabljajo v stavbah in so namenjene uporabi s profilnimi cilindri.

Ta evropski standard določa lastnosti in druge zahteve glede trdnosti, varnosti, trajnosti, delovanja in odpornosti profilnih cilindrov in njihovih izvirnih ključavnic na korozijo. Določa eno kategorijo uporabe, tri kategorije trajnosti, dve kategoriji, pri čemer je vsaka namenjena odpornosti na ogenj in korozijo, vse na podlagi preskusov delovanja, ter tudi šest razredov s ključem povezane varnosti na podlagi zahtev glede zasnove in tri razrede na podlagi preskusov delovanja, ki simulirajo napad.

Ta evropski standard zajema preskuse zadovoljivega delovanja pri temperaturah med –20 °C in +65 °C. Določa preskusne metode, ki se uporabljajo za profilne cilindre in zaščitne ukrepe, povezane s temi cilindri, ki jih priporoča proizvajalec.

Odpornost na korozijo se določa s sklicevanjem na zahteve evropskega standarda EN 1670 o korozijski odpornosti za ključavnice in stavbno okovje.

Ustreznost cilindrov za uporabo pri sestavih požarnih ali dimnih vrat se določi s preskusi delovanja med požarom, ki se izvajajo poleg preskušanja delovanja, opredeljenega v tem evropskem standardu. Ker ustreznost za uporabo pri požarnih vratih ni bistvena v vseh primerih, lahko proizvajalec navede, ali je cilinder v skladu s temi dodatnimi zahtevami ali ne. Če navede, da to drži, morajo biti cilindri v skladu z zahtevami iz ustreznega evropskega standarda EN 1634-1 ali prEN 1634-2, glej dodatek A.

Ocena požarne odpornosti vrat razreda 1 presega področje uporabe tega standarda.

Občasno lahko obstaja potreba po dodatnih funkcijah v okviru zasnove cilindra. Kupci bi se morali zadovoljiti s tem, da so izdelki ustrezni za njihovo načrtovano uporabo.

General Information

- Status

- Published

- Public Enquiry End Date

- 13-Jan-2014

- Publication Date

- 09-Jul-2015

- Technical Committee

- ISTP - Doors and windows

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 22-Jun-2015

- Due Date

- 27-Aug-2015

- Completion Date

- 10-Jul-2015

- Directive

- 89/106/EEC - Construction products

Relations

- Replaces

SIST EN 1303:2005/AC:2008 - Building hardware - Cylinders for locks - Requirements and test methods - Effective Date

- 01-Sep-2015

- Effective Date

- 01-Sep-2015

- Effective Date

- 23-Jun-2021

Overview

EN 1303:2015 - "Building hardware - Cylinders for locks - Requirements and test methods" is a European Standard (CEN) that defines performance, durability and security requirements plus test methods for lock cylinders and their original keys used in buildings. It applies to cylinders for locks with an operational torque up to 1.2 Nm and covers strength, corrosion resistance, operation at extreme temperatures and resistance to physical attack. Manufacturers may optionally declare conformity for use on fire or smoke doors (see Annex A).

Key topics and technical requirements

- Scope & application: Cylinders for building locks designed for use with removable cylinders; intended test methods and performance criteria.

- Performance classifications: An 8‑digit classification system covering attributes such as category of use, durability, door mass, fire suitability, safety, corrosion/temperature resistance, key‑related security and attack resistance.

- Grades and categories:

- One category of use

- Durability: 3 grades

- Fire suitability: 3 grades (manufacturer may claim compliance; Annex A)

- Corrosion resistance: 4 grades (referenced to EN 1670)

- Key‑related security: 6 design‑based grades and additional performance grades for simulated attack

- Attack resistance: New grading (0, A–D) covering drilling, chisel, twisting and plug/cylinder extraction; plug extraction grades include A, B (and higher grades C/D with defined force)

- Test methods: Standardised procedures for key strength, durability cycles, operation at extreme temperatures (tested over a range, revised to −25 °C to +65 °C), torque resistance of plug/cylinder, and specific attack simulations (drilling, chisel blows, twisting, extraction).

