SIST EN 13160-7:2016+A1:2025

(Main + Amendment)Leak detection systems - Part 7: Requirements and test/assessment methods for interstitial spaces, leak detection linings and leak detection jackets

Leak detection systems - Part 7: Requirements and test/assessment methods for interstitial spaces, leak detection linings and leak detection jackets

This standard gives requirements and the corresponding test/assessment methods applicable to leak detection lining kits and leak detection jacket kits. Leak detection lining kits and leak detection jackets kits intended to be used as post-installed to create an interstitial space or leakage containment in single skin underground or above ground, non-pressurized, tanks designed for water polluting liquids. The kit has to be used only in conjunction with leak detection kits covered by prEN 13160-2 to prEN 13160-4.

Leckanzeigesysteme - Teil 7: Anforderungen und Prüf-/Bewertungsverfahren für Überwachungsräume, Leckschutzauskleidungen und Leckschutzummantelungen

Diese Europäische Norm legt Anforderungen an Leckschutzauskleidungen und Leckschutzummantelungen und die ent¬sprechenden Prüf-/Bewertungsmethoden fest. Leckschutzauskleidungen und Leckschutzummantelungen sind für den Einsatz zur Schaffung eines Überwachungsraums oder eines Leckageraumes in einwandigen, unterirdischen oder oberirdischen, nicht druckbeaufschlagten Tanks vorgesehen, die für wassergefährdende Flüssigkeiten ausgelegt sind. Das System ist ausschließlich in Verbindung mit den von EN 13160 2 bis EN 13160 4 abgedeckten Leckanzeigern zu verwenden.

Systèmes de détection de fuites - Partie 7: Exigences et méthodes d'essai/d'évaluation pour les espaces interstitiels, les détecteurs de fuite des revêtements et les détecteurs de fuite d'enveloppes

La présente Norme européenne spécifie les exigences et les méthodes d'essai/d'évaluation correspondantes applicables aux kits de revêtements intérieurs et aux kits de revêtements extérieurs protecteurs de fuites. Les kits de revêtements intérieurs et les kits de revêtements extérieurs protecteurs de fuites, destinés à être utilisés après installation pour créer un espace interstitiel ou un espace de confinement des fuites dans des réservoirs à simple paroi, aériens ou souterrains, sans pression, conçus pour des liquides polluant l'eau. Le kit est destiné à être utilisé conjointement aux kits de détection de fuites couverts par les EN 13160-2 à l'EN 13160-4.

Sistemi za kontrolo tesnosti - 7. del: Zahteve in metode za preskušanje in ocenjevanje vmesnih prostorov, zunanjih oblog in plaščev za zaznavanje netesnosti (vključno z dopolnilom A1)

Ta evropski standard določa zahteve ter ustrezne metode za preskušanje in ocenjevanje, ki se uporabljajo za komplete zunanjih oblog in komplete plaščev za zaznavanje netesnosti. Kompleti zunanjih oblog in kompleti plaščev za zaznavanje netesnosti so namenjeni za ustvarjanje vmesnih prostorov ali zadrževalnikov pri enoplaščnih podzemnih ali nadzemnih rezervoarjih, ki niso pod tlakom in so zasnovani za tekočine, ki onesnažujejo vodo.

Komplet je treba uporabljati samo skupaj s kompleti za kontrolo tesnosti, zajetimi v standardih od prEN 13160-2 do prEN 13160-4.

General Information

- Status

- Published

- Publication Date

- 11-Dec-2024

- Technical Committee

- TLP - Pressure vessels

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 08-Oct-2024

- Due Date

- 13-Dec-2024

- Completion Date

- 12-Dec-2024

Relations

- Effective Date

- 01-Jan-2025

- Effective Date

- 01-Nov-2025

Overview

EN 13160-7:2016+A1:2024 (CEN) specifies requirements and test/assessment methods for leak detection linings and leak detection jackets used to create an interstitial space or leakage containment in single-skin, non‑pressurized underground and above‑ground tanks storing water‑polluting liquids. This part of the EN 13160 series covers post‑installed kits and must be used together with the sensor and system requirements given in EN 13160‑2 to EN 13160‑4. The document includes Amendment A1 (2024) and is intended for harmonised national implementation across CEN members.

Key topics and technical requirements

- Effectiveness criteria: integrity (tightness) against liquid and vapour under operating conditions; limits on permeation to prevent vapour condensation in the interstitial space.

- Permeability requirements: specified permeation limits for stored products and for deionized water; different criteria apply depending on tank substrate and existing product passage.

- Interstitial hydraulics and ventilation: requirements for free passage of liquid and air through the interstitial space to ensure reliable leak detection and drainage.

- Mechanical performance: resistance to loads imposed by stored media, impact behaviour and flow resistance after impact.

- Chemical resistance and durability: tests and acceptance criteria for resistance to stored media, temperature, chemical attack and mechanical ageing.

- Testing and assessment: detailed test methods, sampling and type‑testing procedures (including criteria for test reports and use of shared results).

- Factory production control (FPC) and AVCP: requirements for ongoing production control, type testing and procedures for modifications, plus marking, labelling, packaging and environmental aspects.

- Annexes: normative method to determine interstitial volume for Class I systems and informative environmental guidance.

Practical applications

- Retrofitting single‑skin tanks to provide a monitored interstitial space for early leak detection.

- Supplying and qualifying leak detection lining kits and jacket kits for fuel, chemical and water‑polluting liquid storage.

- Designing leak detection strategies where vapour permeation, drainage and sensor accessibility are critical.

