SIST EN 14677:2008

(Main)Safety of machinery - Secondary steelmaking - Machinery and equipment for treatment of liquid steel

Safety of machinery - Secondary steelmaking - Machinery and equipment for treatment of liquid steel

This European Standard specifies the general safety requirements for secondary steelmaking machinery and equipment (SSE) as defined in 3.1 to treat liquid steel.

This European Standard covers machinery and equipment involved in the treatment process of liquid steel under vacuum or atmospheric pressure.

This European Standard deals with all significant hazards, hazardous situations and events pertinent to SSE, when used as intended and under conditions foreseen by the manufacturer, but also includes foreseeable faults and malfunctions in case of misuse.

This European Standard specifies the requirements to ensure the safety of persons which are to be met during the design, assembly, transport, commissioning, operation, maintenance and decommissioning of the equipment.

This European Standard assumes that SSE are operated and maintained by adequately trained and competent personnel. Manual intervention for setting, adjustment and maintenance is accepted as part of the normal use of the equipment.

NOTE 1 Annex B shows examples of SSE.

The following equipment is not covered by the scope of this European Standard:

cranes;

fork lift trucks or other transporting equipment;

ladles;

equipment for relining and preheating in the relining area;

burners according to EN 746-2;

dust and fume exhaust systems.

NOTE 2 Significant hazards and hazardous situations due to transporting/positioning of heavy components, e. g., by cranes (e. g., ladles, vessels, covers) are considered in this standard (see 5.2.3).

This European Standard is not applicable to SSE manufactured before the date of publication of this standard in the Official Journal.

Sicherheit von Maschinen - Sekundärmetallurgie - Maschinen und Anlagen zur Behandlung von Flüssigstahl

Diese Europäische Norm spezifiziert die allgemeinen Sicherheitsanforderungen, die durch den Hersteller von Ausrüstungen für die Sekundärmetallurgie, entsprechend der Definition von Maschinen in der EN 292-1, zu erfüllen sind. Sie beschreibt die vorhersehbaren, signifikanten Gefährdungen, Gefährdungssituationen und Ereignisse von Anlagen und bestimmten Ausrüstungen, aus denen sich die Anlage zusammensetzt; sie beschreibt nicht die kompletten Gesundheits- und Sicherheitsanforderungen für jede spezielle Ausrüstung. Sie zeigt vorbeugende Maßnahmen zur Vermeidung von Gefährdungen und zur Reduzierung von Risiken auf. Sie behandelt nicht nur die Gegebenheiten, bei denen die Maschine bestimmungsgemäß genutzt wird, sondern beinhaltet auch andere vom Hersteller vorgesehenen Zustände, wie vorhersehbare Fehler, Fehlfunktionen oder missbräuchliche Nutzung.

Diese Europäische Norm enthält die zu erfüllenden Anforderungen, um die Sicherheit von Personen während der Konstruktion, des Baus, des Transports, der Inbetriebnahme, des Betriebs, der Wartung und der Außerbetriebnahme sicherzustellen.

Diese Norm geht davon aus, dass die Anlagen von entsprechend geschultem und fähigem Personal bedient und gewartet werden. Manuelles Eingreifen zur Einstellung, Anpassung und Wartung wird als Teil des Normalbetriebes der Ausrüstung akzeptiert.

Diese Norm geht davon aus, dass die Maschinen bei entsprechender Arbeitsplatzbeleuchtung gemäß prEN 12464-1 oder gemäß lokaler Bestimmungen genutzt werden.

Diese Norm deckt folgende Ausrüstungen von Anlagen der Sekundärmetallurgie ab (siehe 5.2, Tabelle 1):

a) Ausrüstungen zur Materialbeschickung

Ausrüstungen für Lagerung, Beförderung und Zusatz von Material in den flüssigen Stahl.

