SIST EN 13732:2022

(Main)Food processing machinery - Bulk milk coolers on farms - Requirements for performance, safety and hygiene

Food processing machinery - Bulk milk coolers on farms - Requirements for performance, safety and hygiene

1.1 This document specifies requirements for design, performance, safety and hygiene of refrigerated bulk milk coolers and the related methods of test.

NOTE The informative Annex K gives some elements regarding the estimation and calculation of energy consumption.

This document deals with all significant hazards, hazardous situations and events relevant to bulk milk coolers on farm, when they are installed, used and maintained as intended by the manufacturer (see informative Annex A).

It applies to refrigerated bulk milk tanks with air-cooled condensing units and automatic control intended for installation on farms or at milk collection points. It applies to tanks for two milkings (24 h), four milkings (48 h) and six milkings (72 h), in which the cooling takes place totally (non-pre-cooled milk) or partially (in case of pre-cooled milk) within the tank. It also applies to tanks in combination with a continuous system of milking (e.g. milking with robot).

1.2 This document does not cover:

- mobile tanks;

- tanks intended to be tilted for drainage;

- equipment for delivering the milk to the tank;

- equipment for pre-cooling of the milk;

- the hazards due to the use of other energy than electrical energy;

- pressure aspect of vacuum tanks (tank of which the inner vessel is designed to operate at a pressure below atmospheric pressure);

- calibration requirements for the measurement of the milk volume.

1.3 This document is not applicable to bulk milk coolers on farms which are manufactured before the date of its publication as EN.

Nahrungsmittelmaschinen - Behältermilchkühlanlagen für Milcherzeugerbetriebe - Anforderungen an Leistung, Sicherheit und Hygiene

µ1.1 Dieses Dokument legt die Anforderungen für die Konstruktion, Leistung, Sicherheit und Hygiene von Behälter Milchkühlanlagen und die damit verbundenen Prüfverfahren fest.

ANMERKUNG Der informative Anhang K enthält einige Elemente zur Schätzung und Berechnung der Energieaufnahme.

Dieses Dokument behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die auf Behälter Milchkühlanlagen für Milcherzeugerbetriebe zutreffen, wenn sie bestimmungsgemäß durch den Hersteller verwendet und gewartet werden (siehe informativer Anhang A).

Es ist anzuwenden für Behälter Milchkühlanlagen mit luftgekühlten Verflüssigersätzen und automatischer Steuerung, die für die Aufstellung in Milcherzeugerbetrieben oder in Milchsammelstellen bestimmt sind. Es ist anzuwenden für Kühltanks für zwei Gemelke (24 h), vier Gemelke (48 h) und sechs Gemelke (72 h), bei denen die Kühlung vollständig (nicht vorgekühlte Milch) oder teilweise (im Fall von vorgekühlter Milch) innerhalb des Kühltanks erfolgt. Es ist auch anzuwenden für Tanks in Verbindung mit einer kontinuierlichen Melkanlage (z. B. Melkautomat).

1.2 Dieses Dokument gilt nicht für:

— mobile Tanks;

— Tanks, die zur Entleerung gekippt werden;

— die Ausrüstung für die Befüllung des Tanks mit Milch;

— die Ausrüstung für das Vorkühlen der Milch;

— die Gefährdungen durch die Verwendung anderer Energie als Elektrizität;

— die Druckaspekte von Vakuumtanks (Tank, bei dem der Innenbehälter für den Betrieb bei einem Druck unter dem Atmosphärendruck ausgelegt ist);

— Kalibrieranforderungen für die Messung des Milchvolumens.

1.3 Dieses Dokument ist nicht anzuwenden für Behälter Milchkühlanlagen für Milcherzeugerbetriebe, die vor dem Datum seiner Veröffentlichung als EN hergestellt wurden.

Machines pour les produits alimentaires - Refroidisseurs de lait en vrac à la ferme - Prescriptions pour les performances, la sécurité et l'hygiène

1.1 Le présent document spécifie les prescriptions relatives à la conception, aux performances, à la sécurité et à l’hygiène des refroidisseurs de lait en vrac avec groupe frigorifique ainsi que les méthodes d’essai correspondantes.

NOTE L’Annexe K, informative, donne des éléments concernant l’estimation et le calcul de la consommation d’énergie.

Le présent document traite tous les phénomènes dangereux, situations dangereuses et événements dangereux significatifs spécifiques aux refroidisseurs de lait en vrac à la ferme, lorsqu’ils sont installés, utilisés et maintenus normalement par le constructeur (voir Annexe A informative).

Il s’applique aux refroidisseurs de lait en vrac avec groupe frigorifique refroidi par air et commande automatique, destinés à être installés dans des fermes ou dans des centres de ramassage du lait. Il s’applique aux refroidisseurs « deux traites » (24 h), « quatre traites » (48 h) et « six traites » (72 h), dans lesquels le refroidissement s’effectue entièrement (lait non prérefroidi) ou partiellement (lait prérefroidi) dans la cuve. Il s’applique également aux refroidisseurs associés à un système de traite en continu (par exemple, traite effectuée par un robot).

1.2 Le présent document ne couvre pas :

- les refroidisseurs mobiles ;

- les refroidisseurs prévus pour être basculés lors de la vidange ;

- l’équipement d’introduction du lait dans le refroidisseur ;

- l’équipement de prérefroidissement du lait ;

- les phénomènes dangereux engendrés par l’utilisation d’une énergie autre qu’électrique ;

- la question de la pression des refroidisseurs sous vide (c’est-à-dire, des refroidisseurs où la cuve intérieure est destinée à fonctionner à une pression inférieure à la pression atmosphérique) ;

- les prescriptions d’étalonnage pour le mesurage du volume de lait.