- Certifying products and establishing factory production control for market compliance within the EU/EEA.

Who should use this standard

- Tank manufacturers and lining/jacket kit suppliers

- Installation contractors and system integrators for leak detection systems

- Testing laboratories and certification bodies performing type tests and AVCP

- Environmental compliance officers, site operators and consultants specifying tank retrofit solutions

Related standards

- EN 13160‑1 (General principles)

- EN 13160‑2 to EN 13160‑4 (pressure/vacuum systems, liquid systems, sensor‑based systems)

- Referenced material and test standards (EN ISO plastics tests, waterproofing sheet standards, EN 14879‑4, etc.)

Keywords: EN 13160-7:2016+A1:2024, leak detection systems, interstitial spaces, leak detection linings, leak detection jackets, tank leak detection, CEN test methods, permeation, factory production control.

Frequently Asked Questions

SIST EN 13160-7:2016+A1:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Leak detection systems - Part 7: Requirements and test/assessment methods for interstitial spaces, leak detection linings and leak detection jackets". This standard covers: This standard gives requirements and the corresponding test/assessment methods applicable to leak detection lining kits and leak detection jacket kits. Leak detection lining kits and leak detection jackets kits intended to be used as post-installed to create an interstitial space or leakage containment in single skin underground or above ground, non-pressurized, tanks designed for water polluting liquids. The kit has to be used only in conjunction with leak detection kits covered by prEN 13160-2 to prEN 13160-4.

This standard gives requirements and the corresponding test/assessment methods applicable to leak detection lining kits and leak detection jacket kits. Leak detection lining kits and leak detection jackets kits intended to be used as post-installed to create an interstitial space or leakage containment in single skin underground or above ground, non-pressurized, tanks designed for water polluting liquids. The kit has to be used only in conjunction with leak detection kits covered by prEN 13160-2 to prEN 13160-4.

SIST EN 13160-7:2016+A1:2025 is classified under the following ICS (International Classification for Standards) categories: 23.020.01 - Fluid storage devices in general; 23.040.99 - Other pipeline components; 29.260.20 - Electrical apparatus for explosive atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13160-7:2016+A1:2025 has the following relationships with other standards: It is inter standard links to SIST EN 13160-7:2016, oSIST prEN 13160-7:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13160-7:2016+A1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2025

Nadomešča:

SIST EN 13160-7:2016

Sistemi za kontrolo tesnosti - 7. del: Zahteve in metode za preskušanje in

ocenjevanje vmesnih prostorov, zunanjih oblog in plaščev za zaznavanje

netesnosti (vključno z dopolnilom A1)

Leak detection systems - Part 7: Requirements and test/assessment methods for

interstitial spaces, leak detection linings and leak detection jackets

Leckanzeigesysteme - Teil 7: Anforderungen und Prüf-/Bewertungsverfahren für

Überwachungsräume, Leckschutzauskleidungen und Leckschutzummantelungen

Systèmes de détection de fuites - Partie 7: Exigences et méthodes d'essai/d'évaluation

pour les espaces interstitiels, les détecteurs de fuite des revêtements et les détecteurs

de fuite d'enveloppes

Ta slovenski standard je istoveten z: EN 13160-7:2016+A1:2024

ICS:

23.020.01 Vsebniki za shranjevanje Fluid storage devices in

tekočin na splošno general

23.040.99 Drugi sestavni deli za Other pipeline components

cevovode

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13160-7:2016+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2024

EUROPÄISCHE NORM

ICS 23.020.01; 23.040.99; 29.260.20 Supersedes EN 13160-7:2016

English Version

Leak detection systems - Part 7: Requirements and

test/assessment methods for interstitial spaces, leak

detection linings and leak detection jackets

Systèmes de détection de fuites - Partie 7: Exigences et Leckanzeigesysteme - Teil 7: Anforderungen und Prüf-

méthodes d'essai/d'évaluation pour les espaces /Bewertungsverfahren für Überwachungsräume,

interstitiels, les détecteurs de fuite des revêtements et Leckschutzauskleidungen und

les détecteurs de fuite d'enveloppes Leckschutzummantelungen

This European Standard was approved by CEN on 8 April 2016 and includes Amendment 1 approved by CEN on 11 September

2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13160-7:2016+A1:2024 E

worldwide for CEN national Members.

