kSIST FprEN 13289:2018

(Main)Pasta processing plant - Dryers and coolers - Safety and hygiene requirements

Pasta processing plant - Dryers and coolers - Safety and hygiene requirements

This document applies to shaker dryers, belt dryers, rotary dryers, nest pasta dryers, long pasta dryers and coolers (see Clause 3), used in continuous pasta processing plants.

These machines are usually used in a production line, but can also operate independently.

When the machines are part of a line, this standard does not cover the other constituent units of the line and their interfaces.

This document specifies the safety requirements for the design, manufacture and information for safe use of dryers and coolers and deals with all significant hazards, hazardous situations, and events when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4).

It deals with the hazards during the following phases of the machines' lifetime: transport, assembly and installation, commissioning, setting and adjusting, operation, cleaning, fault finding, maintenance, decommissioning, dismantling, disabling and scrapping.

The measures for risk reduction are given in Clause 5.

This document does not apply to:

- machines fed under manual control and working in cycles (batch machines, static or semi-automatic),

- machines for special application (i.e. experimental dryers),

- equipment used to supply hot or cold fluids to dryers and coolers.

The significant hazards covered by this standard are listed in Clause 4. This document is not applicable to machines in its scope which are manufactured before the date of its publication as EN.

Maschinen zur Teigwarenherstellung - Trockner und Kühler - Sicherheits- und Hygieneanforderungen

Diese Norm gilt für Schütteltrockner, Bandtrockner, Trommeltrockner, Nesttrockner, Trockner für lange Teigwaren und Kühler (siehe Abschnitt 3), die in kontinuierlich arbeitenden Teigwarenherstellungsanlagen verwendet werden.

Sie werden üblicherweise in Produktionslinien verwendet, eignen sich jedoch auch für den unabhängigen Betrieb.

Bei Maschinen, die Teil einer Produktionslinie sind, sind andere Bestandteile der Linie und deren Schnittstellen nicht Gegenstand dieser Norm.

Diese Europäische Norm spezifiziert die Sicherheitsanforderungen in Bezug auf die Konstruktion, die Herstellung und Informationen für den sicheren Einsatz von Trocknern und Kühlern und behandelt alle schwerwiegenden Gefährdungen, gefährdende Situationen und Ereignisse bei bestimmungsgemäßer Verwendung sowie unter Bedingungen der vom Hersteller vorhersehbaren missbräuchlichen Verwendung (siehe Abschnitt 4).

Sie behandelt Gefährdungen während den folgenden Lebensphasen der Maschine: Transport, Montage und Einrichtung, Inbetriebnahme, Einstellung und Justierung, Betrieb, Reinigung, Fehlersuche, Instandhaltung, Außerbetriebnahme, Demontage, Abschaltung und Verschrottung.

Die Maßnahmen für die Risikominderung sind in Abschnitt 5 aufgeführt.

Diese Norm gilt nicht für:

- Maschinen mit manuell gesteuerter Produktzuführung, die in Zyklen arbeiten (Batchmaschinen, statisch oder halbautomatisch),

- Maschinen für Spezialanwendungen (z. B. experimentelle Trockner),

- Anlagen zur Versorgung von Trocknern und Kühlern mit heißen oder kalten Flüssigkeiten.

Die signifikanten von dieser Norm erfassten Gefährdungen sind in Abschnitt 4 aufgeführt.

Dieser Europäische Normentwurf gilt nicht für Maschinen des Anwendungsbereichs dieser Norm, die vor Veröffentlichung als EN hergestellt wurden.

Installations de production de pâtes - Séchoirs et refroidisseurs - Prescriptions relatives à la sécurité et à l’hygiène

Le présent document s’applique aux séchoirs à secousses, séchoirs à tapis, rotatifs, à alvéoles, pour le séchage et le refroidissement des pâtes longues (voir Article 3) utilisés dans les installations de transformation en continu des pâtes alimentaires.

Ces machines sont habituellement utilisées dans une ligne de production mais elles peuvent également fonctionner de manière indépendante.

Lorsque les machines font partie d'une ligne de production, la présente norme ne couvre pas les autres unités composant la ligne ni leurs interfaces.

Le présent document spécifie les prescriptions de sécurité relatives à la conception, à la fabrication et aux informations pour l'utilisation en toute sécurité des séchoirs et refroidisseurs, et traite de tous les phénomènes dangereux, situations et événements dangereux significatifs lorsqu'elles sont utilisées normalement et dans les conditions de mauvais usage raisonnablement prévisible par le fabricant (voir Article 4).

Il traite des phénomènes dangereux survenant dans les phases suivantes de la durée de vie de la machine : transport, assemblage et installation, mise en service, paramétrage et réglage, fonctionnement, nettoyage, recherche de défauts, maintenance, mise hors service, démontage et mise au rebut.

Les mesures de réduction du risque sont données à l'Article 5.

Le présent document ne s'applique pas :

- machines chargées sous contrôle manuel et fonctionnant par cycles (machines en discontinu, statiques ou semi-automatiques).

- machines destinées à une application particulière (c'est-à-dire, séchoirs expérimentaux),

- équipements utilisés pour fournir des fluides chauds ou froids aux séchoirs et refroidisseurs.

