SIST EN 13941-1:2019/oprA1:2021

(Amendment)District heating pipes - Design and installation of thermal insulated bonded single and twin pipe systems for directly buried hot water networks - Part 1: Design

District heating pipes - Design and installation of thermal insulated bonded single and twin pipe systems for directly buried hot water networks - Part 1: Design

This European Standard specifies requirements for design, calculation and installation of factory made thermal insulated bonded single and twin pipe systems for directly buried hot water networks for continuous operation with treated hot water at various temperatures up to 120 ºC and occasionally with peak temperatures up to 140 ºC and maximum internal pressure 2,5 MPa. Flexible pipe systems according to EN 15632 are not under the scope of this standard.

The standard EN 13941, Design and installation of thermal insulated bonded single and twin pipe systems for directly buried hot water networks consists of two parts:

a) prEN 13941-1: Design;

b) prEN 13941-2: Installation.

The requirements and stipulations in this part: EN 13941-1, form an unbreakable unity with those of prEN 13941-2. This part shall therefore exclusively be used in combination with prEN 13941-2.

The principles of the standard may be applied to thermal insulated pipe systems with pressures higher than 2,5 MPa, provided that special attention is paid to the effects of pressure.

Adjacent pipes, not buried, but belonging to the network (e. g. pipes in ducts, valve chambers, road crossings above ground etc.) may be designed and installed according to this standard.

This standard presupposes the use of treated water, which by softening, demineralisation, de-aeration, adding of chemicals, or otherwise has been treated to effectively prevent internal corrosion and deposits in the pipes.

NOTE For further information on water qualities to be used in district heating pipe systems see also [1].

This standard is not applicable for such units as:

a) pumps;

b) heat exchangers;

c) boilers, tanks;

d) systems behind domestic substations.

Fernwärmerohre - Auslegung und Bauausführung von gedämmten Ein- und Doppelrohr-Verbundsystemen für direkt erdverlegte Fernwärmenetze - Teil 1: Auslegung

Tuyaux de chauffage urbain - Conception et installation des systèmes bloqués de monotubes ou bitubes isolés thermiquement pour les réseaux d'eau chaude enterrés directement - Partie 1 : Conception

Cevi za daljinsko ogrevanje - Projektiranje in vgradnja toplotno izoliranih spojenih eno- in dvocevnih sistemov za neposredno zakopana vročevodna omrežja - 1. del: Projektiranje - Dopolnilo A1

General Information

- Status

- Not Published

- Public Enquiry End Date

- 30-Jun-2021

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 4020 - Public enquire (PE) (Adopted Project)

- Start Date

- 03-May-2021

- Due Date

- 20-Sep-2021

- Completion Date

- 12-Jul-2021

Relations

- Effective Date

- 29-Sep-2021

- Effective Date

- 13-Jan-2021

Overview

EN 13941-1:2019/prA1 (CEN) defines the design requirements for factory-made, thermal insulated bonded single and twin pipe systems used in directly buried district heating hot water networks. The standard covers continuous operation with treated hot water at temperatures up to 120 °C, occasional peak temperatures up to 140 °C, and a maximum internal pressure of 2,5 MPa. Part 1 (Design) is intended to be used in combination with Part 2 (Installation) and forms an integral set of requirements for safe, durable district heating pipe systems.

Key considerations in the standard include material and cross-section analysis, thermal expansion, axial and lateral stiffness, limit states for steel, and heat loss calculations. Flexible pipe systems covered by EN 15632 are explicitly excluded from this part.

Key Topics

- Scope and application: Factory-made bonded single and twin pipes for directly buried hot water networks; adjacent above-ground pipes in ducts, chambers or crossings may also be designed to this standard.

- Temperature and pressure limits: Continuous operation up to 120 °C, occasional peaks to 140 °C, and maximum internal pressure 2,5 MPa. The principles may be applied to higher pressures with special consideration of pressure effects.

- Water quality requirement: Presupposes treated water (softening, de-aeration, demineralisation or chemical treatment) to prevent internal corrosion and deposits.

- Design methods: Cross-section analysis, assessment of resultant stresses, fatigue and limit state checks, thermal expansion and soil-pipe interaction, and calculation of specific heat loss.

- Amendment prA1 highlights: Updates to normative references, terminology and symbol tables, modifications to load classification and factors, corrections to formulae and figures, and updates across several subclauses and annexes to clarify design calculations.

