SIST EN 1993-2:2007

(Main)Eurocode 3 - Design of steel structures - Part 2: Steel Bridges

Eurocode 3 - Design of steel structures - Part 2: Steel Bridges

EN 1993-2 provides a general basis for the structural design of steel bridges and steel parts of composite bridges. It gives provisions that supplement, modify or supersede the equivalent provisions given in the various parts of EN 1993-1. (2) The design criteria for composite bridges are covered in EN 1994-2. (3) The design of high strength cables and related parts are included in EN 1993-1-11. (4) This European Standard is concerned only with the resistance, serviceability and durability of bridge structures. Other aspects of design are not considered. (5) For the execution of steel bridge structures, EN 1090 should be taken into account. NOTE: As long as EN 1090 is not yet available a provisional guidance is given in Annex C. (6) Execution is covered to the extent that is necessary to indicate the quality of the construction materials and products that should be used and the standard of workmanship needed to comply with the assumptions of the design rules. (7) Special requirements of seismic design are not covered. Reference should be made to the requirements given in EN 1998, which complements and modifies the rules of EN 1993-2 specifically for this purpose.

Eurocode 3 - Bemessung und konstruktion von Stahlbauten - Teil 2: Stahlbrücken

1.1.1 Anwendungsbereich des Eurocode 3

(1) Siehe EN 1993 1 1, 1.1.1(1), (2), (3), (4), (5) und (6).

1.1.2 Anwendungsbereich des Eurocode 3, Teil 2

(1) EN 1993 2 liefert die Grundlagen für den Entwurf von Stahlbrücken und Stahlbauteilen von Verbund¬brücken und enthält Regelungen, die die Regelungen in den verschiedenen Teilen von EN 1993 1 ergänzen, ändern oder ersetzen.

(2) Regelungen für Verbundbrücken sind in EN 1994 2 angegeben.

(3) Regelungen für Seile und Zugglieder befinden sich in EN 1993 1 11.

(4) Die Regelungen in EN 1993 2 beziehen sich nur auf die Tragsicherheit, die Gebrauchstauglichkeit und die Dauerfestigkeit von Brückentragwerken. Andere Entwurfsaspekte werden nicht behandelt.

(5) In der Regel ist für die Ausführung von Stahlbrücken EN 1090 zu beachten.

ANMERKUNG Da EN 1090 noch nicht zur Verfügung steht, werden vorläufig Hinweise in Anhang C gegeben.

(6) Die Ausführung wird in EN 1993 2 nur in dem Umfang behandelt, der zur Beschreibung der Qualität der einsetzbaren Baustoffe und Bauprodukte sowie der Ausführungsqualität notwendig ist, damit die den Bemessungsregeln zugrunde liegenden Annahmen erfüllt sind.

(7) EN 1993 2 behandelt keine besonderen Anforderungen für Brücken in Erdbebengebieten; vielmehr wird auf EN 1998 verwiesen, die die Regelungen in EN 1993 2 in dieser Hinsicht ergänzt.

Eurocode 3 - Calcul des structures en acier - Partie 2: Ponts métalliques

Les Etats Membres de l'UE et de l'AELE reconnaissent que les Eurocodes servent de documents de référence pour les usages suivants :

comme moyen de prouver la conformité des bâtiments et des ouvrages de génie civil aux exigences essentielles de la Directive du Conseil 89/106/CEE, en particulier à l'Exigence Essentielle N°1 Stabilité et résistance mécanique et à l'Exigence Essentielle N°2 Sécurité en cas d'incendie ;

comme base de spécification des contrats pour les travaux de construction et les services techniques associés ;

comme cadre d'établissement de spécifications techniques harmonisées pour les produits de construction (EN et ATE).

Les Eurocodes, dans la mesure où ils concernent les ouvrages eux-mêmes, ont une relation directe avec les Documents Interprétatifs ) visés à l'Article 12 de la DPC, bien qu'ils soient d'une nature différente de celle de la norme harmonisée de produit ). En conséquence, les aspects techniques résultant des travaux effectués pour les Eurocodes nécessitent d'être pris en considération de façon adéquate par les Comités techniques du CEN et/ou les groupes de travail de l'EOTA travaillant sur les normes de produits en vue de parvenir à une complète compatibilité de ces spécifications techniques avec les Eurocodes.

Les normes Eurocodes fournissent des règles de conception structurale communes d'usage quotidien pour le calcul de structures entières et des produits composants de nature traditionnelle ou innovatrice. Les formes de construction ou les conceptions inhabituelles ne sont pas spécifiquement couvertes, et il appartiendra en ce cas au concepteur de se procurer des bases spécialisées supplémentaires

Evrokod 3: Projektiranje jeklenih konstrukcij – 2. del: Mostovi

General Information

- Status

- Published

- Publication Date

- 28-Feb-2007

- Technical Committee

- KON - Structures

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Mar-2007

- Due Date

- 01-Mar-2007

- Completion Date

- 01-Mar-2007

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 01-Mar-2007

- Corrected By

SIST EN 1993-2:2007/AC:2009 - Eurocode 3 - Design of steel structures - Part 2: Steel Bridges - Effective Date

- 01-Oct-2009

- Effective Date

- 19-Jun-2019

Overview

EN 1993-2:2006 (Eurocode 3 - Part 2: Steel Bridges) is the European Standard published by CEN that provides the structural design rules for steel bridges and steel components of composite bridges. It supplements and, where necessary, modifies the generic steel design rules in EN 1993-1, focusing on the resistance, serviceability and durability of bridge structures. Execution guidance, testing, detailing and special component specifications are included to the extent needed to match the assumptions of the design rules.

Key topics

- Limit state design and verification using the partial factor method (resistance and serviceability focus).

- Structural analysis methods, global modelling and treatment of imperfections.

- Materials and durability: requirements for structural steels, connections, bearings and other bridge components.

- Member stability: buckling resistance of members, plates and built-up sections.

- Connections and fabrication: bolt, rivet and weld detailing and quality considerations.

- Fatigue assessment: load models, stress ranges, fatigue strength and post‑weld treatment.

- Serviceability criteria: deflection, vibration, clearance gauges and visual performance for road, rail and pedestrian bridges.

- Design assisted by testing: procedures for aerodynamic, fatigue and other tests.

- Informative annexes: technical specifications and recommendations (bearings, expansion joints, bridge deck detailing, buckling lengths, and wheel-load combinations).

Practical applications

- Design and verification of new steel bridge structures (highways, railways, pedestrian bridges).

- Structural assessment and retrofitting of existing steel or composite bridge components where Eurocode rules are applied.

- Preparation of contract specifications, fabrication and QA requirements for bridge projects.

- Basis for project approval by regulatory authorities and for harmonised product standards referencing Eurocodes.

