SIST EN 13160-5:2016+A1:2025

(Main + Amendment)Leak detection systems - Part 5: Requirements and test/assessment methods for in-tank gauge systems and pressurised pipework systems

Leak detection systems - Part 5: Requirements and test/assessment methods for in-tank gauge systems and pressurised pipework systems

This standard gives requirements and corresponding test\assessment methods applicable to leak detection kits, based upon volumetric loss from within the tank and/or pipework system. The kits usually comprise:

- Measuring Device

- Evaluation Device

- Alarm Device

Intended use:

Leak Detection kits are intended to be used in\with single or double skin underground tanks or single or double skin underground and/or aboveground, pipework designed for flammable liquids having a flash point not exceeding 100 °C.

Leckanzeigesysteme - Teil 5: Anforderungen und Prüf-/Bewertungsmethoden für Tankinhaltsmesssysteme und druckbeaufschlagte Rohrleitungen

Diese Europäische Norm legt Anforderungen an und die einschlägigen Prüf-/Bewertungsmethoden für Leckanzeiger, die auf dem Volumenverlust aus dem Inneren des Tanks und/oder Rohrleitungssystems basieren, fest. Die Systeme bestehen in der Regel aus:

- Messeinrichtung;

- Auswerteeinrichtung;

- Alarmeinrichtung.

Vorgesehener Verwendungszweck:

Leckanzeiger sind für den Einsatz in/mit ein- oder doppel¬wandigen unterirdischen Tanks oder ein- oder doppelwandigen unterirdischen und/oder oberirdischen Rohrleitungen vorgesehen, die für brennbare Flüssigkeiten mit einem Flammpunkt von höchstens 100 °C ausgelegt sind.

Systèmes de détection de fuites - Partie 5: Exigences et méthodes d'essai/d'évaluation des systèmes de détection de fuites en citernes et des systèmes de tuyauterie sous pression

La présente Norme européenne spécifie les exigences et les méthodes d'essai/d'évaluation correspondantes applicables aux kits de détection de fuites, fondées sur la perte volumétrique dans le réservoir et/ou dans le système de tuyauteries. Les kits sont généralement constitués des éléments suivants :

— Dispositif de mesurage

— Dispositif d'évaluation

— Dispositif d'alarme

Usage prévu :

Les kits de détection de fuites sont destinés à être utilisés dans/avec des réservoirs souterrains à simple ou double paroi ou des tuyauteries à simple ou double paroi, souterraines et/ou aériennes, conçus pour des liquides inflammables ayant un point d'éclair inférieur ou égal à 100 °C.

Sistemi za kontrolo tesnosti - 5. del: Zahteve in metode za preskušanje in ocenjevanje sistemov za zaznavanje netesnosti, vgrajenih v rezervoarje in tlačne cevovode (vključno z dopolnilom A1)

Ta standard določa zahteve ter ustrezne metode za preskušanje in ocenjevanje, ki se uporabljajo za komplete za kontrolo tesnosti, ki temeljijo na volumetrični izgubi v rezervoarju ali cevovodu. Kompleti so običajno sestavljeni iz:

– merilne naprave;

– naprave za ocenjevanje;

– alarmne naprave.

Predvidena uporaba:

Kompleti za kontrolo tesnosti so namenjeni za uporabo z eno- ali dvoplaščnimi podzemnimi rezervoarji ali eno- ali dvoplaščnimi podzemnimi in/ali nadzemnimi cevovodi, ki so zasnovani za vnetljive tekočine s plameniščem do 100 °C, oziroma za vgradnjo vanje.

General Information

- Status

- Published

- Publication Date

- 11-Dec-2024

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 08-Oct-2024

- Due Date

- 13-Dec-2024

- Completion Date

- 12-Dec-2024

Relations

- Effective Date

- 01-Jan-2025

Overview

SIST EN 13160-5:2016+A1:2025 (equivalent to EN 13160-5:2016+A1:2024) defines requirements and test/assessment methods for in‑tank gauge systems and pressurised pipework systems used for leak detection. The standard applies to leak detection kits that detect volumetric loss from tanks and/or pipework and typically include a Measuring Device, an Evaluation Device and an Alarm Device. It covers systems for single or double skin underground tanks and for single or double skin underground and/or aboveground pipework carrying flammable liquids with a flash point ≤ 100 °C.

Key technical topics and requirements

- Effectiveness criteria - Functional requirements to reliably detect volumetric loss and trigger alarms.

- Component requirements - Expectations for measuring devices, evaluation/control units and alarm devices (including cable and signal integrity).

- Software validation - Test methods and datasets for leak‑detection software (Annex A/B for field data acquisition and validation).

- Durability of effectiveness - Performance under temperature variation, chemical exposure, hydraulic shock, fatigue/mechanical wear and microbiological growth.

