SIST EN 12621:2025

(Main)Machinery for supply and circulation of liquid coating materials - Safety requirements

Machinery for supply and circulation of liquid coating materials - Safety requirements

This document deals with all significant hazards, hazardous situations and events which are relevant to machinery for supply and circulation of liquid coating material, when used as intended and under the conditions foreseen by the manufacturer, including reasonably foreseeable misuse.

See Annex A for significant hazards.

Together with this document, EN 50050 1:2013, EN 50059:2025, EN 50176:2025 or EN 50348:2010 give requirements for electrostatic machinery for supply and circulation of liquid coating material.

The specific significant risks related to the use of machinery for supply and circulation of liquid coating material with foodstuffs and pharmaceutical products are not dealt with in this document.

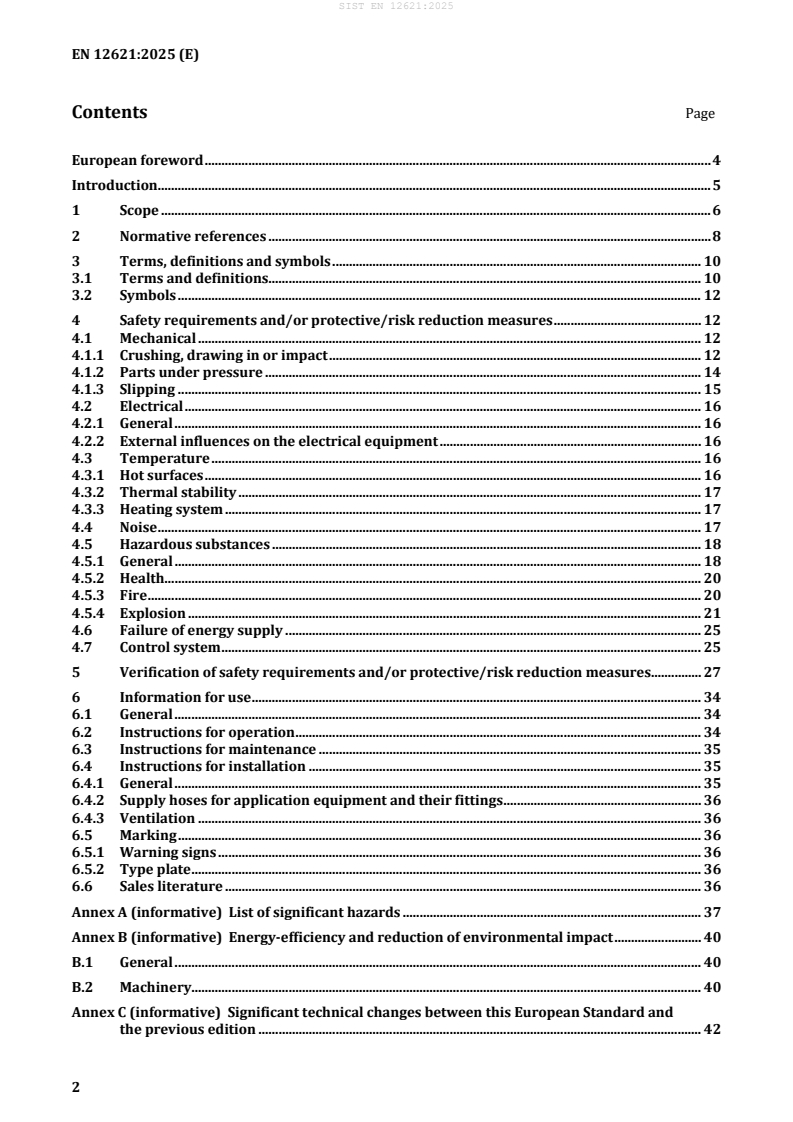

Interfaces to connected machinery and systems are given in Figure 1, to specify the limit of the machinery for supply and circulation of liquid coating material.

[Figure 1]

Figure 1 - Limits of the machinery

This document does not apply to:

- pressure related hazards of equipment classified as higher than category 1 of Directive 2014/68/EU Article 13;

NOTE 1 For equipment of higher category than category 1 of Directive 2014/68/EU, see EN 13445 (all parts) and EN 13480 (all parts).

- machinery for the supply of powder coating material;

- machinery for coating material recycling;

- hand-held agitators;

- agitators of more than 3 kW electrical power supply;

- offline heating systems;

- supply systems for CO2 shot-blasting machinery;

- equipment used for manufacturing of coating material;

- coating material packaging units (drums, containers, etc.).

This document is not applicable to machinery for supply and circulation of liquid coating material manufactured before the date of its publication.

Förder- und Umlaufanlagen für flüssige Beschichtungsstoffe - Sicherheitsanforderungen

Dieses Dokument behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die für Förder- und Umlaufanlagen für flüssige Beschichtungsstoffe bei bestimmungsgemäßer Verwendung und unter den vom Hersteller vorgesehenen Betriebsbedingungen, einschließlich vernünftigerweise vorhersehbarer Fehlanwendungen relevant sind.

Siehe Anhang A für signifikante Gefährdungen.

Zusammen mit diesem Dokument, geben EN 50050 1:2013, EN 50059:2025, EN 50176:2025, oder EN 50348:2010 Anforderungen für elektrostatische Förder- und Umlaufanlagen für flüssige Beschichtungsstoffe.

Die spezifischen signifikanten Risiken im Zusammenhang mit der Verwendung von Förder- und Umlaufanlagen für flüssige Beschichtungsstoffe mit Lebensmitteln und pharmazeutischen Produkten werden in diesem Dokument nicht behandelt.

Schnittstellen zu angeschlossenen Maschinen und Systemen sind in Bild 1 dargestellt, um die Grenzen der Förder- und Umlaufanlagen für flüssige Beschichtungsstoffe festzulegen.