1.3 Le présent document ne s’applique pas aux refroidisseurs de lait en vrac à la ferme construits avant sa date de publication en tant que norme EN.

Stroji za predelavo hrane - Hladilniki za shranjevanje namolzenega mleka - Zahteve za zmogljivost, varnost in higieno

General Information

- Status

- Published

- Public Enquiry End Date

- 29-Nov-2019

- Publication Date

- 10-Nov-2022

- Technical Committee

- VSN - Safety of machinery

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 22-Jul-2022

- Due Date

- 26-Sep-2022

- Completion Date

- 11-Nov-2022

Relations

- Effective Date

- 13-Jul-2022

Overview

SIST EN 13732:2022 (EN 13732:2022) specifies requirements for the design, performance, safety and hygiene of refrigerated bulk milk coolers intended for use on farms and milk collection points. It applies to stationary refrigerated bulk milk tanks with air‑cooled condensing units and automatic control used to cool milk for two, four or six milkings (24 h, 48 h, 72 h) and to installations combined with continuous milking systems (e.g., milking robots). The standard replaces EN 13732:2013 and adds guidance on continuous milking and energy estimation (informative Annex K).

Key technical topics and requirements

The standard addresses the full lifecycle of bulk milk coolers - design, testing, installation, use and maintenance - and covers the significant hazards associated with these machines. Major technical topics include:

Safety and protective measures

- Mechanical hazards, guards and access

- Electrical safety requirements (references to EN 60204‑1 and EN 60335‑1)

- Thermal hazards and safe contact surfaces

- Noise limits and testing (Annex B, acoustic standards)

Hygiene and cleanability

- Cleanability tests and cleaning performance (Annex F)

- Mixing and sampling methods for milk testing (Annexes E, G)

- Stainless steel equivalence and corrosion evaluation (Annex I)

Performance and testing

- Cooling performance, thermal insulation and mixing tests (Annex E)

- Verification and test procedures for conformity

Energy and ergonomics

- Informative guidance for estimation/measurement of energy consumption (Annex K)

- Ergonomic considerations for operation and maintenance

Documentation and marking

- Information for use, instruction handbook, installation/maintenance instructions, warning signs and minimum marking

What the standard does not cover: mobile tanks, tanks tilted for drainage, milk delivery/pre‑cooling equipment, non‑electrical energy hazards, vacuum/pressure aspects of vacuum tanks, and calibration of milk volume measurement.

Practical applications - who uses this standard

SIST EN 13732:2022 is intended for:

- Manufacturers of farm bulk milk coolers (design and conformity)

- Test laboratories performing performance, hygiene and noise tests

- Farm managers, dairy cooperatives and milk collection points assessing equipment safety and hygiene

- Installers and maintenance providers for safe installation and servicing

- Regulators and market surveillance bodies for compliance with machine safety and hygiene rules

Compliance helps ensure milk quality, operator safety, reliable refrigeration performance and energy-aware operation.

Related standards (selected)

EN 13732 references several normative standards, including:

- EN 378 (refrigerating systems safety)

- EN 1672‑2 (food machinery hygiene)

- EN 60204‑1 / EN 60335‑1 (electrical safety)

- EN ISO 12100 (machine safety / risk assessment)

- EN 10088 (stainless steels) and various acoustic ISO/EN standards

Keywords: EN 13732:2022, SIST EN 13732, bulk milk coolers, farm milk tanks, milk refrigeration, hygiene and safety, cleanability tests, energy consumption.

Frequently Asked Questions

SIST EN 13732:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Food processing machinery - Bulk milk coolers on farms - Requirements for performance, safety and hygiene". This standard covers: 1.1 This document specifies requirements for design, performance, safety and hygiene of refrigerated bulk milk coolers and the related methods of test. NOTE The informative Annex K gives some elements regarding the estimation and calculation of energy consumption. This document deals with all significant hazards, hazardous situations and events relevant to bulk milk coolers on farm, when they are installed, used and maintained as intended by the manufacturer (see informative Annex A). It applies to refrigerated bulk milk tanks with air-cooled condensing units and automatic control intended for installation on farms or at milk collection points. It applies to tanks for two milkings (24 h), four milkings (48 h) and six milkings (72 h), in which the cooling takes place totally (non-pre-cooled milk) or partially (in case of pre-cooled milk) within the tank. It also applies to tanks in combination with a continuous system of milking (e.g. milking with robot). 1.2 This document does not cover: - mobile tanks; - tanks intended to be tilted for drainage; - equipment for delivering the milk to the tank; - equipment for pre-cooling of the milk; - the hazards due to the use of other energy than electrical energy; - pressure aspect of vacuum tanks (tank of which the inner vessel is designed to operate at a pressure below atmospheric pressure); - calibration requirements for the measurement of the milk volume. 1.3 This document is not applicable to bulk milk coolers on farms which are manufactured before the date of its publication as EN.

1.1 This document specifies requirements for design, performance, safety and hygiene of refrigerated bulk milk coolers and the related methods of test. NOTE The informative Annex K gives some elements regarding the estimation and calculation of energy consumption. This document deals with all significant hazards, hazardous situations and events relevant to bulk milk coolers on farm, when they are installed, used and maintained as intended by the manufacturer (see informative Annex A). It applies to refrigerated bulk milk tanks with air-cooled condensing units and automatic control intended for installation on farms or at milk collection points. It applies to tanks for two milkings (24 h), four milkings (48 h) and six milkings (72 h), in which the cooling takes place totally (non-pre-cooled milk) or partially (in case of pre-cooled milk) within the tank. It also applies to tanks in combination with a continuous system of milking (e.g. milking with robot). 1.2 This document does not cover: - mobile tanks; - tanks intended to be tilted for drainage; - equipment for delivering the milk to the tank; - equipment for pre-cooling of the milk; - the hazards due to the use of other energy than electrical energy; - pressure aspect of vacuum tanks (tank of which the inner vessel is designed to operate at a pressure below atmospheric pressure); - calibration requirements for the measurement of the milk volume. 1.3 This document is not applicable to bulk milk coolers on farms which are manufactured before the date of its publication as EN.