- Mechanical construction & thermal effects - Integrity under thermal contraction and mechanical stress.

- Testing and assessment methods - Type testing, sample selection, compliance criteria and test reporting (detailed in Clause 5).

- Assessment and verification of constancy of performance (AVCP) - Type testing and factory production control (FPC) requirements for manufacturers.

- Marking, labelling and packaging - Identification and information requirements for delivered kits.

- Normative/informative annexes - Annex A (Category A software data acquisition), Annex B (Category B(2) software), Annex C (Category B(1) system tests).

Practical applications and users

Who will use this standard:

- Manufacturers of leak detection kits, in‑tank gauges and pressurised pipework monitoring equipment.

- Test laboratories and notified bodies performing type testing, software validation and AVCP.

- Fuel storage and fuel distribution operators managing underground/aboveground tanks and pressurised piping at filling stations and storage terminals.

- System integrators, specifiers and safety engineers responsible for regulatory compliance and environmental protection.

Practical benefits:

- Provides uniform test methods to verify detection sensitivity and durability.

- Ensures interoperability of measuring/evaluation/alarm components and consistent reporting for compliance.

- Supports risk reduction for spills of flammable liquids and environmental contamination.

Related standards

- EN 13160 series (Parts 1–7): Part 1 general principles; Part 2 pressure/vacuum systems; Part 3 liquid systems for tanks; Part 4 sensor‑based systems; Part 6 monitoring wells; Part 7 leak detection linings.

- National adoption: Implemented by CEN members; national versions (SIST in Slovenia) carry equal status.

Keywords: leak detection systems, in‑tank gauge systems, pressurised pipework, leak detection kits, volumetric loss, EN 13160‑5, software validation, AVCP, factory production control.

Frequently Asked Questions

SIST EN 13160-5:2016+A1:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Leak detection systems - Part 5: Requirements and test/assessment methods for in-tank gauge systems and pressurised pipework systems". This standard covers: This standard gives requirements and corresponding test\assessment methods applicable to leak detection kits, based upon volumetric loss from within the tank and/or pipework system. The kits usually comprise: - Measuring Device - Evaluation Device - Alarm Device Intended use: Leak Detection kits are intended to be used in\with single or double skin underground tanks or single or double skin underground and/or aboveground, pipework designed for flammable liquids having a flash point not exceeding 100 °C.

This standard gives requirements and corresponding test\assessment methods applicable to leak detection kits, based upon volumetric loss from within the tank and/or pipework system. The kits usually comprise: - Measuring Device - Evaluation Device - Alarm Device Intended use: Leak Detection kits are intended to be used in\with single or double skin underground tanks or single or double skin underground and/or aboveground, pipework designed for flammable liquids having a flash point not exceeding 100 °C.

SIST EN 13160-5:2016+A1:2025 is classified under the following ICS (International Classification for Standards) categories: 23.020.10 - Stationary containers and tanks; 23.040.99 - Other pipeline components. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13160-5:2016+A1:2025 has the following relationships with other standards: It is inter standard links to SIST EN 13160-5:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13160-5:2016+A1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2025

Nadomešča:

SIST EN 13160-5:2016

Sistemi za kontrolo tesnosti - 5. del: Zahteve in metode za preskušanje in

ocenjevanje sistemov za zaznavanje netesnosti, vgrajenih v rezervoarje in tlačne

cevovode (vključno z dopolnilom A1)

Leak detection systems - Part 5: Requirements and test/assessment methods for in-tank

gauge systems and pressurised pipework systems

Leckanzeigesysteme - Teil 5: Anforderungen und Prüf-/Bewertungsmethoden für

Tankinhaltsmesssysteme und druckbeaufschlagte Rohrleitungen

Systèmes de détection de fuites - Partie 5: Exigences et méthodes d'essai/d'évaluation

des systèmes de détection de fuites en citernes et des systèmes de tuyauterie sous

pression

Ta slovenski standard je istoveten z: EN 13160-5:2016+A1:2024

ICS:

23.020.10 Nepremične posode in Stationary containers and

rezervoarji tanks

23.040.99 Drugi sestavni deli za Other pipeline components

cevovode

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13160-5:2016+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2024

EUROPÄISCHE NORM

ICS 23.020.10; 23.040.99 Supersedes EN 13160-5:2016

English Version

Leak detection systems - Part 5: Requirements and

test/assessment methods for in-tank gauge systems and

pressurised pipework systems

Systèmes de détection de fuites - Partie 5: Exigences et Leckanzeigesysteme - Teil 5: Anforderungen und Prüf-

méthodes d'essai/d'évaluation des systèmes de /Bewertungsmethoden für Tankinhaltsmesssysteme

détection de fuites en citernes et des systèmes de und druckbeaufschlagte Rohrleitungen

tuyauterie sous pression

This European Standard was approved by CEN on 8 April 2016 and includes Amendment 1 approved by CEN on 11 September

2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13160-5:2016+A1:2024 E

worldwide for CEN national Members.

