SIST EN 12355:2022

(Main)Food processing machinery - Derinding-, skinning- and membrane removal machines - Safety and hygiene requirements

Food processing machinery - Derinding-, skinning- and membrane removal machines - Safety and hygiene requirements

This document deals with all significant hazards, hazardous situations or hazardous events relevant to derinding, skinning and membrane removal machines, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex D).

This document deals with the hazards which can arise during all the lifetime of the machinery (see EN ISO 12100:2010, 5.4).

This document is not applicable to derinding, skinning, and membrane removal machines for domestic purposes, hand-guided machines and table-top machines.

This document is not applicable to fish heading and filleting machines as described in EN 15467:2014.

This document is not applicable to derinding, skinning and membrane removal machines manufactured before the date of its publication.

Nahrungsmittelmaschinen - Entschwartungs-, Enthäutungs- und Entvliesmaschinen - Sicherheits- und Hygieneanforderungen

Dieses Dokument behandelt alle signifikanten Gefährdungen, Gefährdungssituationen oder Gefährdungsereignisse, die auf Entschwartungs-, Enthäutungs- und Entvliesmaschinen zutreffen, wenn sie bestimmungsgemäß und unter Bedingungen von durch den Hersteller vernünftigerweise vorhersehbaren Fehlanwendungen verwendet werden (siehe Anhang D).

Dieses Dokument behandelt die Gefährdungen, die während der gesamten Lebensdauer der Maschinen auftreten können (siehe EN ISO 12100:2010, 5.4).

Dieses Dokument gilt nicht für Entschwartungs-, Enthäutungs- und Entvliesmaschinen für den Hausgebrauch sowie handgeführte und Tischmaschinen.

Dieses Dokument gilt nicht für Fischköpf- und -filetiermaschinen wie in EN 15467:2014 beschrieben.

Dieses Dokument gilt nicht für Entschwartungs-, Enthäutungs- und Entvliesmaschinen, die vor dem Veröffentlichungsdatum dieses Dokuments hergestellt wurden.

Machines pour les produits alimentaires - Machines à découenner, éplucher et peler - Prescriptions relatives à la sécurité et à l'hygiène

Le présent document traite de tous les phénomènes dangereux, situations dangereuses ou événements dangereux spécifiques aux machines à découenner, éplucher et peler, lorsqu’elles sont utilisées normalement ou dans des conditions de mauvaise utilisation raisonnablement prévisible par le fabricant.

Le présent document traite des phénomènes dangereux susceptibles de se produire tout au long de la durée de la vie de la machine (voir l’EN ISO 12100:2010, 5.4).

Le présent document ne s'applique pas aux machines à découenner, éplucher et peler à usage domestique, aux machines guidées à main et aux machines de table.

Le présent document ne s'applique pas aux machines à étêter le poisson et aux machines à lever des filets telles que décrites dans l’EN15647:2014.

Le présent document ne s’applique pas aux machines à découenner, éplucher et peler fabriquées avant la date de sa publication.

Stroji za predelavo hrane - Stroji za odstranjevanje kože - Varnostne in higienske zahteve

General Information

- Status

- Published

- Public Enquiry End Date

- 26-Jan-2020

- Publication Date

- 10-Nov-2022

- Technical Committee

- VSN - Safety of machinery

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 03-Aug-2022

- Due Date

- 08-Oct-2022

- Completion Date

- 11-Nov-2022

Relations

- Effective Date

- 03-Aug-2022

Overview

EN 12355:2022 - issued by CEN - is the European type‑C standard that specifies safety and hygiene requirements for derinding, skinning and membrane removal machines used in food processing. It covers all significant hazards and hazardous events throughout the machine lifecycle (design, manufacturing, installation, operation, cleaning, maintenance), when used as intended and under reasonably foreseeable misuse. The standard supersedes EN 12355:2003+A1:2010 and was approved in July 2022.

Key scope notes:

- Applies to industrial derinding, skinning and membrane removal machines (not domestic, hand‑guided or table‑top machines).

- Excludes fish heading and filleting machines (see EN 15467:2014).

- Not applicable to machines manufactured before the publication date.

Key Topics and Requirements

EN 12355:2022 structures safety and hygiene content into clear technical topics and prescriptive measures, including:

- Risk assessment and design - Alignment with EN ISO 12100:2010 for risk assessment and mitigation.

- Mechanical hazards - Requirements for cutting devices, blade rollers, transport and tooth rollers, guards, interlocks and safe distances.

- Electrical safety - Conformance to EN 60204‑1 for electrical equipment of machines.

- Safety‑related control systems - Reference to EN ISO 13849‑1 for performance levels and control principles.

- Electromagnetic compatibility (EMC) - Measures to prevent functional hazards from EMC issues.

- Stability, noise and ergonomics - Requirements for loss of stability prevention, noise testing (Annex A), and human factors (EN 614‑1, EN 1005 series).

- Hygiene and cleanability - Design principles to ensure cleanability and food‑safe construction (detailed in Annex B and linked to EN 1672‑2).

- Verification and information for use - Tests, validation, marking and instruction handbook content necessary for safe operation and CE conformity.

- Annexes - Annex A (noise test code), Annex B (cleanability design principles), Annex C (performance level summary), Annex D (list of significant hazards), Annex ZA (relationship with Directive 2006/42/EC).

