SIST EN 14620-5:2025

(Main)Design and manufacture of site built, vertical, cylindrical, flat-bottomed tank systems for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and -196 °C - Part 5: Testing, drying, purging and cool-down

Design and manufacture of site built, vertical, cylindrical, flat-bottomed tank systems for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and -196 °C - Part 5: Testing, drying, purging and cool-down

This document is applicable to the design and manufacture of site built, vertical, cylindrical, flat-bottomed tank systems for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and –196°C. It specifies the requirements for testing, drying, purging, cool-down and decommissioning of refrigerated liquefied gas storage tank systems.

The tank systems covered by this document are used to store large volumes of hydrocarbon products, ammonia and other non-hydrocarbon gases with low temperature boiling points, generally called “Refrigerated Liquefied Gases” (RLGs). Typical products stored in the tank systems are: methane, ethane, propane, butane, ethylene, propylene, butadiene (this range includes Liquefied Natural Gas (LNG) and Liquefied Petroleum Gas (LPG), ammonia, nitrogen, oxygen and argon.

NOTE Properties of the gases are given in Annex A EN 14620-1:2024.

This document provides requirements and specifies measures to be taken following completion of major tank construction activities and before the tank is brought in to service. It provides requirements for full-height and partial height hydrostatic testing to check the structural integrity of tanks and the capacity of the foundations. Settlement monitoring of the foundations at this stage form the starting point of an annual settlement monitoring programme for the tank foundation. Recommendations are given for marker systems for such monitoring. Requirements for water quality of both fresh water and seawater used during hydrotest, are provided to avoid the risk of corrosion of tanks and appurtenances.

Guidance and requirements for positive and negative pneumatic tests to further check tank structural integrity, leak tightness of welds and the function of pressure and vacuum relief valve systems are also given. Requirements specific to testing of double wall and membrane type tanks is included.

Rules and procedures for commissioning activities, including drying and purging with inert and product gas are provided, including required oxygen concentrations for various RLG’s. The document also provides guidance for cool-down procedures and suggestions for temperature monitoring, including an informative Annex A.

For major maintenance inspection or at the end of the life of the tank, decommissioning will be required. Guidance on safe decommissioning processes is provided.

Suggested procedures for Global testing for membrane tanks are provided in informative Annex B

This document is applicable to the design and manufacture of site built, vertical, cylindrical, flat-bottomed tank systems for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and -196°C.

Auslegung und Herstellung standortgefertigter, stehender, zylindrischer Flachboden-Tanksysteme für die Lagerung von tiefkalt verflüssigten Gasen bei Betriebstemperaturen zwischen 0 °C und -196 °C – Teil 5: Prüfen, Trocknen, Inertisieren und Kaltfahren

Dieses Dokument ist für die Auslegung und Herstellung standortgefertigter, stehender, zylindrischer Flachboden-Tanksysteme für die Lagerung von tiefkalt verflüssigten Gasen bei Betriebstemperaturen zwischen 0 °C und −196 °C anwendbar. Es legt Anforderungen an das Prüfen, Trocknen, Inertisieren, Kaltfahren und die Außerbetriebnahme von Tanks für die Lagerung von tiefkalt verflüssigten Gasen fest.

Die in diesem Dokument behandelten Tanksysteme werden zur Lagerung großer Mengen von Kohlenwasserstoffprodukten, Ammoniak und anderen Nicht-Kohlenwasserstoffgasen mit niedrigen Siedepunkten verwendet, die im Allgemeinen als „tiefkalt verflüssigte Gase“ (RLG, en: refrigerated liquefied gases) bezeichnet werden. Übliche in Tanksystemen gelagerte Lagergüter sind: Methan, Ethan, Propan, Butan, Ethylen, Propylen, Butadien (dazu gehören auch verflüssigtes Erdgas (LNG, en: liquefied natural gas) und Flüssiggas (LPG, en: liquefied petroleum gas), Ammoniak, Stickstoff, Sauerstoff und Argon.

ANMERKUNG Die Eigenschaften der Gase sind in EN 14620 1:2024, Anhang A, angegeben.

Dieses Dokument enthält Anforderungen und legt Maßnahmen fest, die nach Abschluss größerer Bautätigkeiten am Tank und vor der Inbetriebnahme des Tanks zu treffen sind. Es enthält Anforderungen für die Wasserprobe in voller Höhe und in reduzierter Höhe, um die Unversehrtheit der Konstruktion von Tanks und die Tragfähigkeit der Gründung zu überprüfen. Die Überwachung zur Setzung von Gründungen in dieser Phase stellen den Beginn eines jährlichen Überwachungsprogramms zur Setzung an der Gründung des Tanks dar. Es werden Empfehlungen für Messmarken für eine solche Überwachung gegeben. Es werden Anforderungen an die Wassergüte von frischem Wasser und Meerwasser gestellt, die während der Wasserprobe verwendet werden, um das Risiko der Korrosion von Tanks und Zubehör zu vermeiden.

Es werden auch Anleitungen und Anforderungen für die Überdruck- und Unterdruckprüfung zur weiteren Überprüfung der Unversehrtheit der Konstruktion von Tanks, der Dichtheit von Schweißnähten und der Funktion von (Unterdruck-)Sicherheitsventilen angegeben. Es werden auch spezifische Anforderungen an die Prüfung von doppelwandigen Tanks und Membrantanks gestellt.

Es werden Regeln und Verfahren für die Inbetriebnahme, einschließlich Trocknen, Inertisieren mit Inert- und Lagergutgas, angegeben, einschließlich erforderlicher Sauerstoffkonzentrationen für verschiedene RLG. Das Dokument enthält auch Anleitungen für Kaltfahrverfahren und Vorschläge für die Überwachung der Temperatur, einschließlich eines informativen Anhang A.

Bei größeren Wartungsinspektionen oder am Ende der Lebensdauer des Tanks ist eine Außerbetriebnahme erforderlich. Es werden Leitlinien für sichere Außerbetriebnahmevorgänge angegeben.