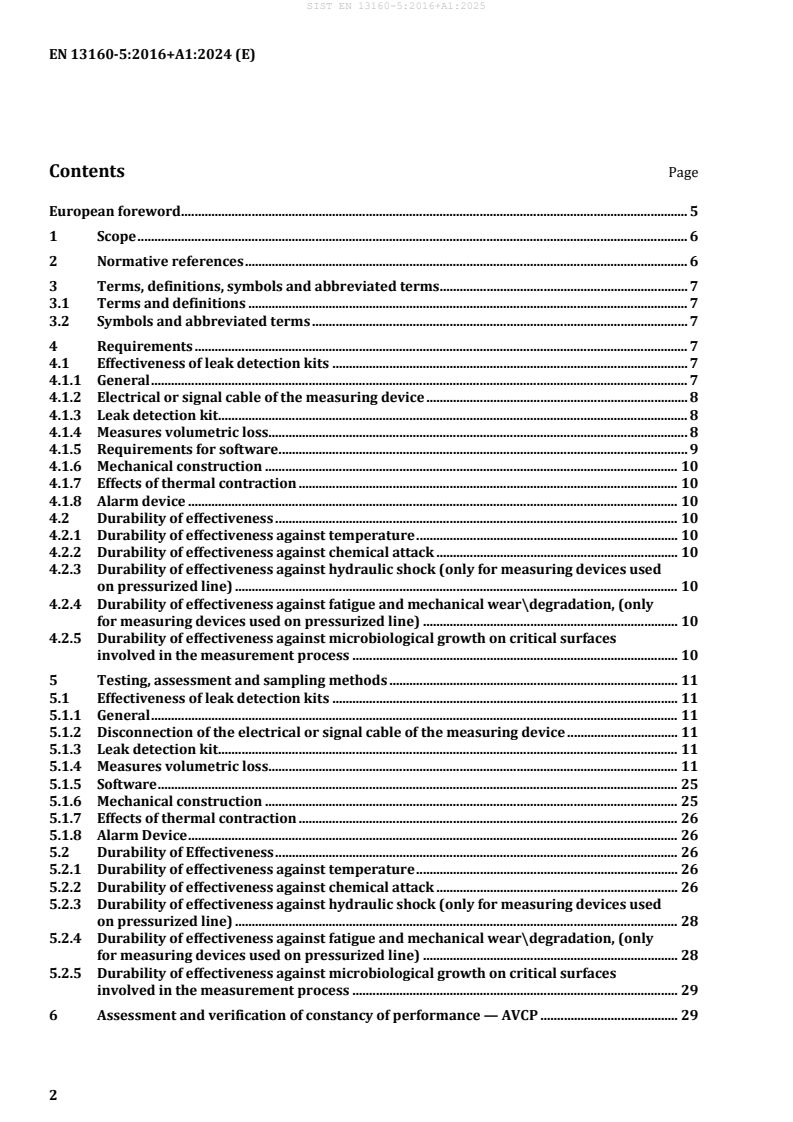

Contents Page

European foreword . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions, symbols and abbreviated terms . 7