Les phénomènes dangereux significatifs couverts par la présente norme sont énumérés à l'Article 4. Le présent document ne s’applique pas aux machines répondant à son domaine d’application qui ont été fabriquées avant sa date de publication en tant qu’EN.

Stroji za izdelavo testenin - Sušilniki in ohlajevalniki - Varnostne in higienske zahteve

General Information

- Status

- Not Published

- Public Enquiry End Date

- 02-Feb-2016

- Technical Committee

- VSN - Safety of machinery

- Current Stage

- 5020 - Formal vote (FV) (Adopted Project)

- Start Date

- 02-Jul-2018

- Due Date

- 20-Aug-2018

- Completion Date

- 24-Aug-2018

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 01-Jan-2016

Overview

The European Standard kSIST FprEN 13289:2018 titled "Pasta processing plant - Dryers and coolers - Safety and hygiene requirements" specifies essential safety and hygiene regulations for various dryers and coolers used in continuous pasta production plants. Developed by CEN’s Technical Committee CEN/TC 153, this standard addresses shaker dryers, belt dryers, rotary dryers, nest pasta dryers, long pasta dryers, and coolers typically integrated into production lines.

The standard ensures the safe design, manufacturing, and operation of dryers and coolers by detailing measures to control significant hazards during all phases including transport, installation, commissioning, operation, cleaning, maintenance, and dismantling. It excludes batch-fed machinery and equipment supplying heating or cooling fluids.

Key Topics

Scope of Application

Targets stationary dryers and coolers capable of continuous pasta drying at production rates exceeding 100 kg/h. It applies specifically to those used in automated production lines and excludes manual, experimental, or semi-automatic batch processes.Hazard Identification

Safety risks addressed include mechanical hazards from moving and protruding parts, electrical risks, thermal hazards, noise, and slip or fall hazards. Also covered are hygiene-related risks arising from contamination or poor sanitation practices.Safety Requirements

The standard details protective measures to avoid injury and ensure machine integrity, such as guards on moving parts, prevention of unexpected machine start-up, adequate electrical isolation, thermal protection, and noise control. Specific measures support hygienic design principles.Hygiene and Cleanability

Special emphasis is placed on machine design facilitating easy cleaning to prevent food contamination. Materials of construction, surface finish, assembly methods, and ventilation details ensure adherence to strict hygiene standards appropriate for food industry machinery.Verification and Information

Includes verification methods for safety features, noise testing protocols, and mandatory machine marking and operator information to ensure clarity for safe use.

Applications

Food Industry Equipment

kSIST FprEN 13289:2018 is essential for manufacturers and end users of pasta production facilities seeking compliance with European safety regulations.Continuous Pasta Processing Plants

The standard supports the reliable operation of dryers and coolers which reduce moisture content and stabilize pasta by cooling, improving product quality and shelf life.Machine Design and Safety Engineering

Engineers can apply the requirements to develop safer pasta processing machinery, minimizing hazards to workers and enhancing operational hygiene.Maintenance and Installation

Technical personnel benefit from the comprehensive lifecycle safety guidance covering installation, routine maintenance, and decommissioning stages.

Related Standards

- EN ISO 12100 – Safety of machinery – Basic concepts and general principles for design

- EN 953 – Safety of machinery – Guards design and construction requirements

- EN 1037 – Prevention of unexpected start-up

- EN 60204-1 – Electrical equipment of machines – Safety requirements

- EN 1672-2 – Food processing machinery – Hygiene requirements

- EN 60529 – Degrees of protection by enclosures (IP code)

These harmonized standards complement kSIST FprEN 13289:2018 by addressing broader machinery safety, electrical, and hygiene concerns relevant to food processing equipment.

kSIST FprEN 13289:2018 provides a robust safety and hygiene framework for dryers and coolers used in pasta manufacturing. By following this standard, manufacturers and plant operators ensure compliance with European directives, reduce workplace hazards, and support hygienic food production processes.

Frequently Asked Questions

kSIST FprEN 13289:2018 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Pasta processing plant - Dryers and coolers - Safety and hygiene requirements". This standard covers: This document applies to shaker dryers, belt dryers, rotary dryers, nest pasta dryers, long pasta dryers and coolers (see Clause 3), used in continuous pasta processing plants. These machines are usually used in a production line, but can also operate independently. When the machines are part of a line, this standard does not cover the other constituent units of the line and their interfaces. This document specifies the safety requirements for the design, manufacture and information for safe use of dryers and coolers and deals with all significant hazards, hazardous situations, and events when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). It deals with the hazards during the following phases of the machines' lifetime: transport, assembly and installation, commissioning, setting and adjusting, operation, cleaning, fault finding, maintenance, decommissioning, dismantling, disabling and scrapping. The measures for risk reduction are given in Clause 5. This document does not apply to: - machines fed under manual control and working in cycles (batch machines, static or semi-automatic), - machines for special application (i.e. experimental dryers), - equipment used to supply hot or cold fluids to dryers and coolers. The significant hazards covered by this standard are listed in Clause 4. This document is not applicable to machines in its scope which are manufactured before the date of its publication as EN.

