SIST EN 1953:2025

(Main)Application equipment for coating materials - Safety

Application equipment for coating materials - Safety

This document deals with all significant hazards, hazardous situations and hazardous events which are relevant to hand-held and automatic application equipment for coating material, when used as intended and under the conditions foreseen by the manufacturer, including reasonably foreseeable misuse.

See Annex A for significant hazards.

Together with this document, EN 50050 1:2013, EN 50050 2:2013, EN 50050 3:2013, EN 50059:2025, EN 50176:2025, EN 50177:20091, EN 50223:2015 or EN 50348:2010 give requirements for electrostatic application equipment.

The specific significant risks related to the use of application equipment with foodstuffs and pharmaceutical products are not dealt with in this document.

This document is not applicable to:

- application equipment designed for pneumatic working pressure above 15 bar;

- application equipment with rotating bell/disc designed for hydraulic working pressures above 25 bar;

- non-atomizing application equipment (e.g. extruding equipment, dispenser);

- fluidised bed powder coating machinery;

- application equipment covered by EN 50580:20125;

- supply hoses;

- airbrushes for graphic and artistic works;

- machinery for the supply and circulation of coating materials (see EN 12621:2025).

This document is not applicable to application equipment manufactured before the date of its publication.

Applikationsgeräte für Beschichtungsstoffe - Sicherheitsanforderungen

Dieses Dokument behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die für handgehaltene und automatische Applikationsgeräte für Beschichtungsstoffe bei bestimmungsgemäßer Verwendung und unter den vom Hersteller vorgesehenen Betriebsbedingungen, einschließlich vernünftigerweise vorhersehbarer Fehlanwendungen relevant sind.

Siehe Anhang A für signifikante Gefährdungen.

Zusammen mit diesem Dokument, geben EN 50050 1:2013, EN 50050 2:2013, EN 50050 3:2013, EN 50059:2025, EN 50176:2025, EN 50177:20091, EN 50223:2015 oder EN 50348:2010 Anforderungen für elektrostatische Applikationsgeräte.

Die spezifischen signifikanten Risiken im Zusammenhang mit der Verwendung von Applikationsgeräten mit Lebensmitteln und pharmazeutischen Produkten werden in diesem Dokument nicht behandelt.

Dieses Dokument ist nicht anwendbar für:

- Applikationsgeräte, die für einen pneumatischen Betriebsdruck über 15 bar ausgelegt sind;

- Applikationsgeräte mit rotierender Glocke/Scheibe, die für einen hydraulischen Betriebsdruck über 25 bar ausgelegt sind;

- nicht-zerstäubende Applikationsgeräte (z. B. Extrudiergeräte, Dosiergeräte);

- Fließbett-Pulverbeschichtungsanlagen;

- Applikationsgeräte, nach EN 50580:20125;

- Versorgungsschläuche;

- Air-Brush-Pistolen für grafische und künstlerische Arbeiten;

- Förder- und Umlaufanlagen für flüssige Beschichtungsstoffe (siehe EN 12621:2025).

Diese Norm ist nicht anwendbar für Maschinen, die vor Veröffentlichung dieser Europäischen Norm hergestellt wurden.

Equipements d'application pour produits de revêtement - Exigences de sécurité

Le présent document traite tous les phénomènes dangereux, situations dangereuses et événements dangereux significatifs qui sont pertinents pour les équipements d'application manuels et automatiques pour les produits de revêtement, lorsqu'ils sont utilisés normalement et dans les conditions prévues par le fabricant, y compris tout mauvais usage raisonnablement prévisible.

Voir l’Annexe A pour les phénomènes dangereux significatifs.

Avec le présent document, l’EN 50050 1:2013, l’EN 50050 2:2013, l’EN 50050 3:2013, l’EN 50059:2025, l’EN 50176:2025, l’EN 50177:20091, l’EN 50223:2015 ou l’EN 50348:2010 donnent des exigences pour les équipements d'application électrostatiques.

Les risques significatifs spécifiques relatifs à l'utilisation des équipements d'application pour les produits alimentaires et pharmaceutiques ne sont pas traités dans le présent document.