3.1 Terms and definitions . 7

3.2 Symbols and abbreviated terms . 7

4 Requirements . 7

4.1 Effectiveness of leak detection kits . 7

4.1.1 General . 7

4.1.2 Electrical or signal cable of the measuring device . 8

4.1.3 Leak detection kit. 8

4.1.4 Measures volumetric loss . 8

4.1.5 Requirements for software . 9

4.1.6 Mechanical construction . 10

4.1.7 Effects of thermal contraction . 10

4.1.8 Alarm device . 10

4.2 Durability of effectiveness . 10

4.2.1 Durability of effectiveness against temperature . 10

4.2.2 Durability of effectiveness against chemical attack . 10

4.2.3 Durability of effectiveness against hydraulic shock (only for measuring devices used

on pressurized line) . 10

4.2.4 Durability of effectiveness against fatigue and mechanical wear\degradation, (only

for measuring devices used on pressurized line) . 10

4.2.5 Durability of effectiveness against microbiological growth on critical surfaces

involved in the measurement process . 10

5 Testing, assessment and sampling methods . 11

5.1 Effectiveness of leak detection kits . 11

5.1.1 General . 11

5.1.2 Disconnection of the electrical or signal cable of the measuring device . 11

5.1.3 Leak detection kit. 11

5.1.4 Measures volumetric loss . 11

5.1.5 Software . 25

5.1.6 Mechanical construction . 25

5.1.7 Effects of thermal contraction . 26

5.1.8 Alarm Device . 26

5.2 Durability of Effectiveness . 26

5.2.1 Durability of effectiveness against temperature . 26

5.2.2 Durability of effectiveness against chemical attack . 26

5.2.3 Durability of effectiveness against hydraulic shock (only for measuring devices used

on pressurized line) . 28

5.2.4 Durability of effectiveness against fatigue and mechanical wear\degradation, (only

for measuring devices used on pressurized line) . 28

5.2.5 Durability of effectiveness against microbiological growth on critical surfaces

involved in the measurement process . 29

6 Assessment and verification of constancy of performance — AVCP . 29

6.1 General . 29

6.2 Type testing . 29

6.2.1 General . 29

6.2.2 Test samples, testing and compliance criteria . 30

6.2.3 Test reports . 31

6.2.4 Shared other party results . 31

6.2.5 Cascading determination of the product type results . 31

6.3 Factory production control (FPC) . 32

6.3.1 General . 32

6.3.2 Requirements . 33

6.3.3 Product specific requirements . 35

6.3.4 Procedure for modifications . 36

6.3.5 One-off products, pre-production products (e.g. prototypes) and products produced

in very low quantity . 36

7 Marking, labelling and packaging . 37

Annex A (normative) Acquisition of field data to provide a standard database for testing

software leak detection systems Category A . 38

A.1 Objective . 38

A.2 Requirements . 39

A.3 Equipment . 40

A.4 Method . 41

A.5 Data up-loading and verification . 43

A.6 Induced leak rates – quantitative systems . 44

A.7 Induced leak rates – qualitative systems . 44

A.8 Test sequence . 44

A.9 Simulated leak test results . 45

A.10 Qualification for use . 45

A.11 Statistical analysis . 46

Annex B (informative) Acquisition of field data to provide a standard database for testing

software leak detection systems Category B(2) . 51

B.1 General . 51

B.2 File sorting and selection . 51

B.3 Data set Requirements . 51

B.4 Induced leak rates – quantitative systems . 52

B.5 Induced leak rates – qualitative systems . 52

B.6 Test sequence . 52

B.7 Evaluation of simulated leak test results . 53

B.8 Qualification for use . 53

B.9 Statistical analysis . 53

B.10 Comparison of variable and constant leak rate pairs . 57

B.11 Validation of conditions of use . 57

Annex C (normative) Leak detection systems Category B(1) . 59

C.1 Preparation . 59

C.2 Stabilization and trial run . 59

C.3 Procedure. 59

C.4 Test results . 63

C.5 Evaluation . 63

Bibliography . 66

European foreword

This document (EN 13160-5:2016+A1:2024) has been prepared by Technical Committee CEN/TC 393

“Equipment for storage tanks and for filling stations”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2025, and conflicting national standards shall be

withdrawn at the latest by August 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 11 September 2024.

This document supersedes !EN 13160-5:2016".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

!deleted text"

According to EN 13160-5:2004 the following fundamental changes are given:

— Requirement for a device for simulating a leak deleted;

— requirements from EN 13160-1:2003 included, which are no longer contained in EN 13160-1:2016;

— Pressure line leak detection kits included.

This European Standard, Leak detection systems, consists of 7 parts:

— Part 1: General principles

— Part 2: Requirements and test/assessment methods for pressure and vacuum systems

— Part 3: Requirements and test/assessment methods for liquid systems for tanks

— Part 4: Requirements and test/assessment methods for sensor based leak detection systems

— Part 5: Requirements and test/assessment methods for in-tank gauge systems and pressurized

pipework systems

— Part 6: Sensors in monitoring wells

— Part 7: Requirements and test/assessment methods for leak detection linings

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the

United Kingdom.

1 Scope

This European Standard gives requirements and corresponding test\assessment methods applicable to

leak detection kits, based on volumetric loss from within the tank and/or pipework system. The kits

usually comprise:

— Measuring Device

— Evaluation Device

— Alarm Device

Intended use:

Leak Detection kits are intended to be used in\with single or double skin underground tanks or single

or double skin underground and/or aboveground pipework designed for flammable liquids having a

flash point not exceeding 100 °C.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 228, Automotive fuels — Unleaded petrol — Requirements and test methods

EN 590, Automotive fuels — Diesel — Requirements and test methods

EN 976-1, Underground tanks of glass-reinforced plastics (GRP) — Horizontal cylindrical tanks for the

non-pressure storage of liquid petroleum based fuels — Part 1: Requirements and test methods for single

wall tanks

EN 981:1996+A1:2008, Safety of machinery — System of auditory and visual danger and information

signals

EN 12285-1, Workshop fabricated steel tanks — Part 1: Horizontal cylindrical single skin and double skin

tanks for the underground storage of flammable and non-flammable water polluting liquids

