SIST EN 16603-32-08:2016

(Main)Space engineering - Materials

Space engineering - Materials

ECSS-E-ST-32-08 specifies the mechanical engineering requirements for materials. This Standard also encompasses the mechanical effects of the natural and induced environments to which materials used for space applications can be subjected.

This standard specifies requirements for the establishment of the mechanical and physical properties of the materials to be used for space applications, and the verification of these requirements.

Verification includes destructive and non-destructive test methods. Quality assurance requirements for materials (e.g. procurement and control) are covered by ECSS-Q-ST-70.

This standard may be tailored for the specific characteristics and constrains of a space project in conformance with ECSS-S-ST-00.

Raumfahrttechnik - Werkstoffe

Ingénierie spatiale - Matériaux

Vesoljska tehnika - Materiali

ECSS-E-ST-32-08 določa strojniške zahteve za materiale. Ta standard zajema tudi mehanske učinke naravnih in umetno ustvarjenih okolij, ki so jim lahko izpostavljeni materiali, uporabljeni za vesoljske namene. Ta standard določa zahteve za vzpostavitev mehanskih in fizikalnih lastnosti materialov za uporabo za vesoljske namene in preverjanje teh zahtev. Preverjanje vključuje porušitvene in neporušitvene preskusne metode. Zahteve za zagotavljanje kakovosti materialov (npr. naročanje in nadzor) so zajete v standardu ECSS-Q-ST-70. Ta standard se lahko prilagodi posameznim lastnostim in omejitvam vesoljskega projekta v skladu s standardom ECSS-S-ST-00.

General Information

- Status

- Published

- Public Enquiry End Date

- 29-Mar-2016

- Publication Date

- 11-Oct-2016

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Sep-2016

- Due Date

- 06-Nov-2016

- Completion Date

- 12-Oct-2016

Relations

- Effective Date

- 31-Aug-2016

- Effective Date

- 01-Mar-2016

EN 16603-32-08:2016 - Overview

EN 16603-32-08:2016 (derived from ECSS‑E‑ST‑32‑08) is the CEN European standard for space engineering - materials. It specifies mechanical engineering requirements and verification methods for materials used in space applications, including the mechanical effects of natural and induced space environments. The standard covers establishment of mechanical and physical properties and the verification of those properties using destructive and non‑destructive testing. Quality assurance for materials procurement and control is handled by ECSS‑Q‑ST‑70, and the standard may be tailored to project constraints per ECSS‑S‑ST‑00.

Key topics and technical requirements

- Material review and governance: Materials for space structures shall be reviewed by a Materials, Mechanical Parts and Processes Control Board (MPCB).

- Strength and load cases: Material strength must be established for the worst realistic combinations of mechanical and thermal loading over the item lifetime.

- Elastic modulus: For composites, Young’s modulus (tension/compression) must be verified by representative tests; metallic values may be manufacturer‑certified.

- Fatigue and fracture toughness: Components exposed to alternating stresses require demonstration that property degradation stays within limits for the mission. Fracture toughness (Kic, Kiscc) shall be measured per customer‑approved procedures, particularly for metals in corrosive environments.

- Creep and micro‑yielding: Risk analyses are required; where creep or micro‑yielding is predicted, dedicated test campaigns or dimensional‑stability tests must be performed.

- Thermal and moisture stability: Projects must define coefficients of thermal expansion (CTE) and moisture expansion (CME) for high‑stability applications; CTE/CME measurement and sensitivity analyses (including manufacturing variability) are mandated for composites and hygroscopic materials.

- Interfaces, coatings and joining: Requirements cover anodizing, chemical conversions, metallic and hard coatings, moisture/thermal barriers, coatings on CFRP, organic paints, bolted and riveted joints, and inserts.

- Verification and inspection: Verification includes destructive testing, non‑destructive inspection (NDT/NDE/NDI) and data exchange requirements; personnel qualification references (e.g., EN 4179) apply.

Practical applications and users

This standard is targeted at:

- Space system engineers and structural/materials engineers designing spacecraft structures and components

- Materials suppliers and manufacturers providing metals, composites (CFRP, MMC, CMC), coatings and fasteners for space projects

- Test laboratories performing mechanical, environmental, fracture‑mechanics and NDT services for space hardware

- Project quality and assurance managers who must ensure compliance, procurement control and MPCB reviews

Typical applications include selection and verification of structural materials, design allowables derivation, fatigue/fracture testing programs, thermal/moisture stability assessments, and qualification of coatings and joining methods for launch and orbital environments.

Related standards

- ECSS‑E‑ST‑32 (Structural engineering)

- ECSS‑Q‑ST‑70 (Space product assurance - materials & processes)

- ECSS‑S‑ST‑00 (ECSS tailoring rules)

- EN 4179 (Qualification/approval of NDT personnel)

Keywords: space engineering materials, EN 16603‑32‑08, ECSS, mechanical properties, verification, fracture toughness, fatigue testing, composites, CTE, CME, non‑destructive testing.