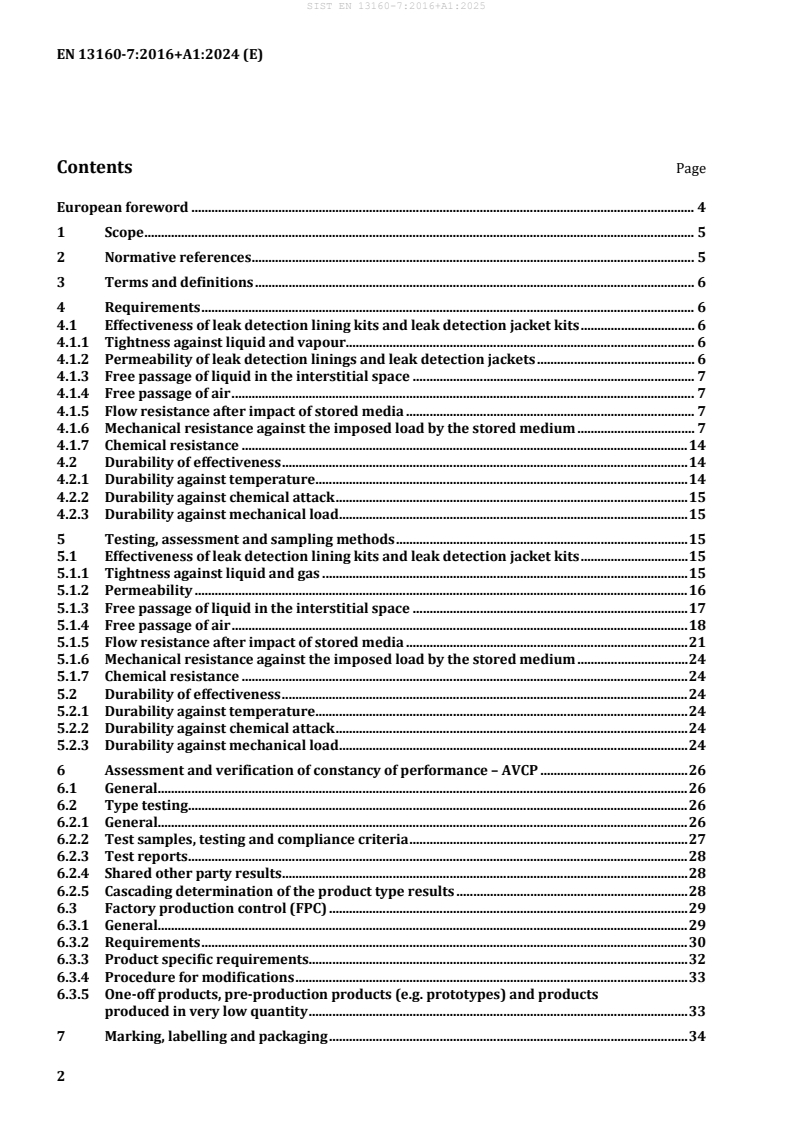

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Requirements . 6

4.1 Effectiveness of leak detection lining kits and leak detection jacket kits . 6

4.1.1 Tightness against liquid and vapour. 6

4.1.2 Permeability of leak detection linings and leak detection jackets . 6

4.1.3 Free passage of liquid in the interstitial space . 7

4.1.4 Free passage of air . 7

4.1.5 Flow resistance after impact of stored media . 7

4.1.6 Mechanical resistance against the imposed load by the stored medium . 7

4.1.7 Chemical resistance . 14

4.2 Durability of effectiveness . 14

4.2.1 Durability against temperature . 14

4.2.2 Durability against chemical attack . 15

4.2.3 Durability against mechanical load . 15

5 Testing, assessment and sampling methods . 15

5.1 Effectiveness of leak detection lining kits and leak detection jacket kits . 15

5.1.1 Tightness against liquid and gas . 15

5.1.2 Permeability . 16

5.1.3 Free passage of liquid in the interstitial space . 17

5.1.4 Free passage of air . 18

5.1.5 Flow resistance after impact of stored media . 21

5.1.6 Mechanical resistance against the imposed load by the stored medium . 24

5.1.7 Chemical resistance . 24

5.2 Durability of effectiveness . 24

5.2.1 Durability against temperature . 24

5.2.2 Durability against chemical attack . 24

5.2.3 Durability against mechanical load . 24

6 Assessment and verification of constancy of performance – AVCP . 26

6.1 General. 26

6.2 Type testing . 26

6.2.1 General. 26

6.2.2 Test samples, testing and compliance criteria . 27

6.2.3 Test reports . 28

6.2.4 Shared other party results . 28

6.2.5 Cascading determination of the product type results . 28

6.3 Factory production control (FPC) . 29

6.3.1 General. 29

6.3.2 Requirements . 30

6.3.3 Product specific requirements. 32

6.3.4 Procedure for modifications . 33

6.3.5 One-off products, pre-production products (e.g. prototypes) and products

produced in very low quantity . 33

7 Marking, labelling and packaging . 34

8 Environmental aspects . 34

Annex A (normative) Determination of the interstitial space volume for class I-systems . 35

A.1 Test equipment. 35

A.2 Preparation . 35

A.3 Procedure . 36

A.4 Evaluation. 38

Annex B (informative) Environmental aspects . 39

European foreword

This document (EN 13160-7:2016+A1:2024) has been prepared by Technical Committee CEN/TC 393

“Equipment for storage tanks and for filling stations”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2025, and conflicting national standards shall be

withdrawn at the latest by August 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 11 September 2024.

This document supersedes !EN 13160-7:2016".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

!deleted text"

According to edition 2003 the following fundamental changes are given:

— requirements and tests for permeation added;

— material properties revised;

— requirements from EN 13160-1:2003 included, which are no longer contained in

EN 13160-1:2016.

This European Standard Leak detection systems consists of 7 parts:

— Part 1: General principles

— Part 2: Requirements and test/assessment methods for pressure and vacuum systems

— Part 3: Requirements and test/assessment methods for liquid systems for tanks

— Part 4: Requirements and test/assessment methods for sensor based leak detection systems

— Part 5: Requirements and test/assessment methods for in-tank gauge systems and pressurized

pipework systems

— Part 6: Sensors in monitoring wells

— Part 7: Requirements and test/assessment methods for interstitial spaces, leak detection linings and

leak detection jackets

Any feedback and questions on this document should be directed to the users’ national standards

body. A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary,

Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,

Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye

and the United Kingdom.

1 Scope

This European Standard gives requirements and the corresponding test/assessment methods

applicable to leak detection lining kits and leak detection jacket kits. Leak detection lining kits and leak

detection jackets kits intended to be used to create an interstitial space or leakage containment in

single skin underground or above ground, non-pressurized, tanks designed for water polluting liquids.