Practical Applications and Users

EN 12355:2022 is essential for:

- Machine manufacturers designing and building industrial derinding/skinning equipment to meet EU safety and hygiene expectations and support CE marking.

- Food processors and plant engineers selecting equipment, validating cleaning regimes, and setting safe operating procedures.

- Safety officers, maintenance teams and integrators who perform risk assessments, install guards/interlocks, and maintain hygiene standards.

- Regulators and market surveillance bodies assessing conformity with machinery safety and hygiene requirements.

Using this standard helps reduce injury risk, improve cleanability and food safety, support regulatory compliance, and document verification for audits.

Related Standards

Notable normative references integrated into EN 12355:2022:

- EN ISO 12100 (risk assessment)

- EN ISO 13849‑1 (control system performance)

- EN 60204‑1 (electrical safety)

- EN 1672‑2 (hygiene and cleanability)

- EN ISO 11201 / 3744 / 3746 / 4871 (noise measurement)

For full technical requirements and prescriptive clauses, consult the official EN 12355:2022 text through your national standards body or the CEN webshop.

Frequently Asked Questions

SIST EN 12355:2022 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Food processing machinery - Derinding-, skinning- and membrane removal machines - Safety and hygiene requirements". This standard covers: This document deals with all significant hazards, hazardous situations or hazardous events relevant to derinding, skinning and membrane removal machines, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex D). This document deals with the hazards which can arise during all the lifetime of the machinery (see EN ISO 12100:2010, 5.4). This document is not applicable to derinding, skinning, and membrane removal machines for domestic purposes, hand-guided machines and table-top machines. This document is not applicable to fish heading and filleting machines as described in EN 15467:2014. This document is not applicable to derinding, skinning and membrane removal machines manufactured before the date of its publication.

This document deals with all significant hazards, hazardous situations or hazardous events relevant to derinding, skinning and membrane removal machines, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex D). This document deals with the hazards which can arise during all the lifetime of the machinery (see EN ISO 12100:2010, 5.4). This document is not applicable to derinding, skinning, and membrane removal machines for domestic purposes, hand-guided machines and table-top machines. This document is not applicable to fish heading and filleting machines as described in EN 15467:2014. This document is not applicable to derinding, skinning and membrane removal machines manufactured before the date of its publication.

SIST EN 12355:2022 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 12355:2022 has the following relationships with other standards: It is inter standard links to SIST EN 12355:2003+A1:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 12355:2022 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, EUR-PUB; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 12355:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2022

Nadomešča:

SIST EN 12355:2003+A1:2010

Stroji za predelavo hrane - Stroji za odstranjevanje kože - Varnostne in higienske

zahteve

Food processing machinery - Derinding-, skinning- and membrane removal machines -

Safety and hygiene requirements

Nahrungsmittelmaschinen - Entschwartungs-, Enthäutungs- und Entvliesmaschinen -

Sicherheits- und Hygieneanforderungen

Machines pour les produits alimentaires - Machines à découenner, éplucher et peler -

Prescriptions relatives à la sécurité et à l'hygiène

Ta slovenski standard je istoveten z: EN 12355:2022

ICS:

67.260 Tovarne in oprema za živilsko Plants and equipment for the

industrijo food industry

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12355

EUROPEAN STANDARD

NORME EUROPÉENNE

July 2022

EUROPÄISCHE NORM

ICS 67.260 Supersedes EN 12355:2003+A1:2010

English Version

Food processing machinery - Derinding-, skinning- and

membrane removal machines - Safety and hygiene

requirements

Machines pour les produits alimentaires - Machines à Nahrungsmittelmaschinen - Entschwartungs-,

découenner, éplucher et peler - Prescriptions relatives Enthäutungs- und Entvliesmaschinen - Sicherheits-

à la sécurité et à l'hygiène und Hygieneanforderungen

This European Standard was approved by CEN on 13 June 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12355:2022 E

worldwide for CEN national Members.