Vorgeschlagene Verfahren für umfassende Prüfungen von Membrantanks sind im informativen Anhang B angegeben.

Dieses Dokument ist anwendbar für die Auslegung und Herstellung standortgefertigter, stehender, zylindrischer Flachboden-Tanksysteme für die Lagerung von tiefkalt verflüssigten Gasen bei Betriebstemperaturen von 0 °C bis −196 °C.

Conception et fabrication de réservoirs cylindriques fond plat, verticaux, construits sur site, destinés au stockage des gaz réfrigérés, liquéfiés, dont les températures de service sont comprises entre 0 °C et -196 °C - Partie 5 : Essais, séchage, inertage et mise en froid

Le présent document spécifie les exigences relatives aux essais, séchage, inertage, mise en froid et mise hors service des réservoirs de stockage de gaz liquéfiés réfrigérés.

Le présent document traite de la conception et de la fabrication de réservoirs cylindriques fond plat, verticaux, construits sur site, destinés au stockage des gaz réfrigérés, liquéfiés, dont les températures de service sont comprises entre 0 °C et -196 °C.

Konstruiranje in proizvodnja na mestu postavitve grajenih navpičnih, valjastih jeklenih posod z ravnim dnom za shranjevanje hlajenih utekočinjenih plinov z delovnimi temperaturami med 0 °C in –196 °C - 5. del: Preskušanje, sušenje, inertizacija in ohlajanje

General Information

- Status

- Published

- Public Enquiry End Date

- 02-Oct-2023

- Publication Date

- 09-Nov-2025

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 15-Oct-2025

- Due Date

- 20-Dec-2025

- Completion Date

- 10-Nov-2025

Relations

- Effective Date

- 01-Dec-2025

Overview

EN 14620-5:2025 - Design and manufacture of site built, vertical, cylindrical, flat‑bottomed tank systems for the storage of refrigerated, liquefied gases - Part 5: Testing, drying, purging and cool‑down - is a CEN standard that sets requirements for post‑construction verification, commissioning and safe decommissioning of on‑site RLG (Refrigerated Liquefied Gas) storage tanks. It applies to tanks storing products with operating temperatures from 0 °C to −196 °C (including LNG, LPG, ammonia, nitrogen, oxygen, argon and other low‑boiling gases). The standard replaces EN 14620‑5:2006 and extends coverage and testing guidance for modern tank systems, including membrane and double‑wall designs.

Key topics and technical requirements

- Hydrostatic testing: Full‑height and partial‑height hydrotests to verify structural integrity and foundation capacity; water quality requirements for fresh and seawater to prevent corrosion; procedures for filling, emptying and post‑test cleaning.

- Pneumatic testing: Positive and negative pressure tests to confirm weld tightness, structural behaviour and the function of pressure/vacuum relief systems; specific provisions for negative pressure testing and double‑wall/double‑roof systems.

- Membrane tank testing: Specific hydrostatic, pneumatic and a recommended Global Test procedure (informative Annex B) for membrane tanks.

- Drying and purging: Procedures for drying and inert purging using inert gas or product gas, with required oxygen concentration targets for safe commissioning.

- Cool‑down: Guidance on controlled cool‑down rates and temperature monitoring (informative Annex A) to protect primary containers and membranes during initial commissioning.

- Settlement monitoring & foundations: Guidance on starting an annual settlement monitoring programme and recommendations for marker systems.

- Decommissioning: Safety guidance and procedures for end‑of‑life or major maintenance decommissioning.

- NDE and responsibilities: Normative Annex D supplements non‑destructive examination (NDE) requirements; Annex C gives guidance on duties and responsibilities between parties.

Practical applications and users

This standard is essential for:

- Tank designers and structural engineers specifying testing and commissioning criteria.

- Manufacturers and site construction contractors executing hydrostatic/pneumatic tests and membrane installations.

- Plant operators and commissioning teams responsible for drying, purging and controlled cool‑down of LNG, LPG, ammonia and other RLG storage systems.

- Inspection bodies, NDE specialists and regulators verifying compliance and safe decommissioning.

- Project managers planning testing programmes, settlement monitoring and quality control.

Related standards

- EN 14620‑1:2024 - General requirements and gas properties (see Annex A of Part 1).

- EN 14620‑2:2006 - Metallic components (referenced for steel tank requirements).

Keywords: EN 14620‑5:2025, refrigerated liquefied gases, LNG testing, hydrostatic test, pneumatic test, tank commissioning, membrane tanks, drying and purging, cool‑down, tank decommissioning.

Frequently Asked Questions

SIST EN 14620-5:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Design and manufacture of site built, vertical, cylindrical, flat-bottomed tank systems for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and -196 °C - Part 5: Testing, drying, purging and cool-down". This standard covers: This document is applicable to the design and manufacture of site built, vertical, cylindrical, flat-bottomed tank systems for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and –196°C. It specifies the requirements for testing, drying, purging, cool-down and decommissioning of refrigerated liquefied gas storage tank systems. The tank systems covered by this document are used to store large volumes of hydrocarbon products, ammonia and other non-hydrocarbon gases with low temperature boiling points, generally called “Refrigerated Liquefied Gases” (RLGs). Typical products stored in the tank systems are: methane, ethane, propane, butane, ethylene, propylene, butadiene (this range includes Liquefied Natural Gas (LNG) and Liquefied Petroleum Gas (LPG), ammonia, nitrogen, oxygen and argon. NOTE Properties of the gases are given in Annex A EN 14620-1:2024. This document provides requirements and specifies measures to be taken following completion of major tank construction activities and before the tank is brought in to service. It provides requirements for full-height and partial height hydrostatic testing to check the structural integrity of tanks and the capacity of the foundations. Settlement monitoring of the foundations at this stage form the starting point of an annual settlement monitoring programme for the tank foundation. Recommendations are given for marker systems for such monitoring. Requirements for water quality of both fresh water and seawater used during hydrotest, are provided to avoid the risk of corrosion of tanks and appurtenances. Guidance and requirements for positive and negative pneumatic tests to further check tank structural integrity, leak tightness of welds and the function of pressure and vacuum relief valve systems are also given. Requirements specific to testing of double wall and membrane type tanks is included. Rules and procedures for commissioning activities, including drying and purging with inert and product gas are provided, including required oxygen concentrations for various RLG’s. The document also provides guidance for cool-down procedures and suggestions for temperature monitoring, including an informative Annex A. For major maintenance inspection or at the end of the life of the tank, decommissioning will be required. Guidance on safe decommissioning processes is provided. Suggested procedures for Global testing for membrane tanks are provided in informative Annex B This document is applicable to the design and manufacture of site built, vertical, cylindrical, flat-bottomed tank systems for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and -196°C.