Le présent document ne s’applique pas aux :

- équipements d'application conçus pour une pression pneumatique de service supérieure à 15 bar ;

- équipements d'application avec bol/disque rotatifs conçus pour des pressions de service supérieures à 25 bar ;

- équipements d'application non atomisants (par exemple, équipement d'extrusion, distributeur) ;

- machines de revêtement en lit fluidisé de poudre ;

- équipements d'application couverts par l’EN 50580:20125;

- tuyaux d'alimentation ;

- aérographes pour les travaux graphiques et artistiques ;

- machines pour l'alimentation et la circulation de produit de revêtement (voir l'EN 12621:2025).

Le présent document n'est pas applicable aux équipements d'application fabriqués avant la date de sa publication.

Oprema za nanašanje prekrivnih materialov - Varnostne zahteve

Ta dokument opisuje vsa večja tveganja, nevarne situacije in dogodke z zvezi z opremo za ročno in avtomatsko nanašanje prekrivnih materialov, kadar se uporablja v skladu s predvidenim namenom in pod pogoji, ki jih je predvidel proizvajalec, vključno z razumno predvidljivo nepravilno uporabo. Za večja tveganja glej dodatek A. Skupaj s tem dokumentom standardi EN 50050-1:2013, EN 50050-2:2013, EN 50050-3:2013, EN 50059:2025, EN 50176:2025, EN 50177:20091, EN 50223:2015 oziroma EN 50348:2010 določajo zahteve za opremo za elektrostatično nanašanje. Ta dokument ne obravnava posebnih večjih tveganj, povezanih z uporabo opreme z živili in farmacevtskimi izdelki. Ta dokument se ne uporablja za: – opremo za nanašanje, zasnovano za delovanje pri pnevmatskem delovnem tlaku nad 15 barov; – opremo za nanašanje z rotacijskim razpršilnikom/diskom, zasnovano za delovanje pri hidravličnem delovnem tlaku nad 25 barov; – opremo za nanašanje, ki ni namenjena razprševanju (npr. oprema za iztiskanje, točilne naprave); – stroje za barvanje s potapljanjem v prah; – opremo za nanašanje, ki je zajeta v standardu EN 50580:20125; – oskrbne cevi; – zračne čopiče za grafiko ali umetniška dela; – naprave za dovod in obtok tekočih premaznih materialov (glej standard EN 12621:2025). Ta dokument se ne uporablja za opremo za nanašanje, ki je bila izdelana pred datumom njegove objave.

General Information

- Status

- Published

- Publication Date

- 09-Jun-2025

- Technical Committee

- VSN - Safety of machinery

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 26-Feb-2025

- Due Date

- 03-May-2025

- Completion Date

- 10-Jun-2025

Relations

- Revised

SIST EN 1953:2014 - Atomising and spraying equipment for coating materials - Safety requirements - Effective Date

- 17-Jul-2019

Overview

EN 1953:2025 - Application equipment for coating materials - Safety requirements (CEN) defines safety requirements for hand‑held and automatic application equipment used to apply coating materials. It addresses all significant hazards, hazardous situations and events relevant when equipment is used as intended or under reasonably foreseeable misuse. EN 1953:2025 is a type‑C machinery safety standard (per EN ISO 12100) intended to guide manufacturers, safety authorities and users in reducing risk for modern coating application systems.

Key topics and technical requirements

The standard covers a broad set of safety themes (see Annex A for significant hazards), including:

- Mechanical: mechanical strength, risks from ejection of pressurized fluids or parts, cutting hazards.

- Electrical: safe electrical design and verification in line with machine electrical requirements.

- Temperature: prevention of burns and overheating.

- Noise: noise assessment and relevant test code guidance.

- Explosion / ignition: control of electrostatic, electrical and non‑electrical ignition sources for flammable atmospheres.

- Hazardous materials: protection against contact with coating materials and cleaning liquids, and inhalation of aerosols and solvent vapours.

- Ergonomics: ergonomic design to reduce operator fatigue and misuse.

- Malfunction: requirements for trigger functions, blockage handling and other failure modes.

- Verification & testing: procedures for verifying safety measures (mechanical, electrical, explosion protection, noise, etc.).