Frequently Asked Questions

SIST EN 16603-32-08:2016 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Space engineering - Materials". This standard covers: ECSS-E-ST-32-08 specifies the mechanical engineering requirements for materials. This Standard also encompasses the mechanical effects of the natural and induced environments to which materials used for space applications can be subjected. This standard specifies requirements for the establishment of the mechanical and physical properties of the materials to be used for space applications, and the verification of these requirements. Verification includes destructive and non-destructive test methods. Quality assurance requirements for materials (e.g. procurement and control) are covered by ECSS-Q-ST-70. This standard may be tailored for the specific characteristics and constrains of a space project in conformance with ECSS-S-ST-00.

ECSS-E-ST-32-08 specifies the mechanical engineering requirements for materials. This Standard also encompasses the mechanical effects of the natural and induced environments to which materials used for space applications can be subjected. This standard specifies requirements for the establishment of the mechanical and physical properties of the materials to be used for space applications, and the verification of these requirements. Verification includes destructive and non-destructive test methods. Quality assurance requirements for materials (e.g. procurement and control) are covered by ECSS-Q-ST-70. This standard may be tailored for the specific characteristics and constrains of a space project in conformance with ECSS-S-ST-00.

SIST EN 16603-32-08:2016 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 16603-32-08:2016 has the following relationships with other standards: It is inter standard links to SIST EN 14607-8:2005, SIST EN 14607-8:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 16603-32-08:2016 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 16603-32-08:2016 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Vesoljska tehnika - MaterialiRaumfahrttechnik - WerkstoffeIngénierie spatiale - MatériauxSpace engineering - Materials49.140Vesoljski sistemi in operacijeSpace systems and operationsICS:Ta slovenski standard je istoveten z:EN 16603-32-08:2016SIST EN 16603-32-08:2016en,fr,de01-november-2016SIST EN 16603-32-08:2016SLOVENSKI

STANDARDSIST EN 14607-8:20051DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16603-32-08

August 2016 ICS 49.140 Supersedes EN 14607-8:2004

English version

Space engineering - Materials

Ingénierie spatiale - Matériaux

Raumfahrttechnik - Werkstoffe This European Standard was approved by CEN on 22 May 2016.

CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN and CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels © 2016 CEN/CENELEC All rights of exploitation in any form and by any means reserved worldwide for CEN national Members and for CENELEC Members. Ref. No. EN 16603-32-08:2016 E SIST EN 16603-32-08:2016

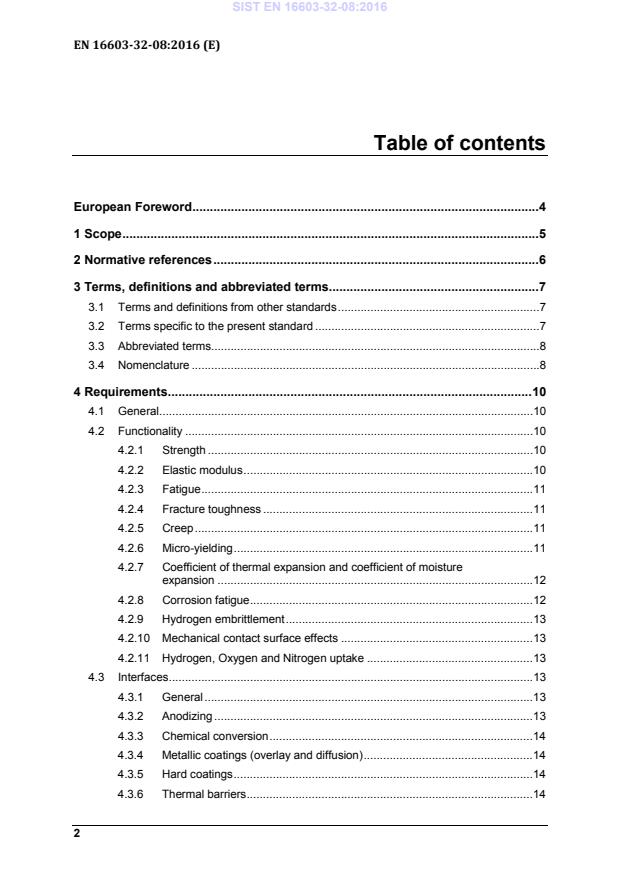

This standard specifies requirements for the establishment of the mechanical and physical properties of the materials to be used for space applications, and the verification of these requirements.