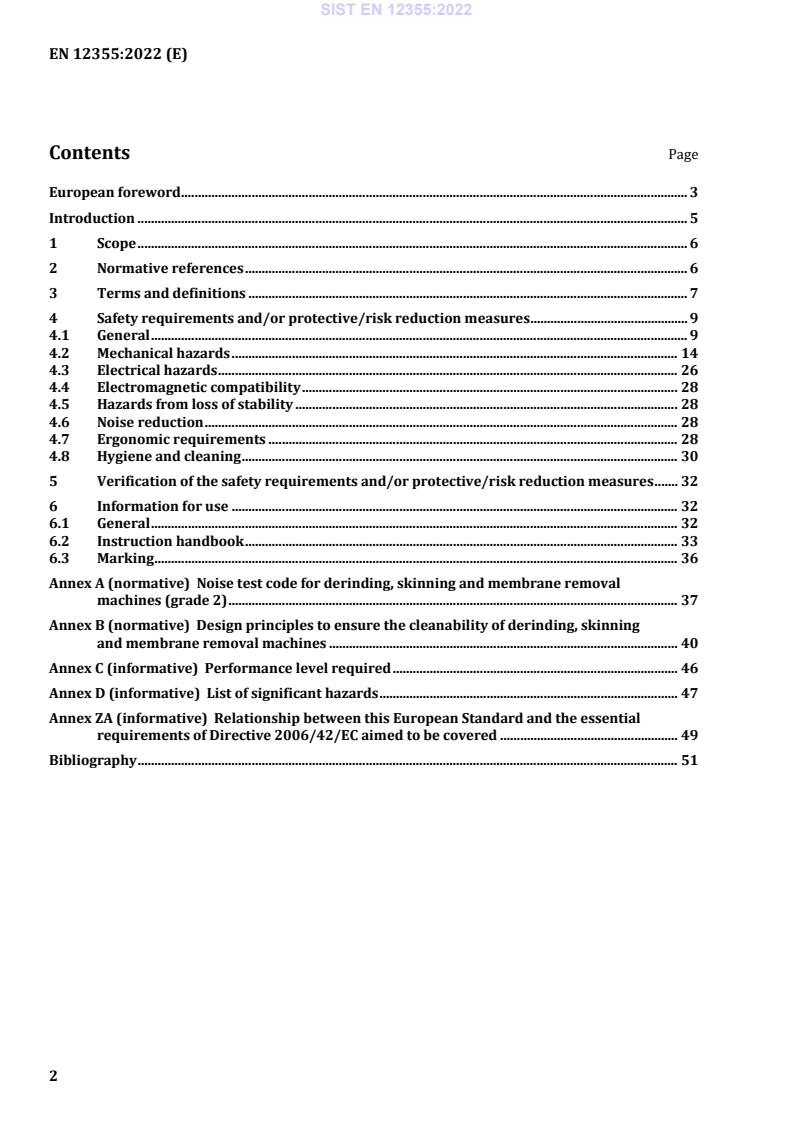

Contents Page

European foreword . 3

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Safety requirements and/or protective/risk reduction measures . 9

4.1 General . 9

4.2 Mechanical hazards . 14

4.3 Electrical hazards . 26

4.4 Electromagnetic compatibility . 28

4.5 Hazards from loss of stability . 28

4.6 Noise reduction . 28

4.7 Ergonomic requirements . 28

4.8 Hygiene and cleaning . 30

5 Verification of the safety requirements and/or protective/risk reduction measures . 32

6 Information for use . 32

6.1 General . 32

6.2 Instruction handbook . 33

6.3 Marking . 36

Annex A (normative) Noise test code for derinding, skinning and membrane removal

machines (grade 2) . 37

Annex B (normative) Design principles to ensure the cleanability of derinding, skinning

and membrane removal machines . 40

Annex C (informative) Performance level required . 46

Annex D (informative) List of significant hazards . 47

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Directive 2006/42/EC aimed to be covered . 49

Bibliography . 51

European foreword

This document (EN 12355:2022) has been prepared by Technical Committee CEN/TC 153 “Machinery

intended for use with foodstuffs and feed”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2023, and conflicting national standards shall

be withdrawn at the latest by January 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12355:2003+A1:2010.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of

EU Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part

of this document.

The significant changes with respect to the previous version EN 12355:2003+A1:2010 are listed below:

— structure adapted to CEN Guide 414:2017;

— figures were improved, partly exchanged or newly inserted;

— Clause 1 Scope: simplified, the description of machine types has been integrated in Clause 4, technical

features have been transformed into requirements;

— Clause 2 Normative references: completed and updated;

— Clause 3 Terms and definitions: completed and updated;

— Clause 4 Safety requirements: safety requirements were revised;

— Clause 5 Verification: adapted to the requirements of Clause 4;

— Clause 6 Information for use: improved and supplemented with references to the relevant clauses;

— Annex A Noise test code: updated;

— Annex B Design principles to ensure the cleanability: updated;

— Annex C Performance level required: added to give a quick-view summary of PLr for each safety

function;

— Annex D List of significant hazards: contains the former Clause 4;

— Annex ZA Relationship to Directive 2006/42/EC: improved and updated.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document is a type-C-standard as stated in EN ISO 12100:2010.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises);

— consumers (in the case of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations or hazardous events are

covered are indicated in the Scope of this document.

When requirements of this type-C-standard are different from those which are stated in type-A- or type-

B-standards, the requirements of this type-C-standard take precedence over the requirements of the

other standards for machines that have been designed and built according to the requirements of this

type-C standard.

1 Scope

This document deals with all significant hazards, hazardous situations or hazardous events relevant to

derinding, skinning and membrane removal machines, when they are used as intended and under

conditions of misuse which are reasonably foreseeable by the manufacturer (see Annex D).

This document deals with the hazards which can arise during all the lifetime of the machinery

(see EN ISO 12100:2010, 5.4).

This document is not applicable to derinding, skinning, and membrane removal machines for domestic

purposes, hand-guided machines and table-top machines.

This document is not applicable to fish heading and filleting machines as described in EN 15467:2014.