- Information for use: required instructions, installation/operation/maintenance information, marking (including ATEX marking where applicable) and sales literature.

Important exclusions and applicability notes:

- Not applicable to equipment manufactured before publication.

- Excludes pneumatic equipment >15 bar, rotating bell/disc hydraulic equipment >25 bar, non‑atomizing dispensers, fluidised bed powder coating machinery, supply hoses, art airbrushes, and machinery covered by other listed standards.

Applications and who uses this standard

EN 1953:2025 is used by:

- Manufacturers of hand‑held and automatic coating application equipment to design compliant products.

- Health & safety regulators, market surveillance and certification bodies for conformity assessment.

- Plant operators, maintenance teams and system integrators to select, install, operate and service safe equipment. Typical sectors: automotive, aerospace, industrial coating lines, surface treatment workshops and industrial maintenance.

Related standards

EN 1953:2025 is intended to be used alongside electrostatic and machinery standards, for example:

- EN 50050‑1/‑2/‑3:2013, EN 50059:2025, EN 50176:2025, EN 50177:2009, EN 50223:2015, EN 50348:2010

- EN 60204‑1 (electrical equipment), EN ISO 4414 (pneumatics), EN ISO 12100 (risk assessment) For full compliance and application details obtain the complete text from your national standards body.

Frequently Asked Questions

SIST EN 1953:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Application equipment for coating materials - Safety". This standard covers: This document deals with all significant hazards, hazardous situations and hazardous events which are relevant to hand-held and automatic application equipment for coating material, when used as intended and under the conditions foreseen by the manufacturer, including reasonably foreseeable misuse. See Annex A for significant hazards. Together with this document, EN 50050 1:2013, EN 50050 2:2013, EN 50050 3:2013, EN 50059:2025, EN 50176:2025, EN 50177:20091, EN 50223:2015 or EN 50348:2010 give requirements for electrostatic application equipment. The specific significant risks related to the use of application equipment with foodstuffs and pharmaceutical products are not dealt with in this document. This document is not applicable to: - application equipment designed for pneumatic working pressure above 15 bar; - application equipment with rotating bell/disc designed for hydraulic working pressures above 25 bar; - non-atomizing application equipment (e.g. extruding equipment, dispenser); - fluidised bed powder coating machinery; - application equipment covered by EN 50580:20125; - supply hoses; - airbrushes for graphic and artistic works; - machinery for the supply and circulation of coating materials (see EN 12621:2025). This document is not applicable to application equipment manufactured before the date of its publication.

This document deals with all significant hazards, hazardous situations and hazardous events which are relevant to hand-held and automatic application equipment for coating material, when used as intended and under the conditions foreseen by the manufacturer, including reasonably foreseeable misuse. See Annex A for significant hazards. Together with this document, EN 50050 1:2013, EN 50050 2:2013, EN 50050 3:2013, EN 50059:2025, EN 50176:2025, EN 50177:20091, EN 50223:2015 or EN 50348:2010 give requirements for electrostatic application equipment. The specific significant risks related to the use of application equipment with foodstuffs and pharmaceutical products are not dealt with in this document. This document is not applicable to: - application equipment designed for pneumatic working pressure above 15 bar; - application equipment with rotating bell/disc designed for hydraulic working pressures above 25 bar; - non-atomizing application equipment (e.g. extruding equipment, dispenser); - fluidised bed powder coating machinery; - application equipment covered by EN 50580:20125; - supply hoses; - airbrushes for graphic and artistic works; - machinery for the supply and circulation of coating materials (see EN 12621:2025). This document is not applicable to application equipment manufactured before the date of its publication.