Applications

- New and replacement district heating networks with directly buried steel service pipes encased in factory-made thermal insulation and outer casing.

- Urban and industrial hot water distribution where reliable long-term performance, reduced heat loss, and controlled thermal expansion are required.

- Design of network sections in ducts, valve chambers and above-ground crossings using the same design principles.

Benefits include improved safety margins, consistent engineering methods for axial/bending stresses, clear heat-loss modelling and compatibility between design and installation when used with Part 2.

Related Standards

- EN 13941-2 - Installation (to be used in combination with Part 1)

- EN 15632 - Flexible district heating pipe systems (excluded from scope)

- EN 17248 - Terms and definitions for district heating and cooling pipe systems

For practitioners, EN 13941-1:2019/prA1 is a practical design reference ensuring cohesive design practice across prefabricated bonded pipe systems within CEN member states.

Frequently Asked Questions

SIST EN 13941-1:2019/oprA1:2021 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "District heating pipes - Design and installation of thermal insulated bonded single and twin pipe systems for directly buried hot water networks - Part 1: Design". This standard covers: This European Standard specifies requirements for design, calculation and installation of factory made thermal insulated bonded single and twin pipe systems for directly buried hot water networks for continuous operation with treated hot water at various temperatures up to 120 ºC and occasionally with peak temperatures up to 140 ºC and maximum internal pressure 2,5 MPa. Flexible pipe systems according to EN 15632 are not under the scope of this standard. The standard EN 13941, Design and installation of thermal insulated bonded single and twin pipe systems for directly buried hot water networks consists of two parts: a) prEN 13941-1: Design; b) prEN 13941-2: Installation. The requirements and stipulations in this part: EN 13941-1, form an unbreakable unity with those of prEN 13941-2. This part shall therefore exclusively be used in combination with prEN 13941-2. The principles of the standard may be applied to thermal insulated pipe systems with pressures higher than 2,5 MPa, provided that special attention is paid to the effects of pressure. Adjacent pipes, not buried, but belonging to the network (e. g. pipes in ducts, valve chambers, road crossings above ground etc.) may be designed and installed according to this standard. This standard presupposes the use of treated water, which by softening, demineralisation, de-aeration, adding of chemicals, or otherwise has been treated to effectively prevent internal corrosion and deposits in the pipes. NOTE For further information on water qualities to be used in district heating pipe systems see also [1]. This standard is not applicable for such units as: a) pumps; b) heat exchangers; c) boilers, tanks; d) systems behind domestic substations.

This European Standard specifies requirements for design, calculation and installation of factory made thermal insulated bonded single and twin pipe systems for directly buried hot water networks for continuous operation with treated hot water at various temperatures up to 120 ºC and occasionally with peak temperatures up to 140 ºC and maximum internal pressure 2,5 MPa. Flexible pipe systems according to EN 15632 are not under the scope of this standard. The standard EN 13941, Design and installation of thermal insulated bonded single and twin pipe systems for directly buried hot water networks consists of two parts: a) prEN 13941-1: Design; b) prEN 13941-2: Installation. The requirements and stipulations in this part: EN 13941-1, form an unbreakable unity with those of prEN 13941-2. This part shall therefore exclusively be used in combination with prEN 13941-2. The principles of the standard may be applied to thermal insulated pipe systems with pressures higher than 2,5 MPa, provided that special attention is paid to the effects of pressure. Adjacent pipes, not buried, but belonging to the network (e. g. pipes in ducts, valve chambers, road crossings above ground etc.) may be designed and installed according to this standard. This standard presupposes the use of treated water, which by softening, demineralisation, de-aeration, adding of chemicals, or otherwise has been treated to effectively prevent internal corrosion and deposits in the pipes. NOTE For further information on water qualities to be used in district heating pipe systems see also [1]. This standard is not applicable for such units as: a) pumps; b) heat exchangers; c) boilers, tanks; d) systems behind domestic substations.