This document is not applicable to derinding, skinning and membrane removal machines manufactured

before the date of its publication.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 614-1:2006+A1:2009, Safety of machinery — Ergonomic design principles — Part 1: Terminology and

general principles

EN 619:2022, Continuous handling equipment and systems — Safety requirements for equipment for

mechanical handling of unit loads

EN 1005-1:2001+A1:2008, Safety of machinery — Human physical performance — Part 1: Terms and

definitions

EN 1005-2:2003+A1:2008, Safety of machinery — Human physical performance — Part 2: Manual

handling of machinery and component parts of machinery

EN 1005-3:2002+A1:2008, Safety of machinery — Human physical performance — Part 3: Recommended

force limits for machinery operation

EN 1005-4:2005+A1:2008, Safety of machinery — Human physical performance — Part 4: Evaluation of

working postures and movements in relation to machinery

EN 1672-2:2020, Food processing machinery — Basic concepts — Part 2: Hygiene and cleanability

requirements

EN 60204-1:2018, Safety of machinery — Electrical equipment of machines — Part 1: General

requirements (IEC 60204-1:2016, modified)

EN 60529:1991 , Degrees of protection provided by enclosures (IP code) (IEC 60529:1989)

EN 61496-1:2013, Safety of machinery — Electro-sensitive protective equipment — Part 1: General

requirements and tests (IEC 61496-1:2012)

As impacted by EN 60529:1991/A1:2000 and EN 60529:1991/A2:2013.

EN ISO 3744:2010, Acoustics — Determination of sound power levels and sound energy levels of noise

sources using sound pressure — Engineering methods for an essentially free field over a reflecting plane

(ISO 3744:2010)

EN ISO 3746:2010, Acoustics — Determination of sound power levels and sound energy levels of noise

sources using sound pressure — Survey method using an enveloping measurement surface over a reflecting

plane (ISO 3746:2010)

EN ISO 4871:2009, Acoustics — Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 11201:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a work station and at other specified positions in an essentially free field over a

reflecting plane with negligible environmental corrections (ISO 11201:2010)

EN ISO 11202:2010, Acoustics — Noise emitted by machinery and equipment — Determination of emission

sound pressure levels at a workstation and at other specified positions applying approximate environmental

corrections (ISO 11202:2010)

EN ISO 11688-1:2009, Acoustics — Recommended practice for the design of low-noise machinery and

equipment — Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

EN ISO 13849-1:2015, Safety of machinery — Safety related parts of control systems — Part 1: General

principles for design (ISO 13849-1:2015)

EN ISO 13857:2019, Safety of machinery — Safety distances to prevent hazard zones being reached by

upper and lower limbs (ISO 13857:2019)

EN ISO 14119:2013, Safety of machinery — Interlocking devices associated with guards — Principles for

design and selection (ISO 14119:2013)

EN ISO 14120:2015, Safety of machinery — Guards — General requirements for the design and

construction of fixed and movable guards (ISO 14120:2015)

EN ISO 21920-2:2022, Geometrical product specifications (GPS) — Surface texture: Profile — Part 2:

Terms, definitions and surface texture parameters (ISO 21920-2:2021)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/

3.1

strip

mechanical process for stripping off skin or membrane from rotating machine parts

3.2

stripper comb

comb-shaped insert to strip off the product residues from the tooth roller

3.3

stripper rake

rake-shaped device to strip skin or membrane or product residues off the hold-down roller

3.4

stripper roller

shaft with teeth to strip skin or membrane off the transport roller

3.5

hold-down roller

device for pushing down the product

Note 1 to entry: The roller may consist of one undivided piece or be divided into several segments. Each roller

may be profiled on the perimeter and/or the width. The inner rollers may also have smaller diameters.

3.6

cutting device

device for cutting the rind, skin or membrane from the product, consisting of blade holder and straight

blade

3.7

blade holder

device to act as a holding tool for the straight blade

Note 1 to entry: The blade holder is not intended for circular blades.

3.8

blade roller

rotating cutting tool with circular blades for the slashing or cutting of products

Note 1 to entry: One or more circular blades are spread across the width. Each circular blade may be profiled on

the perimeter. The inner circular blades may also have smaller diameters. This roller is considered divided.

3.9

combined roller

blade roller with segments of hold-down roller placed between the circular blades

3.10

round product

product of nearly round shape

EXAMPLE Pickled knuckle of pork, hind ham.

3.11

fixed bar

stable element that supports the belt in the area of the inlet and outlet and is strongly connected to the

belt frame

3.12

tunnel-shaped cover

element covering the area between inlet and outlet

3.13

transport roller

component with exclusively longitudinal teeth for moving the product towards the knife

3.14

tooth roller

component with longitudinal teeth as well as stripper grooves for moving the product towards the knife

3.15

cutting thickness

distance between the rotating tooth / transport roller and the tip of the straight blade

3.16

easily cleanable

designed and constructed to be cleanable by a simple cleaning method, if necessary after removing parts

that can be easily dismantled

3.17

stripper grooves

circumferential grooves in the roller for guiding the stripper comb

4 Safety requirements and/or protective/risk reduction measures

4.1 General

Derinding, skinning and membrane removal machines (see Figure 1, Figure 2, Figure 3, Figure 4 and

Figure 5) shall comply with the safety requirements and/or protective/risk reduction measures of this

clause. In addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for

the hazards relevant but not significant, which are not dealt with by this document.