Beispiele für Ausrüstungenen zur Materialbeschickung sind:

¾ Vorratsbunker;

¾ Förderbänder;

¾ Drahtführungen;

¾ Vakuumverschlüsse;

Sécurité des machines - Métallurgie secondaire - Machines et équipements pour traitement d'acier liquide

La présente Norme européenne spécifie les prescriptions de sécurité générales pour les machines et les

équipements de métallurgie secondaire (EMS), tels que définis en 3.1, pour le traitement d’acier liquide.

La présente Norme européenne couvre les machines et les équipements impliqués dans le processus de

traitement d’acier liquide sous vide ou sous pression atmosphérique.

La présente Norme européenne traite tous les phénomènes, situations et événements dangereux significatifs

pertinents pour les EMS, durant l’utilisation normale et dans des conditions prévues par le fabricant, mais

inclut aussi des défauts et défaillances prévisibles en cas de mauvais usage.

La présente Norme européenne spécifie les prescriptions pour assurer la sécurité des personnes devant être

satisfaites lors de la conception, de l’assemblage, du transport, de la mise en service, du fonctionnement, de

la maintenance et de la mise hors service des équipements.

La présente Norme européenne suppose que les équipements EMS sont utilisés et entretenus par du

personnel compétent ayant reçu une formation appropriée. Une intervention manuelle pour le réglage,

l’ajustage et la maintenance est acceptée comme partie intégrante de l’utilisation normale des équipements.

NOTE 1 L’Annexe B fournit des exemples d’équipements EMS.

La présente Norme européenne ne couvre pas les équipements suivants :

- appareils de levage à charge suspendue ;

- chariots élévateurs à fourche ou autres équipements de transport ;

- poches (de coulée) ;

- équipements de regarnissage et de préchauffage dans la zone de regarnissage ;

- brûleurs selon l’EN 746-2 ;

- systèmes d’évacuation de poussières et de fumées.

Varnost strojev - Sekundarna metalurgija - Stroji in oprema za obdelavo tekočega jekla

General Information

- Status

- Published

- Publication Date

- 04-May-2008

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 18-Apr-2008

- Due Date

- 23-Jun-2008

- Completion Date

- 05-May-2008

- Directive

- 98/37/EC - Machinery

Overview

EN 14677:2008 - Safety of machinery - Secondary steelmaking - Machinery and equipment for treatment of liquid steel is a European (CEN) Type C standard that specifies general safety requirements for secondary steelmaking machinery and equipment (SSE) used to treat liquid steel under vacuum or atmospheric conditions. The standard addresses hazards, foreseeable faults and misuse, and sets out safety expectations across the entire equipment lifecycle: design, assembly, transport, commissioning, operation, maintenance and decommissioning. It assumes operation and maintenance by competent, trained personnel.

Key topics and technical requirements

EN 14677:2008 focuses on practical safety measures and verification. Major technical topics include:

- Hazard identification and risk reduction for SSE, including foreseeable malfunctions and misuse.

- Design and layout requirements: safe access, operator positions, ergonomic principles and harmful-area protection.

- Safety control systems and emergency stops, power-loss behavior and grounding requirements for electrically heated or conductive parts.

- Fluid, hydraulic and pneumatic systems safety for media supply/discharge and exchange of lances.

- Vacuum systems and vacuum vessel safety, ventilation and pump considerations for vacuum secondary steelmaking processes.

- Material addition, blowing and stirring equipment safety (positioning, exchange, and interaction with other plant).

- Media handling and deslagging safety measures.

- Temperature measurement, sampling and electrical heating safety.

- Explosion prevention and protection, fire protection and noise reduction (Annex A covers noise test code).

- Verification, marking and documentation: manufacturer’s instruction handbook, operating and maintenance manuals, transport/assembly instructions, and required training of personnel.

The standard also lists what it does not cover (e.g., cranes, fork-lift trucks, ladles, relining/preheating equipment, burners covered by EN 746-2, and dust/fume exhaust systems) while still considering hazards arising from positioning heavy components.