[Bild 1]

Bild 1 - Grenzen der Maschine

Dieses Dokument ist nicht anzuwenden für:

- druckbedingte Gefahren von Geräten, die höher als in Kategorie 1 der Richtlinie 2014/68/EU Artikel 13 eingestuft sind;

ANMERKUNG 1 Für Geräte einer höheren Kategorie als Kategorie 1 der Richtlinie 2014/68/EU, siehe EN 13445 (alle Teile) und EN 13480 (alle Teile).

- Maschinen für die Versorgung mit Pulverbeschichtungsstoffen;

- Maschinen für die Wiederaufarbeitung von Beschichtungsstoff;

- handgehaltene Rührwerke;

- Rührwerke mit einer elektrischen Leistung von mehr als 3 kW;

- externe Heizsysteme;

- Versorgungssysteme für CO2-Strahlanlagen;

- Ausrüstung für die Herstellung von Beschichtungsstoffen;

- Verpackungseinheiten für Beschichtungsstoffe (Fässer, Container usw.).

Dieses Dokument gilt nicht für Förder- und Umlaufanlagen für flüssige Beschichtungsstoffe, die vor dem Datum seiner Veröffentlichung hergestellt wurden.

Installations d'alimentation et de circulation de produits de revêtement liquide - Prescriptions de sécurité

Le présent document traite tous les phénomènes dangereux, situations dangereuses et événements dangereux significatifs spécifiques aux installations d'alimentation et de circulation de produits de revêtement liquides, lorsqu'elles sont utilisées normalement et dans les conditions prévues par le fabricant, y compris tout mauvais usage raisonnablement prévisible.

Voir l’Annexe A pour les phénomènes dangereux significatifs.

Avec le présent document, l’EN 50050 1:2013, l’EN 50059:2025, l’EN 50176:2025 ou l’EN 50348:2010 donne des exigences pour les installations électrostatiques pour l’alimentation et la circulation de produits de revêtement liquides.

Les risques significatifs spécifiques relatifs à l'utilisation d’installations d'alimentation et de circulation de produits de revêtement liquides avec des aliments et des produits pharmaceutiques ne sont pas traités dans le présent document.

Les interfaces avec les machines et systèmes connectés sont indiquées à la Figure 1, afin de spécifier les limites de l’installation d'alimentation et de circulation de produits de revêtement liquides.

[Figure 1]

Figure 1 - Limites de l’installation

Le présent document ne s’applique pas :

- aux phénomènes dangereux liés à la pression d'équipements classés dans une catégorie supérieure à la catégorie 1 de la Directive 2014/68/UE Article 13 ;

NOTE 1 Pour les équipements d'une catégorie supérieure à la catégorie 1 de la Directive 2014/68/UE, voir l'EN 13445 (toutes les parties) et l'EN 13480 (toutes les parties).

- aux installations d'alimentation de produits de revêtements en poudre ;

- aux installations pour le recyclage de produits de revêtement ;

- aux agitateurs manuels ;

- aux agitateurs avec une alimentation électrique de plus de 3 kW ;

- aux systèmes de chauffage autonomes ;

- aux systèmes d'alimentation pour les installations de projection de CO2 ;

- aux équipements utilisés pour la fabrication de produits de revêtement ;

- aux unités de conditionnement du produit de revêtement (bidons, conteneurs, etc.).

Le présent document ne s'applique pas aux installations d’alimentation et de circulation de produits de revêtement liquides construites avant la date de sa publication.

Naprave za dovod in obtok tekočih premaznih materialov - Varnostne zahteve

Ta dokument opisuje vsa večja tveganja, nevarne situacije in dogodke z zvezi z napravami za dovod in obtok tekočih premaznih materialov, kadar se uporabljajo v skladu s predvidenim namenom in pod pogoji, ki jih je predvidel proizvajalec, vključno z razumno predvidljivo nepravilno uporabo.

Za večja tveganja glej dodatek A.

Skupaj s tem dokumentom standard EN 50050-1:2013, EN 50059:2025, EN 50176:2025 oziroma EN 50348:2010 določa zahteve za elektrostatične naprave za dovod in obtok tekočih premaznih materialov.

Ta dokument ne obravnava posebnih večjih tveganj, povezanih z uporabo naprav za dovod in obtok tekočih premaznih materialov z živili in farmacevtskimi izdelki.

Vmesniki do priključenih naprav in sistemov so prikazani na sliki 1, da se določijo omejitve naprav za dovod in obtok tekočih premaznih materialov. Ta dokument se ne uporablja za:

– tveganja, povezana s tlakom, pri opremi, ki je razvrščena v kategorijo, ki je višja od kategorije 1 iz Direktive 2014/68/EU, 13. člen;

OPOMBA 1: Za opremo kategorije, ki je višja od kategorije 1 Direktive 2014/68/EU, glej standarda EN 13445 (vsi deli) in EN 13480 (vsi deli).

– naprave za dovod praškastih premaznih materialov;

– naprave za recikliranje premaznih materialov;

– ročna mešala; – mešala z električno močjo, večjo od 3 kW;

– sisteme za ogrevanje brez povezave;

– sisteme za dovajanje za stroje za peskanje s CO2;

– opremo, ki se uporablja za proizvodnjo premaznih materialov;

– pakirne enote za premazne materiale (sodi, zabojniki itd.).

Ta dokument se ne uporablja za naprave za dovod in obtok tekočih premaznih materialov, ki so bili izdelani pred datumom njegove objave.