This document applies to shaker dryers, belt dryers, rotary dryers, nest pasta dryers, long pasta dryers and coolers (see Clause 3), used in continuous pasta processing plants. These machines are usually used in a production line, but can also operate independently. When the machines are part of a line, this standard does not cover the other constituent units of the line and their interfaces. This document specifies the safety requirements for the design, manufacture and information for safe use of dryers and coolers and deals with all significant hazards, hazardous situations, and events when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). It deals with the hazards during the following phases of the machines' lifetime: transport, assembly and installation, commissioning, setting and adjusting, operation, cleaning, fault finding, maintenance, decommissioning, dismantling, disabling and scrapping. The measures for risk reduction are given in Clause 5. This document does not apply to: - machines fed under manual control and working in cycles (batch machines, static or semi-automatic), - machines for special application (i.e. experimental dryers), - equipment used to supply hot or cold fluids to dryers and coolers. The significant hazards covered by this standard are listed in Clause 4. This document is not applicable to machines in its scope which are manufactured before the date of its publication as EN.

kSIST FprEN 13289:2018 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

kSIST FprEN 13289:2018 has the following relationships with other standards: It is inter standard links to SIST EN 13289:2002+A1:2013, SIST EN 13289:2002+A1:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

kSIST FprEN 13289:2018 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

kSIST FprEN 13289:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

oSIST prEN 13289:2016

01-januar-2016

Stroji za izdelavo testenin - Sušilniki in ohlajevalniki - Varnostne in higienske

zahteve

Pasta processing plant - Dryers and coolers - Safety and hygiene requirements

Maschinen zur Teigwarenherstellung - Trockner und Kühler - Sicherheits- und

Hygieneanforderungen

Installations de production de pâtes - Séchoirs et refroidisseurs - Prescriptions relatives à

la sécurité et à l’hygiène

Ta slovenski standard je istoveten z: prEN 13289

ICS:

67.260 Tovarne in oprema za Plants and equipment for the

živilsko industrijo food industry

oSIST prEN 13289:2016 en,fr,de

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

oSIST prEN 13289:2016

oSIST prEN 13289:2016

DRAFT

EUROPEAN STANDARD

prEN 13289

NORME EUROPÉENNE

EUROPÄISCHE NORM

November 2015

ICS 67.260 Will supersede EN 13289:2001+A1:2013

English Version

Pasta processing plant - Dryers and coolers - Safety and

hygiene requirements

Maschinen zur Teigwarenherstellung - Trockner und

Kühler - Sicherheits- und Hygieneanforderungen

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 153.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2015 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 13289:2015 E

worldwide for CEN national Members.

oSIST prEN 13289:2016

prEN 13289:2015 (E)

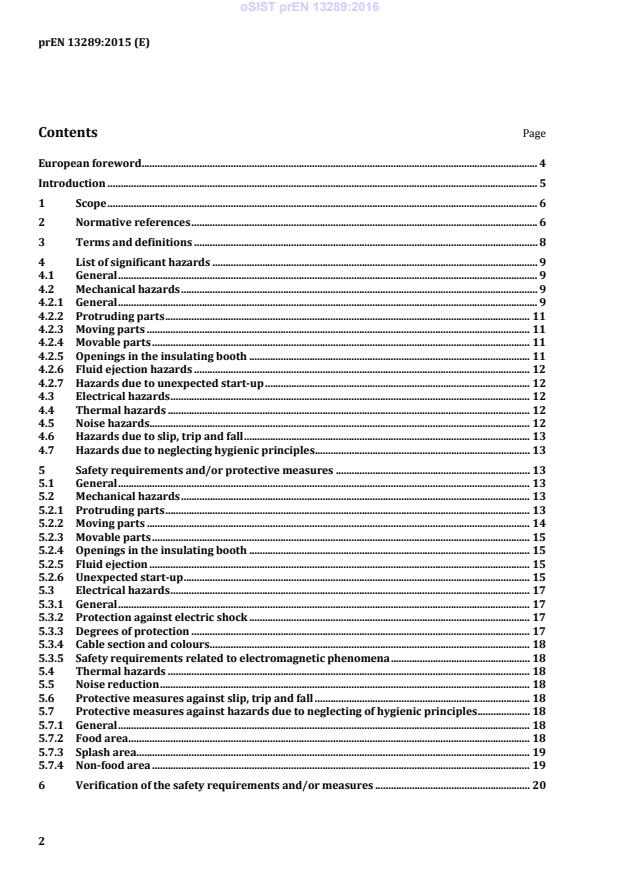

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 8

4 List of significant hazards . 9

4.1 General . 9

4.2 Mechanical hazards . 9

4.2.1 General . 9

4.2.2 Protruding parts . 11

4.2.3 Moving parts . 11

4.2.4 Movable parts . 11

4.2.5 Openings in the insulating booth . 11

4.2.6 Fluid ejection hazards . 12

4.2.7 Hazards due to unexpected start-up . 12

4.3 Electrical hazards . 12

4.4 Thermal hazards . 12

4.5 Noise hazards. 12

4.6 Hazards due to slip, trip and fall . 13

4.7 Hazards due to neglecting hygienic principles . 13

5 Safety requirements and/or protective measures . 13

5.1 General . 13

5.2 Mechanical hazards . 13

5.2.1 Protruding parts . 13

5.2.2 Moving parts . 14

5.2.3 Movable parts . 15

5.2.4 Openings in the insulating booth . 15

5.2.5 Fluid ejection . 15

5.2.6 Unexpected start-up . 15

5.3 Electrical hazards . 17

5.3.1 General . 17

5.3.2 Protection against electric shock . 17

5.3.3 Degrees of protection . 17

5.3.4 Cable section and colours . 18

5.3.5 Safety requirements related to electromagnetic phenomena . 18

5.4 Thermal hazards . 18

5.5 Noise reduction . 18

5.6 Protective measures against slip, trip and fall . 18

5.7 Protective measures against hazards due to neglecting of hygienic principles . 18

5.7.1 General . 18

5.7.2 Food area . 18

5.7.3 Splash area. 19

5.7.4 Non-food area . 19

6 Verification of the safety requirements and/or measures . 20

oSIST prEN 13289:2016

prEN 13289:2015 (E)