- Guidance for laboratory and full-scale testing to confirm aerodynamic performance or fatigue resistance.

Who should use it

- Bridge designers and structural engineers applying Eurocode 3 to steel bridge projects.

- Contractors and fabricators for execution, welding and connection quality control.

- Clients, authorities and procurers specifying performance and compliance.

- Standards committees and product developers drafting complementary ENs or National Annexes.

Related standards (use together)

- EN 1993-1 (general rules for steel structures)

- EN 1994-2 (composite bridges)

- EN 1993-1-11 (high strength cables)

- EN 1090 (execution of steel structures) - referenced for fabrication and workmanship

- EN 1998 (seismic design) - for seismic requirements affecting bridges

Keywords: EN 1993-2:2006, Eurocode 3, steel bridges design, Eurocode, structural design, fatigue, buckling, bearings, EN 1090, EN 1994-2.

Frequently Asked Questions

SIST EN 1993-2:2007 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Eurocode 3 - Design of steel structures - Part 2: Steel Bridges". This standard covers: EN 1993-2 provides a general basis for the structural design of steel bridges and steel parts of composite bridges. It gives provisions that supplement, modify or supersede the equivalent provisions given in the various parts of EN 1993-1. (2) The design criteria for composite bridges are covered in EN 1994-2. (3) The design of high strength cables and related parts are included in EN 1993-1-11. (4) This European Standard is concerned only with the resistance, serviceability and durability of bridge structures. Other aspects of design are not considered. (5) For the execution of steel bridge structures, EN 1090 should be taken into account. NOTE: As long as EN 1090 is not yet available a provisional guidance is given in Annex C. (6) Execution is covered to the extent that is necessary to indicate the quality of the construction materials and products that should be used and the standard of workmanship needed to comply with the assumptions of the design rules. (7) Special requirements of seismic design are not covered. Reference should be made to the requirements given in EN 1998, which complements and modifies the rules of EN 1993-2 specifically for this purpose.

EN 1993-2 provides a general basis for the structural design of steel bridges and steel parts of composite bridges. It gives provisions that supplement, modify or supersede the equivalent provisions given in the various parts of EN 1993-1. (2) The design criteria for composite bridges are covered in EN 1994-2. (3) The design of high strength cables and related parts are included in EN 1993-1-11. (4) This European Standard is concerned only with the resistance, serviceability and durability of bridge structures. Other aspects of design are not considered. (5) For the execution of steel bridge structures, EN 1090 should be taken into account. NOTE: As long as EN 1090 is not yet available a provisional guidance is given in Annex C. (6) Execution is covered to the extent that is necessary to indicate the quality of the construction materials and products that should be used and the standard of workmanship needed to comply with the assumptions of the design rules. (7) Special requirements of seismic design are not covered. Reference should be made to the requirements given in EN 1998, which complements and modifies the rules of EN 1993-2 specifically for this purpose.

SIST EN 1993-2:2007 is classified under the following ICS (International Classification for Standards) categories: 91.010.30 - Technical aspects; 91.080.13 - Steel structures; 93.040 - Bridge construction. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1993-2:2007 has the following relationships with other standards: It is inter standard links to SIST ENV 1993-2:2001, SIST EN 1993-2:2007/AC:2009, kSIST FprEN 1993-2:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1993-2:2007 is associated with the following European legislation: EU Directives/Regulations: 2005-01-4408, 305/2011, 89/106/EEC; Standardization Mandates: M/265, M/BC/CEN/89/11. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1993-2:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Eurocode 3 - Design of steel structures - Part 2: Steel BridgesEvrokod 3: Projektiranje jeklenih konstrukcij – 2. del: MostoviEurocode 3 - Calcul des structures en acier - Partie 2: Ponts métalliquesEurocode 3 - Bemessung und konstruktion von Stahlbauten - Teil 2: StahlbrückenTa slovenski standard je istoveten z:EN 1993-2:2006SIST EN 1993-2:2007en93.040Gradnja mostovBridge construction91.080.10Kovinske konstrukcijeMetal structures91.010.30Technical aspectsICS:SIST ENV 1993-2:20011DGRPHãþDSLOVENSKI

STANDARDSIST EN 1993-2:200701-marec-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1993-2October 2006ICS 91.010.30; 91.080.10; 93.040Supersedes ENV 1993-2:1997

English VersionEurocode 3 - Design of steel structures - Part 2: Steel BridgesEurocode 3 - Calcul des structures en acier - Partie 2:Ponts métalliquesEurocode 3 - Bemessung und konstruktion von Stahlbauten- Teil 2: StahlbrückenThis European Standard was approved by CEN on 9 January 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1993-2:2006: E

EN 1993-2: 2006 (E)