Applications and users

EN 14677:2008 is essential for:

- Machine and equipment designers (OEMs) developing secondary steelmaking systems

- Plant engineers and safety managers at steel mills and foundries

- Integrators and system suppliers for vacuum treatment, stirring, blowing and material-addition systems

- Maintenance teams and commissioning engineers responsible for safe operation and lifecycle compliance

- Notified bodies and conformity assessors verifying compliance with EU machinery directives

Practical benefits include clearer compliance pathways, reduced operational risk, improved operator safety and consistent documentation for commissioning and audits.

Related standards

Relevant normative references and complementary standards include (examples):

- EN ISO 12100 (general principles of risk assessment and risk reduction)

- EN 746-2 (industrial thermoprocessing burners - excluded scope overlap)

- EN 294, EN 349, EN 614‑1/2 (safety distances, ergonomic design)

Using EN 14677:2008 helps organizations align secondary steelmaking machinery with European safety expectations and facilitate regulatory compliance.

Frequently Asked Questions

SIST EN 14677:2008 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Safety of machinery - Secondary steelmaking - Machinery and equipment for treatment of liquid steel". This standard covers: This European Standard specifies the general safety requirements for secondary steelmaking machinery and equipment (SSE) as defined in 3.1 to treat liquid steel. This European Standard covers machinery and equipment involved in the treatment process of liquid steel under vacuum or atmospheric pressure. This European Standard deals with all significant hazards, hazardous situations and events pertinent to SSE, when used as intended and under conditions foreseen by the manufacturer, but also includes foreseeable faults and malfunctions in case of misuse. This European Standard specifies the requirements to ensure the safety of persons which are to be met during the design, assembly, transport, commissioning, operation, maintenance and decommissioning of the equipment. This European Standard assumes that SSE are operated and maintained by adequately trained and competent personnel. Manual intervention for setting, adjustment and maintenance is accepted as part of the normal use of the equipment. NOTE 1 Annex B shows examples of SSE. The following equipment is not covered by the scope of this European Standard: cranes; fork lift trucks or other transporting equipment; ladles; equipment for relining and preheating in the relining area; burners according to EN 746-2; dust and fume exhaust systems. NOTE 2 Significant hazards and hazardous situations due to transporting/positioning of heavy components, e. g., by cranes (e. g., ladles, vessels, covers) are considered in this standard (see 5.2.3). This European Standard is not applicable to SSE manufactured before the date of publication of this standard in the Official Journal.

This European Standard specifies the general safety requirements for secondary steelmaking machinery and equipment (SSE) as defined in 3.1 to treat liquid steel. This European Standard covers machinery and equipment involved in the treatment process of liquid steel under vacuum or atmospheric pressure. This European Standard deals with all significant hazards, hazardous situations and events pertinent to SSE, when used as intended and under conditions foreseen by the manufacturer, but also includes foreseeable faults and malfunctions in case of misuse. This European Standard specifies the requirements to ensure the safety of persons which are to be met during the design, assembly, transport, commissioning, operation, maintenance and decommissioning of the equipment. This European Standard assumes that SSE are operated and maintained by adequately trained and competent personnel. Manual intervention for setting, adjustment and maintenance is accepted as part of the normal use of the equipment. NOTE 1 Annex B shows examples of SSE. The following equipment is not covered by the scope of this European Standard: cranes; fork lift trucks or other transporting equipment; ladles; equipment for relining and preheating in the relining area; burners according to EN 746-2; dust and fume exhaust systems. NOTE 2 Significant hazards and hazardous situations due to transporting/positioning of heavy components, e. g., by cranes (e. g., ladles, vessels, covers) are considered in this standard (see 5.2.3). This European Standard is not applicable to SSE manufactured before the date of publication of this standard in the Official Journal.