7 Information for use . 21

7.1 Technical information . 21

7.2 Indicators. 22

7.2.1 General . 22

7.2.2 Warning signs for residual hazard . 22

7.3 Marking . 22

Annex A (normative) Principles of design to ensure the cleanability of machinery . 24

A.1 Terms and definitions . 24

A.2 Material of construction . 24

A.2.1 Type of materials . 24

A.2.2 Surface conditions . 24

A.3 Design . 25

A.3.1 Connections of internal surfaces . 25

A.3.2 Surface assemblies and overlaps . 29

A.3.3 Fasteners. 34

A.3.4 Machines on the floor . 35

A.3.5 Ventilation openings . 37

A.3.6 Hinges . 37

A.3.7 Control panel . 38

Annex B (normative) Noise test code – Grade 2 or 3 . 39

B.1 Terms and definitions . 39

B.2 Installation and mounting conditions . 39

B.3 Operating conditions . 39

B.4 Measurements . 39

B.5 Emission sound pressure level determination . 39

B.6 Sound power level determination . 40

B.7 Measurement uncertainties . 40

B.8 Information to be recorded . 41

B.9 Information to be reported . 41

B.10 Declaration and verification of noise emission value . 41

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 2006/42/EC on Machinery . 42

Bibliography . 43

oSIST prEN 13289:2016

prEN 13289:2015 (E)

European foreword

This document (prEN 13289:2015) has been prepared by Technical Committee CEN/TC 153

“Machinery intended for use with foodstuffs and feed”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 13289:2001+A1:2013.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive 2006/42/EC.

For relationship with EU Directive 2006/42/EC, see informative Annex ZA, which is an integral part of

this document.

oSIST prEN 13289:2016

prEN 13289:2015 (E)

Introduction

This draft European Standard is a type C standard as stated in EN ISO 12100.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events

are covered are indicated in the scope of this document.

When provisions of this type-C-standard are different from those which are stated in type-A- or -B-

standards, the provisions of this type-C-standard take precedence over the provisions of the other

standards for machines that have been designed and built according to the provisions of this type-C-

standard.

Complementary to the hygiene requirements common to all food processing machines, specific

requirements for cleanability and sanitation of the machines in the scope are formulated.

oSIST prEN 13289:2016

prEN 13289:2015 (E)

1 Scope

This draft European Standard applies to shaker pre-dryers, belt dryers, rotary dryers, nest pasta dryers,

long pasta dryers and coolers (see Clause 3), used in continuous pasta processing plants able to produce

more than 100 kg/h.

This draft European Standard specifies the safety requirements for the design, manufacture and

information for use for the machines mentioned above, known with the name of dryers and coolers,

classified as stationary units which cannot be moved when in operation.

This draft European Standard is not applicable to dryers and coolers, static or semiautomatic requiring

manual loading as well as those for special application (i.e. experimental dryers).

Dryers in a pasta plant are machines which reduce moisture by means of warm air ventilation. In the

drying process the use of a cooler might be necessary in order to reduce the temperature, maintaining

constant the correct moisture of the pasta. The cooling can be obtained in the dryer or in a separate

similar machine.

The significant hazards covered by this standard are listed in Clause 4.

These hazards, as well as the measures for their reduction, are described in the present draft European

Standard

Ancillary equipment which is not an integral part of the machinery (e.g. hoppers, conveyors, equipment

used to produce hot or cold fluids, etc.) is not covered by this draft European Standard.

This draft European Standard is not applicable to machines in its scope which are manufactured before

the date of its publication as EN.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 953:1997+A1:2009, Safety of machinery — Guards — General requirements for the design and

construction of fixed and movable guards

EN 1037:1995+A1:2008, Safety of machinery — Prevention of unexpected start-up

EN 1672-2:2005+A1:2009, Food processing machinery — Basic concepts — Part 2: Hygiene requirements

EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General

requirements (IEC 60204-1:2005)

EN 60332-1 (all parts), Tests on electric and optical fibre cables under fire conditions — Part 1: Test for

vertical flame propagation for a single insulated wire or cable (IEC 60332-1, all parts)

1)

EN 60529:1991 , Degrees of protection provided by enclosures (IP code) (IEC 60529:1989)

EN 60947-5-5, Low-voltage switchgear and controlgear — Part 5-5: Control circuit devices and switching

elements — Electrical emergency stop device with mechanical latching function (IEC 60947-5-5

EN 61310-1, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for visual,

acoustic and tactile signals (IEC 61310-1)

