SIST EN 14179-1:2016

(Main)Glass in building - Heat soaked thermally toughened soda lime silicate safety glass - Part 1: Definition and description

Glass in building - Heat soaked thermally toughened soda lime silicate safety glass - Part 1: Definition and description

This European Standard specifies the heat soak process system together with tolerances, flatness, edgework, fragmentation and physical and mechanical characteristics of monolithic flat heat soaked thermally toughened soda lime silicate safety glass for use in buildings.

Curved heat soaked thermally toughened soda lime silicate safety glass is not part of this European Standard.

Other requirements, not specified in this European Standard, can apply to heat soaked thermally toughened soda lime silicate safety glass which is incorporated into assemblies, e.g. laminated glass or insulating units, or undergo an additional treatment, e.g. coating. The additional requirements are specified in the appropriate product standard. Heat soaked thermally toughened soda lime silicate safety glass, in this case, does not lose its bending strength characteristics and its resistance to temperature differentials.

Surface finished glasses (e.g. sandblasted, acid etched) after toughening are not covered by this European Standard.

Glas im Bauwesen - Heißgelagertes thermisch vorgespanntes Kalknatron-Einscheibensicherheitsglas - Teil 1: Definition und Beschreibung

Diese Europäische Norm legt das Heißlagerungsprozess-System sowie die Grenzabweichungen, Geradheit, Kantenbearbeitung, das Bruchverhalten und physikalische und mechanische Eigenschaften von flachem, heißgelagertem thermisch vorgespanntem Kalknatron-Einscheibensicherheitsglas für die Verwendung in Gebäuden fest.

Gebogenes heißgelagertes thermisch vorgespanntes Kalknatron-Einscheibensicherheitsglas ist nicht Bestandteil dieser Europäischen Norm.

An heißgelagerte thermisch vorgespannte Kalknatron-Einscheibensicherheitsgläser können andere Anforderungen, die in dieser Europäischen Norm nicht beschrieben sind, gestellt werden, wenn sie Bestandteil von Kombinationen sind, wie z. B. Verbundglas oder Isolierglas, oder wenn sie weiterverarbeitet, z. B. beschichtet werden. Die zusätzlichen Anforderungen sind in den entsprechenden Produktnormen festgelegt. In diesem Fall verliert heißgelagertes thermisch vorgespanntes Kalknatron-Einscheibensicherheitsglas seine Biegefestigkeit oder seinen Widerstand gegen Temperaturdifferenzen nicht.

Glas, dessen Oberfläche nach dem thermischen Vorspannen bearbeitet (z. B. sandgestrahlt oder säuregeätzt) wurde, ist nicht Gegenstand dieser Europäischen Norm.

Verre dans la construction - Verre de silicate sodo-calcique de sécurité trempé et traité Heat Soak - Partie 1: Définition et description

La présente Norme européenne spécifie le système fonctionnel de stabilisation thermique ainsi que les tolérances, la planéité, la finition des chants, la fragmentation et les caractéristiques physiques et mécaniques du verre plat monolithique de silicate sodo-calcique de sécurité trempé thermiquement et traité Heat Soak pour la construction.

Le verre bombé de silicate sodo-calcique de sécurité trempé thermiquement et traité Heat Soak ne fait pas partie de la présente Norme européenne.

D'autres exigences, non spécifiées dans la présente Norme européenne, peuvent s'appliquer au verre de silicate sodo-calcique de sécurité trempé thermiquement et traité Heat Soak intégré par transformation, par exemple du verre feuilleté ou des vitrages isolants préfabriqués scellés ou qui subit un traitement supplémentaire, par exemple une couche. Les exigences additionnelles sont spécifiées dans la norme de produit correspondante. Dans ce cas, le verre de silicate sodo-calcique de sécurité trempé thermiquement et traité Heat Soak ne perd pas ses caractéristiques de résistance à la flexion et sa résistance aux écarts de température.

Les verres traités en surface (par exemple, dépolis, gravés à l'acide) après la trempe ne relèvent pas du domaine d'application de la présente Norme européenne.