Key

1 tooth/transport roller 6 foot switch

2 cutting device 7 drive

3 outfeed table 8 sliding plate

4 infeed table h table height

5 ON-/OFF-switch

Figure 1 — Open derinding, skinning and membrane removal machine

a) open derinding machine b) open membrane removal machine

Key

1 product 6 removed product (rind, skin, membrane)

2 infeed table 7 stripper comb

3 blade holder 8 transport roller

4 tooth roller 9 stripper roller

5 straight blade t cutting thickness

Figure 2 — System of open machines

Key

1 outfeed conveyor 5 tooth / transport roller

2 tunnel-shaped cover 6 infeed conveyor

3 hold-down roller, blade roller, combined roller 7 drive

4 cutting device 8 sliding plate

Figure 3 — Automatic machine

Key

1 hold-down roller, blade roller, combined roller 5 stripper comb / roller

2 infeed conveyor 6 cutting device

3 product 7 outfeed conveyor

4 tooth / transport roller 8 hold-down roller, blade roller, combined roller (optional)

Figure 4 — System of an automatic machine

a) hold-down roller (divided)

b) hold-down roller (undivided)

c) blade roller (divided) d) combined roller (divided)

Figure 5 — Examples of rollers

On derinding, skinning and membrane removal machines, a normal stop device shall be provided on each

workstation to stop the machine. The normal stop device requires a performance level PL of at least “c”

r

in accordance with EN ISO 13849-1:2015. The stopping function of the normal stop device shall be in

accordance with EN 60204-1:2018, 9.2.2, Category 0. In the instruction handbook the manufacturer shall

indicate that the normal stop device shall be operated immediately after each use of open derinding,

skinning and membrane removal machines (see 6.2 d)).

When power is recovered or when the power supply is switched on, restarting of the machine shall be

prevented.

Figure 6 is showing the significant danger zones of the different machine types.

a) Derinding machine b) Skinning and membrane removal machine

c) Automatic machines

Key

1 zone 1

2 zone 2

3 zone 3

4 zone 4

5 zone 5

Figure 6 — Danger zones on machines

4.2 Mechanical hazards

4.2.1 General

Machines shall be designed and constructed in accordance with the requirements mentioned below.

The interlocking devices associated with guards shall at least comply with EN ISO 14119:2013 Type 1 or

Type 3 and shall not be positioned in the food area (e.g. inside the machine housing or another housing).

Machine safety functions are implemented and assured through Safety-Related Parts of the Control

System (SRP/CS) that shall achieve a required Performance Level (PL) in accordance with

r

EN ISO 13849-1:2015. This requirement is given for each safety function in the relevant subclauses of

Clause 4.

Table C.1 summarizes PL for each safety function; however, the provisions of Clause 4 remain the sole

r

and complete normative set of requirements and explanations.

The access to the danger points on the drive system shall be prevented by the following measures:

— at the drive system guards (e.g. doors) shall be provided according to EN ISO 14120:2015. The

guards shall be:

— fixed or;

— movable and interlocked, the required performance level PL of the safety-related parts of the

r

control system shall present at least a performance level “c” according to EN ISO 13849-1:2015;

— openings in the guard shall comply with EN ISO 13857:2019, Table 4.

Fixing systems of fixed guards shall remain attached to these guards or to the machine when the guards

are removed.

4.2.2 Open derinding machine

4.2.2.1 General

When operating an open machine, the operator shall wear protective gloves. Metal wire mesh gloves, or

metal wire reinforced gloves or synthetic fibre reinforced gloves shall not be worn. In the instruction

handbook the manufacturer shall indicate the use of protective gloves (see 6.2 d)).

4.2.2.2 Rotating tooth roller and straight blade — Zone 1

The access to the cutting area and gap between the rotating tooth roller and the cutting device shall be

prevented. This shall be achieved by the following measures:

The cutting thickness of the straight blade shall be t ≤ 5 mm (see Figure 7).

The pitch of the tooth shall be P ≤ 6,5 mm and the depth d ≤ 5 mm (see Figure 7).

Key

1 tooth roller

2 straight blade

3 stripper groove

p tooth pitch

d tooth depth

t cutting thickness

Figure 7 — Dimensions of the tooth roller

The straight blade and the blade holder shall be designed in such a way that the straight blade can only

be placed in a defined position (see Figure 8).

Figure 8 — Design examples for defined position of the straight blade

The free part of the tooth roller between knife and front edge of the table is not allowed to be more than

35° of the circumference of the roller for a table height between 800 mm and 1 050 mm. In the case of

exceptionally tall round products an infeed table can be used which permits a free part of the tooth roller

not more than 120° for a table height ≥ 800 mm (see Figure 9). The processing of exceptionally tall round

products shall be indicated in the instruction handbook (see 6.2 d)).

Key

1 tooth roller

2 straight blade

3 product

4 infeed table raised

5 infeed table lowered

Figure 9 — Free part of the tooth roller

The operation switch for the drive system of the tooth roller shall be a hold-to-run control. The tooth

roller shall stop within 2 s after the operator has released the operation switch. The required

performance level PL of the safety-related parts of the control system shall present at least a

r

performance level “c” according to EN ISO 13849-1:2015. The operation switch can be e.g. foot-, knee- or

belly-operated and shall be protected against unintentional actuation.

If the blade holder is equipped with a second blade, at least the following residual hazards shall be

indicated in the instruction handbook (see 6.2 d)):

— cutting at the second blade;

— drawing-in point between installed second blade and toothed roller.