EN 13160-1:2016, Leak detection systems — Part 1: General principles

EN 13160-2, Leak detection systems — Part 2: Requirements and test/assessment methods for pressure

and vacuum systems

EN 13352:2012, Specification for the performance of automatic tank contents gauges

EN 14879-4:2007, Organic coating systems and linings for protection of industrial apparatus and plants

against corrosion caused by aggressive media — Part 4: Linings on metallic components

EN 60296, Fluids for electrotechnical applications — Unused mineral insulating oils for transformers and

switchgear (IEC 60296)

EN 60529, Degrees of protection provided by enclosures (IP Code) (IEC 60529)

EN 61672-1, Electroacoustics — Sound level meters — Part 1: Specifications (IEC 61672-1)

ISO 8601, Data elements and interchange formats — Information interchange — Representation of dates

and times

3 Terms, definitions, symbols and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 13160-1:2016 and the

following apply.

3.1.1

quantitative output

numerical indication of the leak rate

3.1.2

qualitative output

pass/fail indication for a given test with reference to a specified leak rate

3.2 Symbols and abbreviated terms

B is the bias

LL is the lower confidence bound for probability of detection

UL is the upper confidence bound for probability of detection

MSE is the mean squared error

PD is the probability of detection

PFA is the probability of false alarm

PI (all) is the proportion of invalid records for all records

PI (leak) is the proportion of invalid records for leaking tanks

PI (tight) is the proportion of invalid records for tight tanks

R is the simulated leak rate

C is the criterion or threshold for indicating a leak

B is the estimated bias of the system

SD is the standard deviation

t is the two-sample t-test bias

b

4 Requirements

4.1 Effectiveness of leak detection kits

4.1.1 General

This type of leak detection kit is classified according to EN 13160-1:2016 as class IV.

The general requirements on leak detection systems according to Clause 5 of EN 13160-1:2016 shall be

met.

The measuring device shall fulfil the requirements according to 5.1of EN 13352:2012.

The level to volume conversion methodology shall fulfil the requirements according to Annex B of

EN 13352:2012.

A complete documentation shall be provided by the manufacturer. The documentation shall contain the

technical values according to 4.1.2 to 4.1.8 and 4.2.

4.1.2 Electrical or signal cable of the measuring device

In the event of disconnection of the electrical or signal cable or malfunction of the measuring device an

alarm condition shall result.

4.1.3 Leak detection kit

The leak detection kit shall consist of:

— measuring device;

— evaluation device;

— alarm device.

4.1.4 Measures volumetric loss

4.1.4.1 General

Table 1 — Performance requirements for categories of leak detection

Alarm

Maximum time of

threshold

detection

Category Type

leak rate

h

-1

l ⋅ h

A Dynamic leak detection using Type 2 ≥ 0,8 336

the comparison of sales data with

Type 1 ≥ 0,4 336

tank volume changes

B(1) Static leak detection Type 2 ≥ 0,8 4

Type 1 ≥ 0,4 8

B(2) Statistical quiet Type 2 ≥ 0,8 24

period detection

C Pressure line leak detection Type 3 ≥ 12 1

(catastrophic loss)

C Pressure line leak detection Type 2 ≥ 0,8 12

C Pressure line leak detection Type 1 ≥ 0,4 12

Any gauge system to be used for category A, B(1) and B(2) of leak detection shall have water detection

capability.

The operating condition of the evaluation device shall be clearly indicated, i.e. through the provision of

a fault, light or similar indicator.

For categories A and B, the requirements of a gauge control device as defined in EN 13352 shall be met.

An alarm shall be activated whenever a leak rate for Type 1 is detected at the specified rate or above, in

accordance with Table 1.

Where performance in accordance with Table 1 for category A and category B is not achievable within

the required levels of probability, the results shall be reported as inconclusive.

The leak detection kit shall have a device for automatically shut-off the submersible pump in the event

of an alarm condition.

4.1.4.2 Category A – Dynamic leak detection

4.1.4.2.1 Type 2

For this type, the system shall communicate with the metering system, associated with the withdrawal

of product from the storage tank, in order to receive details of all volumes dispensed from the tank. At

the specified leak rate according to Table 1, the system shall have a probability of detection of at least

95 % while a false alarm rate shall not exceed 5 %.

4.1.4.2.2 Type 1

For this type, the system shall communicate with the metering system, associated with the withdrawal

of product from the storage tank, in order to receive details of all volumes dispensed from the tank. At

the specified leak rate according to Table 1, the system shall have a probability of detection of at least

95 % while a false alarm rate shall not exceed 5 %.

4.1.4.3 Category B (1) – Static leak detection

4.1.4.3.1 Type 2

For this type, the system shall be capable of detecting the specified leak rate according to Table 1 with a

probability of at least 95 % while operating at a false alarm rate of 5 % or less.