The kit has to be used only in conjunction with leak detection kits covered by EN 13160-2 to

EN 13160-4.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments)

applies.

EN 228, Automotive fuels — Unleaded petrol — Requirements and test methods

EN 495–5, Flexible sheets for waterproofing — Determination of foldability at low temperature — Part

5: Plastic and rubber sheets for roof waterproofing

EN 1107-2, Flexible sheets for waterproofing — Determination of dimensional stability — Part 2: Plastic

and rubber sheets for roof waterproofing

EN 1849-2, Flexible sheets for waterproofing — Determination of thickness and mass per unit area —

Part 2: Plastic and rubber sheets

EN 10300:2005, Steel tubes and fittings for onshore and offshore pipelines — Bituminous hot applied

materials for external coating

EN 13121-1, GRP tanks and vessels for use above ground — Part 1: Raw materials — Specification

conditions and acceptance conditions

EN 13121-2:2003, GRP tanks and vessels for use above ground — Part 2: Composite materials —

Chemical resistance

EN 13160-1:2016, Leak detection systems — Part 1: General principles

!EN 13160-2:2016+A1:2024", Leak detection systems — Part 2: Requirements and test/assessment

methods for pressure and vacuum systems

!EN 13160-3", Leak detection systems — Part 3: Requirements and test/assessment methods for

liquid systems for tanks

!EN 13160-4", Leak detection systems — Part 4: Requirements and test/assessment methods for

sensor based leak detection systems

EN 14879-4:2007, Organic coating systems and linings for protection of industrial apparatus and plants

against corrosion caused by aggressive media — Part 4: Linings on metallic components

EN ISO 62, Plastics — Determination of water absorption (ISO 62)

EN ISO 75-1, Plastics — Determination of temperature of deflection under load — Part 1: General test

method (ISO 75-1)

EN ISO 75-2, Plastics — Determination of temperature of deflection under load — Part 2: Plastics and

ebonite (ISO 75-2)

EN ISO 75-3, Plastics — Determination of temperature of deflection under load — Part 3: High-strength

thermosetting laminates and long-fibre-reinforced plastics (ISO 75-3)

EN ISO 175, Plastics — Methods of test for the determination of the effects of immersion in liquid

chemicals (ISO 175)

EN ISO 178, Plastics — Determination of flexural properties (ISO 178)

EN ISO 179-1, Plastics — Determination of Charpy impact properties — Part 1: Non-instrumented

impact test (ISO 179-1)

EN ISO 179-2, Plastics — Determination of Charpy impact properties — Part 2: Instrumented impact test

(ISO 179-2)

EN ISO 527-1, Plastics — Determination of tensile properties — Part 1: General principles (ISO 527-1)

EN ISO 527-3, Plastics — Determination of tensile properties — Part 3: Test conditions for films and

sheets (ISO 527-3)

EN ISO 604, Plastics — Determination of compressive properties (ISO 604)

EN ISO 1183-1, Plastics — Methods for determining the density of non-cellular plastics — Part 1:

Immersion method, liquid pyknometer method and titration method (ISO 1183-1)

EN ISO 24345, Resilient floor coverings — Determination of peel resistance (ISO 24345)

ISO 2528, Sheet materials — Determination of water vapour transmission rate — Gravimetric (dish)

method

ISO 6133, Rubber and plastics — Analysis of multi-peak traces obtained in determinations of tear

strength and adhesion strength

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 13160-1:2016 apply.

4 Requirements

4.1 Effectiveness of leak detection lining kits and leak detection jacket kits

4.1.1 Tightness against liquid and vapour

The integrity of the leak detection linings and leak detection jackets shall be maintained under all

operating pressures.

4.1.2 Permeability of leak detection linings and leak detection jackets

The permeation shall be according to Table 1 and Table 2.

No condensation of vapour of the stored product in the interstitial space should occur.

Table 1 — Permeation of leak detection linings

Property Required value

Passage of stored products at installation of the leak protecting lining in max 100 g/m ⋅ day

metal tanks with a passage of stored product of 0 g/m ⋅ d

Passage of stored products at installation of the leak protecting lining in max 0,1 g/m ⋅ day

tanks with a passage of stored product > 0 g/m ⋅ d

Passage of deionized water max 4 g/m ⋅ day

NOTE By permeation rates > 0 g/m ⋅ d the exhaust line of the leak detector should be connected

to the vapour space of the stored tank.

Table 2 — Permeation of leak detection jackets

Property Required value

Passage of stored product

max 2 g/m ⋅ day

Passage of deionized water max 4 g/m ⋅ day

4.1.3 Free passage of liquid in the interstitial space

The quantity of liquid, calculated according to !EN 13160-2:2016+A1:2024", Formula (4) and the

specific volume V according to Annex A shall enter the interstitial space by a vacuum change from

sp

(60 ± 5) kPa (p ) to (30 ± 5) kPa (p ).

PA PE

Additional for leak detection systems class II according to EN 13160-3 the flow rate at the test nozzles

shall be > 0,5 l/min.

4.1.4 Free passage of air

4.1.4.1 Free passage of air through intermediate layer

The back pressure of the intermediate layer shall not be higher than 1 kPa at a volume flow of

(85 ± 5) l/h of air.

4.1.4.2 Free passage of air through double skin tanks and pipes

An opening of the interstitial space shall result in a pressure change in the interstitial space.

4.1.5 Flow resistance after impact of stored media

The flow resistance shall not exceed the value of 1 kPa at an air volume flow of (85 ± 5) l/h.