SIST EN 1953:2025 is classified under the following ICS (International Classification for Standards) categories: 87.100 - Paint coating equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1953:2025 has the following relationships with other standards: It is inter standard links to SIST EN 1953:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1953:2025 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2014/34/EU; Standardization Mandates: M/396, M/596, M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1953:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2025

Oprema za nanašanje prekrivnih materialov - Varnostne zahteve

Application equipment for coating materials - Safety

Applikationsgeräte für Beschichtungsstoffe - Sicherheitsanforderungen

Equipements d'application pour produits de revêtement - Exigences de sécurité

Ta slovenski standard je istoveten z: EN 1953:2025

ICS:

87.100 Oprema za nanašanje Paint coating equipment

premazov

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1953

EUROPEAN STANDARD

NORME EUROPÉENNE

February 2025

EUROPÄISCHE NORM

ICS 87.100 Supersedes EN 1953:2013

English Version

Application equipment for coating materials - Safety

requirements

Équipements d'application pour produits de Applikationsgeräte für Beschichtungsstoffe -

revêtement - Exigences de sécurité Sicherheitsanforderungen

This European Standard was approved by CEN on 22 December 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1953:2025 E

worldwide for CEN national Members.

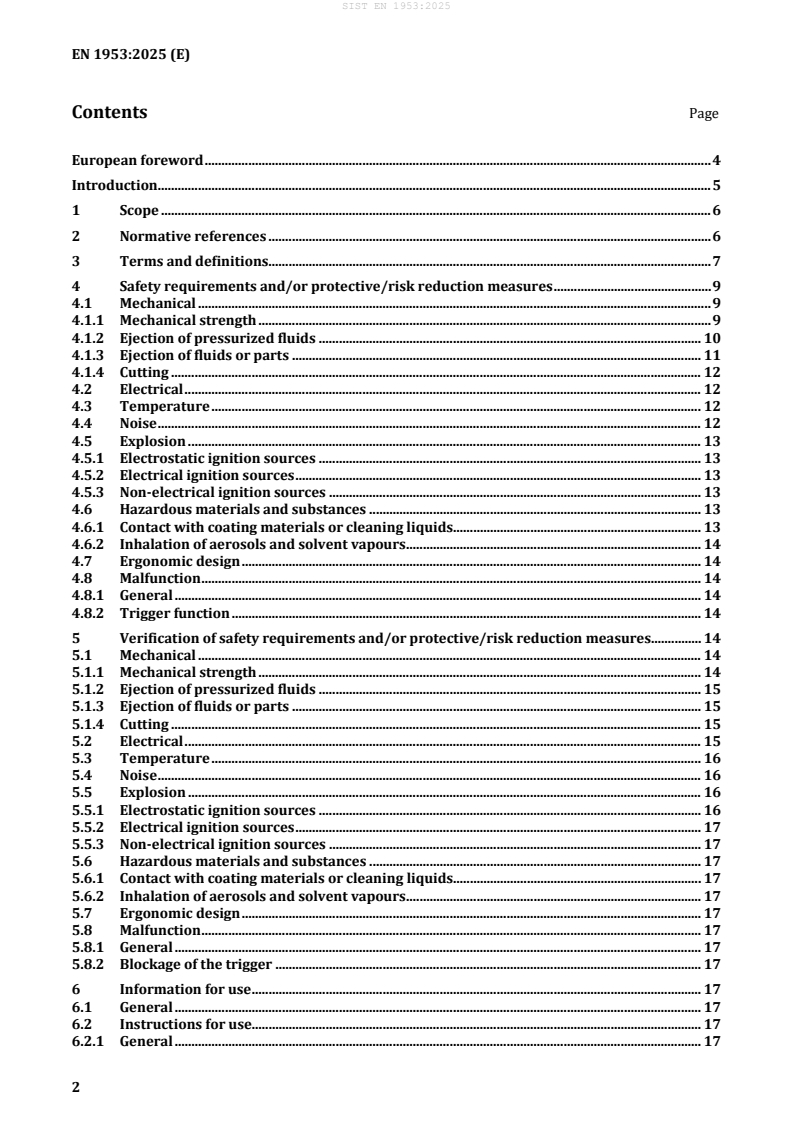

Contents Page

European foreword . 4

Introduction. 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions. 7

4 Safety requirements and/or protective/risk reduction measures . 9

4.1 Mechanical . 9

4.1.1 Mechanical strength . 9

4.1.2 Ejection of pressurized fluids . 10

4.1.3 Ejection of fluids or parts . 11

4.1.4 Cutting . 12

4.2 Electrical . 12

4.3 Temperature . 12

4.4 Noise . 12

4.5 Explosion . 13

4.5.1 Electrostatic ignition sources . 13

4.5.2 Electrical ignition sources . 13

4.5.3 Non-electrical ignition sources . 13

4.6 Hazardous materials and substances . 13

4.6.1 Contact with coating materials or cleaning liquids. 13

4.6.2 Inhalation of aerosols and solvent vapours . 14

4.7 Ergonomic design . 14

4.8 Malfunction . 14

4.8.1 General . 14

4.8.2 Trigger function . 14

5 Verification of safety requirements and/or protective/risk reduction measures. 14

5.1 Mechanical . 14

5.1.1 Mechanical strength . 14

5.1.2 Ejection of pressurized fluids . 15

5.1.3 Ejection of fluids or parts . 15

5.1.4 Cutting . 15

5.2 Electrical . 15

5.3 Temperature . 16

5.4 Noise . 16

5.5 Explosion . 16

5.5.1 Electrostatic ignition sources . 16

5.5.2 Electrical ignition sources . 17

5.5.3 Non-electrical ignition sources . 17

5.6 Hazardous materials and substances . 17

5.6.1 Contact with coating materials or cleaning liquids. 17

5.6.2 Inhalation of aerosols and solvent vapours . 17

5.7 Ergonomic design . 17

5.8 Malfunction . 17

5.8.1 General . 17

5.8.2 Blockage of the trigger . 17