SIST EN 13941-1:2019/oprA1:2021 is classified under the following ICS (International Classification for Standards) categories: 23.040.07 - Pipeline and its parts for district heat; 23.040.10 - Iron and steel pipes; 91.140.10 - Central heating systems. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13941-1:2019/oprA1:2021 has the following relationships with other standards: It is inter standard links to SIST EN 13941-1:2019+A1:2022, SIST EN 13941-1:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13941-1:2019/oprA1:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2021

Cevi za daljinsko ogrevanje - Projektiranje in vgradnja toplotno izoliranih spojenih

eno- in dvocevnih sistemov za neposredno zakopana vročevodna omrežja - 1. del:

Projektiranje - Dopolnilo A1

District heating pipes - Design and installation of thermal insulated bonded single and

twin pipe systems for directly buried hot water networks - Part 1: Design

Fernwärmerohre - Auslegung und Bauausführung von gedämmten Ein- und Doppelrohr-

Verbundsystemen für direkt erdverlegte Fernwärmenetze - Teil 1: Auslegung

Tuyaux de chauffage urbain - Conception et installation des systèmes bloqués de

monotubes ou bitubes isolés thermiquement pour les réseaux d'eau chaude enterrés

directement - Partie 1 : Conception

Ta slovenski standard je istoveten z: EN 13941-1:2019/prA1

ICS:

23.040.07 Cevovodi za daljinsko Pipeline and its parts for

ogrevanje in njihovi deli district heat

91.140.10 Sistemi centralnega Central heating systems

ogrevanja

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

EN 13941-1:2019

NORME EUROPÉENNE

EUROPÄISCHE NORM

prA1

April 2021

ICS 23.040.07; 23.040.10; 91.140.10

English Version

District heating pipes - Design and installation of thermal

insulated bonded single and twin pipe systems for directly

buried hot water networks - Part 1: Design

Tuyaux de chauffage urbain - Conception et installation Fernwärmerohre - Auslegung und Bauausführung von

des systèmes bloqués de monotubes ou bitubes isolés gedämmten Ein- und Doppelrohr-Verbundsystemen

thermiquement pour les réseaux d'eau chaude enterrés für direkt erdverlegte Fernwärmenetze - Teil 1:

directement - Partie 1 : Conception Auslegung

This draft amendment is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 107.

This draft amendment A1, if approved, will modify the European Standard EN 13941-1:2019. If this draft becomes an

amendment, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for

inclusion of this amendment into the relevant national standard without any alteration.

This draft amendment was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13941-1:2019/prA1:2021 E

worldwide for CEN national Members.