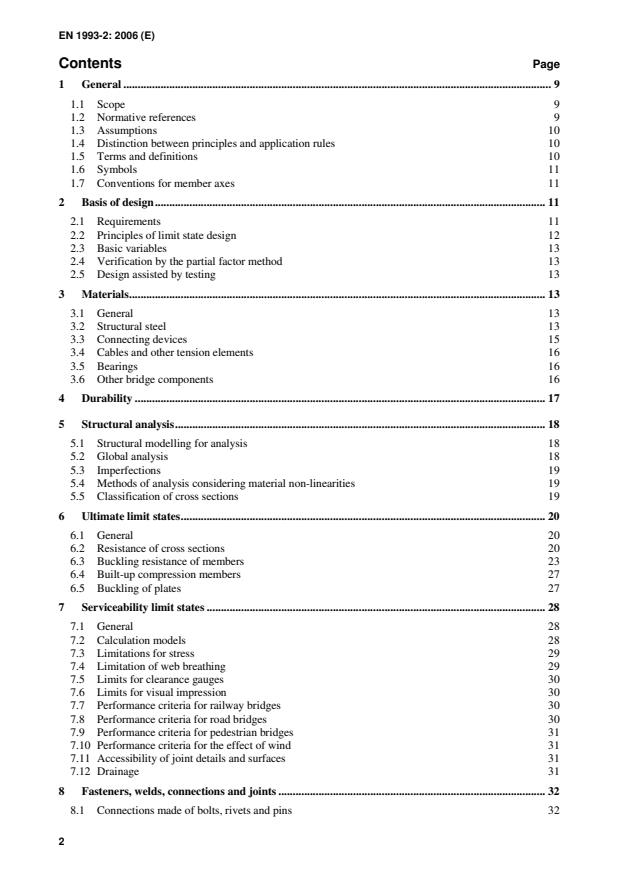

2 Contents Page 1 General.9 1.1 Scope 9 1.2 Normative references 9 1.3 Assumptions 10 1.4 Distinction between principles and application rules 10 1.5 Terms and definitions 10 1.6 Symbols 11 1.7 Conventions for member axes 11 2 Basis of design.11 2.1 Requirements 11 2.2 Principles of limit state design 12 2.3 Basic variables 13 2.4 Verification by the partial factor method 13 2.5 Design assisted by testing 13 3 Materials.13 3.1 General 13 3.2 Structural steel 13 3.3 Connecting devices 15 3.4 Cables and other tension elements 16 3.5 Bearings 16 3.6 Other bridge components 16 4 Durability.17 5 Structural analysis.18 5.1 Structural modelling for analysis 18 5.2 Global analysis 18 5.3 Imperfections 19 5.4 Methods of analysis considering material non-linearities 19 5.5 Classification of cross sections 19 6 Ultimate limit states.20 6.1 General 20 6.2 Resistance of cross sections 20 6.3 Buckling resistance of members 23 6.4 Built-up compression members 27 6.5 Buckling of plates 27 7 Serviceability limit states.28 7.1 General 28 7.2 Calculation models 28 7.3 Limitations for stress 29 7.4 Limitation of web breathing 29 7.5 Limits for clearance gauges 30 7.6 Limits for visual impression 30 7.7 Performance criteria for railway bridges 30 7.8 Performance criteria for road bridges 30 7.9 Performance criteria for pedestrian bridges 31 7.10 Performance criteria for the effect of wind 31 7.11 Accessibility of joint details and surfaces 31 7.12 Drainage 31 8 Fasteners, welds, connections and joints.32 8.1 Connections made of bolts, rivets and pins 32

EN 1993-2: 2006 (E)

3 8.2 Welded connections 34 9 Fatigue assessment.36 9.1 General 36 9.2 Fatigue loading 37 9.3 Partial factors for fatigue verifications 37 9.4 Fatigue stress range 38 9.5 Fatigue assessment procedures 40 9.6 Fatigue strength 47 9.7 Post weld treatment 48 10 Design assisted by testing.48 10.1 General 48 10.2 Types of tests 48 10.3 Verification of aerodynamic effects on bridges by testing 48 Annex A [informative] – Technical specifications for bearings.50 A.1 Scope 50 A.2 Symbols 51 A.3 General 51 A.4 Preparation of the bearing schedule 54 A.5 Supplementary rules for particular types of bearings 64 Annex B [informative] – Technical specifications for expansion joints for road bridges.66 B.1 Scope 66 B.2 Technical specifications 67 B.3 Imposed loads, displacements and rotations from bridge movements 69 Annex C [informative] – Recommendations for the structural detailing of steel bridge decks.70 C.1 Highway bridges 70 C.2 Railway bridges 80 C.3 Tolerances for semi-finished products and fabrication 83 Annex D [informative] – Buckling lengths of members in bridges and assumptions for geometrical imperfections.91 D.1 General 91 D.2 Trusses 91 D.3 Arched Bridges 96 Annex E [informative] – Combination of effects from local wheel and tyre loads and from global traffic loads on road bridges.101 E.1 Combination rule for global and local load effects 101 E.2 Combination factor 102

EN 1993-2: 2006 (E)

4 Foreword

This European Standard EN 1993-2, Eurocode 3: Design of steel structures Part 2: Steel bridges, has been prepared by Technical Committee CEN/TC250 « Structural Eurocodes », the Secretariat of which is held by BSI. CEN/TC250 is responsible for all Structural Eurocodes.

This European Standard shall be given the status of a National Standard, either by publication of an identical text or by endorsement, at the latest by April 2007 and conflicting National Standards shall be withdrawn at latest by March 2010.

This Eurocode supersedes ENV 1993-2.

According to the CEN-CENELEC Internal Regulations, the National Standard Organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Background of the Eurocode programme

In 1975, the Commission of the European Community decided on an action programme in the field of construction, based on article 95 of the Treaty. The objective of the programme was the elimination of technical obstacles to trade and the harmonisation of technical specifications.

Within this action programme, the Commission took the initiative to establish a set of harmonised technical rules for the design of construction works which, in a first stage, would serve as an alternative to the national rules in force in the Member States and, ultimately, would replace them.

For fifteen years, the Commission, with the help of a Steering Committee with Representatives of Member States, conducted the development of the Eurocodes programme, which led to the first generation of European codes in the 1980’s.

In 1989, the Commission and the Member States of the EU and EFTA decided, on the basis of an agreement1 between the Commission and CEN, to transfer the preparation and the publication of the Eurocodes to the CEN through a series of Mandates, in order to provide them with a future status of European Standard (EN). This links de facto the Eurocodes with the provisions of all the Council’s Directives and/or Commission’s Decisions dealing with European standards (e.g. the Council Directive 89/106/EEC on construction products – CPD – and Council Directives 93/37/EEC, 92/50/EEC and 89/440/EEC on public works and services and equivalent EFTA Directives initiated in pursuit of setting up the internal market).

The Structural Eurocode programme comprises the following standards generally consisting of a number of Parts: EN 1990 Eurocode 0: Basis of structural design EN 1991 Eurocode 1: Actions on structures EN 1992 Eurocode 2: Design of concrete structures EN 1993 Eurocode 3: Design of steel structures EN 1994 Eurocode 4: Design of composite steel and concrete structures EN 1995 Eurocode 5: Design of timber structures EN 1996 Eurocode 6: Design of masonry structures EN 1997 Eurocode 7: Geotechnical design

1 Agreement between the Commission of the European Communities and the European Committee for Standardisation (CEN) concerning the work on EUROCODES for the design of building and civil engineering works (BC/CEN/03/89).

EN 1993-2: 2006 (E)

5 EN 1998 Eurocode 8: Design of structures for earthquake resistance EN 1999 Eurocode 9: Design of aluminium structures Eurocode standards recognise the responsibility of regulatory authorities in each Member State and have safeguarded their right to determine values related to regulatory safety matters at national level where these continue to vary from State to State. Status and field of application of Eurocodes

The Member States of the EU and EFTA recognise that Eurocodes serve as reference documents for the following purposes : – as a means to prove compliance of building and civil engineering works with the essential requirements of Council Directive 89/106/EEC, particularly Essential Requirement N°1 - Mechanical resistance and stability - and Essential Requirement N°2 - Safety in case of fire; – as a basis for specifying contracts for construction works and related engineering services; – as a framework for drawing up harmonised technical specifications for construction products (ENs and ETAs)

The Eurocodes, as far as they concern the construction works themselves, have a direct relationship with the Interpretative Documents2 referred to in Article 12 of the CPD, although they are of a different nature from a harmonised product standard3. Therefore, technical aspects arising from the Eurocodes work need to be adequately considered by CEN Technical Committees and/or EOTA Working Groups working on product standards with a view to achieving a full compatibility of these technical specifications with the Eurocodes.