6 Information for use . 17

6.1 General . 17

6.2 Instructions for use . 17

6.2.1 General . 17

6.2.2 Information on installation . 18

6.2.3 Information on operation . 19

6.2.4 Information on maintenance and inspection . 20

6.3 Marking . 20

6.3.1 General . 20

6.3.2 Supplementary marking for ATEX equipment . 20

6.3.3 Marking of very small equipment . 21

6.4 Sales literature . 21

Annex A (informative) List of significant hazards . 22

Annex B (informative) Significant technical changes between this European Standard and

the previous edition . 26

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 27

Annex ZB (informative) Relationship between this European Standard and the essential

Health and Safety requirements of Directive 2014/34/EU aimed to be covered . 29

Bibliography . 31

European foreword

This document (EN 1953:2025) has been prepared by Technical Committee CEN/TC 271 “Surface

treatment equipment - safety”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by August 2025, and conflicting national standards shall be

withdrawn at the latest by August 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1953:2013.

See Annex B, Table B.1 for the technical modifications which have been made in comparison with

EN 1953:2013.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annexes ZA and ZB, which are an integral part

of this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100:2010.

This document is of relevance in particular for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions);

— service providers, e. g. for maintenance (small, medium and large enterprises).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the Scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or type-B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

1 Scope

This document deals with all significant hazards, hazardous situations and hazardous events which are

relevant to hand-held and automatic application equipment for coating material, when used as intended

and under the conditions foreseen by the manufacturer, including reasonably foreseeable misuse.

See Annex A for significant hazards.

Together with this document, EN 50050-1:2013, EN 50050-2:2013, EN 50050-3:2013, EN 50059:2025,

EN 50176:2025, EN 50177:2009 , EN 50223:2015 or EN 50348:2010 give requirements for electrostatic

application equipment.

The specific significant risks related to the use of application equipment with foodstuffs and

pharmaceutical products are not dealt with in this document.

This document is not applicable to:

— application equipment designed for pneumatic working pressure above 15 bar;

— application equipment with rotating bell/disc designed for hydraulic working pressures above

25 bar;

— non-atomizing application equipment (e.g. extruding equipment, dispenser);

— fluidised bed powder coating machinery;

— application equipment covered by EN 50580:2012 ;

— supply hoses;

— airbrushes for graphic and artistic works;

— machinery for the supply and circulation of coating materials (see EN 12621:2025).