This document is applicable to the design and manufacture of site built, vertical, cylindrical, flat-bottomed tank systems for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and –196°C. It specifies the requirements for testing, drying, purging, cool-down and decommissioning of refrigerated liquefied gas storage tank systems. The tank systems covered by this document are used to store large volumes of hydrocarbon products, ammonia and other non-hydrocarbon gases with low temperature boiling points, generally called “Refrigerated Liquefied Gases” (RLGs). Typical products stored in the tank systems are: methane, ethane, propane, butane, ethylene, propylene, butadiene (this range includes Liquefied Natural Gas (LNG) and Liquefied Petroleum Gas (LPG), ammonia, nitrogen, oxygen and argon. NOTE Properties of the gases are given in Annex A EN 14620-1:2024. This document provides requirements and specifies measures to be taken following completion of major tank construction activities and before the tank is brought in to service. It provides requirements for full-height and partial height hydrostatic testing to check the structural integrity of tanks and the capacity of the foundations. Settlement monitoring of the foundations at this stage form the starting point of an annual settlement monitoring programme for the tank foundation. Recommendations are given for marker systems for such monitoring. Requirements for water quality of both fresh water and seawater used during hydrotest, are provided to avoid the risk of corrosion of tanks and appurtenances. Guidance and requirements for positive and negative pneumatic tests to further check tank structural integrity, leak tightness of welds and the function of pressure and vacuum relief valve systems are also given. Requirements specific to testing of double wall and membrane type tanks is included. Rules and procedures for commissioning activities, including drying and purging with inert and product gas are provided, including required oxygen concentrations for various RLG’s. The document also provides guidance for cool-down procedures and suggestions for temperature monitoring, including an informative Annex A. For major maintenance inspection or at the end of the life of the tank, decommissioning will be required. Guidance on safe decommissioning processes is provided. Suggested procedures for Global testing for membrane tanks are provided in informative Annex B This document is applicable to the design and manufacture of site built, vertical, cylindrical, flat-bottomed tank systems for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and -196°C.

SIST EN 14620-5:2025 is classified under the following ICS (International Classification for Standards) categories: 23.020.10 - Stationary containers and tanks. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14620-5:2025 has the following relationships with other standards: It is inter standard links to SIST EN 14620-5:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14620-5:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2025

Nadomešča:

SIST EN 14620-5:2007

Konstruiranje in proizvodnja na mestu postavitve grajenih navpičnih, valjastih

jeklenih posod z ravnim dnom za shranjevanje hlajenih utekočinjenih plinov z

delovnimi temperaturami med 0 °C in –196 °C - 5. del: Preskušanje, sušenje,

inertizacija in ohlajanje

Design and manufacture of site built, vertical, cylindrical, flat-bottomed tank systems for

the storage of refrigerated, liquefied gases with operating temperatures between 0 °C

and -196 °C - Part 5: Testing, drying, purging and cool-down

Auslegung und Herstellung standortgefertigter, stehender, zylindrischer Flachboden-

Tanksysteme für die Lagerung von tiefkalt verflüssigten Gasen bei Betriebstemperaturen

zwischen 0 °C und -196 °C – Teil 5: Prüfen, Trocknen, Inertisieren und Kaltfahren

Conception et fabrication de réservoirs cylindriques fond plat, verticaux, construits sur

site, destinés au stockage des gaz réfrigérés, liquéfiés, dont les températures de service

sont comprises entre 0 °C et -196 °C - Partie 5 : Essais, séchage, inertage et mise en

froid

Ta slovenski standard je istoveten z: EN 14620-5:2025

ICS:

23.020.10 Nepremične posode in Stationary containers and

rezervoarji tanks

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14620-5

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2025

EUROPÄISCHE NORM

ICS 23.020.10 Supersedes EN 14620-5:2006

English Version

Design and manufacture of site built, vertical, cylindrical,

flat-bottomed tank systems for the storage of refrigerated,

liquefied gases with operating temperatures between 0 °C

and -196 °C - Part 5: Testing, drying, purging and cool-

down

Conception et fabrication de réservoirs cylindriques Auslegung und Herstellung standortgefertigter,

fond plat, verticaux, construits sur site, destinés au stehender, zylindrischer Flachboden-Tanksysteme für

stockage des gaz réfrigérés, liquéfiés, dont les die Lagerung von tiefkalt verflüssigten Gasen bei

températures de service sont comprises entre 0 °C et - Betriebstemperaturen zwischen 0 °C und -196 °C - Teil

196 °C - Partie 5 : Essais, séchage, inertage et mise en 5: Prüfen, Trocknen, Inertisieren und Kaltfahren

froid

This European Standard was approved by CEN on 27 July 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14620-5:2025 E

worldwide for CEN national Members.