4.1.6 Mechanical resistance against the imposed load by the stored medium

4.1.6.1 Influence of the mechanical resistance to the free passage in the interstitial space

The flow resistance of the intermediate layer shall not be higher than 1 kPa at a volume flow of

(85 ± 5) l/h of air under load.

4.1.6.2 Mechanical properties

Mechanical properties for polyvinylchloride (PVC) shall be according to Table 3.

Table 3 — Mechanical properties for polyvinylchloride (PVC)

No. Property Test method Dimension Required value

1 Tensile strength, EN ISO 527-1 and N/mm ≥ 15

EN ISO 527-3;

Lengthwise and across

Test speed:

200 mm/min ± 10 %

Specimen: Type 2

2 Tensile elongation, EN ISO 527-1 and

% > 200

EN ISO 527-3;

Lengthwise and across

Test speed:

200 mm/min ± 10 %

Specimen: Type 2

3 Reaction of joint to shear EN ISO 527-1 and — Off-joint

test EN ISO 527-3; fracture,

Test speed: joint

200 mm/min ± 10 % Specimen: factor ≥ 0,65

Type 2

4 Adhesion of multilayered In conformity with N/mm ≥ 2,0

sheet material EN ISO 24345, ISO 6133,

EN ISO 527-1 and

EN ISO 527-3;

Test speed:

100 mm/min ± 10 %

Specimen: Type 2

5 Variation in dimension in EN 1107-2; in a hot cabinet 2 h % ≤ 2,0

either direction after in air of (80 ± 2) °C and then

storage at 80 °C 30 min at normal climate on a

cover, which shall not affect the

dimensions

6 Reaction in either direction EN 495-5 — No fissures may

to folding at a temperature occur on either

of −20 °C top or bottom

surface

7 Thickness EN 1849-2 % Middle

deviation ± 10

Deviation of

single value ≤ 12

8 Density EN ISO 1183-1 % Middle

deviation ± 2

Effects of test media for polyvinylchloride (PVC) shall be according to Table 4.

Table 4 — Effects of test media for polyvinylchloride (PVC)

Property Test method Dimension Required value

Change of mass after storage in In conformity with EN ISO 62 at ≤ 15

deionized water and stored normal climate, change shall be

%

product or test liquids according determined after the following

to Annex C of EN 14879-4:2007 storage periods: 3, 14 and 56 d

Change of tensile strength and EN ISO 527-1 and EN ISO 527-3 ≤ 25

elongation, in either direction after

for tensile

Test speed:

storage in deionized water and

200 mm/min ± 10 % Specimen: elongation the

%

stored product (56 d at 23 °C) or

Type 2 measured value as

test liquids according to Annex C

per Table 3

of EN 14879-4:2007

Change of tensile strength and EN ISO 527-1 and EN ISO 527-3 ≤ 25

elongation, in either direction after

Test speed:

storage in of folded materials in

200 mm/min ± 10 % Specimen:

deionized water and stored

Type 2

%

product

(56 d at 23 °C) or test liquids

according to Annex C of EN 14879-

4:2007

Change of reaction of the joint to EN ISO 527-1 and EN ISO 527-3 Off-joint fracture

shear test after storage in

Test speed:

deionized water and stored

200 mm/min ± 10 % Specimen:

—

product (56 d at 23 °C) or test

Type 2

liquids according to Annex C of

EN 14879-4:2007

Mechanical properties for thermoplastic and thermoplastic elastomers except polyvinylchloride (PVC)

shall be according to Table 5.

Table 5 — Mechanical properties for thermoplastic and thermoplastic elastomers except

polyvinylchloride (PVC)

No. Property Test method Dimension Required value

1 Tensile strength, EN ISO 527-1 and EN ISO 527-3; N/mm ≥ 15

Lengthwise and across Test speed: 200 mm/min ± 10 %

Specimen: Type 2

2 Tensile elongation, EN ISO 527-1 and EN ISO 527-3; % > 200

Lengthwise and across Test speed: 200 mm/min ± 10 %

Specimen: Type 2

3 Reaction of joint to EN ISO 527-1 and EN ISO 527-3; — Off-joint

shear test fracture,

Test speed: 200 mm/min ± 10 %

Specimen: Type 2 joint factor ≥ 0,5

4 Adhesion of In conformity with EN ISO 24345,

N/mm ≥ 1,0

multilayered sheet ISO 6133, EN ISO 527-1 and

material EN ISO 527-3;

Test speed: 100 mm/min ± 10 %

Specimen: Type 2

5 Variation in dimension EN 1107-2; in a hot cabinet 2 h in air % ≤ 10

in either direction after of (80 ± 2) °C and then 30 min at

storage at 80 °C normal climate on a cover, which

shall not affect the dimensions

6 Reaction in either EN 495-5 — No fissures may

direction to folding at a occur on either

temperature of −20 °C top or bottom

surface

7 thickness EN 1849-2 % Middle

deviation ± 10

8 density EN ISO 1183-1 % Middle

deviation ± 10 %

Effects of test media for thermoplastic and thermoplastic elastomers except polyvinylchloride (PVC)

shall be according to Table 6.