The Eurocode standards provide common structural design rules for everyday use for the design of whole structures and component products of both a traditional and an innovative nature. Unusual forms of construction or design conditions are not specifically covered and additional expert consideration will be required by the designer in such cases. National Standards implementing Eurocodes

The National Standards implementing Eurocodes will comprise the full text of the Eurocode (including any annexes), as published by CEN, which may be preceded by a National title page and National foreword, and may be followed by a National annex (informative). The National Annex (informative) may only contain information on those parameters which are left open in the Eurocode for national choice, known as Nationally Determined Parameters, to be used for the design of buildings and civil engineering works to be constructed in the country concerned, i.e. : – values for partial factors and/or classes where alternatives are given in the Eurocode, – values to be used where a symbol only is given in the Eurocode, – geographical and climatic data specific to the Member State, e.g. snow map, – the procedure to be used where alternative procedures are given in the Eurocode, – references to non-contradictory complementary information to assist the user to apply the Eurocode.

2 According to Art. 3.3 of the CPD, the essential requirements (ERs) shall be given concrete form in interpretative documents for the creation of the necessary links between the essential requirements and the mandates for hENs and ETAGs/ETAs.

3 According to Art. 12 of the CPD the interpretative documents shall : a) give concrete form to the essential requirements by harmonising the terminology and the technical bases and indicating classes or levels for each requirement where necessary ; b) indicate methods of correlating these classes or levels of requirement with the technical specifications, e.g. methods of calculation and of proof, technical rules for project design, etc. ; c) serve as a reference for the establishment of harmonised standards and guidelines for European technical approvals. The Eurocodes, de facto, play a similar role in the field of the ER 1 and a part of ER 2.

EN 1993-2: 2006 (E)

Links between Eurocodes and product harmonised technical specifications (ENs and ETAs)

There is a need for consistency between the harmonised technical specifications for construction products and the technical rules for works4. Furthermore, all the information accompanying the CE Marking of the construction products which refer to Eurocodes should clearly mention which Nationally Determined Parameters have been taken into account. Additional information specific to EN 1993-2

EN 1993-2 is the second part of six parts of EN 1993 – Design of Steel Structures – and describes the principles and application rules for the safety and serviceability and durability of steel structures for bridges.

EN 1993-2 gives design rules which are supplementary to the generic rules in EN 1993-1-1.

EN 1993-2 is intended to be used with Eurocodes EN 1990 – Basis of design, EN 1991 – Actions on structures and the parts 2 of EN 1992 to EN 1998 when steel structures or steel components for bridges are referred to. Matters that are already covered in those documents are not repeated.

EN 1993-2 is intended for use by – committees drafting design related product, testing and execution standards, – clients (e.g. for the formulation of their specific requirements), – designers and constructors, – relevant authorities.

Numerical values for partial factors and other reliability parameters are recommended as basic values that provide an acceptable level of reliability. They have been selected assuming that an appropriate level of workmanship and quality management applies. National annex for EN 1993-2

This standard gives alternative procedures, values and recommendations with notes indicating where national choices may have to be made. The National Standard implementing EN 1993-2 should have a National Annex containing all Nationally Determined Parameters to be used for the design of steel structures to be constructed in the relevant country. National choice is allowed in EN 1993-2 through: – 2.1.3.2(1) – 2.1.3.3(5) – 2.1.3.4(1) – 2.1.3.4(2) – 2.3.1(1) – 3.2.3(2) – 3.2.3(3) – 3.2.4(1) – 3.4(1) – 3.5(1) – 3.6(1)

See Art.3.3 and Art.12 of the CPD, as well as clauses 4.2, 4.3.1, 4.3.2 and 5.2 of ID 1.

EN 1993-2: 2006 (E)

7 – 3.6(2) – 4(1) – 4(4) – 5.2.1(4) – 5.4.1(1) – 6.1(1)P – 6.2.2.3(1) – 6.2.2.4(1) – 6.3.2.3(1) – 6.3.4.2(1) – 6.3.4.2(7) – 7.1(3) – 7.3(1) – 7.4(1) – 8.1.3.2.1(1) – 8.1.6.3(1) – 8.2.1.4(1) – 8.2.1.5(1) – 8.2.1.6(1) – 8.2.10(1) – 8.2.13(1) – 8.2.14(1) – 9.1.2(1) – 9.1.3(1) – 9.3(1)P – 9.3(2)P – 9.4.1(6) – 9.5.2(2) – 9.5.2(3) – 9.5.2(5) – 9.5.2(6) – 9.5.2(7) – 9.5.3(2) (two places) – 9.6(1) (two places) – 9.7(1) – A.3.3(1)P – A.3.6(2) – A.4.2.1(2) – A.4.2.1(3) – A.4.2.1(4) – A.4.2.4(2) – C.1.1(2)

EN 1993-2: 2006 (E)

– C.1.2.2(1) – C.1.2.2(2) – E.2(1)

EN 1993-2: 2006 (E)

9 1 General 1.1 Scope 1.1.1 Scope of Eurocode 3 (1) See 1.1.1(1), (2), (3), (4), (5) and (6) of EN 1993-1-1. 1.1.2 Scope of Part 2 of Eurocode 3 (1) EN 1993-2 provides a general basis for the structural design of steel bridges and steel parts of composite bridges. It gives provisions that supplement, modify or supersede the equivalent provisions given in the various parts of EN 1993-1. (2) The design criteria for composite bridges are covered in EN 1994-2.

(3) The design of high strength cables and related parts are included in EN 1993-1-11.

(4) This European Standard is concerned only with the resistance, serviceability and durability of bridge structures. Other aspects of design are not considered.

(5) For the execution of steel bridge structures, EN 1090 should be taken into account.

NOTE:

As long as EN 1090 is not yet available a provisional guidance is given in Annex C.

(6) Execution is covered to the extent that is necessary to indicate the quality of the construction materials and products that should be used and the standard of workmanship needed to comply with the assumptions of the design rules. (7) Special requirements of seismic design are not covered. Reference should be made to the requirements given in EN 1998, which complements and modifies the rules of EN 1993-2 specifically for this purpose. 1.2 Normative references

(1) This European Standard incorporates, by dated or undated reference, provisions from other publications. These normative references are cited at the appropriate places in the text and the publications are listed hereafter. For dated references, subsequent amendments to or revisions of any of these publications apply to this European Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the publication applies (including amendments).