1) This document is currently impacted by the two amendments EN 60529:1991/A1:2000 and EN 60529:1991/A2:2013.

oSIST prEN 13289:2016

prEN 13289:2015 (E)

EN ISO 3744, Acoustics — Determination of sound power levels and sound energy levels of noise sources

using sound pressure — Engineering methods for an essentially free field over a reflecting plane

(ISO 3744)

EN ISO 3746, Acoustics — Determination of sound power levels and sound energy levels of noise sources

using sound pressure — Survey method using an enveloping measurement surface over a reflecting plane

(ISO 3746)

EN ISO 3747, Acoustics — Determination of sound power levels and sound energy levels of noise sources

using sound pressure — Engineering/survey methods for use in situ in a reverberant environment

(ISO 3747)

EN ISO 4413, Hydraulic fluid power — General rules and safety requirements for systems and their

components (ISO 4413)

EN ISO 4414, Pneumatic fluid power — General rules and safety requirements for systems and their

components (ISO 4414)

EN ISO 4871, Acoustics — Declaration and verification of noise emission values of machinery and

equipment (ISO 4871)

EN ISO 7731, Ergonomics — Danger signals for public and work areas - Auditory danger signals

(ISO 7731)

EN ISO 9614-1:2009, Acoustics — Determination of sound power levels of noise sources using sound

intensity — Part 1: Measurement at discrete points (ISO 9614-1:1993)

EN ISO 9614-2, Acoustics — Determination of sound power levels of noise sources using sound intensity —

Part 2: Measurement by scanning (ISO 9614-2)

EN ISO 11201, Acoustics - Noise emitted by machinery and equipment - Determination of emission sound

pressure levels at a work station and at other specified positions in an essentially free field over a reflecting

plane with negligible environmental corrections (ISO 11201)

EN ISO 11202, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a work station and at other specified positions applying approximate

environmental corrections (ISO 11202)

EN ISO 11204, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a work station and at other specified positions applying accurate environmental

corrections (ISO 11204)

EN ISO 11688-1, Acoustics — Recommended practice for the design of low-noise machinery and

equipment — Part 1: Planning (ISO/TR 11688-1)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13732-1, Ergonomics of the thermal environment — Methods for the assessment of human

responses to contact with surfaces — Part 1: Hot surfaces (ISO 13732-1)

EN ISO 13849-1, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1)

oSIST prEN 13289:2016

prEN 13289:2015 (E)

EN ISO 13850, Safety of machinery — Emergency stop — Principles for design (ISO 13850)

EN ISO 13857:2008, Safety of machinery — Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2008)

EN ISO 14119, Safety of machinery — Interlocking devices associated with guards — Principles for design

and selection (ISO 14119)

EN ISO 14122 (all parts), Safety of machinery — Permanent means of access to machinery (ISO 14122, all

parts)

IEC 60417, Graphical symbols for use on equipment

ISO 447, Machine tools — Direction of operation of controls

ISO 468, Surface roughness — Parameters, their values and general rules for specifying requirements

ISO 3864-1, Graphical symbols — Safety colours and safety signs — Part 1: Design principles for safety

signs and safety markings

ISO 3864-2, Graphical symbols — Safety colours and safety signs — Part 2: Design principles for product

safety labels

ISO 3864-3, Graphical symbols — Safety colours and safety signs — Part 3: Design principles for graphical

symbols for use in safety signs

ISO 7001, Graphical symbols — Public information symbols

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

3.1

dryer

assembly where the pasta is dried

3.2

shaker pre-dryer

assembly of metal mesh tables (usually in stainless steel) which is made to vibrate by different types of

systems causing the product to advance towards the outlet and which is used for drying short cut pasta

(e.g. macaroni), in the first stages of the process, when the pasta advances in thin layers to allow the

evaporation of great quantities of water (see Figure 1)

3.3

belt dryer

assembly of belts which conveys the pasta and which is used for drying short cut pasta and placed just

after the shaker pre-dryers in the drying line (see Figure 2)

3.4

rotary dryer

assembly of a rotating drum which consists of conveying channels placed along the periphery of the

drum and which, as a rule it is used for small dimension short cut pasta and for pastina (e.g. soup pasta,

see Figure 3)

oSIST prEN 13289:2016

prEN 13289:2015 (E)

3.5

nest pasta dryer

assembly of special containers in which the nest-shaped pasta is conveyed through the dryer frame

3.6

long pasta dryer

assembly in which long cut pasta (e.g. spaghetti) is hung out on sticks which are conveyed through the

dryer

3.7

cooler

final part of the process having the same handling system as the dryer described in 3.1 to 3.6, but with

low inside air temperature in order to reduce the temperature of the pasta; it may be separate from the

dryer

3.8

insulating booth

interface between the process area and the exterior

3.9

movable part

elements other than guards which can be opened or removed

4 List of significant hazards

4.1 General

This clause covers all the hazards, as far as they are considered in this draft European Standard,

identified by risk assessment to be significant for this type of machinery and requiring an action to

eliminate or reduce the risk.

4.2 Mechanical hazards

4.2.1 General

The significant mechanical hazards are:

— crushing hazard;

— cutting or severing hazard;

— entanglement hazard;

— shearing hazard;

— fluid ejection hazard;

— impact hazard;

— trapping hazard.