SIST EN 13732:2022 is classified under the following ICS (International Classification for Standards) categories: 65.040.10 - Livestock buildings, installations and equipment; 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13732:2022 has the following relationships with other standards: It is inter standard links to SIST EN 13732:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13732:2022 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13732:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2022

Nadomešča:

SIST EN 13732:2013

Stroji za predelavo hrane - Hladilniki za shranjevanje namolzenega mleka - Zahteve

za zmogljivost, varnost in higieno

Food processing machinery - Bulk milk coolers on farms - Requirements for

performance, safety and hygiene

Nahrungsmittelmaschinen - Behältermilchkühlanlagen für Milcherzeugerbetriebe -

Anforderungen an Leistung, Sicherheit und Hygiene

Machines pour les produits alimentaires - Refroidisseurs de lait en vrac à la ferme -

Prescriptions pour les performances, la sécurité et l'hygiène

Ta slovenski standard je istoveten z: EN 13732:2022

ICS:

65.040.10 Poslopja, naprave in oprema Livestock buildings,

za živino installations and equipment

67.260 Tovarne in oprema za živilsko Plants and equipment for the

industrijo food industry

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13732

EUROPEAN STANDARD

NORME EUROPÉENNE

July 2022

EUROPÄISCHE NORM

ICS 65.040.10; 67.260 Supersedes EN 13732:2013

English Version

Food processing machinery - Bulk milk coolers on farms -

Requirements for performance, safety and hygiene

Machines pour les produits alimentaires - Nahrungsmittelmaschinen - Behältermilchkühlanlagen

Refroidisseurs de lait en vrac à la ferme - Prescriptions für Milcherzeugerbetriebe - Anforderungen an

pour les performances, la sécurité et l'hygiène Leistung, Sicherheit und Hygiene

This European Standard was approved by CEN on 10 January 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13732:2022 E

worldwide for CEN national Members.

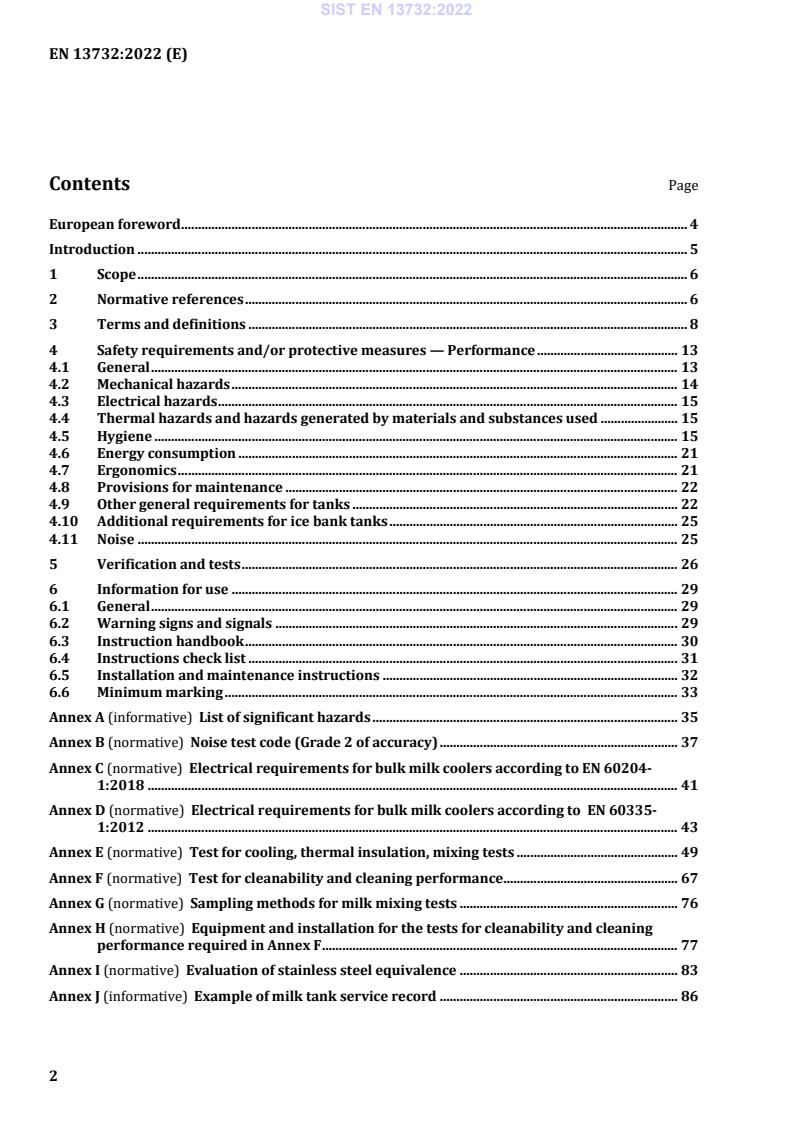

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 8

4 Safety requirements and/or protective measures — Performance . 13

4.1 General . 13

4.2 Mechanical hazards . 14

4.3 Electrical hazards . 15

4.4 Thermal hazards and hazards generated by materials and substances used . 15

4.5 Hygiene . 15

4.6 Energy consumption . 21

4.7 Ergonomics . 21

4.8 Provisions for maintenance . 22

4.9 Other general requirements for tanks . 22

4.10 Additional requirements for ice bank tanks . 25

4.11 Noise . 25

5 Verification and tests . 26

6 Information for use . 29

6.1 General . 29

6.2 Warning signs and signals . 29

6.3 Instruction handbook . 30

6.4 Instructions check list . 31

6.5 Installation and maintenance instructions . 32

6.6 Minimum marking . 33

Annex A (informative) List of significant hazards . 35

Annex B (normative) Noise test code (Grade 2 of accuracy) . 37

Annex C (normative) Electrical requirements for bulk milk coolers according to EN 60204-