(2) In addition to the normative references given in EN 1990 and EN 1993-1 the following references should apply: EN 1090 Execution of steel structures and aluminium structures EN 1337 Structural bearings EN 10029:1991 Specification for tolerances on dimensions, shape and mass for hot rolled steel plates 3 mm thick or above. EN 10164 Steel products with improved deformation properties perpendicular to the surface of the product - Technical delivery conditions. EN ISO 5817 Arc-welded joints in steel - Guidance on quality levels for imperfections. EN ISO 12944-3 Paints and varnishes - Corrosion protection of steel structures by protective paint systems - Design considerations. EN ISO 9013:2002 Thermal cutting - Classification of thermal cuts - Geometrical product specification and quality tolerances.

EN 1993-2: 2006 (E)

10 EN ISO 15613 Specification and qualification of welding procedures for metallic materials - Qualification based on pre-production welding test EN ISO 15614-1 Specification and qualification of welding procedures for metallic materials - Welding procedure test - Part 1: Arc and gas welding of steels and arc welding of nickel and nickel alloys 1.3 Assumptions

(1) See 1.3(1) of EN 1993-1-1. 1.4 Distinction between principles and application rules

(1) See 1.4(1) of EN 1993-1-1. 1.5 Terms and definitions

(1) The terms and definitions given in EN 1990, EN 1993-1 and the following apply: 1.5.1

bridges civil engineering construction works mainly intended to carry traffic or pedestrian loads over a natural obstacle or a communication line

NOTE:

Railway bridges and bridges which carry canals, service pipes or other vehicles such as an aircraft are also covered. 1.5.2

abutment any end support of a bridge

NOTE:

A distinction is made between rigid abutments and flexible abutments where relevant. 1.5.3

integral abutment abutment that is connected to the deck without any movement joint 1.5.4

pier intermediate support of a bridge, situated under the deck 1.5.5

bearing structural support located between the superstructure and an abutment or pier of the bridge that transfers loads from the deck to the abutment or pier 1.5.6

cable stay tensioned element which connects the deck of a bridge to the pylon or pylons above the deck 1.5.7

prestress permanent effect due to controlled forces and /or controlled deformations imposed within a structure

NOTE:

Various types of prestress are distinguished from each other as relevant (such as prestress by tendons or prestress by imposed deformation of supports). 1.5.8

headroom clear height available for traffic

EN 1993-2: 2006 (E)

11 1.5.9

breathing (of plates) out-of-plane deformation of a plate caused by repeated application of in-plane loading 1.5.10

secondary structural elements structural elements that do not form part of the main structure of the bridge

NOTE:

The secondary structural elements are provided for other reasons, such as guard rails, parapets, ladders and access covers. 1.6 Symbols

(1) The symbols in EN 1990 und EN 1993-1 apply. Further symbols are given as follows: Ed,ser, Ed,ser nominal stresses from the characteristic load combination l, l1, l2, l3, l4, lmax, lloc, lglo

damage equivalent factors 2, loc, glo damage equivalent impact factors p, loc, glo stress ranges from load p k characteristic value of friction coefficient

partial factor for friction

factor depending on type of bearing and number of bearings with adverse or relieving forces T0max, T0min, T0 temperatures T0, TK, T temperature differences T partial factor for temperature K, Kfoundation, Kpier, Kbearing spring stiffness Sd, ST slide path

(2) Additional symbols are defined in the text where they first occur. 1.7 Conventions for member axes

(1) See 1.7(1), (2), (3) and (4) of EN 1993-1-1. 2 Basis of design 2.1 Requirements 2.1.1 Basic requirements (1) See 2.1.1(1), (2) and (3) of EN 1993-1-1. 2.1.2 Reliability management (1) See 2.1.2(1) of EN 1993-1-1. 2.1.3 Design working life, durability and robustness 2.1.3.1 General

(1) See 2.1.3.1(1) of EN 1993-1-1. (2)P Bridges shall be designed for fatigue for the duration of their design working life.

EN 1993-2: 2006 (E)

12 2.1.3.2 Design working life

(1) The design working life should be taken as the period for which a bridge is required to be used for its intended purpose, taking into account anticipated maintenance but not major repair.

NOTE 1:

The National Annex may specify the design working life.

A design working life of a permanent bridge of 100 years is recommended.

NOTE 2:

For temporary bridges the design working life may be stated in the project specifications.

(2) For structural elements that cannot be designed for the total design life of the bridge, see 2.1.3.3. 2.1.3.3 Durability

(1) To ensure durability, bridges and their components may be designed to minimise damage or be protected from excessive deformation, deterioration, fatigue and accidental actions that are expected during the design working life. (2) Structural parts of a bridge to which guardrails or parapets are connected, should be designed to ensure that plastic deformations of the guardrails or parapets can occur without damaging the structure.

(3) Where a bridge includes components that need to be replaceable, see 4(6), the possibility of their safe replacement should be verified as a transient design situation.

(4) Permanent connections of structural parts of the bridge should be made with preloaded bolts in a Category B or C connection. Alternatively closely fitted bolts, rivets or welding may be used to prevent slipping. (5) Joints where the transmission of forces is purely by contact may be used where justified by fatigue assessments. NOTE:

The National Annex may give additional recommendations for durable details. 2.1.3.4 Robustness and structural integrity

(1) The design of the bridge should ensure that when the damage of a component due to accidental actions occurs, the remaining structure can sustain at least the accidental load combination with reasonable means.

NOTE:

The National Annex may define components that are subject to accidental design situations and also details for assessments. Examples of such components are hangers, cables, bearings.

(2) The effects of corrosion or fatigue of components and material should be taken into account by appropriate detailing, see also EN 1993-1-9 and EN 1993-1-10.

NOTE 1:

EN 1993-1-9, section 3 provides assessment methods using the principles of damage tolerance or safe life.

NOTE 2:

The National Annex may give a choice of the design method to be used for fatigue assessment.

NOTE 3:

For guidance on access, maintenance and inspection, see section 4.

2.2 Principles of limit state design

(1) See 2.2(1) and (2) of EN 1993-1-1. (3) For damage limitation at the ultimate limit state global analysis models should be elastic for transient and persistent design situations, see 5.4.

EN 1993-2: 2006 (E)

13 (4) The required fatigue life should be achieved through design for fatigue and/or appropriate detailing, see Annex C, and by serviceability checks. 2.3 Basic variables 2.3.1 Actions and environmental influences (1) Actions for the design of bridges should be taken from EN 1991. For the combination of actions and partial factors for actions see Annex A.2 of EN 1990.

NOTE 1:

For actions on steel bridge decks of road bridges, see Annex E.

NOTE 2:

For actions not specified in EN 1991, see the National Annex.