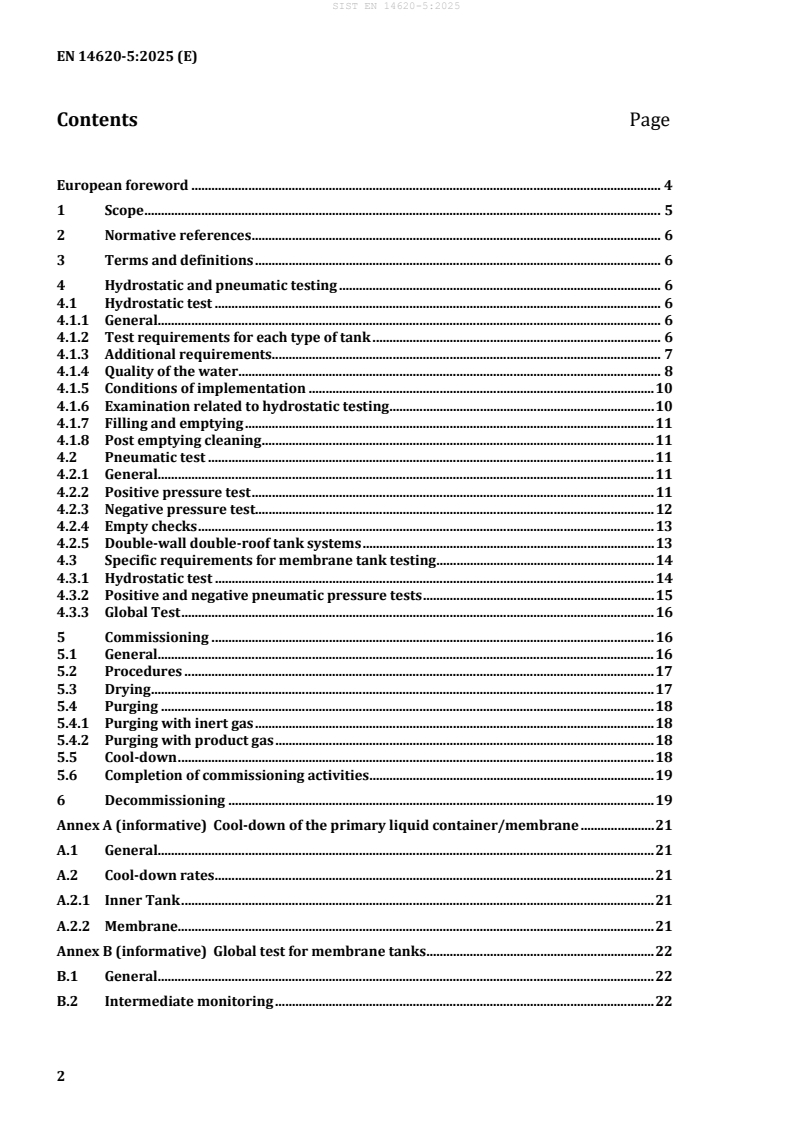

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 6

3 Terms and definitions . 6

4 Hydrostatic and pneumatic testing . 6

4.1 Hydrostatic test . 6

4.1.1 General. 6

4.1.2 Test requirements for each type of tank . 6

4.1.3 Additional requirements. 7

4.1.4 Quality of the water . 8

4.1.5 Conditions of implementation . 10

4.1.6 Examination related to hydrostatic testing . 10

4.1.7 Filling and emptying . 11

4.1.8 Post emptying cleaning . 11

4.2 Pneumatic test . 11

4.2.1 General. 11

4.2.2 Positive pressure test . 11

4.2.3 Negative pressure test. 12

4.2.4 Empty checks . 13

4.2.5 Double-wall double-roof tank systems . 13

4.3 Specific requirements for membrane tank testing . 14

4.3.1 Hydrostatic test . 14

4.3.2 Positive and negative pneumatic pressure tests . 15

4.3.3 Global Test . 16

5 Commissioning . 16

5.1 General. 16

5.2 Procedures . 17

5.3 Drying . 17

5.4 Purging . 18

5.4.1 Purging with inert gas . 18

5.4.2 Purging with product gas . 18

5.5 Cool-down . 18

5.6 Completion of commissioning activities . 19

6 Decommissioning . 19

Annex A (informative) Cool-down of the primary liquid container/membrane . 21

A.1 General. 21

A.2 Cool-down rates . 21

A.2.1 Inner Tank . 21

A.2.2 Membrane . 21

Annex B (informative) Global test for membrane tanks . 22

B.1 General. 22

B.2 Intermediate monitoring . 22

B.3 Test Phases . 22

B.3.1 Concrete outer tank . 22

B.3.2 Steel outer tank . 23

Annex C (informative) Guidance for duties and responsibilities between parties . 25

Annex D (normative) Requirements for non-destructive examinations (NDE) of steel

containers supplementary to Table 14 EN 14620-2:2006 . 26

D.1 For steel primary containers . 26

D.2 For steel secondary containers. 26

D.3 For steel membrane tank outer containers . 26

D.3.1 Hydrotested prior to Membrane installation . 26

D.3.2 Hydrotested after Membrane installation . 26

Bibliography . 28

European foreword

This document (EN 14620-5:2025) has been prepared by Technical Committee CEN/TC 265 “Metallic

tanks for the storage of liquids”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2026, and conflicting national standards shall be

withdrawn at the latest by April 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14620-5:2006.

— Table 1 ‘Hydrostatic test requirements’ updated and adjusted to relate to product temperature;

— product temperature range extended to −196°C to include LIN, LOX and LAR;

— permitted use of small temporary safety opening in primary steel liquid container after hydrostatic

test added;

— requirements for inspection of concrete surfaces during pressure test added;

— negative pressure test details clarified;

— negative pressure test requirements for double-wall double-roof tanks clarified;

— purging of bottom insulation space clarified;

— decommissioning guidance improved;

— new informative annex for global test for membrane tanks added;

— new informative annex for guidance for duties and responsibilities between parties added;

— new normative annex for NDE of steel containers supplementary to EN 14620-Part 2:2006.