This document is not applicable to application equipment manufactured before the date of its publication.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 14462:2015, Surface treatment equipment - Noise test code for surface treatment equipment including

its ancillary handling equipment - Accuracy grades 2 and 3

EN 50050-1:2013, Electrostatic hand-held spraying equipment - Safety requirements - Part 1: Hand-held

spraying equipment for ignitable liquid coating materials

EN 50050-2:2013, Electrostatic hand-held spraying equipment - Safety requirements - Part 2: Hand-held

spraying equipment for ignitable coating powder

EN 50050-3:2013, Electrostatic hand-held spraying equipment - Safety requirements - Part 3: Hand-held

spraying equipment for ignitable flock

EN 50059:2025, Electrostatic hand-held spraying equipment — Safety requirements — Hand-held spraying

equipment for non-ignitable coating materials

EN 50176:2025, Stationary electrostatic application equipment for ignitable liquid coating material —

Safety requirements

EN 50177:2009 , Stationary electrostatic application equipment for ignitable coating powders — Safety

requirements

EN 50223:2015, Stationary electrostatic application equipment for ignitable flock material - Safety

requirements

EN 50348:2010, Stationary electrostatic application equipment for non-ignitable liquid coating material -

Safety requirements

EN 60204-1:2018, Safety of machinery - Electrical equipment of machines - Part 1: General requirements

(IEC 60204-1:2016, modified)

EN IEC 60079-0:2018, Explosive atmospheres — Part 0: Equipment — General requirements

(IEC 60079-0:2017)

EN ISO 4414:2010, Pneumatic fluid power - General rules and safety requirements for systems and their

components (ISO 4414:2010)

EN ISO 11688-1:2009, Acoustics - Recommended practice for the design of low-noise machinery and

equipment - Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100:2010, Safety of machinery - General principles for design - Risk assessment and risk reduction

(ISO 12100:2010)

EN ISO 13732-1:2008, Ergonomics of the thermal environment - Methods for the assessment of human

responses to contact with surfaces - Part 1: Hot surfaces (ISO 13732-1:2006)

EN ISO 13849-1:2023, Safety of machinery - Safety-related parts of control systems - Part 1: General

principles for design (ISO 13849-1:2023)

EN ISO 80079-36:2016, Explosive atmospheres — Part 36: Non-electrical equipment for explosive

atmospheres — Basic method and requirements (ISO 80079-36:2016)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/

3.1

application equipment

equipment for application of coating materials, which can consist of the following elements:

— air cap;

— material nozzle;

— trigger;

As impacted by EN 50177:2009/A1:2012.

As impacted by EN IEC 60079-0:2018/AC:2020-02 and EN IEC 60079-0:2018/A11:2024.

As impacted by EN ISO 80079-36:2016/AC:2019.

— filter;

— swivel joint;

— control systems;

— turbine;

— rotating bell/disc;

— pressurized cup;

— electrical elements (e.g. heating system)

Note 1 to entry: Electrostatic application equipment can consist of additional electric components, see

EN 50050-1:2013, EN 50050-2:2013, EN 50050-3:2013, EN 50059:2025, EN 50176:2025, EN 50177:2009 ,

EN 50348:2010.

Note 2 to entry: Application equipment is adressed as "applicator" in EN 50050-1:2013, EN 50050-2:2013,

EN 50050-3:2013 and EN 50059:2025, and as "spraying system" in EN 50176:2025, EN 50177:2009 and

EN 50348:2010.

3.2

cleaning liquid

all liquids which can be used for cleaning and/or flushing of application equipment

Note 1 to entry: A distinction is made between aqueous and organic cleaning liquids.

Note 2 to entry: Cleaning liquids can consist of or contain organic solvents.

3.3

coating material

product, in liquid, powder or fibre form, that, when applied to a substrate, forms a layer possessing

protective, decorative and/or other specific properties

Note 1 to entry: In general, coating materials consist of binders, pigments, dyestuff, fillers and other additives.

Moreover, liquid coating materials can contain organic solvents and /or water.

Note 2 to entry: Coating materials are, for instance, paints, lacquers, varnishes, impregnating varnishes, paste

fillers, filling materials, impregnating agents, anti-noise agents, fire resisting agents, stains, burnishes, adhesives,

sealing compounds, coating powders as well as flock.