The instruction handbook (see 6.2 d)) shall indicate that the operator must switch off the machine with

the OFF-button and remove the second blade when quitting the machine.

4.2.2.3 Rotating tooth roller and stripper comb — Zone 2

The access to the in-running nip between tooth roller and stripper comb shall be prevented. This shall be

achieved by the following measures:

— the angle between tooth roller and stripper comb shall be > 90° (see Figure 10 a));

— an interlocked stripper comb to prevent the operation of the machine without the stripper comb, the

required performance level PLr of the safety-related parts of the control system shall be at least a

performance level “c” according to EN ISO 13849-1:2015.

a) without protective bar b) with protective bar

Key

1 tooth roller

2 stripper comb

3 fixed machine part

4 protective bar

d distance without protective bar

e distance with protective bar

Figure 10 — tooth roller with stripper comb

4.2.2.4 Rotating tooth roller and fixed machine parts — Zone 3

Access to the in-running nip between rotating tooth roller and fixed machine parts shall be prevented.

This shall be achieved by the following measures:

— the distance between a rotating tooth roller and a fixed machine part shall be d ≥ 80 mm

(see Figure 10 a)), or

— the distance shall be guarded by a protective bar, where the distance between protective bar and

tooth roller shall be e ≤ 2 mm (see Figure 10 b)); when the protective bar is not fixed, it shall be

interlocked with the machine to prevent the operation of the machine without the protective bar; the

required performance level PL of the safety-related parts of the control system shall present at least

r

a performance level “c” according to EN ISO 13849-1:2015.

4.2.3 Open skinning and membrane removal machine

4.2.3.1 General

Open skinning and membrane removal machines are intended to remove skin or membrane from flat and

round products, this shall be indicated in the instruction handbook (see 6.2 d)).

When operating an open machine, the operator shall wear protective gloves. Metal wire mesh gloves, or

metal wire reinforced gloves or synthetic fibre reinforced gloves shall not be worn. In the instruction

handbook the manufacturer shall indicate the use of protective gloves (see 6.2 d)).

4.2.3.2 Rotating transport roller and straight blade — Zone 1

Access to the cutting edge and the pinch point between the rotating transport roller and the straight blade

shall be prevented. This will be achieved by the following measures:

The cutting thickness shall be t ≤ 0,5 mm (see Figure 11).

The pitch of the grooves shall be P ≤ 2,5 mm and the groove depth d ≤ 2,0 mm. The transport roller shall

not have circumferential grooves (see Figure 11).

Key

1 transport roller

2 roller with circumferential grooves (not allowed as transport roller)

3 divided transport roller

p groove pitch

d groove depth

t cutting thickness

Figure 11 — Dimensions on the transport roller

For removing the membrane and the tendons at the same time a divided transport roller is necessary.

This transport roller has fine and also rough grooves. The length of the rough grooves shall be ≤ 50 % of

the length of the transport roller.

At the rough side, the pitch of the grooves shall be P ≤ 5,5 mm and the groove depth d ≤ 3,5 mm

(see Figure 11).

The straight blade and the blade holder shall be designed in a way that the straight blade can only be

placed in a defined position (see Figure 8).

The operation switch for the drive of the transport roller shall be a hold-to-run control device. The

transport roller shall stop within 2 s after the operator has released the operation switch. The required

performance level PL of the operation switch shall present at least a performance level “c” according to

r

EN ISO 13849-1:2015. The operation switch can be e.g. foot-, knee- or belly-operated and shall be

protected against unintentional actuation.

4.2.3.3 Rotating tooth roller and stripper roller — Zone 2

The access to the pinch point between the rotating tooth roller and the stripper roller shall be prevented.

This shall be achieved by the following measures:

To prevent the risk of drawing in, these rollers shall have the same direction of rotation.

4.2.3.4 Rotating roller and fixed machine parts — Zone 3

The access to the pinch point between the rotating roller and fixed machine parts shall be prevented.

This shall be achieved by the measures of 4.2.3.3.

4.2.4 Automatic machines

4.2.4.1 General

Movable guards shall be prevented against falling into the closed position. This shall be achieved by the

following measures:

— the moveable guard in its open position shall be ≥ 5° behind the vertical plane through the point of

balance;

— when the point of gravity of the guard in its rest position is < 5° behind the vertical plane through

the point of balance the guard shall be supported by a counterweight, a spring or a mechanical locking

device to prevent unexpected closing.

Injury by cutting when handling with the cutting device / blade roller shall be prevented. This shall be

achieved by the following measures:

— for handling, transport and storage a container shall be provided;

— the manufacturer shall describe the residual risks when handling the blades and working in the

cutting zone, especially during cleaning and maintenance operations in the instruction manual

(see 6.2 d)). The use and handling of the blade guard shall be described in the instruction manual

(see 6.2 d));

— the instruction manual shall state that cut-resistant gloves shall be worn when handling the blades

and working in the cutting zone (see 6.2 d)). The instruction manual shall also include information

about storage, transportation, maintenance, cleaning and use of the blades (see 6.2 d)).