SIST EN 14677:2008 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery; 77.180 - Equipment for the metallurgical industry. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14677:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2014/34/EU, 94/9/EC, 98/37/EC; Standardization Mandates: M/079, M/396, M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 14677:2008 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.MHNODSicherheit von Maschinen - Sekundärmetallurgie - Maschinen und Anlagen zur Behandlung von FlüssigstahlSécurité des machines - Métallurgie secondaire - Machines et équipements pour traitement d'acier liquideSafety of machinery - Secondary steelmaking - Machinery and equipment for treatment of liquid steel77.180Oprema za metalurško industrijoEquipment for the metallurgical industry13.110Varnost strojevSafety of machineryICS:Ta slovenski standard je istoveten z:EN 14677:2008SIST EN 14677:2008en,fr01-julij-2008SIST EN 14677:2008SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14677April 2008ICS 77.180 English VersionSafety of machinery - Secondary steelmaking - Machinery andequipment for treatment of liquid steelSécurité des machines - Métallurgie secondaire - Machineset équipements pour traitement d'acier liquideSicherheit von Maschinen- Sekundärmetallurgie -Maschinen und Anlagen zur Behandlung von FlüssigstahlThis European Standard was approved by CEN on 23 February 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14677:2008: ESIST EN 14677:2008

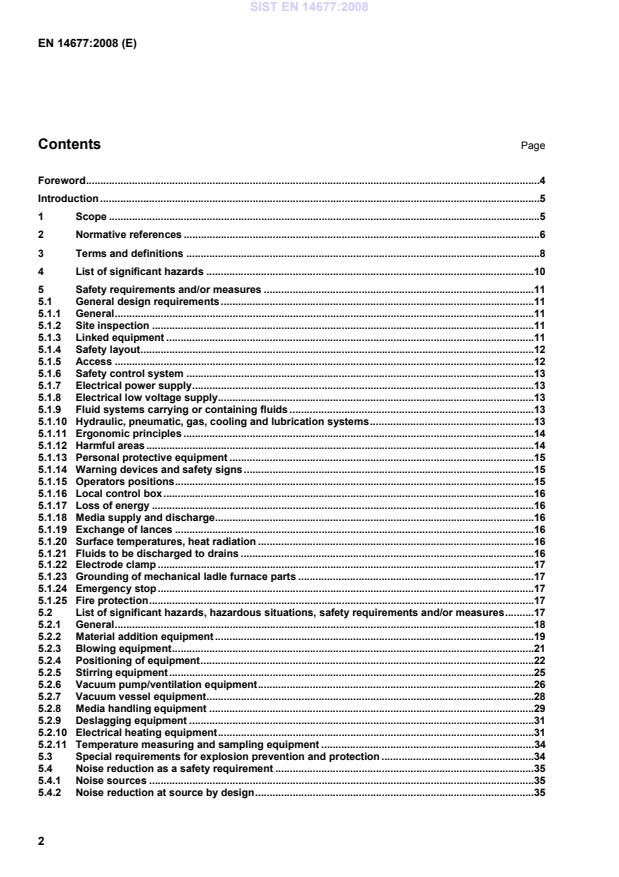

Noise test code.41 A.1 Introduction.41 A.2 Determination of A-weighted sound power level.41 A.3 Determination of A-weighted emission sound pressure levels.42 A.3.1 Determination of the emission sound pressure level at specified measuring points.42 A.3.2 Determination of the emission sound pressure level at work stations.42 A.4 Measurement uncertainty.42 A.5 Operating conditions.42 A.6 Information to be recorded and reported.43 A.7 Declaration and verification of noise emission values.43 A.8 Examples for workstations at RH-process with ladle furnace.44 Annex B (informative)

Examples for secondary steelmaking equipment.46 Annex C (informative)

Examples of secondary steelmaking processes.48 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.49 Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC.50 Annex ZC (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 94/9/EC.51 Bibliography.52

Figures Figure C.1 — Examples of secondary steelmaking processes.48

Tables Table 1 — List of significant hazards, hazardous situations, safety requirements and/or measures.18 Table 2 — Examples for operating instructions.38 Table A.1 — Example of declared dual-number noise emission values for work stations

and specified measuring points.45

1) Will be replaced by prEN 60079-10-1 (2006-07). SIST EN 14677:2008

For the equipment linked to the SSE, e. g., alloying system (tanks/vessels, structures, discharge/conveyor devices, etc.), fume extraction, injection systems, SIST EN 14677:2008

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...