- Corrosion tests: Specified by reference to EN 1670; also includes tests for operation after corrosion exposure.

- Marking and product information: Requirements for classification marking and manufacturer declarations (Annexes C & D).

Applications and who uses this standard

- Manufacturers of cylinders and lock hardware - to design, test and declare performance levels.

- Lock and door hardware specifiers, architects and consultants - to select cylinders with the required durability, corrosion and attack resistance for buildings.

- Testing laboratories and certification bodies - to perform reproducible tests and classify products.

- Door assemblers, installers and building owners/ facility managers - to verify suitability for fire/smoke doors and intended use environments (external doors, high‑traffic areas, corrosive environments).

Practical uses include specifying cylinder grades for residential, commercial or industrial doors, ensuring compliance for fire‑rated assemblies (when claimed), and matching key‑security and attack resistance levels to risk profiles.

Related standards

- EN 1670 - Corrosion resistance of building hardware (referenced)

- EN 1634‑1 / EN 1634‑2 / EN 1634‑3 - Fire resistance and smoke control tests (used for fire/smoke door suitability)

- EN 1906, ISO/EN screw and drill standards - referenced for test apparatus and components

Keywords: EN 1303:2015, cylinders for locks, building hardware, test methods, durability, corrosion resistance, key related security, attack resistance, fire doors.

Frequently Asked Questions

SIST EN 1303:2015 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Building hardware - Cylinders for locks - Requirements and test methods". This standard covers: This European Standard applies to cylinders and their keys for such locks as are normally used in buildings and are designed to be used with cylinders, where the locks have an operational torque of maximum 1,2 Nm. This European Standard specifies performance and other requirements for the strength, security, durability, performance and corrosion resistance of cylinders and their original keys. It establishes one category of use, three grades of durability, three grades for fire and four grades corrosion resistance all based on performance tests as well as six grades of key related security based on design requirements and five grades on performance tests that simulate attack. This European Standard includes tests of satisfactory operation at a range of temperatures. It specifies test methods to be used on cylinders and their protective measures linked with these cylinders and recommended by the manufacturer. Corrosion resistance is specified by reference to the requirements of EN 1670 on corrosion resistance of building hardware. The suitability of cylinders for use on fire or smoke-door assemblies is determined by fire performance tests conducted in addition to the performance testing required by this standard. Since suitability for use on fire doors is not essential in every situation the manufacturer has the option to state if the cylinder conforms to these additional requirements or not. If so claimed, cylinders will comply with the requirements in Annex A. Assessment of fire resistance of grade 1 doors is beyond the scope of this document. On occasions there may be a need for additional functions within the design of the cylinder. Purchasers should satisfy themselves that the products are suitable for their intended use.

This European Standard applies to cylinders and their keys for such locks as are normally used in buildings and are designed to be used with cylinders, where the locks have an operational torque of maximum 1,2 Nm. This European Standard specifies performance and other requirements for the strength, security, durability, performance and corrosion resistance of cylinders and their original keys. It establishes one category of use, three grades of durability, three grades for fire and four grades corrosion resistance all based on performance tests as well as six grades of key related security based on design requirements and five grades on performance tests that simulate attack. This European Standard includes tests of satisfactory operation at a range of temperatures. It specifies test methods to be used on cylinders and their protective measures linked with these cylinders and recommended by the manufacturer. Corrosion resistance is specified by reference to the requirements of EN 1670 on corrosion resistance of building hardware. The suitability of cylinders for use on fire or smoke-door assemblies is determined by fire performance tests conducted in addition to the performance testing required by this standard. Since suitability for use on fire doors is not essential in every situation the manufacturer has the option to state if the cylinder conforms to these additional requirements or not. If so claimed, cylinders will comply with the requirements in Annex A. Assessment of fire resistance of grade 1 doors is beyond the scope of this document. On occasions there may be a need for additional functions within the design of the cylinder. Purchasers should satisfy themselves that the products are suitable for their intended use.