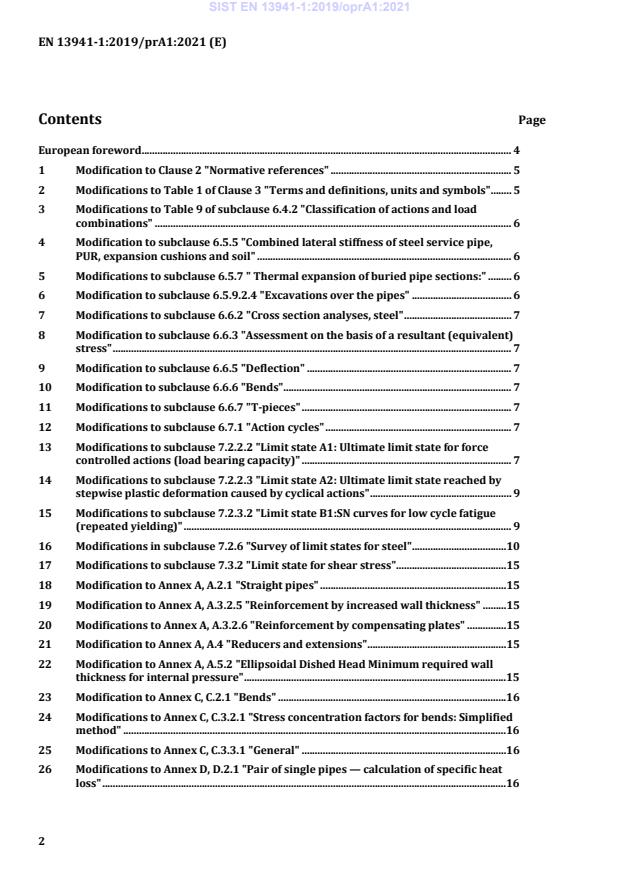

Contents Page

European foreword . 4

1 Modification to Clause 2 "Normative references" . 5

2 Modifications to Table 1 of Clause 3 "Terms and definitions, units and symbols". 5

3 Modifications to Table 9 of subclause 6.4.2 "Classification of actions and load

combinations" . 6

4 Modification to subclause 6.5.5 "Combined lateral stiffness of steel service pipe,

PUR, expansion cushions and soil" . 6

5 Modifications to subclause 6.5.7 " Thermal expansion of buried pipe sections:" . 6

6 Modification to subclause 6.5.9.2.4 "Excavations over the pipes" . 6

7 Modifications to subclause 6.6.2 "Cross section analyses, steel" . 7

8 Modification to subclause 6.6.3 "Assessment on the basis of a resultant (equivalent)

stress" . 7

9 Modification to subclause 6.6.5 "Deflection" . 7

10 Modification to subclause 6.6.6 "Bends" . 7

11 Modifications to subclause 6.6.7 "T-pieces" . 7

12 Modifications to subclause 6.7.1 "Action cycles" . 7

13 Modifications to subclause 7.2.2.2 "Limit state A1: Ultimate limit state for force

controlled actions (load bearing capacity)" . 7

14 Modifications to subclause 7.2.2.3 "Limit state A2: Ultimate limit state reached by

stepwise plastic deformation caused by cyclical actions" . 9

15 Modifications to subclause 7.2.3.2 "Limit state B1:SN curves for low cycle fatigue

(repeated yielding)" . 9

16 Modifications in subclause 7.2.6 "Survey of limit states for steel" .10

17 Modifications to subclause 7.3.2 "Limit state for shear stress".15

18 Modification to Annex A, A.2.1 "Straight pipes" .15

19 Modification to Annex A, A.3.2.5 "Reinforcement by increased wall thickness" .15

20 Modifications to Annex A, A.3.2.6 "Reinforcement by compensating plates" .15

21 Modification to Annex A, A.4 "Reducers and extensions" .15

22 Modification to Annex A, A.5.2 "Ellipsoidal Dished Head Minimum required wall

thickness for internal pressure" .15

23 Modification to Annex C, C.2.1 "Bends" .16

24 Modifications to Annex C, C.3.2.1 "Stress concentration factors for bends: Simplified

method" .16

25 Modifications to Annex C, C.3.3.1 "General" .16

26 Modifications to Annex D, D.2.1 "Pair of single pipes — calculation of specific heat

loss" .16

27 Modification to Annex D, D.2.3 "Using Zero-order approximation for (s) symmetrical

and (a) antisymmetrical problem the heat resistance can be calculated:" . 17

28 Modification to Annex D, D.2.4 "Specific heat loss of pipes" . 18

29 Modification to Figures D.3 "Calculation model for the specific heat loss of twin

pipes" and D.4 "Superposition of calculation cases". 18

30 Modification to Annex D, D.2.6 "Temperatures of pipes" . 19

31 Modifications to Annex D, D.2.7 "(s) symmetrical and (a) antisymmetrical heat loss

factors according to first-order multipole formula:" . 19

32 Modifications to Annex D, D.2.8 "Specific heat loss of pipes" . 19

33 Modification to Annex E, E.3.2 "Soil friction, twin pipe friction length and pipe

expansion" . 20

34 Modifications to Annex E, E.3.3 "Axial stress in the flow and return steel service

pipes" . 20

35 Modification to Annex E, E.3.4.2 "loads on the fixing bars type A" . 20

36 Modification to Annex E, E.3.4.3 "loads on the fixing bars type B" . 20

37 Modification to Annex G, G.2 "General considerations for determination of test

values for bending moments" . 20

38 Addition to the Bibliography . 21

European foreword

This document (EN 13941-1:2019/prA1:2021) has been prepared by Technical Committee CEN/TC 107

“Prefabricated district heating and district cooling pipe system”, the secretariat of which is held by DS.

This document is currently submitted to the CEN Enquiry.

EN 13941, District heating pipes — Design and installation of thermal insulated bonded single and twin

pipe systems for directly buried hot water networks consists of the following parts:

— Part 1: Design;

— Part 2: Installation.

In comparison to EN 13941:2019, the following changes have been made:

a) minor corrections throughout the document.

1 Modification to Clause 2 "Normative references"

Delete footnote 1 "Under preparation. Stage at time of publication: prEN 17248:2018." at the entry of

"EN 17248, District heating and district cooling pipe systems - Terms and definitions".

2 Modifications to Table 1 of Clause 3 "Terms and definitions, units and

symbols"

In Table 1, these modifications are to be applied for the following symbols:

— D /D delete "or m" in the Unit column;

C i

— K add "for cohesive soil and mixed soils" at the end of column "Name";

c

— K add "for granular soil and mixed soils" at the end of column "Name";

q

— "t " is to be replaced by "T ";

s g

— Z replace the unit "m" with "mm".

c

Insert the following row between the rows of "L" and "L ": "

p

L

allowable length between the single use compensators m

all

".