Verification includes destructive and non-destructive test methods. Quality assurance requirements for materials (e.g. procurement and control) are covered by ECSS-Q-ST-70. This standard may be tailored for the specific characteristics and constrains of a space project in conformance with ECSS-S-ST-00. SIST EN 16603-32-08:2016

EN reference Reference in text Title EN 16601-00-01 ECSS-S-ST-00-01

ECSS system - Glossary of terms EN 16603-32 ECSS-E-ST-32 Space engineering -

Structural EN 16602-70 ECSS-Q-ST-70 Space product assurance - Materials, mechanical parts and processes EN 16602-70-37 ECSS-Q-ST-70-37 Space product assurance - Determination of the susceptibility of metals to stress-corrosion cracking EN 16602-70-71 ECSS-Q-ST-70-71 Space product assurance - Material, processes and their data selection

EN 4179:2005 Aerospace series - Qualification and approval of personnel for non-destructive testing SIST EN 16603-32-08:2016

1. A-basis design allowable (A-value) 2. B-basis design allowable (B-value) 3. corrosion 3.2 Terms specific to the present standard 3.2.1 composite sandwich construction panels composed of a lightweight core material, such as honeycomb, foamed plastic, and so forth, to which two relatively thin, dense, high-strength or high stiffness faces or skins are adhered 3.2.2 material design allowable material property that has been determined from test data on a probability basis and has been chosen to assure a high degree of confidence in the integrity of the completed structure 3.2.3 micro-yield applied force to produce a residual strain of 1 × 10-6 mm/m along the tensile or compression loading direction 3.2.4 polymer high molecular weight organic compound, natural or synthetic, with a structure that can be represented by a repeated small unit, the mer NOTE

E.g. polyethylene, rubber, and cellulose. SIST EN 16603-32-08:2016

Meaning ASTM

American Society for Testing Materials CFRP

carbon fibre reinforced plastic CMC

ceramic matrix composites CME

coefficient of moisture expansion CTE

coefficient of thermal expansion DRD

document requirements definition EB

electron beam EN

European Standard Kic

plane strain critical stress intensity factor Kiscc

plane strain critical stress intensity factor for a specific environment LEO

low Earth orbit MIG

metal inert gas MMC

metal matrix composite NDE

non-destructive evaluation NDI

non-destructive inspection NDT

non-destructive test PTFE

polytetrafluoroethylene SCC

stress-corrosion cracking STS

space transportation system TIG

tungsten inert gas UD

uni-directional UV

ultra violet 3.4 Nomenclature The following nomenclature applies throughout this document: a. The word “shall” is used in this standard to express requirements. All the requirements are expressed with the word “shall”. b. The word “should” is used in this standard to express recommendations. All the recommendations are expressed with the word “should”. NOTE It is expected that, during tailoring, recommendations in this document are either converted into requirements or tailored out. c. The words “may” and “need not” are used in this standard to express positive and negative permissions, respectively. All the positive SIST EN 16603-32-08:2016

NOTE

This clause covers only structural subjects affecting materials for use in space projects. 4.2 Functionality 4.2.1 Strength a. The material strength shall be established for the worst combination of mechanical and thermal effects expected during its lifetime. NOTE

The strength of a material is highly dependent on the direction as well as on the sign of the applied load, e.g. axial tensile, transverse compressive, and others. Structural subjects are covered in ECSS-E-ST-32. 4.2.2 Elastic modulus a. For composites, the specified elastic modulus shall be verified by test on representative samples, in tension and in compression directions. NOTE 1 For metallic and alloy, it can be based on values certified by the manufacturer. NOTE 2 The elastic modulus defined as the ratio between the uniaxial stress and the strain (e.g. Young’s modulus, compressive modulus, shear modulus) is for metals and alloys weakly dependant on heat-treatment and orientation. However, for fibre reinforced materials, the elastic modulus depends on the fibre orientation. SIST EN 16603-32-08:2016

Fatigue fracture can form in components which are subjected to alternating stresses. These stresses can exist far below the allowed static strength of the material. For fracture control, see ECSS-E-ST-32-01. 4.2.4 Fracture toughness a. For homogeneous materials the Kic or Kiscc shall be measured according to procedures approved by the customer at MPCB. b. Metallic materials intended for use in corrosive surface environments shall be tested for fracture. NOTE

The fracture toughness is a measure of the damage tolerance of a material containing initial flaws or cracks. The fracture toughness in metallic materials is described by the plain strain value of the critical stress intensity factor. The fracture toughness depends on the environment. For fracture control, see ECSS-E-ST-32-01. 4.2.5 Creep a. A risk analysis shall be performed to assess the risk of creeping. b. If analysis specified in 4.2.5a confirms that creep can occur, the creep testing campaign to be performed shall be agreed with the customer at MPCB. NOTE

Creep is a time-dependant deformation of a material under an applied load. It usually occurs at elevated temperature, although some materials creep at room temperature. If permitted to continue indefinitely, creep terminates in rupture. Extrapolations from simple to complex stress-temperature time conditions are difficult. 4.2.6 Micro-yielding a. A risk analysis shall be performed to assess the risk of micro-yielding. N

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...