A list of all parts in the EN 14620 series, “Design and manufacture of site built, vertical, cylindrical, flat-

bottomed tank systems for the storage of refrigerated, liquefied gases with operating temperatures between

0 °C and −196 °C”, can be found on the CEN website.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document is applicable to the design and manufacture of site built, vertical, cylindrical, flat-bottomed

tank systems for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C

and –196°C. It specifies the requirements for testing, drying, purging, cool-down and decommissioning

of refrigerated liquefied gas storage tank systems.

The tank systems covered by this document are used to store large volumes of hydrocarbon products,

ammonia and other non-hydrocarbon gases with low temperature boiling points, generally called

“Refrigerated Liquefied Gases” (RLGs). Typical products stored in the tank systems are: methane, ethane,

propane, butane, ethylene, propylene, butadiene (this range includes Liquefied Natural Gas (LNG) and

Liquefied Petroleum Gas (LPG), ammonia, nitrogen, oxygen and argon.

NOTE Properties of the gases are given in Annex A EN 14620-1:2024.

This document provides requirements and specifies measures to be taken following completion of major

tank construction activities and before the tank is brought in to service. It provides requirements for full-

height and partial height hydrostatic testing to check the structural integrity of tanks and the capacity of

the foundations. Settlement monitoring of the foundations at this stage form the starting point of an

annual settlement monitoring programme for the tank foundation. Recommendations are given for

marker systems for such monitoring. Requirements for water quality of both fresh water and seawater

used during hydrotest, are provided to avoid the risk of corrosion of tanks and appurtenances.

Guidance and requirements for positive and negative pneumatic tests to further check tank structural

integrity, leak tightness of welds and the function of pressure and vacuum relief valve systems are also

given. Requirements specific to testing of double-wall and membrane type tanks is included.

Rules and procedures for commissioning activities, including drying and purging with inert and product

gas are provided, including required oxygen concentrations for various RLG’s. The document also

provides guidance for cool-down procedures and suggestions for temperature monitoring, including an

informative Annex A.

For major maintenance inspection or at the end of the life of the tank, decommissioning will be required.

Guidance on safe decommissioning processes is provided.

Suggested procedures for Global testing for membrane tanks are provided in informative Annex B

This document is applicable to the design and manufacture of site built, vertical, cylindrical, flat-bottomed

tank systems for the storage of refrigerated, liquefied gases with operating temperatures between 0 °C

and –196°C.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 14620-1:2024, Design and manufacture of site built, vertical, cylindrical, flat-bottomed tank systems for

the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and -196 °C - Part 1:

General

EN 14620-2:2006, Design and manufacture of site built, vertical, cylindrical, flat-bottomed steel tanks for

the storage of refrigerated, liquefied gases with operating temperatures between 0 °C and -165 °C - Part 2:

Metallic components

3 Terms and definitions

For the purposes of this document, the definitions given in EN 14620-1:2024 and the following terms

apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

4 Hydrostatic and pneumatic testing

4.1 Hydrostatic test

4.1.1 General

A hydrostatic test shall be carried out. The hydrostatic test shall demonstrate that:

— the tank system is designed and constructed to contain the product under normal operating

conditions;

— the foundation is able to support the tank and its contents.

NOTE A hydrostatic test might also aid the relief of residual stresses for steel tanks.

Details can be found in 4.1.2 to 4.1.7 and 4.3.1.

4.1.2 Test requirements for each type of tank

For the various tank types, the hydrostatic test shall be carried out in accordance with Table 1.

Hydrostatic testing of secondary liquid containers of double and full containment systems (see Table 1)

is not required unless explicitly required by the project specification.

A comprehensive specification shall be prepared which includes the requirements of equipment and

methodologies for safe execution of all stages of the hydrostatic test. The testing shall be subject to a

quality management system in accordance with EN 14620-1:2024. The test results shall be documented.

NOTE See Annex C

For products with specific gravity between 0,8 and 1,0 (e.g. LIN) the overload requirements of 4.1.3

cannot be met. However, load applied during hydrotest exceeds loads applied during operation.

If product specific gravity exceeds 1,0, (e.g. LOX and LAR), it is accepted that the hydrotest would not

demonstrate objectives outlined in 4.1.1. In this case special provisions, such as long-term monitoring of

foundation settlement during operation may be required.

Table 1 — Hydrostatic test requirements

Product Single Double

Full containment Membrane tank

Boiling containment containment

c

Point

a

≥ −50 °C Primary liquid Primary liquid Primary liquid Membrane barrier

container - steel container - steel container – steel

FH FH FH

Secondary liquid Secondary liquid Outer container -

container - steel container - steel steel

No test No Test FH

Secondary liquid Secondary liquid Outer container -

container - pre- container – pre- pre-stressed

stressed concrete stressed concrete concrete

a,b

No test No test PH

a

< −50 °C Primary liquid Primary liquid Primary liquid Membrane barrier

container - steel container - steel container - steel

b b b

PH PH PH

Secondary liquid Secondary liquid Outer container –

container - steel container – steel steel

b

No test No test PH

Secondary liquid Secondary liquid Outer container –

container – pre- container – pre- pre-stressed

stressed concrete stressed concrete concrete

a,b

No test No test PH

NOTE FH means Full height hydrostatic test, PH means Partial height hydrostatic test.

a

In the case of a membrane tank, there is no general requirement for the membrane barrier to be hydrostatically

tested but refer also to 4.3.1.3. Refer to 4.3 for hydrotesting of membrane tank outer container.

b

For products where the specific gravity exceeds 0,8, the equivalent full height hydrotest will apply.

c

Product Boiling Point as defined in Table A.1, Annex A in EN 14620-1:2024.

4.1.3 Additional requirements

The following additional requirements shall apply:

— Leak testing shall be completed by means of the welding examination and inspection requirements

described in Annex D and EN 14620-2:2006.

— For a full height hydrostatic test, the primary liquid container shall be filled to the maximum design

liquid level.