SIST EN 1303:2015 is classified under the following ICS (International Classification for Standards) categories: 91.190 - Building accessories. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1303:2015 has the following relationships with other standards: It is inter standard links to SIST EN 1303:2005/AC:2008, SIST EN 1303:2005, kSIST FprEN 1303:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1303:2015 is associated with the following European legislation: EU Directives/Regulations: 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1303:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Baubeschläge - Schließzylinder für Schlösser - Anforderungen und PrüfverfahrenQuincaillerie pour le bâtiment - Cylindres de serrures - Exigences et méthodes d'essaiBuilding hardware - Cylinders for locks - Requirements and test methods91.190Stavbna opremaBuilding accessoriesICS:Ta slovenski standard je istoveten z:EN 1303:2015SIST EN 1303:2015en,fr,de01-september-2015SIST EN 1303:2015SLOVENSKI

STANDARDSIST EN 1303:2005/AC:2008SIST EN 1303:20051DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1303

June 2015 ICS 91.190 Supersedes EN 1303:2005English Version

Building hardware - Cylinders for locks - Requirements and test methods

Quincaillerie pour le bâtiment - Cylindres de serrures - Exigences et méthodes d'essai

Schlösser und Baubeschläge - Schließzylinder für Schlösser - Anforderungen und Prüfverfahren This European Standard was approved by CEN on 19 March 2015.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2015 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1303:2015 ESIST EN 1303:2015

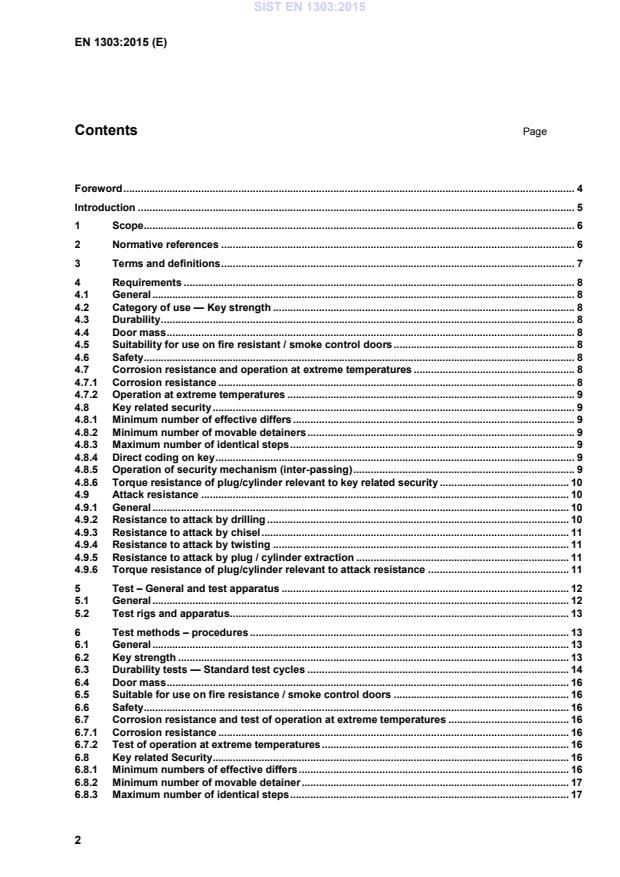

Foreword . 4 Introduction . 5 1 Scope. 6 2 Normative references . 6 3 Terms and definitions . 7 4 Requirements . 8 4.1 General . 8 4.2 Category of use — Key strength . 8 4.3 Durability . 8 4.4 Door mass . 8 4.5 Suitability for use on fire resistant / smoke control doors . 8 4.6 Safety. 8 4.7 Corrosion resistance and operation at extreme temperatures . 8 4.7.1 Corrosion resistance . 8 4.7.2 Operation at extreme temperatures . 9 4.8 Key related security . 9 4.8.1 Minimum number of effective differs . 9 4.8.2 Minimum number of movable detainers . 9 4.8.3 Maximum number of identical steps . 9 4.8.4 Direct coding on key . 9 4.8.5 Operation of security mechanism (inter-passing) . 9 4.8.6 Torque resistance of plug/cylinder relevant to key related security . 10 4.9 Attack resistance . 10 4.9.1 General . 10 4.9.2 Resistance to attack by drilling . 10 4.9.3 Resistance to attack by chisel . 11 4.9.4 Resistance to attack by twisting . 11 4.9.5 Resistance to attack by plug / cylinder extraction . 11 4.9.6 Torque resistance of plug/cylinder relevant to attack resistance . 11 5 Test – General and test apparatus . 12 5.1 General . 12 5.2 Test rigs and apparatus. 13 6 Test methods – procedures . 13 6.1 General . 13 6.2 Key strength . 13 6.3 Durability tests — Standard test cycles . 14 6.4 Door mass . 16 6.5 Suitable for use on fire resistance / smoke control doors . 16 6.6 Safety. 16 6.7 Corrosion resistance and test of operation at extreme temperatures . 16 6.7.1 Corrosion resistance . 16 6.7.2 Test of operation at extreme temperatures . 16 6.8 Key related Security . 16 6.8.1 Minimum numbers of effective differs . 16 6.8.2 Minimum number of movable detainer . 17 6.8.3 Maximum number of identical steps . 17 SIST EN 1303:2015