General Information

- Status

- Published

- Publication Date

- 09-Jun-2025

- Technical Committee

- VSN - Safety of machinery

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 19-Feb-2025

- Due Date

- 26-Apr-2025

- Completion Date

- 10-Jun-2025

Relations

- Effective Date

- 17-Jul-2019

Overview - EN 12621:2025 (CEN)

EN 12621:2025 - "Machinery for supply and circulation of liquid coating materials - Safety requirements" is a European type‑C safety standard prepared by CEN/TC 271 and approved Dec 22, 2024. It defines safety requirements for machinery that supplies, circulates and handles liquid coating materials when used as intended or under reasonably foreseeable misuse. The standard sets the functional and protective limits of the machinery (see Figure 1 interfaces) and replaces EN 12621:2006+A1:2010. It is not applicable to machines manufactured before its publication date.

Key topics and technical requirements

The standard addresses all significant hazards relevant to liquid coating supply and circulation machinery (see informative Annex A). Major technical topics include:

- Mechanical hazards: guarding against crushing, drawing‑in, impacts and hazards from pressurized parts.

- Electrical safety: general electrical requirements and protection against external influences on electrical equipment.

- Temperature control: hot surfaces, thermal stability and heating system safety.

- Noise: requirements for noise assessment and test methods (referencing EN 14462).

- Hazardous substances: health, fire and explosion risk management for coating liquids; explosion prevention measures referencing EN 1127‑1 and ATEX‑related documents.

- Explosion/ATEX interfaces: interface with electrostatic equipment requirements in conjunction with EN 50050‑1:2013, EN 50059:2025, EN 50176:2025 or EN 50348:2010.

- Control systems and energy failures: safe control logic, failure modes and verification procedures.

- Verification and testing: procedures to verify implemented protective measures (see Clause 5).

- Information for use: mandatory instructions for operation, maintenance, installation, marking and sales literature (Clauses 6.x).

- Exclusions: powder coating supply, coating recycling, hand‑held agitators, agitators >3 kW, offline heating systems, CO2 shot‑blasting supply, coating manufacture and packaging units, and equipment with higher pressure categories under Directive 2014/68/EU.

Practical applications and users

EN 12621:2025 is intended for:

- Machine manufacturers and integrators designing supply and circulation systems for liquid coatings.

- Safety engineers and compliance officers applying CE/ATEX requirements.

- Plant operators, maintenance teams and installers specifying, testing and maintaining coating supply systems.

- Regulators and market surveillance bodies assessing conformity to EU directives.

Typical applications include centralized paint supply systems, circulation units feeding application equipment, and stationary pumping/recirculation installations used in surface treatment lines (excluding powder systems).

Related standards

Key referenced and complementary standards:

- EN 50050‑1:2013, EN 50059:2025, EN 50176:2025, EN 50348:2010 (electrostatic equipment)

- EN 1127‑1:2019 (explosive atmospheres)

- EN 60204‑1:2018 (electrical equipment of machines)

- EN ISO 12100:2010 (machine safety principles)

- Annexes ZA/ZB map the standard to EU Directives (2006/42/EC and 2014/34/EU)

Use EN 12621:2025 to ensure safe design, installation and operation of liquid coating supply and circulation machinery and to demonstrate conformity with relevant EU safety and ATEX requirements.

Frequently Asked Questions

SIST EN 12621:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Machinery for supply and circulation of liquid coating materials - Safety requirements". This standard covers: This document deals with all significant hazards, hazardous situations and events which are relevant to machinery for supply and circulation of liquid coating material, when used as intended and under the conditions foreseen by the manufacturer, including reasonably foreseeable misuse. See Annex A for significant hazards. Together with this document, EN 50050 1:2013, EN 50059:2025, EN 50176:2025 or EN 50348:2010 give requirements for electrostatic machinery for supply and circulation of liquid coating material. The specific significant risks related to the use of machinery for supply and circulation of liquid coating material with foodstuffs and pharmaceutical products are not dealt with in this document. Interfaces to connected machinery and systems are given in Figure 1, to specify the limit of the machinery for supply and circulation of liquid coating material. [Figure 1] Figure 1 - Limits of the machinery This document does not apply to: - pressure related hazards of equipment classified as higher than category 1 of Directive 2014/68/EU Article 13; NOTE 1 For equipment of higher category than category 1 of Directive 2014/68/EU, see EN 13445 (all parts) and EN 13480 (all parts). - machinery for the supply of powder coating material; - machinery for coating material recycling; - hand-held agitators; - agitators of more than 3 kW electrical power supply; - offline heating systems; - supply systems for CO2 shot-blasting machinery; - equipment used for manufacturing of coating material; - coating material packaging units (drums, containers, etc.). This document is not applicable to machinery for supply and circulation of liquid coating material manufactured before the date of its publication.

This document deals with all significant hazards, hazardous situations and events which are relevant to machinery for supply and circulation of liquid coating material, when used as intended and under the conditions foreseen by the manufacturer, including reasonably foreseeable misuse. See Annex A for significant hazards. Together with this document, EN 50050 1:2013, EN 50059:2025, EN 50176:2025 or EN 50348:2010 give requirements for electrostatic machinery for supply and circulation of liquid coating material. The specific significant risks related to the use of machinery for supply and circulation of liquid coating material with foodstuffs and pharmaceutical products are not dealt with in this document. Interfaces to connected machinery and systems are given in Figure 1, to specify the limit of the machinery for supply and circulation of liquid coating material. [Figure 1] Figure 1 - Limits of the machinery This document does not apply to: - pressure related hazards of equipment classified as higher than category 1 of Directive 2014/68/EU Article 13; NOTE 1 For equipment of higher category than category 1 of Directive 2014/68/EU, see EN 13445 (all parts) and EN 13480 (all parts). - machinery for the supply of powder coating material; - machinery for coating material recycling; - hand-held agitators; - agitators of more than 3 kW electrical power supply; - offline heating systems; - supply systems for CO2 shot-blasting machinery; - equipment used for manufacturing of coating material; - coating material packaging units (drums, containers, etc.). This document is not applicable to machinery for supply and circulation of liquid coating material manufactured before the date of its publication.