— For a partial height hydrostatic test of the primary liquid container, the test pressure applied by

hydrotest water to the tank bottom shall be equal to 1,25 times the pressure applied to the tank

bottom by the product at the height of the maximum design liquid level.

— In cases where the project specification calls for a secondary liquid container hydrotest, the same

quantity of water as for testing of the primary liquid container shall be used. The hydrotest liquid

level in the annular space shall never exceed the concurrent liquid level in the primary liquid

container. A suitable water barrier shall be provided to prevent test water ingress into the bottom

insulation.

— For the container subject to hydrotest the hydrostatic test shall not be carried out until all welded

accessories to the shell and the bottom of the container are in place. Welding shall not be allowed

after completion of the hydrostatic test. The exception is when approved by the Purchaser, to assist

quick emergency evacuation of construction personnel for tank systems without wall penetrations.

A single circular temporary opening, not smaller than 600mm and not larger than 1000mm in

diameter, may be allowed in the tank after hydrotest. The opening shall be permanently closed by

the welding of a closure plate after personnel access into the hydrotested container is no longer

necessary. The closure plate shall conform to the shape of the shell and be in accordance with

EN 14620-2:2006.

— The circular opening shall be positioned so that it does not cross any shell seams. It should also be at

least the greater of 300mm or 10 times the shell thickness from any other weld in the shell. This

includes shell to bottom weld, shell seams or welds to attachments.

— The butt weld around the perimeter of the closure plate shall be examined over the entirety of its

length. Examination shall comprise liquid penetrant method and radiographic method. The liquid

penetrant inspection is needed on the root pass, on the back gouged surface and on the inside and

outside surfaces of the finished weld. The whole weld shall also be vacuum box leak tested. The

welding and testing procedures shall be in accordance with EN 14620-2:2006.

— For tanks which are to be insulated with expanded perlite, the hydrostatic test shall be carried out

before installation of the expanded perlite and resilient layer (if applicable).

4.1.4 Quality of the water

The water shall be of a quality such that no damage to the steel, concrete or coatings can occur. The

suitability of the water for hydrostatic testing shall be demonstrated.

NOTE 1 See Annex C

Special attention shall be paid to possible corrosion.

The following types of corrosion shall be considered:

— general corrosion;

— galvanic corrosion; and

— localised corrosion (pitting, under deposit corrosion, bacterial corrosion).

NOTE 2 Galvanic corrosion (fresh and sea water) is an electrochemical form of corrosion. It can occur when a

metal or alloy is electrically connected to another metal or alloy with a different electrochemical potential and the

metals (alloys) are exposed to a common electrolyte and electrical path. Welding of metals can lead to dissimilar

metal compositions between the weld, Heat Affected Zone (HAZ) and the plate material. The most anodic material

area will corrode because of the galvanic effect with the cathodic material areas.

NOTE 3 Localised corrosion can occur under the following circumstances in the presence of deposits and or

solids:

a) presence of sulphate reducing bacteria;

b) locations where a low oxygen content is present.

Deposits or solids, present in the seawater, might settle down on the steel surface during hydrostatic

testing and localised corrosion cells might develop. This can lead to high corrosion penetration rates.

For tanks constructed from Type III and IV steels defined in EN 14620-2:2006 the minimum hydrostatic

test water quality shall be as follows:

• Water shall be clean and clear and has no objectional odours (e.g. H S Hydrogen Sulfide)

• Water temperature shall not exceed +50°C

• Water pH shall be between 6 and 8,3

In addition, for Type V steel defined in EN 14620-2:2006, the total halogen content (chloride + bromide

+ iodide) in hydrostatic test water used for testing liquid containers or membrane shall be limited to 50

ppm.

Sea water shall never be used inside stainless steel containers or membrane.

Sea water may be used for hydrostatic testing of 9 % nickel steel tanks having stainless steel internals.

There are corrosion concerns when seawater is used and the concerns listed below shall be properly

addressed before it may be used.

— galvanic activity between plate material, weld and HAZ;

— when soils/deposits are present in the seawater, localized corrosion when cells can develop;

— effect of sulphate reducing bacteria resulting in sour “corrosive” environment and possible formation

of hydrogen;

— the need for protection of stainless-steel internal components and exposed flange gasket surfaces;

— the need for removal/prevention of dried mineral deposits resulting from draining of sea water.

The need for cathodic protection should be investigated to avoid galvanic corrosion and to reduce general

corrosion.

NOTE 4 Cathodic protection promotes the cathodic reaction, which in de-aerated conditions (under deposits)

generates hydrogen and therefore increases the risk of hydrogen stress cracking, if hydrogen sulphide is present at

the same time.

The cathodic protection system (when required) shall be designed so that the risk of hydrogen

embrittlement is avoided.

If the required water quality cannot be achieved then alternative methods utilizing filters or suitable

inhibitors shall be considered.

Before discharging any test water from the Tank System, the environmental impact shall be investigated.

4.1.5 Conditions of implementation

Before the start of the test, the tank shall be cleaned. Any spatter and slag shall be removed from the

welds, and all materials, objects or temporary installations used during its construction, shall also be

removed.

Provisions should be taken in order to ensure that potential settlement during the hydrotest will not put

unacceptable loads on the piping or any structural component connected to the tank.

Hydrostatic test of the tank systems shall be conducted with roof manhole (manholes) open to

atmosphere.

4.1.6 Examination related to hydrostatic testing

4.1.6.1 Peripheral level check

Before filling, permanent markers shall be installed equidistantly around the perimeter of the foundation

of the tank. They shall be spaced at a maximum spacing of 10 m around the circumference and with a

minimum of 8 markers.

For tank systems supported on a common foundation, markers shall also be installed on the primary

liquid container, in double and full containment tank systems. This is so that settlement of the inner tank

can be monitored simultaneously with that of the secondary liquid container.

The markers shall be of such a type that they remain visible/usable after the tank is painted and shall be

referenced to a remote benchmark.

A baseline measurement shall be conducted when the tank is empty and before the start of the hydrostatic

test.