1:2018 . 41

Annex D (normative) Electrical requirements for bulk milk coolers according to EN 60335-

1:2012 . 43

Annex E (normative) Test for cooling, thermal insulation, mixing tests . 49

Annex F (normative) Test for cleanability and cleaning performance . 67

Annex G (normative) Sampling methods for milk mixing tests . 76

Annex H (normative) Equipment and installation for the tests for cleanability and cleaning

performance required in Annex F . 77

Annex I (normative) Evaluation of stainless steel equivalence . 83

Annex J (informative) Example of milk tank service record . 86

Annex K (informative) Estimation and measurement of the energy consumption . 88

Annex L (informative) Safe access and rescue . 93

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 95

Bibliography . 97

European foreword

This document (EN 13732:2022) has been prepared by Technical Committee CEN/TC 153 “Machinery

intended for use with foodstuffs and feed”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2023, and conflicting national standards shall

be withdrawn at the latest by July 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 13732:2013.

In comparison with the previous edition, the following changes have been made:

a) addition of continuous system of milking in the scope;

b) updating of normative references;

c) specification of stainless steel equivalence;

d) new informative annex regarding estimation and measurement of energy consumption;

e) technical and editorial modifications.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part

of this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document is a type-C standard as stated in EN ISO 12100:2010.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document. The machinery concerned and the extent to which hazards, hazardous

situations or hazardous events are covered are indicated in the Scope of this document.

When requirements of this type-C standard are different from those which are stated in type-A or type-B

standards, the requirements of this type-C standard take precedence over the requirements of the other

standards for machines that have been designed and built according to the requirements of this type-C

standard.

1 Scope

1.1 This document specifies requirements for design, performance, safety and hygiene of refrigerated

bulk milk coolers and the related methods of test.

NOTE The informative Annex K gives some elements regarding the estimation and calculation of energy

consumption.

This document deals with all significant hazards, hazardous situations and events relevant to bulk milk

coolers on farm, when they are installed, used and maintained as intended by the manufacturer (see

informative Annex A).

It applies to refrigerated bulk milk tanks with air-cooled condensing units and automatic control intended

for installation on farms or at milk collection points. It applies to tanks for two milkings (24 h), four

milkings (48 h) and six milkings (72 h), in which the cooling takes place totally (non-pre-cooled milk) or

partially (in case of pre-cooled milk) within the tank. It also applies to tanks in combination with a

continuous system of milking (e.g. milking with robot).

1.2 This document does not cover:

— mobile tanks;

— tanks intended to be tilted for drainage;

— equipment for delivering the milk to the tank;

— equipment for pre-cooling of the milk;

— the hazards due to the use of other energy than electrical energy;

— pressure aspect of vacuum tanks (tank of which the inner vessel is designed to operate at a pressure

below atmospheric pressure);

— calibration requirements for the measurement of the milk volume.

1.3 This document is not applicable to bulk milk coolers on farms which are manufactured before the

date of its publication as EN.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 378-1:2016+A1:2020, Refrigerating systems and heat pumps — Safety and environmental

requirements — Part 1: Basic requirements, definitions, classification and selection criteria

EN 378-2:2016, Refrigerating systems and heat pumps — Safety and environmental requirements —

Part 2: Design, construction, testing, marking and documentation

EN 378-3:2016+A1:2020, Refrigerating systems and heat pumps — Safety and environmental

requirements — Part 3: Installation site and personal protection

EN 378-4:2016+A1:2019, Refrigerating systems and heat pumps — Safety and environmental

requirements — Part 4: Operation, maintenance, repair and recovery

EN 1005-3:2002+A1:2008, Safety of machinery — Human physical performance — Part 3: Recommended

force limits for machinery operation

EN 1672-2:2020, Food processing machinery — Basic concepts — Part 2: Hygiene and cleanability

requirements

EN 10088-2:2014, Stainless steels — Part 2: Technical delivery conditions for sheet/plate and strip of

corrosion resisting steels for general purposes

EN 60204-1:2018, Safety of machinery — Electrical equipment of machines — Part 1: General requirements

1)

EN 60335-1:2012 , Household and similar electrical appliances — Safety — Part 1: General requirements

EN 60335-2-34:2013, Household and similar electrical appliances — Safety — Part 2-34: Particular

requirements for motor-compressors

2)

, Degrees of protection provided by enclosures (IP Code)

EN 60529:1991

EN 61310-1:2008, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for

visual, acoustic and tactile signals

EN ISO 1211:2010, Milk — Determination of fat content — Gravimetric method (Reference method)

(ISO 1211:2010)

EN ISO 3651-2:1998, Determination of resistance to intergranular corrosion of stainless steels — Part 2:

Ferritic, austenitic and ferritic-austenitic (duplex) stainless steels — Corrosion test in media containing

sulfuric acid (ISO 3651-2:1998)

EN ISO 3744:2010, Acoustics — Determination of sound power levels and sound energy levels of noise

sources using sound pressure — Engineering methods for an essentially free field over a reflecting plane

(ISO 3744:2010)

EN ISO 4871:2009, Acoustics — Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 11201:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a work station and at other specified positions in an essentially free field over a

reflecting plane with negligible environmental corrections (ISO 11201:2010)

3)

EN ISO 11202:2010 , Acoustics — Noise emitted by machinery and equipment — Determination of

emission sound pressure levels at a work station and at other specified positions applying approximate

environmental corrections (ISO 11202:2010)

1)

As impacted by EN 60335-1:2012/AC:2014, EN 60335-1:2012/A11:2014, EN 60335-1:2012/A13:2017,

EN 60335-1:2012/A1:2019, EN 60335-1:2012/A2:2019 EN 60335-1:2012/A14:2019 and EN 60335-

1:2012/A15:2021.