(2) See 2.3(2), (3), (4) and (5) of EN 1993-1-1. NOTE:

For actions on bearings, see Annex A. 2.3.2 Material and product properties (1) See 2.3.2(1) of EN 1993-1-1. 2.4 Verification by the partial factor method

(1) See 2.4.1(1), 2.4.2(1) and (2), 2.4.3(1) and 2.4.4(1) of EN 1993-1-1. 2.5 Design assisted by testing

(1) See 2.5(1), (2) and (3) of EN 1993-1-1. 3 Materials 3.1 General

(1) See 3.1(1) and (2) of EN 1993-1-1. 3.2 Structural steel 3.2.1 Material properties (1) See 3.2.1(1) of EN 1993-1-1. 3.2.2 Ductility requirements (1) See 3.2.2(1) and (2) of EN 1993-1-1.

EN 1993-2: 2006 (E)

14 3.2.3 Fracture toughness (1) The material should have the required material toughness to prevent brittle fracture within the intended design working life of the structure. (2) No further checks against brittle fracture need to be made if the conditions given in EN 1993-1-10 are met for the lowest service temperature. NOTE 1:

The lowest service temperature to be adopted in design may be taken from EN 1991-1-5.

NOTE 2:

The National Annex may specify additional requirements depending on the plate thickness. An example is given in Table 3.1.

Table 3.1:

Example for additional requirement for toughness of base material Example

Nominal thickness Additional requirement t £ 30 mm T27J = -20 °C in accordance with EN 10025 30 < t £ 80 mm

Fine grain steel in accordance with EN 10025, e.g. S355N/M 1 t > 80 mm Fine grain steel in accordance with EN 10025, e.g. S355NL/ML

(3) For bridge components under compression a suitable minimum toughness property should be selected.

NOTE:

The National Annex may give guidance on the selection of toughness properties for members in compression. The use of Table 2.1 of EN 1993-1-10 for sEd = 0,25 fy(t) is recommended. 3.2.4 Through thickness properties (1) Steel with improved through thickness properties forming to EN 10164 should be used where required, see EN 1993-1-10. NOTE:

Where ZEd values have been determined in accordance with EN 1993-1-10, the required quality class according to EN 10164 may be chosen in the National Annex. The choice in Table 3.2 is recommended.

Table 3.2:

Quality class conforming to EN 10164 Target value ZEd Quality class ZEd £ 10 – 10 < ZEd £ 20 Z15 20 < ZEd £ 30 Z25 ZEd > 30 Z35

3.2.5 Tolerances (1) The dimensional and mass tolerances of rolled steel sections, structural hollow sections and plates should conform with the relevant product standard, ETAG or ETA unless more severe tolerances are specified. (2) For welded components the tolerances in EN 1090 should be applied.

(3) See 3.2.5(3) of EN 1993-1-1. 3.2.6 Design values of material coefficients (1) See 3.2.6(1) of EN 1993-1-1.

EN 1993-2: 2006 (E)

15 3.3 Connecting devices 3.3.1 Fasteners 3.3.1.1 Bolts, nuts and washers

(1) Bolts, nuts and washers should conform to the Reference Standards given in EN 1993-1-8, 2.8: Group 4. (2) The rules in this part are applicable to bolts of grades given in Table 3.3.

(3) The nominal values of the yield strength fyb and the ultimate tensile strength fub are given in Table 3.3 and they should be adopted as characteristic values in calculations.

Table 3.3:

Nominal values of the yield strength fyb and the ultimate tensile strength fub for bolts Bolt grade 4.6 5.6 6.8 8.8 10.9 fyb (N/mm2) 240 300 480 640 900 fub (N/mm2) 400 500 600 800 1000

3.3.1.2 Preloaded bolts

(1) High strength structural bolts of bolt grades 8.8 and 10.9 which conform to the Reference standards given in EN 1993-1-8, 2.8: Group 4 may be used as preloaded bolts when controlled tightening is carried out in accordance with the Reference Standards given in EN 1993-1-8, 2.8: Group 7. 3.3.1.3 Rivets

(1) The material properties, dimensions and tolerances of steel rivets should conform to the Reference Standards given in EN 1993-1-8, 2.8: Group 6. 3.3.1.4 Anchor bolts

(1) The following steel grades may be used for anchor bolts: – Steel grades in accordance with the appropriate Reference Standards given in EN 1993-1-8, 2.8: Group 1; – Steel grades in accordance with the appropriate Reference Standards given in EN 1993-1-8, 2.8: Group 4; – Reinforcing bars conforming to EN 10080. The nominal yield strength for anchor bolts should not exceed 640 N/mm2. 3.3.2 Welding consumables (1) All welding consumables should conform to the Reference Standards given in EN 1993-1-8, 2.8: Group 5. (2) The performance of the weld metal should not be less than the corresponding values specified for steel grade being welded. This should take into account: – specified yield strength; – ultimate tensile strength; – elongation at failure; – minimum Charpy V-notch energy value of the filler metal.

EN 1993-2: 2006 (E)

16 3.4 Cables and other tension elements

(1) For cables and other tension elements see EN 1993-1-11.

NOTE:

The National Annex may specify the types of cables appropriate to the specific bridge types.

3.5 Bearings

(1) Bearings should conform to EN 1337. NOTE:

The National Annex may give guidance on the types of bearings applicable to bridges. 3.6 Other bridge components

(1) Expansion joints, guardrails, parapets and other ancillary items should conform to the relevant technical specifications. NOTE:

The National Annex may give guidance on the types of expansion joint, guardrail, parapet and other ancillary items applicable to bridges.

(2) The bridge deck surfacing system, the products used and the method of application should meet with the relevant technical specification. NOTE:

The National Annex may give guidance on the bridge deck surfacing system, the products used and the method of application applicable to bridges.

EN 1993-2: 2006 (E)

17 4 Durability

(1) See 4(1), (2) and (3) of EN 1993-1-1. NOTE:

The National Annex may give guidance on requirements for access to allow for inspection and maintenance.

(4) For elements that cannot be inspected fatigue checks should be carried out (see EN 1993-1-9) and appropriate corrosion allowances should be provided.

NOTE:

The National Annex may give guidance on sealing against corrosion, measures to ensure air tightness of box girders or the provisions of extra steel thickness for inaccessible surfaces.

(5) The required fatigue life of the structure and its components should be attained by the: – fatigue design of details in accordance with (1), (4) and EN 1993-1-9 and with serviceability checks carried out in accordance with section 7; – structural detailing for orthotropic steel decks; – material chosen in accordance with section 3; – fabrication conforming to EN 1090.

(6) Components that cannot be designed with sufficient reliability to achieve the total design working life of the bridge should be replaceable. These may include: – stays, cables, hangers; – bearings; – expansion joints; – drainage devices; – guardrails, parapets; – asphalt layer and other surface protection; – wind shields; – noise barriers.