4.2.4.2 Rotating transport roller and straight blade — Zone 1

Access from infeed side to the cutting edge shall be prevented. This shall be achieved by the following

measures:

a) the product shall be fed to the tooth/transportation roller and the hold-down roller by means of a

conveyor belt;

b) the frame of the infeed conveyor shall be provided with a fixed bar in the area of the infeed opening;

c) a tunnel-shaped cover shall be provided:

1) a movable tunnel-shaped cover (see Figure 12 a)) shall be interlocked, the machine shall stop

within 2 s after the tunnel-shaped cover has been opened by more than dimension B

(see Table 1), the required performance level PL of the safety-related parts of the control system

r

shall present at least a performance level “c” according to EN ISO 13849-1:2015;

2) a fixed tunnel-shaped cover shall be provided with a trip device (e.g. trip bar or light barrier) at

the upper edge of the infeed opening (see Figure 12 b)), actuating the trip device, the machine

shall stop within 2 s, the required performance level PL of the safety-related parts of the control

r

system shall present at least a performance level “c” according to EN ISO 13849-1:2015;

3) the dimensions of the tunnel-shaped cover depend on the distance from the infeed opening to

the first danger point on the cutting edge of the first blade (straight or circular) or the pinch point

(see Figure 13) and shall meet the following requirements:

i) the tunnel-shaped cover shall cover also the hold-down roller;

ii) openings in the guard, except the infeed and outfeed openings, shall comply with

EN ISO 13857:2019, Table 4;

iii) the infeed and outfeed openings of the tunnel-shaped cover, either itself or in combination

with a light barrier (ESPE electro-sensitive protection equipment) over the infeed conveyor,

shall meet the dimensions in Table 1;

iv) by using a light barrier / light curtain, the length of the solid part of the guard shall be

E ≥ 200 mm (see Figure 12 b)) and the opening height shall be C instead of B;

v) the force to open the movable tunnel-shaped cover shall be ≤ 50 N;

vi) electro-sensitive protection equipment shall comply with ESPE Type 2 of EN 61496-1:2013,

if an active optoelectronic protective device (AOPD, e.g. light curtain) is used, the sensor

detection capability of the electro-sensitive protective device shall be ≤ 40 mm.

a) Movable tunnel-shaped cover b) Fixed tunnel-shaped cover

Key

1 movable cover 3 trip bar

2 fixed cover 4 light barrier or light curtain

A distance from the infeed/outfeed opening to the first danger point

B height of the infeed/outfeed opening at the front edge of the guard or trip bar where the interlocking is

activated to the surface of the belt

C distance from the light barrier to the surface of the belt at the front edge of the guard

E length of the solid part of the tunnel-shaped guard from the first danger point

a

The distances A, B and C are given in Table 1.

Figure 12 —Examples of tunnel-shaped cover

Table 1 — Relation of opening height B and C to distance A

Dimensions in millimetres

A ≥ 230 ≥ 450 ≥ 550 ≥ 850

B ≤ 40 ≤ 95 ≤ 150 ≤ 250

C ≤ 50 ≤ 125 ≤ 180 ≤ 280

A = distance from the infeed/outfeed opening to the first danger point

B = height of the infeed/outfeed opening at the front edge of the guard or

trip bar where the interlocking is activated to the surface of the belt

C = distance from the light barrier to the surface of the belt at the front edge

of the guard

a) hold-down roller (divided) and tooth / b) hold-down roller (undivided) and tooth /

transport roller transport roller

c) raised hold-down roller and raised cutting d) blade / combined roller and tooth /

device and tooth / transport roller transport roller

e) hold-down roller and blade roller (instead f) blade roller (instead of hold-down roller

of tooth / transport roller and cutting device) and cutting device) and transport roller

g) blade roller and transport roller (without h) hold-down roller and tooth / transport

cutting device) with upstream hold-down roller roller with upstream blade roller

Key

1 product 8 hold-down roller (undivided)

2 infeed conveyor 9 hold-down roller (divided)

3 outfeed conveyor 10 blade roller

4 fixed bar 11 combined roller

5 tunnel-shaped cover 12 transport roller

6 cutting device 13 tooth roller

7 stripper rake t cutting thickness

A distance from the infeed/outfeed opening to the first danger point

B height of the infeed/outfeed opening at the front edge of the guard or trip bar where the interlocking is

activated to the surface of the belt

D distance between hold-down roller and tunnel-shaped cover

F distance between transport roller and hold-down roller

G = 25 mm

a

The distances A and B are given in Table 1.

Figure 13 — Examples of automatic machines with different types and arrangement of rollers

4.2.4.3 Rotating tooth roller and the stripper comb / stripper roller— Zone 2

Access to the in-running nip between the rotating tooth roller and the stripper comb / stripper roller

shall be prevented. This shall be achieved by the following measures:

Safety requirements see 4.2.2.3, Zone 2.

The pitch of the teeth shall be P ≤ 12 mm and the depth d ≤ 5 mm (see Figure 14).

Key

1 tooth roller

p tooth pitch

d tooth depth

Figure 14 — Dimensions of the tooth roller

4.2.4.4 Rotating roller and fixed machine parts — Zone 3

Access to the in-running nip between the rotating roller and fixed machine parts shall be prevented. This

shall be achieved by the following measures:

Safety requirements see 4.2.2.4, Zone 3.