2)

As impacted by EN 60529:1991/A1:2000, EN 60529:1991/A2:2013 and EN 60529:1991/AC:2016-12.

3)

As impacted by EN ISO 11202:2010/A1:2021.

EN ISO 11463:2020, Corrosion of metals and alloys — Guidelines for the evaluation of pitting corrosion

(ISO 11463:2020)

EN ISO 11688-1:2009, Acoustics — Recommended practice for the design of low-noise machinery and

equipment — Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13732-1:2008, Ergonomics of the thermal environment — Methods for the assessment of human

responses to contact with surfaces — Part 1: Hot surfaces (ISO 13732-1:2006)

EN ISO 13849-1:2015, Safety of machinery — Safety-related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13857:2019, Safety of machinery — Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2019)

EN ISO 14119:2013, Safety of machinery — Interlocking devices associated with guards — Principles for

design and selection (ISO 14119:2013)

EN ISO 14120:2015, Safety of machinery — Guards — General requirements for the design and

construction of fixed and movable guards (ISO 14120:2015)

EN ISO 14122-2:2016, Safety of machinery — Permanent means of access to machinery — Part 2: Working

platforms and walkways (ISO 14122-2:2016)

EN ISO 14122-3:2016, Safety of machinery — Permanent means of access to machinery — Part 3: Stairs,

stepladders and guard-rails (ISO 14122-3:2016)

EN ISO 21920-3:2022, Geometrical product specifications (GPS) — Surface texture: Profile — Part 3:

Specification operators (ISO 21920-3:2021)

ASTM G48-11:2015, Standard test methods for pitting and crevice corrosion resistance of stainless steels

and related alloys by use of ferric chloride solution

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010,

EN 1672-2:2020 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

refrigerated bulk milk tank

equipment for refrigeration and bulk storage of refrigerated raw milk freshly milked

Note 1 to entry: In the following text, "refrigerated bulk milk tank" is referred as "tank".

Note 2 to entry: Milk freshly milked is milk less than 2 h after being milked.

3.2

silo tank

vertical closed tank designed to be standing on a flat horizontal surface

Note 1 to entry: See Figure 1.

Figure 1 — Examples of silo tank

3.3

open tank

tank equipped with a lid which in the open position allows manual washing of the inner vessel

Note 1 to entry: See Figure 2.

Figure 2 — Example of open tank

3.4

closed tank

horizontal tank equipped with automatic washing of the inner vessel and manhole with a cover for

inspection

Note 1 to entry: Access through the manhole is only for maintenance.

Note 2 to entry: See Figure 3.

Figure 3 — Example of closed tank

3.5

pre-cooled milk

milk partially or completely cooled to storage temperature before entering the tank

3.6

automatic control

arrangement by which the equipment functions under normal operating conditions, without requiring

action by the operator

3.7

agitator

device to mix the milk to promote heat transfer and to ensure uniform distribution of butter fat

3.8

reference position

position specified by the manufacturer for correct installation and operation of the tank

3.9

maximum volume

V

m

volume to which the inner vessel in its reference position and without agitation may be filled without

overflowing (expressed in l)

3.10

rated volume

V

r

volume of the maximum permissible filling of the tank under operating conditions as stated by the

manufacturer (expressed in l)

3.11

direct cooling system

cooling system in which the evaporator of the refrigerating system is in direct thermal contact with the

milk or the inner vessel

3.12

indirect cooling system

cooling system in which the evaporator of the refrigerating system is not in direct thermal contact with

the milk or the inner vessel and the heat is transferred from the milk to the refrigerant through a cooling

medium

3.13

batch filling tank

tank intended to be filled by a number of milkings

3.14

ice bank tank

tank with an indirect integrated cooling system in which the cooling medium is water and in which ice is

built on the evaporator

3.15

milking

batch of milk (or test water) which is added to the tank and cooled in a specific cooling time

3.16

tank for two milkings

tank intended for cooling and storing milk where the milk is added in two batches, each with a volume

equal to 50 % of the tank rated volume

3.17

tank for four milkings

tank intended for cooling and storing milk where the milk is added in four batches, each with a volume

equal to 25 % of the tank rated volume

3.18

tank for six milkings

tank intended for cooling and storing milk where the milk is added in six batches each, with a volume

equal to 16,7 % of the tank rated volume

3.19

operating conditions

state during which the tank is in use for the cooling and storage of milk in accordance with its design

requirements and all accessories are functioning effectively

3.20

ambient atmosphere

atmosphere surrounding the tank and in front of the air-cooled condenser of the refrigerating system

3.21

mean temperature

calculated average of the different temperatures (in °C) of a medium (air, test water, milk) measured at

different measuring points, at the same time

3.22

ambient temperature

mean temperature of the ambient atmosphere (in °C)

3.23

performance temperature

PT

ambient temperature (in °C) to be used when measuring the milk cooling time

3.24

safe operating temperature

SOT

highest limit of the range of ambient temperatures (in °C) at which the equipment is required to function

3.25

initial temperature

IT

mean temperature (in °C) of the milk to be cooled at the time of the commencement of the cooling test

3.26

storage temperature

mean temperature (in °C) to which the milk to be cooled is reduced for storage

3.27

cooling time

time (in h) required to cool a milking from initial temperature to +4 °C

3.28

cooling cycle

period between two successive milk collections

3.29

specific energy consumption

energy consumption in watt-hours per litre (Wh/l) of cooled milk, measured as the mean consumption

of all components (excluding cleaning) during a cooling test under the test conditions appropriate to the

performance class

Note 1 to entry: The specific energy consumption may be also estimated as indicated in the informative Annex K.