Table 6 — Effects of test media for thermoplastic and thermoplastic elastomers except

polyvinylchloride (PVC)

Property Test method Dimension Required

value

Change of mass after storage in In conformity with EN ISO 62 at ≤ 20

deionized water and stored normal climate, change shall be

product or test liquids determined after the following %

according to Annex C of storage periods: 3 d, 14 d and

EN 14879-4:2007 56 d

Change of tensile strength and EN ISO 527-1 and EN ISO 527-3 ≤ 50

elongation, in either direction

Test speed: 200 mm/min ± 10 %

after storage in deionized water

Specimen: Type 2

%

and stored product (56 d at

23 °C) or test liquids according

to Annex C of EN 14879-4:2007

Change of tensile strength and EN ISO 527-1 and EN ISO 527-3 ≤ 60

elongation, in either direction for tensile

Test speed: 200 mm/min ± 10 %

after storage in of folded elongation the

Specimen: Type 2

materials in deionized water measured

%

and stored product value as per

(56 d at 23 °C) or test liquids Table 5

according to Annex C of

EN 14879-4:2007

Change of reaction of the joint EN ISO 527-1 and EN ISO 527-3 Off-joint

to shear test after storage in fracture

Test speed: 200 mm/min ± 10 %

deionized water and stored

Specimen: Type 2

—

product (56 d at 23 °C) or test

liquids according to Annex C of

EN 14879-4:2007

Requirements for inner layer of leak detection linings and outer layer of leak detection jackets with

epoxide resin (EP) or unsaturated polyester resin (UP) moulding materials shall be according to

Table 7. The inner layer by leak detection linings/outer layer by leak detection jacket of original height

without spacer shall be used for testing.

Table 7 — Requirements for inner layer of leak detection linings and outer layer of leak

detection jackets with epoxide resin (EP) or unsaturated polyester resin (UP) moulding

materials

Property Dimensio Test method Sample Mean

n value of

dimension number

property

mm

Flexural strength MPa EN ISO 178 EN ISO 178 5 ≥ 80

Impact strength kJ/m EN ISO 179-1 and EN ISO 179-1 5 ≥ 5

EN ISO 179-2

Dimensional stability under °C EN ISO 75-1 EN ISO 75-2 3 ≥ 50

heat

EN ISO 75-2 EN ISO 75-3

EN ISO 75-3

Change in weight after %

28 days storage

— distilled water at

EN ISO 175 EN ISO 175 3 +4

(20 ± 5) °C

−2

The sample shall Cut surfaces 3

— stored product at

be wiped dry and shall be

(20 ± 5) °C or test

weighed sealed.

liquids according to

immediately after

Annex C of EN 14879–

the storage.

4:2007

Change of flexural strength %

after 28 days storage

— distilled water at

EN ISO 178 EN ISO 178 5 ≤ −30

(20 ± 5) °C

Cut surfaces

— stored product at

shall be

(20 ± 5) °C or test

sealed.

liquids according to

Annex C of EN 14879–

4:2007

The mean values of the flexural strength and of the impact strength shall fulfil the requirements of

Table 7. The single value of the flexural strength may be up to 15 % and the single value of the impact

strength may be up to 30 % under the values of Table 7. The single value of the other properties shall

fulfil the requirements of Table 7.

Requirements for intermediate layer of resin and spacer of leak detection linings and of leak detection

jackets according to Figure 1 shall be according to Table 8.

Table 8 — Requirements for intermediate layer of resin and spacer of leak detection linings

and of leak detection jackets

sample

Test

Property Dimension Values of property

dimension numbe

method

mm r

Compression strength at length and ≥ 1,0 (no break)

condition at time of supply width according

for tanks with a

to EN ISO 604

height or diameter

height: sampling of ≤ 3 m

2 height

N/mm EN ISO 604 5 ≥ 3,0 (no break)

for tanks with a

height or diameter

of > 3 m

Change of compression ≥ 0,6 (no break)

length and

strength after 112 days

for tanks with a

width according

storage at ambient

height or diameter

to EN ISO 604

temperature in water and

of ≤ 3 m

% EN ISO 604 height: sampling 5

stored product or test

≥ 1,8 (no break)

height

liquids according to

for tanks with a

Annex C of EN 14879–

Cut surfaces

height or diameter

4:2007

shall be sealed.

of > 3 m

The construction of leak detection linings and leak detection jackets can be according to Figure 1.

a)

b)

c)

NOTE Before installation of the leak detection lining/leak detection jacket the tank wall may be coated

according to EN 14879-4.

Key

1 inner layer by leak detection linings/outer layer by leak detection jackets

2 intermediate layer

3 tank wall

4 inner layer by leak detection linings/ outer layer by leak detection jackets combined with spacer

5 inner layer by leak detection linings/outer layer by leak detection jacket combined with spacer,

fixed to the tank wall

Figure 1 — Construction of leak detection linings and leak detection jackets

4.1.7 Chemical resistance

4.1.7.1 Inner layer and outer layer in contact with the stored liquid

The components of the thermoplastic and thermoplastic elastomers leak detection lining kits

according to Table 4 and Table 6.

The components of the UP and EP leak detection lining kits or leak detection jacket kits according to

EN 13121-1 and 5.2, 5.5 and 5.6 of EN 13121-2:2003.

4.1.7.2 Intermediate layer and spacer of leak detection linings or of leak detection jackets in

contact with the stored liquid

After the test according to 5.1.5 the flow resistance shall not exceed the value of 1 kPa at an air volume

flow of (85 ± 5) l/h.

4.2 Durability of effectiveness

4.2.1 Durability against temperature

For thermoplastic and thermoplastic elastomers leak detection linings according to Table 3 and

Table 5.

For intermediate layer according to 5.1.4.2.

For UP and EP leak detection linings or leak detection jackets according to Table 7.

4.2.2 Durability against chemical attack

The thermoplastic and thermoplastic elastomers leak detection linings according to Table 4 and

Table 6.