Insert the following two rows between the rows of "q" and "q ": "

u

q

Flow line W/m

f

q

Return line W/m

r

".

Replace the following rows: "

σ

Design stress (allowable) MPa

d

σ

Design stress (allowable) of the compensating plate material MPa

dp

σ

Calculated hoop stress from internal (design) pressure MPa

dp

" with: "

σ Design stress ( )

R T/ γ

( ) MPa

d

e m

σ

Design stress (allowable) of the compensating plate material MPa

dp

σ

Calculated hoop stress from internal (design) pressure MPa

pd

".

And delete the following row: "

σ

Hoop stress from internal (over)pressure MPa

p

".

3 Modifications to Table 9 of subclause 6.4.2 "Classification of actions and load

combinations"

In Table 9, replace "safety" with "load" changing the title to read "Classification of actions, partial load

factor and Load Combinations (LC)" and the first heading to "PARTIAL LOAD FACTORS γ ".

a

Delete the term "(Max foam compression)" in the cell for operational phase LC 3 "Force controlled and

deformation controlled actions"

Replace the load factor "Operating pressure" from LC 2, LC 3 and LC 4 "1,2" with "1,25".

4 Modification to subclause 6.5.5 "Combined lateral stiffness of steel service

pipe, PUR, expansion cushions and soil"

To change " D " in Formula (20b) to " D " replace the formula with

0 c

" kk⋅ D (20b)"

2 h2, c

and insert "for D " at Formula (21b) in front of "see Figure 13" resulting in

cu

" kk⋅ D for D see Figure 13 (21b)".

cu

3 h,3 cu

5 Modifications to subclause 6.5.7 " Thermal expansion of buried pipe sections:"

In the last line of the key to Figure 16 "Partly and fully restrained pipe sections" replace "NR" with "N "

R .

Replace the undefined "N " in Formula (24) with "N " changing it from

r R

σ σ

p p

" N=NN+ =A⋅ + N " to " N=NN+ =A⋅+ N ".

x pr R x pR R

2 2

In the paragraph above Formula (27) and the one which follows, increment the numbering of "Figure 16"

and "Figure 15" by one to read as:

"For systems as Figure 17 where fixed points or other methods ensure that the distance l from the fixed

point to an expansion facility is shorter than or equal to the friction length L, or where the distance

between two expansion facilities is less than 2L, the axial stresses in the steel service pipe are calculated

as:

N

F 1

R

σσ=−−l − (27)

xp

A 2 A

Expansion at the free pipe end from the partly restrained pipe (see Figure 16) is calculated as:".

6 Modification to subclause 6.5.9.2.4 "Excavations over the pipes"

π ⋅ EI≤⋅

To replace the "≤" sign from Formula (44) with "·"replace theformula " L= " with "

γγ⋅⋅ N

aM

π ⋅ EI⋅

".

L=

γγ⋅⋅ N

aM

=

=

7 Modifications to subclause 6.6.2 "Cross section analyses, steel"

Replace "Figure 20" with "Figure 21" in the sentence "Stresses and internal forces are illustrated in

Figure 20." resulting in "Stresses and internal forces are illustrated in Figure 21.".

Replace “t-pieces” with “T-pieces” in the sentence after Formula (46), so that it reads “For T-pieces the

outside diameters d and d and the thickness t and t for run pipe and branch, respectively, are

ro bo r b

inserted.”.

Delete "normally" in the following note:

"NOTE The effect of vertical top load from soil pressure and traffic actions can normally be ignored for

pipe dimensions DN ≤ 300.".

8 Modification to subclause 6.6.3 "Assessment on the basis of a resultant

(equivalent) stress"

From the two sentences above Formula (47), delete the last one, thus replace

"The equivalent stress can be calculated both with the minimum distortion energy hypothesis (by von

Mises´ equation), or with the shear-stress hypothesis (by Tresca equation):

The equivalent stress is calculated from the axial and tangential stress components (calculated with sign)

by Tresca or by von Mises’ equation:" with

"The equivalent stress can be calculated both with the minimum distortion energy hypothesis (by von

Mises´ equation), or with the shear-stress hypothesis (by Tresca eq

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...