4.1.4.3.2 Type 1

For this type, the system shall be capable of detecting the specified leak rate according to Table 1 with a

probability of at least 95 % while operating at a false alarm rate of 5 % or less.

4.1.4.4 Category B (2) – Statistical quiet period detection – Type 2

For this type, the system shall communicate with the metering system, associated with the withdrawal

of product from the storage tank, in order to receive details of all volumes dispensed from the tank. At

the specified leak rate according to Table 1, the system shall have a probability of detection of at least

95 % while a false alarm rate shall not exceed 5 %.

4.1.4.5 Category C – Pressure line leak detection – Type 1

For this type, the system shall be capable, when no product is being dispensed of detecting the specified

leak rate according to Table 1 with a probability of 99 %.

4.1.4.6 Category C – Pressure line leak detection - Type 2

For this type, the system shall be capable, when no product is being dispensed of detecting the specified

leak rate according to Table 1 with a probability of 99 %.

4.1.4.7 Category C – Pressure line leak detection - Type 3

For this type, the system shall be capable, when no product is being dispensed of detecting the specified

leak rate according to Table 1 with a probability of99 %.

4.1.5 Requirements for software

The software, where provided, shall have a facility for self-checking by fulfilling the following

requirements:

— a self-diagnostic mode to test the integrity of the system at start up and periodically during use. A

negative result of self-diagnostic mode shall result in an alarm condition;

— a facility to check the consistency of the input and output data, malfunction shall result in an alarm

condition.

The software shall also provide an algorithmic determination of volumetric loss.

4.1.6 Mechanical construction

Ingress protection for the measuring device shall be at least IP 68 according to EN 60529.

4.1.7 Effects of thermal contraction

The evaluation device for category C shall feature a provision to filter the effects of

expansion\contraction resulting from thermal volume change of the fluid and associated vessels and

pipework systems.

4.1.8 Alarm device

The alarm device shall generate an audible and visible alarm. The audible alarm shall have a sound level

of ≥ 70 dB (A) in a distance of minimum 1 m with a signal according to Table 1 of

EN 981:1996+A1:2008 which shall be maintained for a minimum period of 36 h. The audible alarm may

be able to be switched off, but the status off should be visible.

The visible alarm shall be clearly indicated. The visible alarm shall have no switch off option.

The alarm device should be designed for connecting an additional alarm device, e.g. signal horn. The

output parameter shall be stated.

A test possibility shall be provided to test the functionality of the audible and visible alarm.

4.2 Durability of effectiveness

4.2.1 Durability of effectiveness against temperature

The components of a leak detection system shall meet the requirement as given in EN 13352.

4.2.2 Durability of effectiveness against chemical attack

Parts of leak detection kits which can come into contact with the stored liquid/water or its vapour shall

be resistant.

4.2.3 Durability of effectiveness against hydraulic shock (only for measuring devices used on

pressurized line)

The measuring devices shall withstand a transient pressure not less than 1,4 MPa.

4.2.4 Durability of effectiveness against fatigue and mechanical wear\degradation, (only for

measuring devices used on pressurized line)

At a temperature of (20 ± 5) °C the measuring device shall continue to operate according to Table 1,

Category C after 50 000 cycles at a pressure range from 0 kPa to 350 kPa.

4.2.5 Durability of effectiveness against microbiological growth on critical surfaces involved in

the measurement process

Microbiological growth is generated based on the presence of water. To minimize the effect of microbial

growth on the measurement process a means of detecting water shall be provided.

5 Testing, assessment and sampling methods

5.1 Effectiveness of leak detection kits

5.1.1 General

For the tests the following documentation shall be provided by the manufacturer:

— manual(s);

— datasheet of the parts of the leak detection kit;

— electrical diagrams of the parts of the leak detection kit;

— design and application drawings;

— parts lists of the used components including material data;

— and shall be inspected visually.

5.1.2 Disconnection of the electrical or signal cable of the measuring device

The measuring device shall be disconnected.

The disconnection of the measuring device shall result in an alarm.

5.1.3 Leak detection kit

Visual test shall be carried out that the leak detection kit consists of measuring device, evaluation

device, alarm device and shut-off device for the submersible pump.

5.1.4 Measures volumetric loss

5.1.4.1 General

The test shall be carried out at a temperature of (20 ± 5) °C.

The test liquid shall be diesel according to EN 590 or transformer oil according to EN 60296.

5.1.4.2 Category A - Dynamic leak detection

5.1.4.2.1 Type 2

5.1.4.2.1.1 Test equipment

The manufacturer shall supply the algorithmic method representative of the system under test in the

form of software loaded onto a computer which is capable of reading in and processing files from the

standard test database previously collected from representative locations. These files shall be provided

in a standard format according to Annex A and shall be accepted without any pre-processing.