Steklo v gradbeništvu - HS-preskus kaljenega natrij-kalcijevega silikatnega varnostnega stekla - 1. del: Definicije in opis

Ta evropski standard določa sistem procesa toplotne obdelave (HS) s toleranco, ploskostjo, obdelavo robov, drobljenjem ter fizičnimi in mehanskimi lastnostmi monolitnega ploskega HS-preskušenega kaljenega zemljoalkalijskega silikatnega varnostnega stekla, ki se uporablja v gradbeništvu. Informacije o ukrivljenem HS-preskušenem kaljenem natrij-kalcijevem silikatnem varnostnem steklu so navedene v dodatku B, vendar ta proizvod ni del tega evropskega standarda. Druge zahteve, ki niso določene v tem evropskem standardu, je mogoče uporabiti za HS-preskušeno kaljeno natrij-kalcijevo silikatno varnostno steklo, ki je vgrajeno v sestave, npr. lepljeno steklo ali izolacijsko steklo, ali pa ga je treba dodatno obdelati, npr. z nanosi. Dodatne zahteve so določene v ustreznem standardu za proizvod. HS-preskušeno kaljeno natrij-kalcijevo silikatno varnostno steklo v tem primeru ne izgubi mehanskih ali toplotnih lastnosti. Steklo, ki je po kaljenju površinsko obdelano (npr. peskano, kislinsko jedkano), ne spada na področje uporabe tega evropskega standarda.

General Information

- Status

- Published

- Public Enquiry End Date

- 30-Dec-2014

- Publication Date

- 13-Sep-2016

- Technical Committee

- STV - Steklo, svetloba in razsvetljava v gradbeništvu

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 18-Aug-2016

- Due Date

- 23-Oct-2016

- Completion Date

- 14-Sep-2016

Relations

- Effective Date

- 01-Oct-2016

Overview

EN 14179-1:2016 - Glass in building: Heat soaked thermally toughened soda lime silicate safety glass (Part 1: Definition and description) defines the heat soak process system and the product characteristics for monolithic, flat heat soaked thermally toughened soda lime silicate safety glass used in buildings. It covers tolerances, flatness, edgework, fragmentation behaviour and physical/mechanical characteristics. Curved panes and surface‑finished glass after toughening are excluded. The standard also notes residual risk from nickel sulphide (NiS) inclusions (statistically no more than one break per 400 t).

Key topics and technical requirements

- Scope & definitions: Clear definitions for heat soaked and thermally toughened soda lime silicate safety glass and the concept of residual risk from NiS inclusions.

- Heat soak process system: Requirements for ovens, glass support, separation, calibration and the full process cycle (heating, holding, cooling) to reduce spontaneous breakage risk.

- Dimensions & tolerances: Nominal thicknesses, size tolerances, flatness criteria (including roller‑wave distortion) and squareness expressed via diagonal difference.

- Edgework and cut‑outs: Rules for permissible edge finishing, holes, notches and shaped panes prior to toughening.

- Fragmentation characteristics: Fragmentation test procedure, particle counts and maximum particle length criteria to verify safety breakage behaviour.

- Mechanical & thermal properties: Requirements covering bending strength, thermal durability and resistance to temperature differentials.

- Marking & documentation: Product identification and records for conformity and traceability.

- Normative references: Links to related product and test standards (e.g., EN 572 series, EN 1096‑1, EN 1288‑3).

Applications and who uses it

EN 14179-1 is used by:

- Glass manufacturers and heat‑soak process operators to define and control production and oven calibration.

- Fabricators and processors to ensure correct edgework, holes and cut‑outs before toughening.

- Specifiers, architects and façade engineers to select appropriate safety glass for windows, doors, balustrades and cladding where monolithic heat‑soaked toughened glass is required.

- Testing laboratories and conformity assessors for fragmentation and mechanical tests.

- Product certifiers and building inspectors for compliance checks.

Note: When heat soaked toughened glass is incorporated into assemblies (laminated glass, insulating glass units) or receives additional treatments (coatings), additional product standards apply and must be consulted.

Related standards

- EN 14179-2 (Evaluation of conformity / Product standard)

- EN 572‑1 to EN 572‑8 (Basic soda lime silicate glass products)

- EN 1096‑1 (Coated glass)

- EN 1288‑3 (Bending strength tests)

- EN 12600 (classification for accidental human impact - referenced for safety classification)

Keywords: EN 14179-1:2016, heat soaked glass, thermally toughened safety glass, soda lime silicate, heat soak testing, NiS inclusions, fragmentation test, glass tolerances.

Frequently Asked Questions

SIST EN 14179-1:2016 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Glass in building - Heat soaked thermally toughened soda lime silicate safety glass - Part 1: Definition and description". This standard covers: This European Standard specifies the heat soak process system together with tolerances, flatness, edgework, fragmentation and physical and mechanical characteristics of monolithic flat heat soaked thermally toughened soda lime silicate safety glass for use in buildings. Curved heat soaked thermally toughened soda lime silicate safety glass is not part of this European Standard. Other requirements, not specified in this European Standard, can apply to heat soaked thermally toughened soda lime silicate safety glass which is incorporated into assemblies, e.g. laminated glass or insulating units, or undergo an additional treatment, e.g. coating. The additional requirements are specified in the appropriate product standard. Heat soaked thermally toughened soda lime silicate safety glass, in this case, does not lose its bending strength characteristics and its resistance to temperature differentials. Surface finished glasses (e.g. sandblasted, acid etched) after toughening are not covered by this European Standard.