3.30

milk

bovine mammary secretion without either addition thereto or extraction therefrom, untreated and not

standardised, complying with Code of Principles concerning milk and milk products, international

standards and standard methods of sampling and analysis for milk products of the Joint FAO/WHO Food

Standards Programme

Note 1 to entry: Food and Agriculture Organisation (FAO)/ World Health Organisation (WHO).

3.31

water

water, suitable for human consumption, meeting the requirements specified in Directive 98/83/EC

relating to the quality of water intended for human consumption

3.32

test water

TW

water used for test purpose in place of milk

Note 1 to entry: The cooling time for water is nearly the same as that for milk.

3.33

filling

volume of the milk (or TW) in the tank

3.34

temperature of the milk

mean temperature of the milk (or TW) at a particular moment

Note 1 to entry: See E.1.5.

3.35

compact and plug-in tank

tank where the condensing unit(s) is (are) mounted on the tank and the equipment which leave(s) the

manufacturer and which does not require further refrigerant and installation work to be in full working

condition

3.36

tank for continuous flow

tank designed for cooling milk when added continuously at a rate of x l/h where x is expressed in steps

of 25 l/h

3.37

minimum and maximum flow

minimum and maximum average milk flow rates (expressed in l/h) at which a tank for continuous flow

is designed to operate

3.38

minimum cooling volume

minimum quantity or flow rate at which the tank may operate without formation of ice:

— two milkings tanks: V × 0,2;

r

— four milkings tanks: V × 0,1;

r

— six milkings tanks: V × 0,067;

r

— continuous flow tank: according to the minimum flow given by the manufacturer

4 Safety requirements and/or protective measures — Performance

4.1 General

Machinery shall comply with the safety requirements and/or protective measures of this clause.

In addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for hazards

relevant but not significant, and for hazards arising under the conditions of misuse which are reasonably

foreseeable and which are not dealt with by this document.

4.2 Mechanical hazards

4.2.1 Lids and covers

4.2.1.1 Lids / open tanks

For open tanks, the open and closed positions of the lid shall be stable. The opening and closing

operations shall require an intentional action.

Hinged lids of open tanks shall have a means to keep them in the open position (e.g. spring, hook, bracket,

etc.) or the centre of gravity of the lid shall be at least 15° over the balancing position.

4.2.1.2 Covers / closed tank

For closed tanks having one or more manholes, the locking of the cover of this manhole(s) in the closed

position shall require an intentional action. Furthermore, it shall be clearly and visibly marked, adjacent

to the manhole(s), that (see also 6.2 and 6.3):

— before the closing of the cover, it shall be checked that nobody is in the vessel;

— before entering the tank, it shall be necessary to read the instruction handbook.

For closed tanks, each opening greater than 240 mm (maximum diameter in the case of a circular or

maximum axis in case of an elliptical opening, side length in the case of a square), and which is located

more than 1,35 m above the inner floor shall be provided with a fixed guard requiring a tool to enable

access or shall be fitted with an interlocking device to stop agitation and cleaning functions of the tank. If

a fixed guard is used, it shall comply with EN ISO 14120:2015.

For reasons of hygiene and safety, the design and instruction for use shall avoid the need to enter the tank

in normal operation.

4.2.2 Agitators

Access to agitator attached to the lid of open tanks shall be safeguarded by interlocking the lid with the

agitator movement in accordance with EN ISO 14119:2013. When opening the lid, the agitator shall stop

within 2 s. The safety-related parts of the control system shall comply at least with the appropriate

performance level determined in accordance with EN ISO 13849-1:2015.

For agitators not attached to the lid (closed tanks, see dimensions in 4.2.1.2), a warning sign close to the

manhole(s) or inspection opening(s) shall warn of the possible automatic start of the agitator (see also

Clause 6). The touching with the rotating agitators blade through the manhole shall be avoided and safety

distances shall be applied according to EN ISO 13857:2019.

4.2.3 Refrigerating system

The refrigerating system shall comply with EN 378-1:2016+A1:2020 and EN 378-2:2016.

4.2.4 Stability

Tanks shall be stable independent of the level of filling. If not stable by itself the manufacturer shall define

the fixing mode.

Tanks with a mass of 75 kg or more when empty shall be so constructed that under normal operating

conditions, it shall not tilt when subjected to an external horizontal force of 750 N applied in any direction

at highest point of the outer shell, according to the test method given in Clause 5.

If the tank is equipped with a step or a platform, it shall not tilt when subjected to an external vertical

force of 1200 N applied on this step or platform.

4.3 Electrical hazards

The electrical equipment shall comply with:

— either EN 60204-1:2018 and the specific requirements stated in Annex C; or

1)

— EN 60335-1:2012 , with the specific requirements stated in Annex D.

4.4 Thermal hazards and hazards generated by materials and substances used

The design of automatic cleaning equipment shall ensure that no cleaning products and hot water may

be splashed or sprayed against an operator either during “pick up” of concentrated product or during the

cleaning cycle (e.g. hoses tightened (e.g. spanner) or tubing fastened (clips), shields over product

dispensing units).