SIST EN 12621:2025 is classified under the following ICS (International Classification for Standards) categories: 87.100 - Paint coating equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12621:2025 has the following relationships with other standards: It is inter standard links to SIST EN 12621:2006+A1:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12621:2025 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2014/34/EU; Standardization Mandates: M/396, M/596, M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 12621:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2025

Naprave za dovod in obtok tekočih premaznih materialov - Varnostne zahteve

Machinery for supply and circulation of liquid coating materials - Safety requirements

Förder- und Umlaufanlagen für flüssige Beschichtungsstoffe - Sicherheitsanforderungen

Installations d'alimentation et de circulation de produits de revêtement liquide -

Prescriptions de sécurité

Ta slovenski standard je istoveten z: EN 12621:2025

ICS:

87.100 Oprema za nanašanje Paint coating equipment

premazov

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12621

EUROPEAN STANDARD

NORME EUROPÉENNE

February 2025

EUROPÄISCHE NORM

ICS 87.100 Supersedes EN 12621:2006+A1:2010

English Version

Machinery for supply and circulation of liquid coating

materials - Safety requirements

Installations d'alimentation et de circulation de Förder- und Umlaufanlagen für flüssige

produits de revêtement liquide - Exigences de sécurité Beschichtungsstoffe - Sicherheitsanforderungen

This European Standard was approved by CEN on 22 December 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12621:2025 E

worldwide for CEN national Members.

Contents Page

European foreword . 4

Introduction. 5

1 Scope . 6

2 Normative references . 8

3 Terms, definitions and symbols . 10

3.1 Terms and definitions. 10

3.2 Symbols . 12

4 Safety requirements and/or protective/risk reduction measures . 12

4.1 Mechanical . 12

4.1.1 Crushing, drawing in or impact . 12

4.1.2 Parts under pressure . 14

4.1.3 Slipping . 15

4.2 Electrical . 16

4.2.1 General . 16

4.2.2 External influences on the electrical equipment . 16

4.3 Temperature . 16

4.3.1 Hot surfaces . 16

4.3.2 Thermal stability . 17

4.3.3 Heating system . 17

4.4 Noise . 17

4.5 Hazardous substances . 18

4.5.1 General . 18

4.5.2 Health. 20

4.5.3 Fire . 20

4.5.4 Explosion . 21

4.6 Failure of energy supply . 25

4.7 Control system . 25

5 Verification of safety requirements and/or protective/risk reduction measures. 27

6 Information for use . 34

6.1 General . 34

6.2 Instructions for operation . 34

6.3 Instructions for maintenance . 35

6.4 Instructions for installation . 35

6.4.1 General . 35

6.4.2 Supply hoses for application equipment and their fittings . 36

6.4.3 Ventilation . 36

6.5 Marking . 36

6.5.1 Warning signs . 36

6.5.2 Type plate . 36

6.6 Sales literature . 36

Annex A (informative) List of significant hazards . 37

Annex B (informative) Energy-efficiency and reduction of environmental impact . 40

B.1 General . 40

B.2 Machinery. 40

Annex C (informative) Significant technical changes between this European Standard and

the previous edition . 42

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 44

Annex ZB (informative) Relationship between this European Standard and the essential

Health and Safety Requirements of Directive 2014/34/EU aimed to be covered . 47

Bibliography . 50

European foreword

This document (EN 12621:2025) has been prepared by Technical Committee CEN/TC 271 “Surface

treatment equipment - safety”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by August 2025, and conflicting national standards shall be

withdrawn at the latest by August 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12621:2006+A1:2010.

See Annex C, Table C.1 for the technical modifications which have been made in comparison with

EN 12621:2006+A1:2010.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annexes ZA and ZB, which are an integral part

of this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100:2010.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions);

— service providers, e.g. for maintenance (small, medium and large enterprises).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the Scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or type-B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

1 Scope

This document deals with all significant hazards, hazardous situations and events which are relevant to

machinery for supply and circulation of liquid coating material, when used as intended and under the

conditions foreseen by the manufacturer, including reasonably foreseeable misuse.

See Annex A for significant hazards.

Together with this document, EN 50050-1:2013, EN 50059:2025, EN 50176:2025 or EN 50348:2010 give

requirements for electrostatic machinery for supply and circulation of liquid coating material.

The specific significant risks related to the use of machinery for supply and circulation of liquid coating

material with foodstuffs and pharmaceutical products are not dealt with in this document.

Interfaces to connected machinery and systems are given in Figure 1, to specify the limit of the machinery

for supply and circulation of liquid coating material.

Key

machinery for supply and circulation of liquid coating material

ditional parts for machinery for supply and circulation of liquid coating material with own forced

ventilation

1 container handling interface and coating material inlet connector

2 inlet connector for recycled coating material

3a pressurized air supply hose assembly (hose and connectors)

3b coating material supply hose assembly (hose and connectors)

4 electrical power supply connector

5 electrostatic high voltage supply connector

6 pressurized air supply connector

7 interface of control system

8 inlet connector of forced ventilation

9 outlet connector of forced ventilation

10 waste process material outlet connector

Figure 1 — Limits of the machinery

This document does not apply to:

— pressure related hazards of equipment classified as higher than category 1 of

Directive 2014/68/EU Article 13;

NOTE 1 For equipment of higher category than category 1 of Directive 2014/68/EU, see EN 13445 (all

parts) and EN 13480 (all parts).

— machinery for the supply of powder coating material;

— machinery for coating material recycling;

— hand-held agitators;

— agitators of more than 3 kW electrical power supply;

— offline heating systems;

— supply systems for CO shot-blasting machinery;

— equipment used for manufacturing of coating material;

— coating material packaging units (drums, containers, etc.).