4.2.4.5 Access from outfeed side — Zone 4

4.2.4.5.1 General

The hazard of drawing in between the blades and rollers shall be prevented. This shall be achieved by the

following measures:

a) the cutting thickness shall be t ≤ 8 mm and the distance between transport roller and hold-down

roller shall be F ≤ 35 mm;

b) the product shall be removed by means of:

1) an outfeed conveyor where the frame shall be provided with a fixed bar in the area of the outfeed

opening (see Figure 13), or

2) by a sliding plate (see Figure 1), whereby the dimensions which refer to the upper surface of the

outfeed conveyor (see Figure 13) also apply to the upper surface of the sliding plate.

4.2.4.5.2 Rotating hold-down roller and stripper rake

Access to the in-running nip between the hold-down rollers and guard shall be prevented. This shall be

achieved by the following measures:

a) undivided hold-down roller, see Figure 13 b), whereby the distance between an undivided hold-

down roller and the guard shall be 80 mm ≤ D ≤ 160 mm;

b) divided hold-down roller, see Figure 13 a), provided with a stripper rake, whereby the stripper rake

shall meet the following requirements (see Figure 15)):

1) the angle between the hold-down roller and the stripper rake shall be α > 90°;

2) the distance between the hold-down roller and the rake bar shall be w ≥ 25 mm;

3) the distance between two stripping elements shall be w ≤ 50 mm;

4) the distance between the stripping elements and the roller segment shall be w3 ≤ 5 mm;

5) the width of the roller segment shall be w4 ≤ 40 mm.

Key

w1 distance between rake bar and roller segment 1 roller segment

w distance between stripping elements 2 stripping element

w3 distance between stripping element and roller segment 3 rake bar

w4 width of roller segment 4 tunnel-shaped cover

α angle against the rotation direction between hold-down roller and stripper rake

Figure 15 — Dimensions of the stripper rake

4.2.4.5.3 Rotating tooth roller/transport roller, blades and hold-down rollers

Access from outfeed side to the blades and the rollers shall be prevented. This shall be achieved by the

following measures:

a) under the following technical conditions, a tunnel-shaped cover shall be provided (Figure 13 c)

to h)):

1) by using of a blade roller (see Figure 13 d) to g));

2) by using of a combined roller with hold-down rollers and circular blades (see Figure 13 d));

3) for a cutting thickness t > 8 mm (see Figure 13 c));

4) for a raised hold-down roller with a permanent distance between transport / tooth roller and

hold-down roller F > 35 mm (see Figure 13 c));

5) by use of a blade roller instead of tooth / transport roller and cutting device (see Figure 13 e));

b) the tunnel-shaped cover shall meet the following requirements:

1) the tunnel-shaped cover (see Figure 12 a)) shall be movable and interlocked, the machine shall

stop within 2 s after the tunnel-shaped cover has been opened by more than dimension B

(see Table 1), the required performance level PL of the safety-related parts of the control system

r

shall present at least a performance level “c” according to EN ISO 13849-1:2015;

2) the tunnel-shaped cover shall meet the dimensions in Table 1;

c) under the following technical conditions, it is permissible to reduce the distance A on the outlet

opening (see Figure 13 c) to h) and Table 1) by using a flapper gate (see Figure 16):

1) the distance to the hazard point shall be H ≥ 120 mm;

2) the flapper gate shall cover the entire width of the outfeed opening and shall consist of several

flaps;

3) the flaps shall only pivot in the direction of transport;

4) the flaps shall not be able to lock in the open position;

5) the flaps shall return to their closed position K ≤ 6 mm by themselves;

6) the distance between the flaps shall be ≤ 20 mm;

7) the flaps shall withstand a force of 200 N against elastic deformation in the axial direction of the

outfeed;

8) flaps that have undergone plastic deformation or those that are broken off shall be replaced

immediately, corresponding information shall be provided in the operating instructions

(see 6.2 d)).

a) distance to the straight b) distance to the upper surface of the conveyor

blade

Key

1 flapper gate 6 outfeed conveyor

2 cutting device 7 flap

3 roller H distance between flap and straight blade

4 tunnel-shaped cover K distance between flap and upper surface of the conveyor

5 fixed bar

a flap in closed position b flap in open position

Figure 16 — Dimensions of the flapper gate

4.2.4.6 Rotating conveyor belt and drive and guide roller — Zone 5

Access to the drawing-in points of the conveyor belts and also the drive and guide rollers shall be

prevented by one of the following measures:

— a fixed guard shall be installed (e.g. lateral cover plate), the dimensions shall be in accordance with

EN ISO 13857:2019, Table 4;

— a nip guard (see Figure 17) according to EN 619:2022, 4.2.1.1.6, the gap x between the belt and the

roller shall not exceed 5 mm.

Key

1 belt

2 roller

3 in-running nip

x gap

Figure 17 —Example of a nip guard

4.2.5 Combining machine

Combining machines are used either as automatic or open machines by simple conversion work by the

operator. In the instruction handbook the manufacturer shall indicate the procedure of the conversion

work (e.g. tunnel-shaped cover, different rollers) needed (see 6.2 d)).

After the conversion work has been completed by the operator, the combining machine shall meet the

requirements for the respective machine type:

— open derinding machine according to 4.2.2;

— open skinning and membrane removal machine according to 4.2.3;

— automatic ma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...