The settlement of the tank shall be monitored during the filling and emptying of the tank. As a minimum,

this shall be done when the tank is a quarter full, half full, three-quarters full, full and after emptying. The

monitoring results shall be permanently recorded. The “after emptying” results shall form the start point

of an annual settlement monitoring programme for the tank foundation.

4.1.6.2 Bottom surface level check

Provisions shall be made so that the settlement profile of the tank base can be monitored. Refer to

EN 14620-1:2024. The minimum requirement is to provide monitoring across two orthogonal tank

diameters.

For ground supported tanks, an inclinometer or suitable measurement system, permanently cast into the

tank base slab shall be used.

For elevated tanks, monitoring may be by means of taking a series of levels on the soffit of the tank base

at permanently marked locations. The number of locations is to suit the tank diameter, shall be sufficient

to produce a reliable settlement profile across the tank and be ≤ 7,5 m spacing for larger tanks.

Alternatively, the same type of inclinometer or measurement system used for ground supported slabs

can be adopted.

4.1.6.3 Additional examination

The tightness of all welded joints above the test water level of an open-top tank shall be inspected by

vacuum box testing.

During filling, the observed settlements shall be compared with the predicted values. If differences occur,

the geotechnical expert, involved in the foundation design, shall be consulted (see EN 14620-1:2024) and

the purchaser shall be informed.

During the test, a visual inspection of the shell welds for possible leakage shall be carried out.

4.1.7 Filling and emptying

The rate of filling shall be determined based on water/equipment availability and subsoil conditions.

The full water load shall be maintained for at least 24 h. During the test, a visual inspection of the shell

welds for possible leakage shall be carried out.

4.1.8 Post emptying cleaning

When the tank is at atmospheric pressure and has been emptied it should be thoroughly cleaned and

dried. If cleaning is to be performed from a floating device while emptying the tank, appropriate safety

precautions shall be put in place and agreed with the purchaser. All residue and sludge shall be removed

and tank bottom cleaned to make bottom welds available for further examination. The walls of the tank

and appurtenances should be washed, if low quality water or seawater is used in the testing.

4.2 Pneumatic test

4.2.1 General

A pneumatic test shall be carried out. The purpose of the tank system pneumatic testing is as follows:

— to demonstrate the ability of the tank system and all its components to resist design internal positive

and negative pressure loads without any failures or damage;

— to perform leak tightness testing for the tank components not previously tested for leak tightness in

accordance with EN 14620-2:2006;

— to check leak tightness of specific welds where the test pressure is expected to cause local

deformations (e.g. around openings or along shell-roof compression area);

— to verify the global tightness of internal pressure boundaries, if any (e.g. in the case of double-wall

double-roof tanks); and

— to verify that pressure and vacuum relief valves operate properly and open at the specified setting

pressures.

Specific requirements for pneumatic testing are provided in the following paragraphs 4.2.2 to 4.2.5.

During pneumatic testing, visual inspection of accessible external surfaces of the roof and walls may be

considered. This is to ensure the structure behaves as predicted by the design. Any concrete surface

cracking in excess of that allowed for in the design, abnormal deformation of steel plates, leakage, or other

defects, shall be reported to the party responsible for the test. If behaviour of the structure is not as

predicted, if necessary, the test shall be suspended and investigation carried out.

Trigonometric levelling of the roof structure may also be considered, to check predicted deflections are

not exceeded, where appropriate, or specified by the owner.

For safety reasons, inspection shall only be undertaken at pressures at, or below 1,0 times the design

pressure.

4.2.2 Positive pressure test

A pressure test for tank components only shall be carried out at a test pressure equal to 1,25 times the

design pressure of the tank. Thereafter the pressure shall be reduced to the design pressure to enable

testing of relief valve set pressure.

For hydrotested fixed roof containers, the test pressure shall be applied to the vapour space above the

hydrotest water level.

For double-wall tanks with open-top inner tank, the inner tank may be completely or partially emptied

of water before the pressure test.

The following actions shall be considered:

— pressure relief valves shall be adjusted to open at the test pressure. Alternatively, a temporary

pressure relief system shall be provided to prevent the pressure exceeding the test pressure. The test

pressure, when reached, shall be held for at least 60 min. Thereafter the test pressure shall be

reduced to the design pressure;

— soap solution tests of all accessible welded joints, subjected to the pressure test, shall be performed

at design pressure;

— soap solution test for accessible welds can be substituted by visual inspection, if the joint has

previously been vacuum-box tested. This relaxation does not apply to the following welds of steel

roofs:

— single sided roof plate welds to the compression ring; and

— welds of roof nozzles and piping.

— repairs shall not be made while the tank is under pressure;

NOTE Repairs can be made later and individually vacuum box tested.

— pressure shall be reduced and pressure relief valves shall be adjusted to open at the design pressure.

The set pressure of the pressure relief valves shall be verified by increasing pressure in the vapour

space.

4.2.3 Negative pressure test

A negative pressure test shall be carried out in two stages. Stage 1 to test the tank and stage 2 to test the

vacuum relief valves.

Except for open-top inner tanks, the negative pressure test shall be carried out while there is still water

in the tank. Downward water pressure on the bottom shall be 200 % of the negative test pressure.

Keeping a pool of water in the tank would help to control the suction effect on the tank bottom and the

bottom part of the thermal protection system (TPS) and help prevent ballooning. For tanks with TPS not

designed for differential pressure, a provision to equalize pressure above and below secondary bottom

/TPS shall be considered in the design.

Stage 1 – The tank shall be tested at a pressure equal to the internal negative design pressure of the tank.

Negative pressure testing of low-pressure tanks is a delicate operation. Utmost care shall be taken not to

exceed the tank design limits. When approaching the test pressure levels, the air/water withdrawal is to

be exercised carefully and at slow rate. Any further vacuum generation shall be terminated once the

required pressure levels have been reached.