3.4

elements of application equipment

3.4.1

air cap

element arranged around the material nozzle in pneumatic application equipment and hydraulic

application equipment combined with air

3.4.2

horns

protruding parts of the air cap with holes from which pressurized air is released to form the spray cone

3.4.3

material nozzle

nozzle

element through which liquid, powder or flock coating material is discharged

3.5

fluid

liquid and/or gas

3.6

hydraulic application equipment

equipment for the application of liquid coating material by pressure atomization

Note 1 to entry: The corresponding process is generally referred to as “airless spraying”.

3.7

hydraulic pressure

3.7.1

dynamic hydraulic pressure

pressure of the liquid coating material in the application equipment with open material nozzle

3.7.2

static hydraulic pressure

pressure of the liquid coating material in the application equipment with closed material nozzle

3.8

maximum hydraulic working pressure

maximum admissible static or dynamic hydraulic pressure for which the application equipment is

designed

3.9

pneumatic application equipment

equipment for the application of coating material using pressurized air

Note 1 to entry: The corresponding process is generally referred to as “air spraying”.

3.10

hydraulic application equipment with air support

equipment for the application of liquid coating material by pressure atomization combined with an air-

cap to support atomization and shape the spray pattern

Note 1 to entry: The corresponding process is generally referred to as “air assisted airless spraying”.

4 Safety requirements and/or protective/risk reduction measures

4.1 Mechanical

4.1.1 Mechanical strength

Application equipment, their fixing elements and the joints for supply hoses shall be designed and

constructed in such a way to withstand the arising forces.

Plastic materials that are used to contain pressure or to shield voltage shall have a temperature index

“TI” or relative temperature index “RTI – mechanical” of at least 20 K higher than the maximum operating

temperature.

Elastomers (e.g. sealings) and materials used for gluing shall have a continuous operating temperature

“COT” between the minimum operating temperature and the maximum operating temperature of the

application equipment plus 20 K.

External forces (e.g. by dropping application equipment, forces of the supply hoses) shall be taken into

account for design and construction of application equipment.

Additionally, the following forces shall be taken into account for design and construction of application

equipment for liquid coating material:

— static hydraulic pressure;

— dynamic hydraulic pressure (e.g. oscillating supply pressure);

— recoil forces during operation.

Application equipment for pressurized liquid coating material shall withstand the test pressures given in

Table 1. Application equipment with rotating bell/disc for liquid coating material shall withstand the test

pressures given in Table 2.

Table 1 — Hydraulic test pressures for application equipment

Maximum hydraulic working Working pressure test Burst pressure test

pressure P

P < 10 bar Not required

4 times of the maximum

hydraulic working pressure

10 bar ≤ P < 375 bar

375 bar ≤ P ≤ 750 bar 1 500 bar

1,2 times of the maximum

hydraulic working pressure

750 bar < P 2 times of the maximum

hydraulic

working pressure

Table 2 — Hydraulic test pressures for application equipment with rotating bell/disc

Maximum hydraulic Working pressure test Burst pressure test

working pressure P

P ≤ 25 bar 1,1 times of the maximum 2 times of the maximum

hydraulic working pressure hydraulic working pressure

4.1.2 Ejection of pressurized fluids

The requirements of this clause apply to hand-held application equipment for liquid coating material.

Upon release of the trigger, a further hazardous release of fluids shall be prevented. The trigger return

mechanism shall be designed to close the nozzle up to a pressure of 1,2 times of the maximum hydraulic

working pressure.

Application equipment with the hazard of penetration of coating material under the skin shall, depending

on the maximum hydraulic working pressure, be equipped with the protective measures given in Table 3.

Table 3 — Protective measures for hand-held application equipment

Protective measure Maximum hydraulic working pressure P

P ≤ 10 bar 10 bar < P ≤ 50 bar P > 50 bar

Blocking device for locking the trigger Not required Required Required

and/or the valve needle to prevent in case of hydraulic

unintentional operation. application

equipment and

hydraulic application

equipment combined

with air

Not required

in case of pneumatic

application

equipment

Guard to prevent unintentional actuation Not required Required Required

of the trigger. The guard shall be

— an integral part of a function-

preserving element. A part of the fluid

supply may serve as guard;

or

— only dismountable by means of a tool.