This document is not applicable to machinery for supply and circulation of liquid coating material

manufactured before the date of its publication.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 619:2022, Continuous handling equipment and systems — Safety requirements for equipment for

mechanical handling of unit loads

EN 809:1998+A1:2009 , Pumps and pump units for liquids — Common safety requirements

EN 842:1996+A1:2008, Safety of machinery — Visual danger signals — General requirements, design and

testing

EN 1127-1:2019, Explosive atmospheres — Explosion prevention and protection — Part 1: Basic concepts

and methodology

EN 14462:2015, Surface treatment equipment — Noise test code for surface treatment equipment including

its ancillary handling equipment — Accuracy grades 2 and 3

EN 50050-1:2013, Electrostatic hand-held spraying equipment — Safety requirements — Part 1: Hand-

held spraying equipment for ignitable liquid coating materials

EN 50059:2025, Electrostatic hand-held spraying equipment — Safety requirements — Hand-held spraying

equipment for non-ignitable coating materials

EN 50176:2025, Stationary electrostatic application equipment for ignitable liquid coating material —

Safety requirements

EN 50348:2010, Stationary electrostatic application equipment for non-ignitable liquid coating material

— Safety requirements

EN 60079-30-1:2017, Explosive atmospheres — Part 30-1: Electrical resistance trace heating — General

and testing requirements (IEC/IEEE 60079-30-1:2015, modified)

EN 60204-1:2018, Safety of machinery — Electrical equipment of machines — Part 1: General requirements

(IEC 60204-1:2016, modified)

EN 62395-1:2013, Electrical resistance trace heating systems for industrial and commercial applications

— Part 1: General and testing requirements (IEC 62395-1:2013)

As impacted by EN 809:1998+A1:2009/AC:2010.

EN IEC 60079-0:2018, Explosive atmospheres — Part 0: Equipment — General requirements (IEC 60079-

0:2017)

EN IEC 60079-10-1:2021, Explosive atmospheres — Part 10-1: Classification of areas — Explosive gas

atmospheres (IEC 60079-10-1:2020 + COR1:2021)

EN ISO 4413:2010, Hydraulic fluid power — General rules and safety requirements for systems and their

components (ISO 4413:2010)

EN ISO 4414:2010, Pneumatic fluid power — General rules and safety requirements for systems and their

components (ISO 4414:2010)

EN ISO 8031:2020, Rubber and plastics hoses and hose assemblies — Determination of electrical resistance

and conductivity (ISO 8031:2020)

EN ISO 11688-1:2009, Acoustics — Recommended practice for the design of low-noise machinery and

equipment — Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13732-1:2008, Ergonomics of the thermal environment — Methods for the assessment of human

responses to contact with surfaces — Part 1: Hot surfaces (ISO 13732-1:2006)

EN ISO 13849-1:2023, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2023)

EN ISO 13851:2019, Safety of machinery — Two-hand control devices — Principles for design and selection

(ISO 13851:2019)

EN ISO 13854:2019, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body

(ISO 13854:2017)

EN ISO 13855:2010, Safety of machinery — Positioning of safeguards with respect to the approach speeds

of parts of the human body (ISO 13855:2010)

EN ISO 13857:2019, Safety of machinery — Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2019)

EN ISO 14120:2015, Safety of machinery — Guards — General requirements for the design and

construction of fixed and movable guards (ISO 14120:2015)

EN ISO 14122-2:2016, Safety of machinery — Permanent means of access to machinery — Part 2: Working

platforms and walkways (ISO 14122-2:2016)

EN ISO 14122-3:2016, Safety of machinery — Permanent means of access to machinery — Part 3: Stairs,

stepladders and guard-rails (ISO 14122-3:2016)

EN ISO 14122-4:2016, Safety of machinery — Permanent means of access to machinery — Part 4: Fixed

ladders (ISO 14122-4:2016)

EN ISO 19353:2019, Safety of machinery — Fire prevention and fire protection (ISO 19353:2019)

As impacted by EN IEC 60079-0:2018/AC:2020-02 and EN IEC 60079-0:2018/A11:2024.

EN ISO 80079-36:2016, Explosive atmospheres — Part 36: Non-electrical equipment for explosive

atmospheres — Basic method and requirements (ISO 80079-36:2016)

ISO 3864-1:2011, Graphical symbols — Safety colours and safety signs — Part 1: Design principles for safety

signs and safety markings

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/

3.1.1

machinery

system for supply and/or circulation of liquid coating materials which may consist of machines and

elements such as:

— pumps (e.g. for processing, supply, circulation);

— rams, lifting equipment and container handling systems if these are integral part of the machinery;

— dosing and mixing units (e.g. for multi component coating materials);

— pressurized and non-pressurized vessels;

— pipes, hoses and their assemblies;

— couplings, valves, pressure regulators;

— agitators;

— filters;

— pulsation dampers;

— control systems;

— forced ventilation systems (for enclosed machinery);

— systems to separate machine parts under high voltage from other machine parts;

— measurement devices;

— sensors;

— equipment for heating and/or cooling of the coating materials

As impacted by EN ISO 80079-36:2016/AC:2019.

3.1.2

coating material

product, in liquid form, that, when applied to a substrate, forms a film possessing protective, decorative

and/or other specific properties

Note 1 to entry: In general, coating materials consist of binders, pigments, dyestuff, fillers and other additives.

Moreover, liquid coating materials can contain organic solvents and /or water.

Note 2 to entry: Coating materials are, for instance, paints, lacquers, varnishes, impregnating varnishes, paste

fillers, filling materials, impregnating agents, anti-noise agents, fire resisting agents, stains, burnishes, adhesives as

well as sealing compounds.

3.1.3

maximum working pressure

maximum admissible static or dynamic fluid pressure as specified by the manufacturer

Note 1 to entry: Individual machinery elements/parts may have individual maximum working pressure values.