The manufacturer shall state the initialization period required for the system under test, which shall not

exceed 28 days.

A computer and associated data transfer peripherals.

Dispenser with digital data connection to transmit the volume withdrawn from the storage tank

5.1.4.2.1.2 Preparation

In each case, tests shall be performed following an initialization period equivalent to a maximum of

28 days operation, during which the system under test processes normal operational data without

induced leaks.

A set of files shall be selected from the standard database, according to the details given in A.1.

For each type of draw-off system and fuel, the files selected shall meet the following conditions:

For each of the draw-off methods and each fuel listed in A.1, between 25 % and 75 % of the data files

selected should be taken from tanks where that type of draw-off system or fuel is in use. The same data

file may cover two or more uses, for example a manifolded tank using pressurized draw-off via multiple

dispensers.

Leak detection systems to be tested will provide a quantitative or a qualitative output. A qualitative

output will indicate a pass/fail result in accordance with Table 1.

The minimum sample sizes for data files, which shall be collected for each of these types, are:

— Systems with a Quantitative Output: ≥ 100 files (not more than 15 from the same tank);

— Systems with a Qualitative Output: ≥ 240 files (not more than 36 from the same tank).The database

files shall be sorted to form an ordered data set which is divided into 5 equal groups according to

the 20th, 40th, 60th and 80th percentiles of the recorded range of shade temperature. Each of the

five groups shall be further divided into 3 equal sub-groups, according to the 33rd and 67th

percentiles of the recorded range of tank sizes, such that sub-groupings are determined

independently for each of the five groups.

For systems with a quantitative output, three files shall be selected at random from each of the 15 sub-

sets, to provide a sample of 45 files for subsequent evaluation.

For systems with a qualitative output, eight files shall be selected at random from each of the 15 sub-

sets, to provide a sample of 120 files for subsequent evaluation.

For example, for data collected over the ranges of shade temperature and tank capacity as defined in

A.1, the files would be sorted as shown in Table 2, and n files selected from each sub-set as shown,

where n = 3 for a quantitative system and n = 8 for a qualitative system:

Table 2 — Selection of data files according to tank capacity and ambient temperature during

collection of the data

Tank Capacity Shade Temperature

-5 °C to 20th 20th to 40th 40th to 60th 60th to 80th 80th

Percentile Percentile Percentile Percentile Percentile

to 30 °C

10 000 l to Select n files Select n files at Select n files at Select n files Select n files

33rd Percentile at random random random at random at random

33rd to 67th Select n files Select n files at Select n files at Select n files Select n files

Percentile at random random random at random at random

67th Percentile Select n files Select n files at Select n files at Select n files Select n files

to 50 000 l at random random random at random at random

5.1.4.2.1.3 Procedure

A software tool shall be provided to simulate the following:

Tank leaks (constant)

Leaks from tanks are simulated as a continuous loss of product from the tank at a constant leak rate.

The figure in a record representing the volume of stored product is reduced by a value equivalent to the

quantity of product that would be lost at the specified rate during the time period between the record

and its predecessor. The simulated losses for all previous time periods are accumulated and the total

subtracted from the figure representing stored volume. These accumulated losses are also carried

forward through each delivery event such that the subtracted figure increases monotonous.

Therefore, the volume figure, v , of the ith record is replaced by v ', calculated according to Formula (1):

i i

i

v = - - R (1)

v t t

′ ( )

i i j j-1

∑

j=1

where

R = simulated leak rate in litre per hour;

t = time stamp of jth record;

j

t = time stamp of predecessor to jth record.

j-1

Where tanks are connected via a siphon, the quantity of product corresponding to the leak over the

specified time interval is divided by the number of tanks in the siphon arrangement and this quantity

subtracted from the records for each of the tanks connected via the siphon.

Tank leaks (variable)

Leaks from tanks are simulated as a continuous loss of product from the tank at a variable leak rate

which reduces as the quantity of stored product is reduced. The figure in a record representing the

volume of stored product is reduced by a value equivalent to the quantity of product which would be

lost at a rate specified for the time period between the record and its predecessor. The records in a file

are divided into sets, each of which comprises all the records between one delivery and the next.

Successive records in a set therefore always exhibit a decrease in stored volume. Where there are n

records in a set, and the stored volume of the jth record is v , the leak rate r for that record is found as a

j j

function of the nominal leak rate to be simulated R, according to Formula (2):

n

v

j

= R (2)

r

j

n

v

k

∑

k=1

Therefore, the volume figure, v , of the ith record is replaced by v ', calculated according to Formula (3):

i i

i

v = - - (3)

′ v t t r

( )

iji j j-1

∑

j=1

The simulated losses for prior periods are accumulated and similarly subtracted from the figure

representing stored volume. These accumulated losses are also carried forward through each delivery

event such that the subtracted figure increases monotonous.