This European Standard specifies the heat soak process system together with tolerances, flatness, edgework, fragmentation and physical and mechanical characteristics of monolithic flat heat soaked thermally toughened soda lime silicate safety glass for use in buildings. Curved heat soaked thermally toughened soda lime silicate safety glass is not part of this European Standard. Other requirements, not specified in this European Standard, can apply to heat soaked thermally toughened soda lime silicate safety glass which is incorporated into assemblies, e.g. laminated glass or insulating units, or undergo an additional treatment, e.g. coating. The additional requirements are specified in the appropriate product standard. Heat soaked thermally toughened soda lime silicate safety glass, in this case, does not lose its bending strength characteristics and its resistance to temperature differentials. Surface finished glasses (e.g. sandblasted, acid etched) after toughening are not covered by this European Standard.

SIST EN 14179-1:2016 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14179-1:2016 has the following relationships with other standards: It is inter standard links to SIST EN 14179-1:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14179-1:2016 is associated with the following European legislation: EU Directives/Regulations: 88/379/EEC; Standardization Mandates: M/135_AM1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 14179-1:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Steklo v gradbeništvu - HS-preskus kaljenega natrij-kalcijevega silikatnega varnostnega stekla - 1. del: Definicije in opisGlas im Bauwesen - Heißgelagertes thermisch vorgespanntes Kalknatron-Einscheibensicherheitsglas - Teil 1: Definition und BeschreibungVerre dans la construction - Verre de silicate sodo-calcique de sécurité trempé et traité Heat Soak - Partie 1: Définition et descriptionGlass in building - Heat soaked thermally toughened soda lime silicate safety glass - Part 1: Definition and description81.040.20Steklo v gradbeništvuGlass in buildingICS:Ta slovenski standard je istoveten z:EN 14179-1:2016SIST EN 14179-1:2016en,fr,de01-oktober-2016SIST EN 14179-1:2016SLOVENSKI

STANDARDSIST EN 14179-1:20051DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14179-1

July

t r s x ICS

z sä r v rä t r Supersedes EN

s v s y {æ sã t r r wEnglish Version

Glass in building æ Heat soaked thermally toughened soda lime silicate safety glass æ Part

sã Definition and description Verre dans la construction æ Verre de silicate sodoæcalcique de sßcuritß trempß et traitß Heat Soak æ Partie

sã Dßfinition et description

Glas im Bauwesen æ Heißgelagertes thermisch vorgespanntes KalknatronæEinscheibensicherheitsglas æ Teil

sã Definition und Beschreibung This European Standard was approved by CEN on

s t May

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s v s y {æ sã t r s x ESIST EN 14179-1:2016