The examples shown in Figures 1 to 3 illustrate the danger zones associated with these hazards.

oSIST prEN 13289:2016

prEN 13289:2015 (E)

Figure 1 — Shaker pre-dryer

Figure 2 — Belt dryer

oSIST prEN 13289:2016

prEN 13289:2015 (E)

Figure 3 — Rotary dryer

4.2.2 Protruding parts

Parts jutting out of the basic outline beyond the machine frame at low level (e.g. valves and pipes of the

heating, cooling and humidifying plant or cables) may cause a trip hazards with the consequence of

broken bones, see zone 1, Figures 2 and 3. Parts jutting out of the basic outline beside the machine

frame at a middle to high level (e.g. motors or gearbox, valves and pipes of the heating, cooling and

humidifying plant) may cause an impact hazard for body parts and the head with the consequence of

manifold injuries, see zone 1 Figures 2 and 3.

4.2.3 Moving parts

4.2.3.1 Moving parts for pasta conveyance systems, such as sticks, belts, drums, frames, and other

containers, may cause hazards of entanglement, cutting, severing and shearing of fingers, hands, arms

and the body; see zone 2, Figures 1, 2 and 3.

4.2.3.2 Moving parts for driving systems such as chains, gears, shafts etc. may cause hazards of

entanglement, cutting, severing and shearing of fingers or hands; see zone 3, Figures 1, 2 and 3.

4.2.3.3 Fan blades may cause hazards of cutting of fingers, hands, arms or other parts of body.

4.2.3.4 Rotating drums may cause hazards of crushing of the body when falling from supports and

hazards of crushing of the fingers and the hands between driving wheels and the rims.

4.2.3.5 Moving parts of air inlet and outlet gates may cause hazards of cutting or severing of fingers

and hands.

4.2.4 Movable parts

When movable parts, e.g. panels of the insulation booth or guiding plates, are handled they may cause

the hazard of crushing of fingers, arms, feet or other parts of the body and the ejection of hot air, which

may cause injury to the head or other parts of the body; see zone 4 Figures 1, 2 and 3.

4.2.5 Openings in the insulating booth

For the operation of the machine, openings are provided for different purposes:

— inlet and outlet for the product;

— inlets and outlets for fluids, e.g. hot air;

oSIST prEN 13289:2016

prEN 13289:2015 (E)

— sampling;

— cleaning and maintenance operations.

Openings may cause burn hazard due to hot air ejection with the consequence of injuries to hands, arms

and other parts of the body. Depending on the installation access to moving parts may be possible that

may cause a cutting and shearing hazard for fingers and hands.

When entrance doors, hoods or cover panels for cleaning and maintenance operations are handled, this

may cause hazards of crushing, cutting or severing of fingers, arms and other parts of the body.

In case the operator can enter into the machine, he can be trapped and suffer severe injuries due to

mechanical and thermal hazards that may occur if the machine starts up unexpectedly.

4.2.6 Fluid ejection hazards

Leakage of pressurized pipes, including heat exchangers, or leakage of hydraulic drives may cause the

hazard of fluid release, e.g. water, superheated water, steam and diathermic oil (heating system),

hydraulic oil (hydraulic drives) and compressed air, which may cause a burn hazard or impact hazard.

A pressure drop in hydraulic and pneumatic drives caused by leakage may result in dangerous

unexpected movements, e.g. when a movable part of the machine is held in the upper position by

pressure. Fluid release may cause the hazard of foodstuff contamination.

4.2.7 Hazards due to unexpected start-up

Unexpected start-up may cause the hazards of contact with dangerous moving parts and/or contact to

hot surfaces. Hazards that are caused by unexpected start-up can arise if components in safety-related

parts of control systems fail. Failures may occur due to mechanical damage, wrong installation, contact

failure or electronic component failure.

Failures can lead to loss of safety functions, resulting in unexpected start-up of moving parts and of the

heating control system. Failures can lead to loss of safety functions resulting from moving parts not

stopped as expected. When the power supply of an electronic drive system is not disconnected during

maintenance operations by using an enabling device such as a hold-to-run control, an electronic hand

wheel or a joy stick complying with EN 60204-1:2006, 9.2.6 and 10.9, there is a risk of unexpected start-

up with consequential mechanical hazards if the control system malfunctions or responds to an external

disturbance such as electromagnetic interference.

4.3 Electrical hazards

Electrical equipment on the machine can generate a potential electric shock hazard from direct or

indirect contact with live components. This hazard is present in control panels, junction boxes, motor

connectors, electrical resistances and in the electrical components. A hazard from the electrical

equipment may arise if the electrical components inside the cabinet do not withstand the thermal and

climate conditions. An external disturbance such as electromagnetic interference can lead to

malfunction or loss of function of electrical equipment. If liquids, e.g. fluids used for pasta processing or

cleaning agents like water, come into contact with the electrical conductors, there is a risk of electric

shock.

4.4 Thermal hazards

Contact with parts of the dryer reaching high temperatures (e.g. pipelines, valves, etc.) and contact with

hot fluids ejected by the dryer, see 4.2.2, 4.2.3, 4.2.4. The burning hazard will usually continue to exist

for a period of time after power has been disconnected.