3.1.4

maximum working temperature

maximum admissible temperature of machinery elements as specified by the manufacturer

3.1.5

enhanced tightness

absence of leakage when, due to the design and measures of maintenance, any of the tightness tests or

tightness monitorings appropriate for the application does not reveal any hazardous leaks during normal

operations and expected malfunctions

[SOURCE: EN 1127-1:2019, 3.2]

3.1.6

normal tightness

absence of leakage when any of the tightness tests or tightness monitoring appropriate for the application

does not reveal any hazardous leaks during normal operation

[SOURCE: EN 1127-1:2019, 3.1]

3.1.7

agitator

device for mixing and preparation of coating material consisting of

— stirrer,

— shaft,

— drive

and optional

— lid,

— lifter,

— pump,

— sensors

3.1.8

container handling system

handling system for coating material containers and which is integral part of the machinery

3.1.9

vessel

pressurized or non-pressurized process containment for liquid coating material which is part of the

machinery

3.1.10

container

containment for liquid coating material which is not part of the machinery

3.1.11

operator accessible enclosure

enclosure for which provision is made for the presence of persons inside the enclosure during normal

operation

3.1.12

ram

drum press

fixed machinery for extracting coating material from an open top container

3.1.13

forced ventilation

technical ventilation consisting of air exhaust system and air inlet openings or air supply system

3.1.14

enclosed machinery

machinery installed in a predominantly closed enclosure

3.1.15

non-enclosed machinery

machinery not installed in an enclosure

3.2 Symbols

For the purposes of this document, the following symbols apply.

T temperature of a liquid (e.g. coating material, flushing/purging liquid)

Liquid

T flashpoint temperature of a liquid

FP

4 Safety requirements and/or protective/risk reduction measures

4.1 Mechanical

4.1.1 Crushing, drawing in or impact

4.1.1.1 General

Moving parts of the machinery shall be designed and safeguarded in accordance with EN ISO 13857:2019,

EN ISO 13854:2019, EN 809:1998+A1:2009 , EN 842:1996+A1:2008, ISO 3864-1:2011 and

EN ISO 14120:2015.

Fixed guards shall be fixed by systems that can be opened or removed only with tools. Their fixing

systems shall remain attached to the guards or to the machinery when the guards are removed. Where

possible, these guards shall be designed in such a way that they can only remain in place using their fixing

system.

Mobile machinery shall be designed and constructed to avoid

— overturning on a slope of up to 10°;

— unintentional movement during operation, by e.g. brakes for wheels or device to retract wheels from

the floor.

4.1.1.2 Agitators

4.1.1.2.1 General

Openings for visual inspection or replenishment shall be safeguarded against access to hazardous moving

parts with

— fixed guards

or

— movable guards interlocked with the hazardous movement.

Rotating parts shall only operate when guarded and in operating position inside the vessel or container.

The presence of vessels or containers which are not fixed parts of the machinery shall be monitored.

Unintentional rotation of stirring vessels or containers shall be prevented by design or a locking device.

See 4.7 for requirements of control systems.

See 6.2 for instructions to be given for operation with containers which are not an integral part of the

machinery.

4.1.1.2.2 Power-driven lids, vessels and containers

For

— power driven lids (e. g. lids mounted on an elevator) and vessels or containers

or

— lids and power-driven vessels or containers (e.g. vessels lifted by an elevator),

the hazardous area between the lid and the vessel or container top shall be safeguarded by either

— a guard according to EN ISO 14120:2015, interlocked with the hazardous movement

or

— a two-hand control device according to EN ISO 13851:2019

or

— a hold-to-run control positioned in at least 2,5 m distance to the hazardous area.

See 4.7 for requirements of control systems.

4.1.1.3 Rams

Rams shall be equipped with guides for positioning of vessels and containers.

The hazardous area between platen and the vessel or container shall be safeguarded by, either

— a guard according to EN ISO 14120:2015, interlocked with the hazardous movement

or

— a two-hand control device according to EN ISO 13851:2019 and its positioning according to

EN ISO 13855:2010. It shall only be possible to enable the production mode if the platen has entered

the vessel or container.

For rams not safeguarded by a guard according to EN ISO 14120:2015,

— the air pressure for the separation of the platen from the coating material shall be limited to 2 bar.

After separation of coating material and platen and during the release of the platen from the drum,

the air pressure between coating material and platen shall be limited to 0,75 bar

and

— devices (e.g. piloted check valve) to avoid hazardous movement of the platen in case of pressure-loss

shall be installed.

See 4.7 for requirements of control systems.

See 6.2 for instructions to be given for operation.

4.1.1.4 Power driven container handling systems

Power driven container handling systems shall be designed according to EN 619:2022.

4.1.2 Parts under pressure

4.1.2.1 General

The maximum working pressure of the machinery shall be specified.

If the maximum working pressure can be exceeded,

— pressure limiting devices (e.g. pressure relief valve for air driven pumps, burst disk) shall be

installed;

— information on maintenance procedures and cycles of pressure limiting devices, especially when

these are subject to contamination by coating material, shall be given in the instruction for

maintenance (see 6.3);

— the pressure limiting devices in multi-component systems shall be placed on the supply lines of the

single components, if the multi-component lines cannot be flushed.

Uncontrolled ejection of coating materials, cleaning and flushing liquids from the machinery (e.g. from

leakages or element/part failures) shall be avoided by design and construction of the elements/parts.

Each element/part shall be stable up to the specific burst pressure specified in Table 1.

Machinery shall be equipped with a device for release of residual pressure (e.g. a valve with connection

to a container). Information on maintenance procedures and cycles of devices for release of residual

pressure, especially when these are subject to contamination by coating material, shall be given in the

instruction for maintenance (see 6.3).