In order to prevent any accidental damage to the tank during testing, robust measures such as vacuum

relief shall be installed. A temporary vacuum relief system shall be provided which can be opened

instantaneously once the test negative pressure is reached. Alternatively, a system should be provided

which is able to counteract vacuum generated by air withdrawal and additional negative pressure not

exceeding 0,15 kPa above set point. The nozzle used for this temporary relieving system shall neither

have any internal piping nor be smaller than 100NB. For this operation, normal vacuum relief valves

should be blocked.

A minimum holding time is not required. The test may be finished as soon as the design internal negative

pressure has been reached.

Stage 2 – The vacuum relief valves installed on the tank, shall be individually tested to verify that they

open at their set pressure.

NOTE 1 The set pressure of the vacuum relief valves will by design, be a smaller value of a negative pressure

than the internal negative design pressure of the tank. For example, if a design negative pressure is specified at

−6 mbarg the setting pressure can be at −3 mbarg, such that when the relief valve is fully open negative pressure

does not exceed the design value.

NOTE 2 See Annex C

The following actions shall be taken:

— all openings shall be closed except those of the vacuum relief valves and the temporary vacuum relief

systems. The required negative pressure may be obtained by lowering the water level or by the use

of an air-ejector;

— Each of the vacuum relief valves shall be sequentially tested to open at the specified set pressure. The

set pressure of the vacuum relief valve shall be verified by withdrawing water or using an air-ejector.

NOTE 3 The actual sequence of stage 1 and 2 can be selected by the Contractor.

4.2.4 Empty checks

When the tank is at atmospheric pressure, has been emptied, dried and cleaned (i.e. all residue and sludge

removed and the walls and base cleaned), the following actions shall be considered:

— anchorage, if provided, shall be re-checked for tightness against the hold-down brackets;

— air pressure, equal to the design pressure, shall be applied to the empty tank, and the anchorage, if

provided, and the foundation shall be checked for uplift;

— bottom shall be checked for abnormalities and all bottom welds shall be vacuum box tested again;

— all welds of connections which are penetrating the tank shell or bottom below liquid design level,

shall be inspected (e.g. nozzle-shell or nozzle-bottom connections). Inspection shall be by 100 %

visual inspection and 100 % dye penetrant or magnetic particle examination; and

— thin, metallic wall liners fixed to embedments on the inner surfaces of the concrete secondary liquid

containers shall be visually inspected. For thick, free-standing metallic wall liners acting as inside

face concrete formwork, no inspection is required.

4.2.5 Double-wall double-roof tank systems

Double-wall double-roof tanks usually consist of two pressure compartments (inner and outer tank), due

to the nature of their design. It shall be ensured that during pneumatic testing the test positive and

negative pressures of the individual tank compartments are not exceeded.

Double-wall double-roof tanks shall be pneumatically tested as follows:

Inner tank:

— Positive pressure test in accordance with 4.2.2.

— Negative pressure test in accordance with 4.2.3.

— The test negative pressure applied to the inner tank structures at Stage 1 testing, shall be the total of

design vacuum in the inner tank and design pressure in the annular space. The test negative pressure

may be reached by concurrently applying inner tank design vacuum and the annular space design

pressure. Alternatively, the pressure may be achieved by creating negative pressure in the inner tank

equal to the required total value. Sufficient amount of water shall be kept in the inner tank during

negative pressure testing to prevent the inner tank bottom ballooning from the applied negative

pressure.

— Empty check of the inner container in accordance with 4.2.4.

Outer tank:

— Positive pressure test in accordance with 4.2.2.

— Ballooning of the inner tank bottom shall be prevented. Additionally, if the outer tank positive test

pressure exceeds the inner tank negative test pressure, equalization needs to be achieved. This may

be done by either pressure equalization between the inner and the outer tank, or pressurization of

the inner container shall be provided.

— Negative pressure test in accordance with 4.2.3.

— Pressure and vacuum relief valves for the purge container shall be tested as required by 4.2.2 and

4.2.3.

4.3 Specific requirements for membrane tank testing

4.3.1 Hydrostatic test

4.3.1.1 General

A hydrostatic test shall be performed on membrane tanks, in accordance with Table 1, to demonstrate:

— the ability of the foundation to support the tank and its contents; and

— the structural adequacy of the membrane tank outer container.

The hydrostatic test method differs according to whether the membrane tank outer container is concrete

or steel (see 4.3.1.2 and 4.3.1.3).

Regardless of the type of membrane tank, the settlements of the tank shall be monitored during the water

filling and emptying, in accordance with 4.1.6. The observed settlements shall be compared with the

predicted values. If differences occur, the geotechnical expert, involved in the foundation design, shall be

consulted, the party responsible for the test shall be informed and if necessary, the test suspended.

4.3.1.2 Concrete outer tank

Generally, the hydrotest is performed before the installation of the insulation and membrane.

Consequently, the prestressed concrete outer tank with its water vapour barrier is directly filled with

water.

NOTE 1 The concrete outer container is designed to accommodate the hydrostatic test loading and the potential

effects of the temporary openings and post tensioning system (see EN 14620-3:2006).

The temporary openings of the membrane tank outer container shall be temporarily closed with water

tight doors, designed to withstand the hydrostatic load.

During hydrotesting of membrane tanks with a concrete outer container, visual inspection of the outer

surface shall be made throughout the test period. This is to ensure the structure behaves as predicted by

the design. Any surface cracking in excess of that allowed for in the design, or other defects, shall be

reported to the party responsible for the test. If behaviour of the structure is not as predicted, if necessary,

the test shall be suspended and an investigation undertaken.

NOTE 2 In the specific case when the hydrotest is to be performed after the membrane installation, the purpose

of the test is not to test the membrane tightness. The same provisions, requirements and checks as described above

apply.

4.3.1.3 Steel outer tank

It is recommended that the hydrostatic test of a membrane tank with steel outer tank is done after

membrane installation. This is due to the requirement for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...