An audio or visual signal (see 6.2) shall indicate that the automatic cleaning is in progress (including

pauses and delays).

The temperature of the touchable outside walls shall conform to EN ISO 13732-1:2008, 4.2.1, for a time

of contact of 1 s.

Safety sign(s) shall warn about the remaining hazards, and the instruction handbook shall give advice on

the use of proper protective wear (see 6.2/6.3).

The safety signals, visual and audio, shall comply with EN 61310-1:2008.

4.5 Hygiene

4.5.1 Adequate cooling and safe storage of milk

4.5.1.1 Control of the cooling system

The cooling of the first milking shall be started either manually or automatically. Then the control

equipment shall ensure that cooling starts automatically after commencing to add the second and

following milkings.

The equipment for the control of the milk temperature shall operate satisfactorily (see 4.5.1.2.3 and

4.5.1.2.5) with any volume of milk between the minimum cooling volume and 100 % of the rated volume

of the tank at any milk temperature from 0 °C to +35 °C and at any ambient temperature between +5 °C

and the Safe Operating Temperature (SOT). This requirement shall include the filling with high volumes

during a short time period (conventional milking: batch filling) and with small amounts of milk

throughout the day (tanks for continous flow as used with automatic milking systems).

On a direct cooling system the agitator shall operate whenever the condensing unit of the refrigerating

systems is operating.

On an indirect cooling system the agitator shall operate whenever the cooling medium circulation is

operating.

4.5.1.2 Cooling and agitation performances

4.5.1.2.1 Performance classes

4.5.1.2.1.1 General

The performance classes of a tank shall be specified according to 4.5.1.2.1.2 to 4.5.1.2.1.6.

4.5.1.2.1.2 Classification according to number of milkings

The numeral “2” shall designate a tank for two milkings.

The numeral “4” shall designate a tank for four milkings.

The numeral “6” shall designate a tank for six milkings.

The figure “F” shall designate a tank designed to operate in continuous flow.

4.5.1.2.1.3 Classification according to ambient temperature

Classification shall be according to Table 1.

Table 1 — Classification according to ambient temperature

Energy

Performance Safe operating consumption

temperature (PT) temperature (SOT) temperature

Classification

(ECT)

°C °C

°C

A 38 43 20

B 32 38 15

C 25 32 10

4.5.1.2.1.4 Classification according to milk cooling time

Classification for batch filling and continuous flow shall be according to Table 2.

Table 2 — Classification according to milk cooling time

For batch filling For continuous flow

T T T

1 5 6

Specified cooling time for Specified cooling Specified cooling

Classification

all milkings from +35 °C or time from +35 °C or P time from +35 °C or P

P XX °C to +4 °C XX °C to 10 °C XX °C to 4 °C

h h h

0 2 / 1

I 2,5 1 3

II 3 2 5

III 3,5 3 7

Classification for continuous flow shall be:

F with the addition of the ambient temperature classification and the flow rate of milk

EXAMPLE F 100-200 B II

where

F = Flow

100 = minimum flow (l/h)

200 = maximum flow (l/h)

B = Ambient class temperature

II = cooling time

4.5.1.2.1.5 Classification according to milk inlet temperature

Addition of “P” in case of pre-cooled milk at P XX °C.

XX: Pre-cool temperature defined by the manufacturer

See 4.5.1.2.1.6 for examples.

4.5.1.2.1.6 Examples of performance class marking

In case of non-pre-cooled milk: 4 B ll

In case of milk pre-cooled to 18 °C: 4 B ll P18

In case of continuous flow milk pre-cooled to 18 °C: F 100-200 B II P18

In case of continuous flow milk pre-cooled completely to 4 °C: F 100-200 B II P4

4.5.1.2.2 Milk cooling rate

When a tank for two milkings is either empty or contains 50 % of its rated volume of milk at +4 °C, and

50 % of the rated volume of milk at +35 °C or P XX °C (in case of pre-cooled milk) is added in one batch,

all of the milk shall be cooled to +4 °C in not more than the specified cooling time (see Table 2).

When a tank for four milkings is either empty or contains 25 %, 50 % or 75 % of the rated volume of milk

at +4 °C, and 25 % of the rated volume of milk at +35 °C or P XX °C (in case of pre-cooled milk) is added

in one batch, all of the milk shall be cooled to +4 °C in not more than the specified cooling time (see

Table 2).

When a tank for six milkings is either empty or contains 16,7 %, 33,3 %, 50 %, 66,7 % or 83,3 % of its

rated volume of milk at +4 °C and 16,7 % of the rated volume of milk at +35 °C or P XX °C (in case of pre-

cooled milk) is added in one batch, all of the milk shall be cooled to +4 °C in not more than the specified

cooling time (see Table 2).

When a tank for continuous flow has milk added at a flow rate greater than or equal to its rated minimum

rated flow, but less than or equal to its maximum rated flow, all of the milk shall be cooled from initial

temperature to +10 °C and then to +4 °C in not more than the specified cooling time (see Table 2).

The above requirements shall apply at ambient temperatures between +5 °C and the performance

temperature (PT).

4.5.1.2.3 Storage of the milk

Under normal operating conditions the storage temperature of the milk, between cooling periods shall

be not higher than +4 °C. This requirement shall apply at ambient temperatures between +5 °C and the

PT.

4.5.1.2.4 Thermal insulation

The tank shall be provided with thermal insulation the efficiency of which shall be such that at the PT the

rate of rise of the mean temperature of the milk, initially at +4 °C, shall not exceed +3 °C in 12 h when the

rated volume is allowed to stand undisturbed, without agitation nor refrigeration.