NOTE Seals can suffer leaks depending on design and function.

4.1.2.2 Pipes, hoses and their assemblies

Pipes, hoses and their assemblies shall be

— adequately protected against harmful external stress (e.g. mechanical damage by abrasion);

— adequately installed to minimize external stress, (e.g. sufficient radius, length);

— resistant against pressure pulsation.

Pipes, hoses and their assemblies shall comply with the requirements of Table 1.

Table 1 — Minimum burst pressures for pipes, hoses and their assemblies

Minimum burst pressure

Maximum working Pipes Hoses and Hoses and their assemblies subjected to stress

pressure P their by torsion, friction, elongation

assemblies

Supply hoses and their Supply hoses and

not

assemblies for automatic their assemblies

subjected to

application equipment and for manual

stress by

hoses installed inside of application

torsion,

robots equipment

friction,

elongation

4-times of the

3-times of the maximum

P < 375 bar maximum working

working pressure

pressure

3-times of the maximum

2-times of the maximum

375 bar ≤ P ≤ 750 bar working pressure, but not 1 500 bar

working pressure

higher than 1 500 bar

P > 750 bar 2-times of the maximum working pressure

Hydraulic power systems and components shall comply with EN ISO 4413:2010.

Pneumatic power systems and components shall comply with EN ISO 4414:2010.

See 4.3.2 for requirements on thermal stability.

For instructions on operation, see 6.2.

For instructions on inspection and maintenance of pipes, hoses and their assemblies, see 6.3.

4.1.2.3 Pumps

Pumps shall comply with EN 809:1998+A1:2009 .

For air driven pumps the pressure limiting device can be installed on the air supply side.

Instructions on pressure relief procedure shall be given in the information for use, see 6.2 and 6.3.

4.1.3 Slipping

Leakage of liquids from the material supply system shall be minimized. Requirements against leakage are

given in 4.5.1.4.

Floor gratings, platforms, steps and walkways which are part of the machinery shall be designed

according to EN ISO 14122-2:2016, EN ISO 14122-3:2016, EN ISO 14122-4:2016.

If the floor is made of detachable elements:

— any hazardous horizontal movement of these elements shall be prevented, e.g. by fasteners and/or

frames;

— it shall be possible to inspect fixings in order to detect any corrosion or any hazardous loosening or

change of position of clamps.

Information shall be given in the user information on

— slip-resistant floor design in working areas around the machinery (see 6.4.1),

— the provision of retention volume (see 6.4.1),

NOTE Requirements for retention devices can be subject to national regulation.

— coating material handling (see 6.2),

— cleaning and maintenance (see 6.2 and 6.3).

4.2 Electrical

4.2.1 General

This clause deals with requirements for electrical safety of humans. See 4.5.4.4.3 for safety requirements

related to electrical ignition hazards.

The electrical equipment (e.g. digital displays, heating systems, initiators) shall comply with

EN 60204-1:2018.

NOTE For use in explosive atmosphere, see further information in EN IEC 60079-0:2018 and 4.5.4.4.

For liquid material supply machinery of electrostatic application systems, EN 50176:2025,

EN 50050-1:2013, EN 50348:2010 or EN 50059:2025 shall be applied.

4.2.2 External influences on the electrical equipment

The electrical equipment shall be selected and installed to prevent damage e.g. by:

— influences of temperature due to e.g. thermal conduction or convection;

— contact with hot parts, drips or molten particles of the materials being processed;

— chemical attack by substances released or processed, e.g. solvents and other aggressive liquids.

4.3 Temperature

4.3.1 Hot surfaces

The maximum surface temperature of machinery parts which are touched repeatedly or permanently

(e.g. material supply hose for manual application equipment) shall be 43 °C or lower.

Warning signs shall be fixed to warn of hot surfaces.

Information shall be given in the instructions for use, on

— instruction and training of operators and maintenance staff;

— machinery parts with hot surfaces;

— required PPE (e.g. thermal protective gloves).

Burns due to unintentional touching of hot surfaces can occur when the maximum working temperature

is above

— 58 °C for smooth metal surfaces (e.g. on pumps, platen, heaters, motors, heated vessels, heated

tubes);

— 76 °C for smooth plastic surfaces (e.g. on heated plastic tubes).

The following protection measures against burns shall be applied:

— reduction of the surface temperature (e.g. by installation of a motor with power reserve). Reduction

of surface temperature is not possible for machinery parts heated due to the material supply working

temperature;

— insulation of heated vessels and heated tubes;

— guards to restrict access to pumps, heaters, motors and heated pipes;

— increasing the distance between machinery parts which are intentionally touched and hot surfaces

of heaters and heated tubes.

NOTE EN ISO 13732-1:2008 provides information on the assessment of and measures against hot surfaces.

4.3.2 Thermal stability

Machinery elements (e.g. hoses and their assemblies, gauges, sealings) shall be designed and/or selected

according to the maximum working temperature.

4.3.3 Heating system

The heating system shall not restart automatically after failure of the heating system.

Electrical heating devices shall comply with EN 62395-1:2013.

See 4.5.4.4.6 for requirements against ignition sources from hot surfaces.

The heating temperature shall be monitored. The overrun of the maximum working temperature shall be

avoided by temperature limiting devices installed at all machinery elements/parts equipped with a

heating device.

NOTE Different machinery elements/parts can have different maximum working temperatures.

The heating system shall be shut off if the maximum working temperature is exceeded.

See 4.7 for requirements of control systems.

A temperature limiting device is not required, if the heating device, even in the case of failure, cannot heat

the machinery elements/parts above their maximum working temperature.

4.4 Noise

The machinery shall be designed and constructed so that the risks resulting from emission of airborne

noise are reduced to the lowest level, taking into account technical progress and availability of means for

noise reduction, especially at source.