4.5 Noise hazards

Noise generated by dryers and coolers can lead to:

oSIST prEN 13289:2016

prEN 13289:2015 (E)

— permanent loss of hearing,

— ringing in the ears,

— fatigue, stress,

— interference with speech communication, acoustic signals.

4.6 Hazards due to slip, trip and fall

Walkways, stairs and gangways may cause slip, trip and fall with possibility of broken bones. Trip

accidents may occur if parts of the machine protrude beyond the machine frame at low level, or if cables

and pipes associated with the machine are installed without proper consideration of tripping hazards.

See also 4.2.2.

4.7 Hazards due to neglecting hygienic principles

Neglecting hygienic principles may cause a hazard to human health and unacceptable modification of

foodstuff (e.g. contamination by microbial growth or foreign materials and pests).

5 Safety requirements and/or protective measures

5.1 General

Machinery shall comply with the safety requirements and/or protective measures of this clause. In

addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for relevant,

but not significant hazards, which are not dealt with by this document.

5.2 Mechanical hazards

5.2.1 Protruding parts

The design of the machine shall avoid assemblies at low level that are likely to pose a trip hazard and

assemblies at middle to high level that may cause impact hazard (see Figure 4). Where this is not

possible, the manufacturer shall provide railings or some other form of barrier, which guides people

away from the trip hazard.

Collision with protruding parts shall be prevented by a handrail. The handrail is required where the

protruding parts are less than 2500 mm from the access level (h), sticking out for more than

300 mm (s), and less than 1 000 mm high (l).

The handrail shall be 1 000 mm high and positioned at least at the same dimension as the parts that

protrude (s).

Protruding parts located more than 2 500 mm from the access level (h) need not be guarded.

oSIST prEN 13289:2016

prEN 13289:2015 (E)

Key

A dryer or cooler

B protruding part

C access level

h distance from the access level

s sticking of protruding part

l height of protruding part

Figure 4 — Scheme of protruding parts

5.2.2 Moving parts

5.2.2.1 Access to moving parts for pasta conveyance systems as described in 4.2.3.1 and located

outside the insulation booth shall be safeguarded in accordance with EN 953:1997+A1:2009, 3.2. For

the access to moving parts through openings of the insulation booth see 5.2.4.

5.2.2.2 Moving parts for drive systems as described in 4.2.3.2 that are located outside the insulation

booth shall be safeguarded in accordance with EN 953:1997+A1:2009, 3.2.

5.2.2.3 Fan blades as described in 4.2.3.3 that are located outside the insulation booth shall be

safeguarded by fixed guards complying with this clause and EN 953:1997+A1:2009, 3.2. For fan blades

that are located inside the insolation booth and that shall not be guarded, the nearest openings in the

insulation booth shall be dimensioned and positioned so that the safety distances comply with those

specified in Clause 4 and in EN ISO 13857:2008, Annexes A and B.

5.2.2.4 For the axial slide control of the drum of a rotary dryer as described in 4.2.3.4, the following

requirements apply: the axial slide control can be realized by mechanical measures e.g. with rollers. For

that particular case measures shall be taken that the construction can withstand the mechanical forces

of the drum. Measures shall be taken against the crushing and drawing-in hazard for the fingers and

hands between the rims and the rollers for axial slide control, e.g. safeguarding.

The axial slide control can be realized by position sensors integrated in a safety-related function of the

electrical control system. The position sensors (for example position switch, proximity switch) shall be

so arranged that they will not be damaged in the event of over-travel. The position sensors shall have

direct opening action. Measures, e.g. safeguarding, shall be taken against the crushing and drawing-in

hazard for the fingers and hands between the driving wheels and the rims.

oSIST prEN 13289:2016

prEN 13289:2015 (E)

5.2.2.5 Moving parts of the air inlet and outlet gates as described in 4.2.3.5 shall be safeguarded by

fixed guards (e.g. meshes, grids, connection pipelines) complying with this clause and

EN 953:1997+A1:2009, 3.2.

5.2.3 Movable parts

Movable parts that have to be removed, e.g. for cleaning and maintenance operations, shall not have a

mass heavier than 25 kg; if heavier, they shall be fitted with supporting devices. The force to open these

movable parts shall not exceed 200 N.

Panels covering openings which need to be removed, e.g. for checking operations and sample drawing,

shall be designed to prevent the operator from being injured by the weight of the panels. The movable

parts with a mass lower than 25 kg shall have a handling system. Unexpected movement caused by the

centre of gravity during handling shall be prevented.

5.2.4 Openings in the insulating booth

Openings which give access to dangerous parts or hot surfaces inside the insulating booth shall be

designed and dimensioned according to EN ISO 13857 to avoid the risk or shall be fitted with fixed

guards or interlocked movable guards in accordance with EN ISO 14119.

Openings for sampling shall be protected with movable guards. Inside the insulating booth the access

shall be protected with guards against mechanical hazards or shall be permitted by means of a special

tool supplied by the manufacturer. To reduce the hot air ejection at the openings the following

measures shall be considered: negative pressure in relation to the external environment, air blades,

reduction of openings or other technical measures reaching the same result.

Openings for cleaning and maintenance operations that allow the entry of the operator inside the

insulating booth shall be protected with fixed guards (panels). The guards shall be stable in the open

position, otherwise they need supporting devices which maintain the panels stable in the open position.