4.5.1.2.5 Freezing of the milk

Ice shall not form in the milk under the milk surface during either cooling or storage when the tank is

used in ambient temperature between +5 °C and the PT and,

a) in the case of a batch filling tank, the tank is filled with milk to a volume value of:

1) for two milking tanks: between 20 % and 100 % of its rated volume;

2) for four milking tanks: between 10 % and 100 % of its rated volume;

3) for six milking tanks: between 6,7 % and 100 % of its rated volume.

b) or in the case of a tank for continuous flow, when milk is added at a rate between the minimum flow

and maximum flow rate.

4.5.1.2.6 Agitation of the milk

Operating of the agitator shall not cause milk to overflow when the tank contains any volume of milk up

to 100 % of its rated volume.

The agitator shall be capable of producing a uniform distribution of the fat throughout the milk, so that

the fat content of samples, randomly selected from the tank, does not differ by more than 0,1 g of fat per

100 g of milk.

This requirement shall be achieved by operating the agitator for not more than 2 min, when the tank

contains any volume of milk between 10 % and 100 % of its rated volume at +4 °C and after allowing to

stand unagitated for 1 h.

For tanks utilising a continuous agitation system, this requirement shall be achieved by operating the

agitator for not more than 10 min.

These requirements shall be achieved without the formation of froth or butter.

The milk used for these agitation tests shall be bulk raw whole milk with fat content of 4 g ± 0,5 g per

100 g of milk at a temperature of +4 °C ± 1 °C.

4.5.1.2.7 Safe operating temperature

The tank shall be capable of cooling any milking or continuous flow as detailed in 4.5.1.2.2, under

automatic control without time limit, when the equipment is operated at the specified SOT.

However, the cooling time of the first milking of the batch filling tank shall not exceed the specified cooling

time as given in Table 2 by more than 25 %.

4.5.2 Prevention of milk contamination

4.5.2.1 General

4.5.2.1.1 The design and construction of tanks shall comply with the requirements of EN 1672-2:2020

and the following.

4.5.2.1.2 The following parts shall be considered to be in the food area as defined in EN 1672-2:2020:

— inside surfaces of the inner vessel;

— outside surfaces of components inside the inner vessel;

— the inner part of the lid(s),

— the inner part of the outlet including valve and connections.

The manufacturer shall define adequate solutions for cleaning and disinfection (see Clause 6 and for

automatic cleaning Annex F).

4.5.2.1.3 The following parts shall be considered to be in the splash area as defined in EN 1672-2:2020:

— the outside parts of the equipment at the proximity of manholes;

— and other openings where splashing may occur.

The inner parts of the cleaning circuit shall comply with the requirements for splash areas.

4.5.2.1.4 Materials in contact with cleaning water and chemicals shall be resistant to cleaning and

disinfecting agents in normal conditions of dosage and temperature so that they shall not impart a taint

to milk.

4.5.2.2 Inner vessel

Any bridge or bracket required to be supported from the top of the inner vessel shall be welded to it and

provided with upturned edges not less than 10 mm high. The bridge or bracket shall be designed in such

a way that liquid is drained away from the inner vessel.

All joints shall be welded and shall have a surface finish, strength and corrosion resistance not less than

as specified hereafter.

Inner vessel and all attachments which are in or may come into contact with milk shall:

— be manufactured from austenitic stainless steel or from a material complying with relevant European

specifications (see Bibliography);

— have a surface roughness R ≤ 1 µm where R is as defined in EN ISO 21920-3:2022;

a a

— use a grade of steel which quality shall be at least equivalent to that of stainless steel X5CrNi18-10

(1.4301), as defined in EN 10088-2:2014, especially with regard to resistance to corrosion. Annex I

shall be used to verify the equivalence of stainless steel.

All inside corners of the inner vessel shall have radii R not less than 20 mm (see Figure 4) unless the angle

α > 135 ° (2,36 rad). All other corners in the inner vessel shall have radii not less than 3 mm.

Key

R radius

α angle

Figure 4 — Inside corners

Every component which is permanently attached within the inner vessel shall be welded to it. The welds

shall have radii not less than 3 mm and the angles shall be not less than 90° (1,57 rad). All components

which are not practical to be welded to the inner vessel shall be fastened so that they may be easily

removed for cleaning.

4.5.2.3 Openings and lids in connection with the inner vessel

a) Each opening on the horizontal surface shall have upturned edges not less than 10 mm high.

b) Each opening shall be provided with a lid which overlaps the opening and has adequate downturned

edges not less than 5 mm high to protect the milk from contamination (see Figure 5).

Dimensions in millimetres

Key

1 lid

2 opening

Figure 5 — Opening

c) On tanks to be cleaned manually the openings and lids shall be so constructed that all internal parts

of the inner vessel may be cleaned safely from outside, whenstanding next to the tank.

d) Openings and lids shall have all inside corners constructed to provide internal radii of not less than

3 mm.

e) Any aperture in a lid or in a bridge which forms part of a tank lid assembly shall also be provided

with a cover. All apertures and covers shall comply with above requirements with regard to upturns,

downturns and radii.

f) Lids and covers over openings and apertures shall provide the inner vessel with a degree of

protection against the ingress of foreign solid parts and water not less than IP 43 as detailed in

2)

EN 60529:1991 .

4.5.2.4 Thermometers

Glass thermometers and thermometers with mercury shall not be used.

4.5.2.5 Agitators

The agitation device shall be so designed and constructed that:

a) shaft seals shall be provided against any contamination of the milk which may enter the inner vessel

from outside;

b) material and surface roughness in the food area shall comply with 4.5.2.2;

c) corners in the food area shall have angles not less than 1,57 rad (90°), welds and corners shall have

radii not less than 3 mm;

d) the lowest point of any coupling of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...