The generation and emission of airborne noise by the machinery shall be reduced as far as possible by

— machinery parts with reduced noise emission,

— avoiding pressure fluctuation (e.g. choice of pump type),

— vibration damping or resilient support for membrane pumps and piston pumps,

— silencers for pneumatic machinery parts (e.g. valves at handling devices, stirrers and motors).

If by above measures the A weighted emission sound pressure levels are not reduced to levels below

80 dB, sound isolating enclosures shall be installed either for the complete machinery or for relevant

parts. The A weighted emission sound pressure level outside of the enclosures should be below 80 dB.

NOTE 1 According to the current state of the art, machinery for supply and circulation of liquid coating materials

can be designed so that the A-weighted emission sound pressure level, measured according to the noise test code

given in EN 14462:2015, A.6.2 does not exceed 78 dB.

When designing the machinery, the recommendations given in EN ISO 11688-1:2009 shall be taken into

account.

NOTE 2 EN ISO 11688-2:2000 gives information on noise generation mechanisms in machinery.

The determination of noise emission of the machinery shall be carried out according to EN 14462:2015.

4.5 Hazardous substances

4.5.1 General

4.5.1.1 General

The probability of formation of air containing vapours of coating material in hazardous concentrations in

the environment of the machinery shall be evaluated by a risk assessment, taking into account

— the properties of the coating material (i.e. flashpoint, toxicity);

— the intended use, i.e. procedures of colour changing;

— potential evaporation sources;

— the expected leakage rate of all relevant machinery elements/parts;

— the environment of the machinery (e.g. outside of buildings, spacious production environment with

natural ventilation).

The formation of air containing vapours of coating material in hazardous concentrations in the

environment of the machinery shall be avoided by

— prevention of open surfaces of vessels and containers according to 4.5.1.2;

— prevention of overfilling of vessels according to 4.5.1.3;

— minimization of leakage of hazardous fluids according to 4.5.1.4;

— safe draining according to 4.5.1.5.

Ventilation according to 4.5.1.6 is required, if the formation of air containing vapours of coating material

in hazardous concentrations in the environment of the machinery cannot be avoided.

4.5.1.2 Open surfaces of vessels and containers

Open surfaces of vessels and containers shall be avoided.

Information shall be given in the user information, that vessels and containers shall be covered with lids.

4.5.1.3 Overfilling

Overfilling of vessels shall be prevented in the case of automatic filling. The maximum fill level shall be

monitored. When the maximum fill level is reached, filling shall be stopped.

See 4.7 for requirements of control systems.

4.5.1.4 Leakage

Leakage of hazardous fluids shall be minimized by e.g.:

— tightness of fluid-filled parts of the machinery;

— pressure proof construction of fluid-filled parts of the machinery under pressure;

— designated pressure relief points.

Hoses and their assemblies shall be resistant against chemical attack (e.g. ozone, solvents).

Machinery elements/parts with enhanced tightness are e.g.:

— piping,

— fittings with sealing of the stem passage by a bellow and safety compression gland.

Joints for pipes, hoses and their assemblies with enhanced tightness are e.g.:

— permanent joints, e.g. by welding,

— detachable joints which are rarely detached during normal operation,

— NPT threads (National Pipe Taper Thread), or other tapered pipe threads with thread sealings up to

DN 50, as far as they are not exposed to varying thermal loads (ΔT > 100 K).

Machinery elements/parts with normal tightness are e.g.:

— non-regularly maintained dynamic sealings to the exterior, e.g. of gear pumps,

— direct face to face flanges (without intermediate sealing),

— detachable joints which are regularly detached during normal operation.

All parts of machinery which may be subject to leakage shall be easily accessible. Leakage shall be

detectable (e.g. by monitoring of solvent vapours or liquids or visual inspection).

If machinery elements/parts with normal tightness are regularly maintained and monitored, they can be

considered as machinery elements/parts with enhanced tightness.

Connections between machinery elements/parts shall be

— selected and installed according to the expected mechanical stress (e.g. vibrations),

and

— designed and installed to avoid transfer of hazardous vibration.

All machinery elements/parts shall be selected and installed according to the expected thermal stress

including alternating thermal stress.

Information shall be given in the user information on

— the provision of retention devices (see 6.4.1),

NOTE Requirements for retention devices can be subject to national regulation.

— coating material handling (see 6.2).

4.5.1.5 Draining

The machinery shall be designed and constructed to allow safe draining of all machinery parts containing

hazardous substances.

Draining points shall be marked.

The draining procedure shall be described in the instructions.

4.5.1.6 Ventilation

If the formation of air containing vapours of coating material in hazardous concentrations in the

environment of the machinery cannot be avoided with the measures given in 4.5.1.2, 4.5.1.3, 4.5.1.4 and

4.5.1.5, the measures given in Table 2 shall be applied.

Table 2 — Forced ventilation requirements depending on the health hazard and the

temperature (T ) in relation to the flash point (T ) of the processed liquid

Liquid FP

T < T – 15 K T ≥ T – 15 K T ≥ T – 15 K

Liquid FP Liquid FP Liquid FP

a

permanently occasionally permanently

Health hazardous The machinery shall be fitted with a forced The machinery shall be

liquid ventilation which is effective at the sources of fitted with an enclosure

release. A minimum air volume flow of 50 l/h per with forced ventilation.

emission source shall be ensured. The forced ventilation

shall ensure a minimum

Non health No forced ventilation is required

air exchange rate of 5-

hazardous liquid

times of the enclosure

volume per hour

NOTE Exposure limit values and requirements for emissions to atmosphere can be subject to national

regulation.

a

Less than 15 min in 8 h. See ISO/TR 14121-2:2012.

The total air volume flow of the forced ventilation shall be monitored. Underperformance of the forced

ventilation shall be indicated by an alarm.

See 4.7 for requi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...