Guard to avoid dangerous proximity of Not required Required Required

body tissue to the outlet opening of the

material nozzle as far as possible; the

guard shall

Not required Required minimum Required minimum

— ensure an axial distance between body

a

distance is 8 mm distance is 25 mm

tissue and discharge point of the

nozzle;

Not required Required Required

— be a function-preserving element of

the application equipment;

Not required Required Required

— have the smallest possible radial

distance to the outlet opening of the

material nozzle at which its excessive

contamination by sprayed coating

material is avoided;

or

a two-hand control. Not required Required Required

a

This requirement can be satisfied by the design and construction of the horns.

4.1.3 Ejection of fluids or parts

Application equipment shall be designed and constructed in such a way that hazards of ejection of fluids

or parts are reduced to a minimum.

Pneumatic and hydraulic joints shall not be interchangeable.

Joints to pressurized coating material supply hoses of application equipment:

— shall only be detachable with tools; or

— shall be self-closing.

Filters which can be detached manually shall not be detachable under working pressure.

Pneumatic connectors shall comply with EN ISO 4414:2010.

Information on safe detaching of hoses and filters shall be given (see 6.2.4 b), c)).

4.1.4 Cutting

Application equipment with rotating bell/disc with exposed edge shall be equipped with an interface for

the exchange of safety related signals to allow the interlocking of the rotation drive power with means of

access of a spray booth at PLa according to EN ISO 13849-1:2023. Access shall only be possible, if the

rotation drive power is shut off and a braking system actively reduces the rotation speed below

1 000 rpm.

Information on requirements related to the interlocking shall be given (see 6.2.2).

4.2 Electrical

For hand-held electrostatic application equipment EN 50050-1:2013, EN 50050-2:2013,

EN 50050-3:2013 or EN 50059:2025 shall be applied.

For automatic electrostatic application equipment EN 50176:2025, EN 50177:2009 , EN 50223:2015 or

EN 50348:2010 shall be applied.

For electrical elements (e.g. digital displays, heating systems, initiators) EN 60204-1:2018 shall be

applied.

NOTE For use in explosive atmosphere, see further information in 4.5.

4.3 Temperature

Protection against burns from contact with hot surfaces shall be ensured by thermal insulation of

touchable elements of the application equipment, which can be reached during normal operation.

Hand-held application equipment shall be designed to prevent the surface temperature of handle and

trigger exceeding 43 °C as indicated in EN ISO 13732-1:2008. Technical means to fulfil this requirement

are for example:

— sufficient distance between material supply and handle;

— use of thermally insulating materials.

For areas which are touched for adjustment or maintenance, a contact time of 4 s shall be used to

determine the relevant maximum surface temperatures for the different materials according to

EN ISO 13732-1:2008.

If contact with surfaces heated to temperatures higher than those specified in EN ISO 13732-1:2008

cannot be prevented, the use of protective clothing shall be indicated. The requirements for protective

clothing shall be specified (see 6.2.3 d)).

4.4 Noise

The machinery shall be designed and constructed in such a way that risks resulting from the emission of

airborne noise are reduced to the lowest level, taking account of technical progress and the availability

of means of reducing noise, in particular at source.

NOTE 1 The main source of noise are turbulences due to different speed of air and coating material needed for

the atomization process. Noise reduction is not possible without negative influence on the atomization process.

When designing application equipment for coating materials, the information and technical measures to

control noise at the source given in EN ISO 11688-1:2009 shall be taken into account (see 6.2.1. c)).

NOTE 2 EN ISO 11688-2:2000 contains information related to generation of noise in machinery, plants and

systems.

Information on appropriate hearing protectors shall be given, if applicable (see 6.2.3 e)).

4.5 Explosion

4.5.1 Electrostatic ignition sources

Application equipment made of conductive or dissipative material shall be equipped with a connection

to enable dissipation of static electricity with a resistance ≤ 100 MΩ. Information on grounding the

application equipment shall be given in the information for installation.

NOTE 1 The connection can be made via the pneumatic or hydraulic hose connection.

NOTE 2 See CLC/TR 60079-32-1:2018.

NOTE 3 Plastic feed cups

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...