Where tanks are connected via a siphon, the quantity of product corresponding to the leak over the

specified time interval is divided by the number of tanks in the siphon arrangement and this quantity

subtracted from the records for each of the tanks connected via the siphon.

Pipe leaks (suction and pressurized draw-off)

Leaks from draw-off pipes are simulated as a loss of product from the pipe at a constant leak rate but

only while dispensers are idle and the pipe is pressurized where applicable. Each data file is first

processed to accumulate the total time that fuel is being drawn from the pipe. The total volume of

product which would be lost over the period(T) covered by data set within the file at a constant leak

rate, R, is calculated and divided by the total dispensing time to give a leak rate, R´, during dispensing,

see Formula (4):

R ⋅ T

R′ = (4)

n

( - )

te ts

jj

∑

j=1

where

t = end time of the jth dispensing transaction;

ej

t = start time of the jth dispensing transaction;

sj

n = total number of dispensing transactions in the file;

T = elapsed time from start to end of file in minutes.

The figure in a record representing the volume of stored product is reduced by a value equivalent to the

quantity of product which would be lost at the rate R´ during the time period between the record and its

predecessor, but only when a dispenser was drawing fuel during that period. The simulated losses for

all previous time periods are accumulated and the total subtracted from the figure representing stored

volume in this and all subsequent records (including periods where no fuel is drawn from the tank).

These accumulated losses are also carried forward over each delivery event such that the subtracted

figure increases monotonous.

Therefore, the volume figure, v , of the ith record is replaced by v ', calculated according to Formula (5):

i i

m

′

v = - - R (5)

′ v te ts

i i ( jj)

∑

j=1

Where

m number of dispensing transactions whose end time is earlier than the time stamp of the ith record.

Where tanks are connected via a manifold arrangement, the quantity of product corresponding to the

leak over the specified time interval is divided by the number of tanks connected to the manifold and

this quantity subtracted from the records for each of the tanks so connected

5.1.4.2.1.4 Evaluation

-1

Tests has to be passed if a leak rate of 0,8 l⋅h is detected within 336 h with a probability of detection

not less than 95 % and a probability of false alarms not greater than 5 %.

5.1.4.2.2 Type 1

5.1.4.2.2.1 Test equipment

According to 5.1.4.2.1.1

5.1.4.2.2.2 Preparation

According to 5.1.4.2.1.2

5.1.4.2.2.3 Procedure

According to 5.1.4.2.1.3

5.1.4.2.2.4 Evaluation

-1

Tests has to be passed if a leak rate of 0,4 l⋅h is detected within 336 h with a probability of detection

not less than 95 % and a probability of false alarms not greater than 5 %.

5.1.4.3 Category B(1) – Static leak detection

5.1.4.3.1 Type 2

5.1.4.3.1.1 Test equipment

— A double wall storage tank with a size and shape that represents the applicable circumstances of

usage, according to EN 12285-1 or EN 976-1 of minimum capacity 30 000 l installed underground

or that is constructed such that the tank used for test is surrounded with a material having a

-1 -1 -1 -1

specific heat capacity of between 0,80 kJ kg K and 1,48 kJ kg K .

— The tank shall be fitted with an independent leak detection system according to EN 13160-2 for

Class I to prove tightness during test.

— A suitable apparatus fitted to the test tank for the continuous monitoring of product temperature

i.e. a temperature measurement device with an accuracy of 1 K. The device consists of a vertical

array of temperature sensors over the height of the test tank with a spacing of (300 ± 10) mm

between the temperature sensors.

— A second tank (e.g. an above- or underground tank or a tanker truck) having a minimum nominal

tank capacity of 15 000 l, together with a pump and suitable hoses for transferring product to and

from the test tank.

— A heat exchanger or other suitable heating device capable of heating and cooling the test fluid

by ± 5 K, within an uncertainly of ± 1 K, before it is transferred into the test tank.

— A variable-rate peristaltic or other suitable pump capable of withdrawing liquid from the test tank

-1 -1

at present rates between 0,2 l⋅h and 0,8 l⋅h within an accuracy of 0,25 %.

— A time measuring device having a time indication in steps of 1 s to a minimum total of 24 h, within

an accuracy of ± 1 s.

— Barometric pressure and atmospheric temperature measuring equipment suitable for continuous

monitoring of environmental conditions in the areas of the test facility where components of the

system under test are installed.

5.1.4.3.1.2 Preparation

The liquid surface in the tank shall be stabilized for a time given by the manufacturer after the last

filling and after the last removal from the tank which ever happens later.

5.1.4.3.1.3 Pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...