Cylinders suitable for use on fire resistant / smoke control doors . 27 Annex B (informative)

Tables of test sequence . 28 Annex C (informative)

Product information . 29 Annex D (informative)

Manufacturer’s declaration of compliance . 30 Annex E (informative)

Comparison table between EN 1303:2005 and EN 1303:2015 . 32 Bibliography . 33

4.4 Door mass There is no requirement on the cylinder related to the door mass. 4.5 Suitability for use on fire resistant / smoke control doors The cylinder shall conform to the requirements of Annex A. Verified in accordance with 6.5. 4.6 Safety There is no requirement on the cylinder related to safety. 4.7 Corrosion resistance and operation at extreme temperatures 4.7.1 Corrosion resistance It shall be possible to operate the cylinder with its proper key using a maximum torque of 1,5 Nm after tested according to grade 3 of EN 1670. This corrosion test shall apply to the functionality only. No distinction is made between the inside and the outside of cylinder and/or door. SIST EN 1303:2015

4.9 Attack resistance 4.9.1 General The cylinders, including any reinforcement or protection device supplied with them shall be tested as one unit. In case of a double cylinder, it is assumed that the grades for the attack resistance apply to the attack side / outside of the cylinder. This side shall have a proper indication, either on the product or on the documents with the product. If both sides are identical, it is not necessary to put an indication on the product. 4.9.2 Resistance to attack by drilling It shall not be possible to rotate the cam using a maximum torque of 5 Nm without the correct key, after the drilling time specified in Table 3. It is not necessary for the correct key to operate the cylinder after testing. SIST EN 1303:2015

4.9.2 Resistance to drilling 6.9.1 Time Net/Total - 3/5 5/10 3/5 5/10 Min. 4.9.3 Resistance to attack by chisel 6.9.2 Blows - 30 40 30 40 No 4.9.4 Resistance to attack by twisting 6.9.3 Twists - 20 30 20 30 No 4.9.5 Resistance to attack by plug/cylinder extraction 6.9.4 Force Net/Total - - - 10 5/15 15 5/15 kN min 4.9.6 Torque resistance of plug/cylinder 6.9.5 Torque - a 20 30 20 30 Nm a See requirement of key related security 4.8.6.

5 Test – General and test apparatus 5.1 General In order to minimize the number of samples to be tested some samples may be used for several tests. In the event of a test failure it shall not, at that point, be considered a failure to meet the standard. Two further cylinders, with the same design, shall be tested according to the failed test and both of them shall pass the test. In case of a double cylinder, it is assumed that the grades for key related security apply to the attack side / outside of the cylinder. This side shall have a proper indication, either on the product or on the documents with the product. If both sides are identical it is not necessary to put an indication on the product. Where a product range is submitted for evaluation the test authority shall consider each individual test for each cylinder type. Where (by engineering judgement) it can be shown that a weaker or equivalent cylinder type is to be evaluated then no further testing needs to be carried out. Check the cylinders and keys conform to 4.8.1 to 4.8.6 before commencing the performance tests. An example of a test sequence is shown in Annex B. If additional instructions for testing are required, the manufacturer shall supply such additional instructions. These additional instructions shall be documented in the test report. SIST EN 1303:2015

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...