EN 1993-2: 2006 (E)

18 5 Structural analysis 5.1 Structural modelling for analysis 5.1.1 Structural modelling and basic assumptions (1) See 5.1.1(1), (2) and (3) of EN 1993-1-1. (4) For the structural modelling and basic assumptions for components of bridges see EN 1993-1-1.

NOTE:

For the design of plated components and cables see also EN 1993-1-5 and EN 1993-1-11. 5.1.2 Joint modelling (1) See 5.1.2(1), (2), (3) and (4) of EN 1993-1-1 and EN 1993-1-8.

(5) For bridges, the type of joint and its modelling should be chosen to ensure that the required fatigue life can be attained. NOTE:

Rigid joints appropriate to the fatigue categories given in EN 1993-1-9 are suitable to be employed between members of bridges except for bearings or pinned connections or cables. 5.1.3 Ground structure interaction (1) See 5.1.3(1) of EN 1993-1-1. NOTE 2:

The stiffness of the supports may be based on the deformation characteristics of the bearings, piers and foundation. 5.2 Global analysis 5.2.1 Effects of deformed geometry of the structure

(1) See 5.2.1(1), (2) and (3) of EN 1993-1-1. (4) The bridges and components may be checked with first order theory if the following criterion is satisfied for each section: 10³cra

(5.1) where acr is defined in 5.2.1(3) of EN 1993-1-1

NOTE:

The National Annex may give further guidance for the definition and calculation of acrit.

(5) See 5.2.1(5) and (6) of EN 1993-1-1. 5.2.2 Structural stability of frames (1) See 5.2.2(1), (2), (3) and (4) of EN 1993-1-1. (5) Where the behaviour of a bridge or its components is governed by the first buckling mode (single degree of freedom) the second order effects MII may be calculated by applying a factor to the bending moments MI as follows:

crIIIMMa111-= (5.2) where acr > 3.

EN 1993-2: 2006 (E)

(6) See 5.2.2(7) and (8) of EN 1993-1-1. 5.3 Imperfections 5.3.1 Basis (1) See 5.3.1(1), (2) and (3) of EN 1993-1-1. 5.3.2 Imperfections for global analysis of frames (1) See 5.3.2(1), (2) and (3) of EN 1993-1-1. NOTE 1:

For piers am would be applicable, if cumulative effects from contributions of various piers occur (e.g. for piers forming a frame with the superstructure).

NOTE 2:

For the use of member imperfections see also Annex D.

(4) See 5.3.2(6), (7), (8), (10) and (11) of EN 1993-1-1. 5.3.3 Imperfection for analysis of bracing systems (1) See 5.3.3(1), (2), (3), (4) and (5) of EN 1993-1-1. 5.3.4 Member imperfections (1) See 5.3.4(1), (2) and (3) of EN 1993-1-1. 5.4 Methods of analysis considering material non-linearities 5.4.1 General (1) Elastic analysis should be used to determine the internal forces and moments for all persistent and transient design situations. NOTE:

The National Annex may give guidance to enable the user to determine when a plastic global analysis may be used for accidental design situations. For plastic global analysis see 5.4 and 5.5 of EN 1993-1-1. 5.4.2 Elastic global analysis (1) See 5.4.2(1), (2) and (3) of EN 1993-1-1. (4) If all sections are class 1 the effects of differential temperature, shrinkage and settlement at the ultimate limit state may be ignored. 5.5 Classification of cross sections 5.5.1 Basis (1) See 5.5.1(1) of EN 1993-1-1. 5.5.2 Classification (1) See 5.5.2(1), (2), (3), (4), (5), (6), (7), (8), (9) and (10) of EN 1993-1-1.

EN 1993-2: 2006 (E)

20 6 Ultimate limit states 6.1 General

(1)P The partial factors gM as defined in 2.4.3 of EN 1993-1-1 shall be applied to the various characteristic values of resistance in this section, see Table 6.1:

Table 6.1:

Partial factors a) resistance of members and cross section: – resistance of cross sections to excessive yielding including local buckling gM0 – resistance of members to instability assessed by member checks gM1 – resistance of cross sections in tension to fracture gM2 b) resistance of joints – resistance of bolts – resistance of rivets – resistance of pins – resistance of welds – resistance of plates in bearing

gM2 – slip resistance – at ultimate limit state (Category C)

– at serviceability limit state

gM3 gM3,ser – bearing resistance of an injection bolt gM4 – resistance of joints in hollow section lattice girders gM5 – resistance of pins at serviceability limit state gM6,ser – preload of high strength bolts gM7

NOTE 1:

For the partial factor gc for the resistance of concrete see EN 1992.

NOTE 2:

The partial factors gMi for bridges may be defined in the National Annex. The following numerical values are recommended: gM0 = 1,00 gM1 = 1,10 gM2 = 1,25 gM3 = 1,25 gM3,ser = 1,10 gM4 = 1,10 gM5 = 1,10 gM6,ser = 1,00 gM7 = 1,10 6.2 Resistance of cross sections 6.2.1 General (1) See 6.2.1(1), (2), (3), (4), (5), (6), (7), (8), (9) and (10) of EN 1993-1-1.

EN 1993-2: 2006 (E)

21 6.2.2 Section properties 6.2.2.1 Gross cross section

(1) See 6.2.1.1(1) of EN 1993-1-1. 6.2.2.2 Net area

(1) See 6.2.2.2(1), (2), (3), (4) and (5) of EN 1993-1-1. 6.2.2.3 Shear lag effects

(1)

See 6.2.2.3(1) and (2) of EN 1993-1-1 and 3.2 and 3.3 of EN 1993-1-5.

NOTE:

The National Annex may give guidance on the treatment of shear lag effects at the ultimate limit state. 6.2.2.4 Effective properties of cross section with class 3 webs and Class 1 or 2 flanges

(1) See 6.2.2.4(1) of EN 1993-1-1 6.2.2.5 Effects of local buckling for class 4 cross sections

(1) The effects of local buckling should be considered using one of the following two methods specified in EN 1993-1-5: 1. effective cross section properties of class 4 sections in accordance with EN 1993-1-5, section 4 2. limiting the stress levels to achieve cross section properties in accordance with EN 1993-1-5, section 10

NOTE:

The National Annex may recommend which method is to be used. In case of the use of the method 2 the National Annex may give further guidance. 6.2.2.6 Effective cross section properties of class 4 sections

(1)

See 6.2.2.5(1), (2), (3), (4) and (5) of EN 1993-1-1.