The UP and EP leak detection linings or leak detection jackets according to Table 7 and intermediate

layer and spacer of leak detection linings and of leak detection jackets according to Table 8.

4.2.3 Durability against mechanical load

4.2.3.1 Leak detection lining kits

The components of the thermoplastic and thermoplastic elastomers leak detection lining kits

according to Table 3 to Table 6.

The components of the UP and EP leak detection lining kits shall fulfil the requirements according to

EN 13121-1.

4.2.3.2 Leak detection jacket kits

There shall be no damage indicated by a crack, de-bonding or delamination after the test according to

5.2.3.2.

5 Testing, assessment and sampling methods

5.1 Effectiveness of leak detection lining kits and leak detection jacket kits

5.1.1 Tightness against liquid and gas

5.1.1.1 Test equipment

— vacuum pump with constant volume flow of 85 l/h;

— pressure pump;

— measuring device for pressure accuracy 0,6 % of the maximum graduated value;

— water;

— bucket with scale.

5.1.1.2 Preparation

The test tank shall be equipped with 3 test nozzles, which shall be distributed over the tank

circumference.

The test pipework shall have a length of minimum 10 m and shall be equipped with four test nozzles.

One particular test nozzle shall be installed at every end of the test pipe and the third and fourth shall

be installed at a distance of 2,5 m apart to the nozzles already available.

5.1.1.3 Procedure

The test shall be carried out at a temperature above the freezing point of water but not exceeding

+40 °C.

The tightness and the strength of the interstitial space shall be proved by a pressure test on a sample

of a tank or pipework at ambient pressure in the tank or pipework.

The difference of the ambient temperature shall be within a range of 1 K at the beginning and at the

end of the test.

The following minimum test pressures (p ) shall be used:

t2

— for interstitial spaces, which are part of a leak detection system working on the basis of leak

detection liquid or pressure at 1,1 times of the set pressure of the pressure relief valve, but at least

at 60 kPa (0,6 bar) pressure;

— for the interstitial spaces, which are part of a leak detection system working on the basis of

vacuum at 1,1 times of the negative working pressure of the leak detector and at 1,1 times of the

operating pressure of the pipework or the tank at pressurization of the pipework or tank at the

same time.

5.1.1.4 Evaluation

The test shall be deemed to have been passed if the condition in Formula (1) is fulfilled:

(p −p )⋅V

B E 1

−1

10≥ in Pa l s (1)

t

where

p is the pressure at the beginning of the test, in Pascal

B

p is the pressure at the end of the test, in Pascal

E

t is the test time, in seconds

V is the volume of the interstitial space according to Annex A in litres

5.1.2 Permeability

5.1.2.1 Test equipment

— Stored product or the following test liquids:

a) For unleaded petrol: According to EN 228

1) with maximum 5 % (V/V) ethanol

47,5 % (V/V) toluene,

30,4 % (V/V) isooctane (2,2,4-trimethylpentane)

17,1 % (V/V) n-heptane

3,0 % (V/V) methanol

2,0 % (V/V) butanol

2) with > 5 % (V/V) and ≤ 20 % (V/V) ethanol

20 % (V/V) ethanol

37,7 % (V/V) toluene

24,2 % (V/V) isooctane (2,2,4- trimethylpentane)

13,5 % (V/V) n-heptane

3 % (V/V) methanol

1,6 % (V/V) butanol

The tolerance for the component of the test liquid shall be 0,1 %.

b) for other products: according to Annex C of EN 14879-4:2007.

— Scale, accuracy of minimum ± 0,1 g.

— Length measuring device, accuracy of minimum ± 1 mm.

— Volume measuring device, accuracy of minimum ± 1 ml.

5.1.2.2 Preparation

The dimension of the test sample (e.g. piece of pipe or bag of lining material) shall be measured and

recorded. A test sample in form of closed volume with a minimum inner surface of 0,12 m shall be

used. The volume of the test sample shall be filled with (1,0 ± 0,1) l of test liquid and shall be weighted.

The end-closures used for the permeation test will need to be fitted with FKM or rubber, seals. The

seal shall be resistant against the test liquid. The test liquid shall be specially selected for their volatile

nature, so that multiple seals may be required to ensure that loss through the end-closures is

negligible.

The closure of the test samples may be grouted.

5.1.2.3 Procedure

Store the samples in air at (23 ± 2) °C using the scale.

In conformity with ISO 2528 at normal climate, passage shall be determined after the following

storage periods: 1, 3, 7, 14 and 56 d.

-1

Determine the rate of mass loss of the 'steady-state’ period (gradient of the regression line) in g ⋅ d .

Calculate the surface area A, where A = π⋅L ⋅ D, in m . Divide the rate of mass loss by A to give the

-2 -1

⋅ d for each specimen.

permeation rate in g ⋅ m

5.1.2.4 Evaluation

The test shall be deemed to have been passed, if the arithmetic average value over 56 d does not

exceed the values according to Table 1.

Each value measured at the different days shall fulfil the requirements of Table 1 and Table 2.

5.1.3 Free passage of liquid in the interstitial space

5.1.3.1 Test equipment

— vacuum pump with constant volume flow of 85 l/h;

— measuring device for pressure accuracy 0,6 % of the maximum graduated value;

— water;

— bucket with scale.

5.1.3.2 Preparation

For the test the vacuum pump shall be connected to the actual interstitial space of the representative

test tank or test pipe.

The test tank shall be equipped with three test nozzles, which shall be distributed over the tank

circumference.

The test pipework shall have a length of minimum 10 m and shall be equipped with four test nozzles.