5.2.5 Fluid ejection

Water, superheated water, steam and diathermic oil piping systems together with their intercepting

and controlling devices shall be designed for a pressure 1,5 times the maximum working pressure.

Manually operated valves shall be fitted at the interface between the dryer/cooler and the incoming

supplies. The valves shall be fitted with a trapped device.

Hydraulic and pneumatic systems shall be designed and manufactured according to EN ISO 4413 and

EN ISO 4414.

To avoid dropping of fluids on the product during the maintenance operation it is necessary to check

the heating/cooling system inside the insulating booth, following the manufacturer information for use

given in the instruction handbook. Chemicals, including lubricants, shall be chosen in order to prevent

product contamination. Lubricant intended to come in contact with the product shall be of a grade

suitable for the intended use.

5.2.6 Unexpected start-up

5.2.6.1 General

To avoid hazard due to unexpected start-up or failure of protective device and their integration in the

control system, control circuits and control functions shall comply with EN 60204-1. For other drives

than electrical, see EN 1037.

oSIST prEN 13289:2016

prEN 13289:2015 (E)

5.2.6.2 Supply disconnecting device

Each machine shall be equipped with power supply disconnecting devices according to

EN 1037:1995+A1:2008, 5.1. In particular, for electric power, disconnecting devices shall be according

to EN 60204-1:2006, 5.3.2 (options a, b, c), capable of being equipped with means to lock them in the

OFF-position (e.g. trapped key system). The manually operated elements of controls shall be easily and

safely accessible and be designed, mounted and marked so as to allow instant recognition of their

purpose, as well as direction and condition of switching (see ISO 447).

5.2.6.3 Emergency stop device

Each machine shall be equipped with emergency stop devices positioned on the control panels and at

the interface with other machines when the interface can create dangerous situations (e.g. spreader).

The emergency stop function shall be a stop of Category 0 or 1 according to EN 60204-1:2006, 9.2.2,

and comply with EN 60204-1:2006, 9.2.5.4.1 and 9.2.5.4.2. The emergency stop shall also comply with

EN ISO 13850. Electrical switchgear and control gear shall comply with EN 60947-5-5.

5.2.6.4 Normal stop

For pasta equipment the normal stop shall follow a procedure to stop each machine according to the

technological process inside (the procedure follows the product passage though the equipment). The

aim is to stop each machine when it is empty. Every machine shall be equipped with a device for normal

stop that shall be of Category 0 or 1 as defined in EN 60204-1:2006, 9.2.5.3. The machinery's stop

control shall have priority over the start controls. Once the machinery or its hazardous functions have

stopped, the energy supply to the actuators concerned shall be cut off.

5.2.6.5 Safety-related parts of control system

When interlocked guards are provided for the entry of the operator into the insulation boot or allow the

entrance although not intended by the manufacturer (predictable behaviour) the safety-related parts of

the control system that deal with the hazards inside the booth shall present at least a performance level

“d” in accordance with EN ISO 13849-1.

5.2.6.6 Automatic start warning

Where any form of automatic starting is provided, machines shall be equipped with a start-up warning

device, complying with EN ISO 7731, in order to alert people to leave the danger zone.

5.2.6.7 Interlocking devices

Interlocking devices shall:

— comply with EN ISO 14119, considering environment conditions inside the machine(i.e.

temperature, moisture) and cleaning procedures;

— comply with hygiene requirements of EN 1672-2 and Annex A of this standard;

— be resistant or protected from the action of cleaning and disinfection agents, oil and liquids.

5.2.6.8 Controls for maintenance operations

The design objective for all machines shall be that adjustments, maintenance, repair, cleaning and

servicing can be carried out while the machine is isolated from all power sources or from outside the

hazard zones as indicated in the information for use by the manufacturer.

If this objective cannot be achieved for technical reasons, a special operation mode which permits

potentially hazardous operations with open guards under reduced risk conditions shall be provided as

given by the manufacturer, i.e. the machine shall allow the introduction of an enabling device, which

oSIST prEN 13289:2016

prEN 13289:2015 (E)

permits the operator to override the control panel (see EN ISO 12100:2010, 6.2.11.9 and 6.2.11.10), and

to operate a specific moving part from a safe position, e.g. a portable control device that plugs into a

local control position. The local control shall be equipped with a hold-to-run control allowing low speed

or limited movements. The local control shall also be provided with an emergency stop device.

5.3 Electrical hazards

5.3.1 General

Unless stated otherwise, all electrical equipment associated with the machine shall comply with the

requirements of EN 60204-1:2006 as indicated in this clause.

5.3.2 Protection against electric shock

5.3.2.1 Direct contact

Live parts shall be located inside enclosures that provide protection against direct contact of at least

IP2X as defined in EN 60529. The opening of enclosure shall only be possible by using a key or tool, or

by disconnecting the live parts before opening the enclosure (see EN 60204-1:2006, 6.2.2, options a

and b).

5.3.2.2 Indirect contact

Protection against indirect contact due to insulation failure between live parts and exposed conductive

parts can be achieved by:

a) use of class-II-equipment or by equivalent insulation (see EN 60204-1:2006, 6.3.2); or

b) use of automatic disconnection of supply; this protective measure comprise both

(see EN 60204-1:2006, 6.3.3):

1) the co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...