(2) For stress limits of circular hollow sections to conform to class 3 section properties, see EN 1993-1-6. 6.2.3 Tension (1)

See 6.2.3(1), (2), (3), (4) and (5) of EN 1993-1-1. 6.2.4 Compression (1)

See 6.2.4(1) of EN 1993-1-1. (2) The design resistance of cross sections for uniform compression Nc,Rd should be determined as follows: a) without local buckling: 0,MyRdcfANg=

for class 1, 2 and 3 cross sections (6.1) b) with local buckling: 0,MyeffRdcfANg=

for class 4 cross sections or (6.2)

0lim,MitRdcANgs=

for stress limits (6.3)

EN 1993-2: 2006 (E)

22 where slimit = rx fy

is the limiting stress of the weakest part of the cross section in compression (see 10(5) of EN 1993-1-5)

(3)

See 6.2.4(3) and (4) of EN 1993-1-1. 6.2.5 Bending moment (1)

See 6.2.5(1) of EN 1993-1-1. (2) The design resistance for bending about the major axis should be determined as follows: a) without local buckling: 0,MyplRdcfWMg=

for class 1 and 2 cross sections (6.4)

0min,,MyelRdcfWMg=

for class 3 cross sections (6.5) b) with local buckling: 0min,,MyeffRdcfWMg=

for class 4 cross sections or (6.6)

0limmin,,MitelRdcWMgs=

for stress limits (6.7) where Wel,min and Weff,min

are the elastic moduli which correspond to the fibre with the maximum elastic stress

slimit is the limiting stress of the weakest part of the cross section in compression (see 2.4 of EN 1993-1-5)

(3)

See 6.2.5(3), (4), (5) and (6) of EN 1993-1-1. 6.2.6 Shear (1)

See 6.2.6(1), (2), (3), (4), (5), (6), (7) and (8) of EN 1993-1-1 and section 5 of EN 1993-1-5. 6.2.7 Torsion 6.2.7.1 General

(1) Torsional and distortional effects should be taken into account for members subject to torsion.

(2) The effects of transverse stiffness in the cross section, or of diaphragms that are built in to reduce distortional deformations, may be taken into account by considering an appropriate elastic model which is subject to the combined effect of bending, torsion and distortion.

(3) Distortional effects in the members may be disregarded where the effects from distortion, due to the transverse bending stiffness in the cross section and/or diaphragm action, do not exceed 10 % of the bending effects. (4) Diaphragms should be designed to take into account the action effects resulting from their load distributing effect. 6.2.7.2 Torsion for which distortional effects may be neglected

(1) See 6.2.7(1), (2), (3), (4), (5), (6), (7), (8), and (9) of EN 1993-1-1.

EN 1993-2: 2006 (E)

23 6.2.8 Bending, axial load, shear and transverse loads

(1) The interaction between bending, axial load, shear and transverse loads may be determined using one of the following two methods: 1. Interaction methods given in 6.2.8 to 6.2.10. NOTE:

For local buckling effects see

EN 1993-1-5, section 4 to 7.

2. Interaction of stresses using the yielding criterion given in 6.2.1

NOTE:

For local buckling effects EN 1993-1-5, see section 10. 6.2.9 Bending and shear (1) See 6.2.8(1), (2), (3), (4), (5) and (6) of EN 1993-1-1. 6.2.10 Bending and axial force 6.2.10.1 Class 1 and class 2 cross sections

(1) See 6.2.9.1(1), (2), (3), (4), (5) and (6) of EN 1993-1-1. 6.2.10.2 Class 3 cross sections

(1) See 6.2.9.2(1) of EN 1993-1-1. (2) The following should be met for local buckling consideration, when the limit stress method is used:

00lim,MyMitEdxfggss££

(6.8) where slimit should be determined from section 10 of EN 1993-1-5. 6.2.10.3 Class 4 cross sections

(1) See 6.2.9.3(1) and (2) of EN 1993-1-1. 6.2.11 Bending, shear and axial force (1) See 6.2.10(1), (2) and (3) of EN 1993-1-1. 6.3 Buckling resistance of members 6.3.1 Uniform members in compression 6.3.1.1 Buckling resistance

(1) See 6.3.1.1(1), (2), (3) and (4) of EN 1993-1-1. 6.3.1.2 Buckling curves

(1) See 6.3.1.2(1), (2), (3) and (4) of EN 1993-1-1. 6.3.1.3 Slenderness for flexural buckling

(1) See 6.3.1.3(1) and (2) of EN 1993-1-1. 6.3.1.4 Slenderness for torsional and torsional flexural buckling

(1) See 6.3.1.4(1), (2) and (3) of EN 1993-1-1.

EN 1993-2: 2006 (E)

24 6.3.1.5 Use of class 3 section properties with stress limits

(1) As an alternative to using class 4 section properties given in equations (6.48), (6.49), (6.51) and (6.53) of EN 1993-1-1, class 3 section properties given in equations (6.47), (6.49), (6.50) and (6.52) of EN 1993-1-1, with stress limits in accordance with section 10 of EN 1993-1-5, may be used, see 6.2.2.5.

6.3.2 Uniform members in bending 6.3.2.1 Buckling resistance

(1) See 6.3.2.1(1), (2), (3) and (4) of EN 1993-1-1. 6.3.2.2 Lateral torsional buckling curves – General case

(1) See 6.3.2.2(1), (2) and (3) of EN 1993-1-1. (4) Lateral torsional buckling effects may be ignored if the slenderness parameter 2,0£LTl or 04,0£critEdMM. 6.3.2.3 Lateral torsional buckling curves for rolled sections or equivalent welded sections

(1) See 6.3.2.3(1) and (2) of EN 1993-1-1. NOTE: The National Annex may give further information 6.3.3 Uniform members in bending and axial compression

(1) Unless second order analysis is carried out using the imperfections given in 5.3.2, the stability of uniform members subject to axial compression and bending in the plane of buckling should be checked in accordance with section 6.3.3 or 6.3.4 of EN 1993-1-1.

NOTE:

As a simplification to equation (6.61) in 6.3.3 of EN 1993-1-1 the following condition may be used:

()9,01,,,,1£D++MRkyEdyEdyomiMRkyEdMMMCNNggc (6.9) where NEd

is the design value of the compression force;

My,Ed is the design value of the maximum moment about the y-y axis of the member obtained from first order analysis without considering imperfections;

DMy,Ed

is the moment due to the shift of the centroidal axis according to 6.2.10.3;

Cmi,o is the equivalent moment factor, see Table A.2 of EN 1993-1-1;

cy is the reduction factors due to flexural buckling from 6.3.1. 6.3.4 General method for lateral and lateral torsional buckling of structural components 6.3.4.1 General method

(1) See 6.3.4(1), (2), (3) and (4) of EN 1993-1-1. 6.3.4.2 Simplified method

(1) See 6.3.2.4(1) of EN 1993-1-1.

EN 1993-2: 2006 (E)

25 NOTE:

The National Annex may g

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...