One particular test nozzle shall be installed at every end of the test pipe and the third and fourth shall

be installed at a distance of 2,5 m apart to the nozzles already available.

A representative sample of the interstitial space of at least 1600 mm × 900 mm shall be used. The test

sample shall include any seams/welds and intermediate layer and shall have at least two test nozzles

at a distance of 1500 mm apart.

5.1.3.3 Procedure

5.1.3.3.1 Admission of water

The determination of the interstitial space volume for class I-systems shall be done according to

Annex A.

The test shall be carried out at a temperature above the freezing point of water.

In the interstitial space a vacuum of (60 ± 5) kPa shall be generated by the vacuum pump. The

measuring device for pressure shall be connected to the test sample at the highest test nozzle.

The admission of water shall be made through the test nozzle, situated at the lowest point of the test

sample, until a vacuum of (30 ± 5) kPa are reached.

The volume of water, sucked into the interstitial space, shall be measured.

5.1.3.3.2 Flow rate

Only for leak detection systems class II the flow rate of water at the outlet at the lowest point shall be

measured.

The test nozzle at the lowest point shall be opened and the water shall be collected over a time.

5.1.3.4 Evaluation

These values shall be identically with the calculated values according to 4.1.3 with a deviation ± 10 %.

5.1.4 Free passage of air

5.1.4.1 Free passage of air through intermediate layer

5.1.4.1.1 Test equipment

— Thickness tester, with an accuracy of 0,01 mm;

— two quadratic steel retaining plates 100 mm × 100 mm, thickness 10 mm;

— two quadratic steel pressure plates 150 mm × 150 mm, thickness 10 mm, with a hole of 10 mm

each in the corner sphere. One steel plate has a hole in the middle of the plate with a diameter of

6 mm and a fitting with a diameter of 6 mm is also welded on in the middle of the plate;

— four locking screws, 8 mm;

— compression device, with an accuracy of 1 %;

— air impermeable foil, e.g. PE 0,75 mm thickness;

— environmental chamber;

— vacuum pump with constant volume flow of 85 l/h;

— measuring device for pressure accuracy 0,6 % of the maximum graduated value;

— measuring device for the volume flow accuracy 0,6 % of the maximum graduated value.

5.1.4.1.2 Preparation

The tests shall be carried out at least at three quadratic test samples with the dimensions of

100 mm × 100 mm.

5.1.4.1.3 Procedure

The test shall be carried out at a temperature for installation in the open air at (60 ± 3) °C or by use in

frost protected area or underground tanks at (40 ± 3) °C.

NOTE The test at (60 ± 3) °C includes the test at (40 ± 3) °C.

For protecting the lining the intermediate layer shall be tested at 1,3 times the maximum possible

surface pressure (p ) according to Formula (2) – but a minimum of 50 kPa (0,5 bar).

MS

For protecting the jacket the intermediate layer shall be tested at a minimum of 1 MPa (10 bar).

Maximum possible surface pressure according to Formula (2):

p = ρ ⋅ g ⋅ h + p (2)

MS PA

First the initial thickness of the intermediate layers (s ) shall be measured with the thickness tester.

After the measurement the intermediate layers shall be laid between the two test plates. Through the

upper test plate the test samples shall be charged with the help of the compression device:

After reaching the steady-state condition but not before a minimum period of 14 days has elapsed the

residual thickness (s ) shall be measured and the test equipment shall be installed in the

environmental chamber. The test samples shall be charged further with the maximum possible surface

pressure (p ) and the measurement of the thickness shall be repeated at the limiting temperatures.

MS

The steady-state condition has been reached, if two measurements of the residual thickness (s ) made

at intervals of 24 h do not differ by more than 1 % from the thickness (s ). If after 90 days the steady-

state condition has not been achieved the test has failed. Following this test the intermediate layers

shall be pressed with the help of the pressure plates and the locking screws until half of the residual

thickness of the intermediate layers (s ) has been achieved or the pressure exceeds 2 ⋅ p .

3 MS

At the fittings, located in the middle of the plate, a vacuum pump with an inserted measuring device

for pressure, e.g. u-tube, shall be connected. At the exit of the vacuum pump a valve for throttling the

volume flow shall be installed, so that the volume flow can be adjusted to the given value of (85 ± 5)

l/h through the secondary measuring device for the volume flow. The length of the connecting line of

the measuring device for pressure to the fittings of the interstitial space shall be 250 mm. The flexible

connecting lines at the connection of the vacuum pump and the measuring device for the volume flow

shall be realized with an internal diameter of 6 mm.

The total length of the connecting line from the fittings to the vacuum pump shall be max. 1 m for the

measurements.

After installation of the test equipment as mentioned above and in Figure 2 the flow resistance shall be

taken from the measuring device for pressure after turning-on the vacuum pump and adjusting the

volume flow to (85 ± 5) l/h. The measurement shall be repeated at each test sample. The mean of the

measured values shall be compared with the limiting value of −1 kPa.

Dimensions in millimetres

Key

1 connection for vacuum pump with 85 l/h air

2 measuring device for pressure

3 test plate

4 intermediate layer

5 air impermeable foil

Test sample Initial Res. thickness at Thickness Flow back pressure at a

thickness p flow of 85 l/h air

MS

s

s (set-up as shown)

1 after loading s

mm

kPa

mm

mm

Figure 2 — Flow rate test set-up

5.1.4.1.4 Evaluation

The test shall be deemed to have been passed, if the air current back pressure emanating from the

intermediate layer with the thickness s3 is not less than −1 kPa (10 mbar) at a volume flow of (85 ± 15)

l/h of a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...