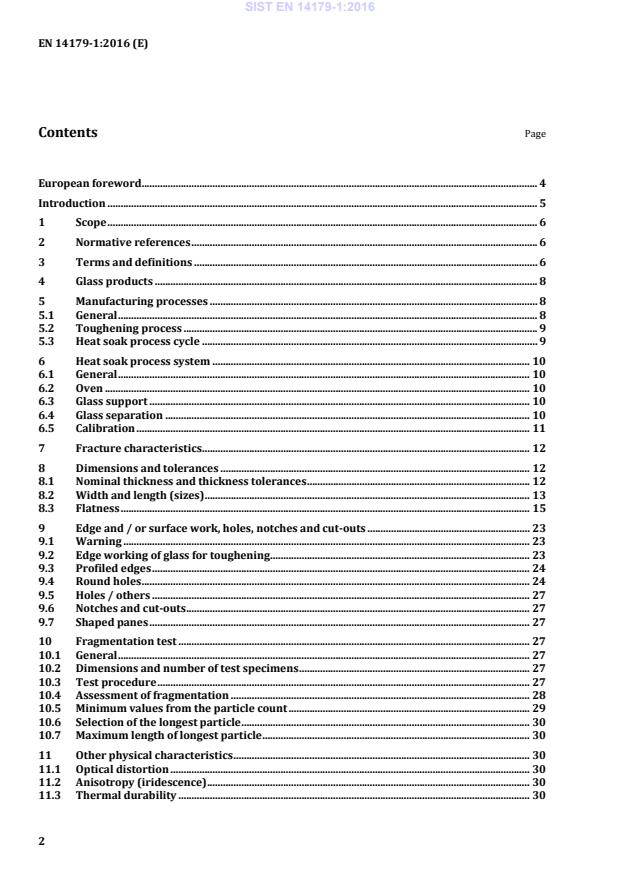

European foreword . 4 Introduction . 5 1 Scope . 6 2 Normative references . 6 3 Terms and definitions . 6 4 Glass products . 8 5 Manufacturing processes . 8 5.1 General . 8 5.2 Toughening process . 9 5.3 Heat soak process cycle . 9 6 Heat soak process system . 10 6.1 General . 10 6.2 Oven . 10 6.3 Glass support . 10 6.4 Glass separation . 10 6.5 Calibration . 11 7 Fracture characteristics . 12 8 Dimensions and tolerances . 12 8.1 Nominal thickness and thickness tolerances . 12 8.2 Width and length (sizes) . 13 8.3 Flatness . 15 9 Edge and / or surface work, holes, notches and cut-outs . 23 9.1 Warning . 23 9.2 Edge working of glass for toughening . 23 9.3 Profiled edges . 24 9.4 Round holes . 24 9.5 Holes / others . 27 9.6 Notches and cut-outs . 27 9.7 Shaped panes . 27 10 Fragmentation test . 27 10.1 General . 27 10.2 Dimensions and number of test specimens . 27 10.3 Test procedure . 27 10.4 Assessment of fragmentation . 28 10.5 Minimum values from the particle count . 29 10.6 Selection of the longest particle . 30 10.7 Maximum length of longest particle . 30 11 Other physical characteristics . 30 11.1 Optical distortion . 30 11.2 Anisotropy (iridescence) . 30 11.3 Thermal durability . 30 SIST EN 14179-1:2016

Heat soak process system calibration test . 32 A.1 Calibration criteria. 32 A.2 Loading of oven and position for glass surface temperature measurement . 32 A.3 Procedure . 33 A.4 Records . 33 A.5 Interpretation of the calibration test . 34 Annex B (informative)

Alternative method for the measurement of roller wave distortion . 39 B.1 Apparatus . 39 B.2 Method . 39 B.3 Limitations . 40 B.4 Alternative use of apparatus . 40 Annex C (informative)

Examples of particle count . 41 Bibliography . 43

Key T glass temperature at any point, °C d ambient temperature t time, h a heating phase 1 first glass to reach 250 °C b holding phase 2 last glass to reach 250 °C c cooling phase Figure 1 — Heat soak process cycle 5.3.2 Heating phase The heating phase commences with all the glasses at ambient temperature and concludes when the surface temperature of the last glass reaches 250 °C. The maximum heating rate is 3° C per minute. The time to reach this temperature is defined in the calibration process. This time will be dependent on the size of the oven, the amount of glass to be treated, the separation between glasses and the heating system capacity. NOTE 1 The glass separation and rate of heating should be controlled to minimize the risk of glass breakage as a result of thermal stress. To facilitate economic heating, the air temperature within the oven may exceed 290 °C. However, the glass surface temperature shall not be allowed to exceed 290 °C. The period of glass surface temperature in excess of 270 °C shall be minimized. NOTE 2 Care should be taken to ensure the maximum temperature of the glass does not exceed 270° C as there is a possibility of the nickel sulphide inclusion reconverting. SIST EN 14179-1:2016

Figure 2 — Example of a vertical glass separator The minimum separation of the glasses shall be determined during the calibration of the oven, see 6.5 and Annex A. Generally, a minimum separation of 20 mm is recommended (see Figure 3). NOTE If glasses of very different size are put on the same stillage, they will require greater separation in order to prevent glass breakage when the furnace is opened after the heat soak process. The same applies to glasses with holes, notches and cut-outs.

Figure 3 — Recommended separation between glass The positioning of the separators, material of the manufacture and their shape shall be specified during the calibration test of the oven and shall be reproduced during the manufacturing process. 6.5 Calibration The heat soak system, e.g. oven, glass separation, separators, etc., shall be calibrated, see Annex A. The calibration shall determine the heating phase of the process, glass separation distance, the positioning, material and shape of separators, the type and positioning of stillage(s) and define the operating conditions for use during manufacture. SIST EN 14179-1:2016

Figure 4 — Examples of width, B, and length, H, relative to the pane shape For heat soaked thermally toughened soda lime silicate safety glass manufactured from patterned glass, the direction of the pattern should be specified relative to one of the dimensions. 8.2.2 Maximum and minimum sizes For maximum and minimum sizes, the manufacturer shall be consulted. 8.2.3 Tolerances and squareness The nominal dimensions for width and length being given, the finished pane shall not be larger than the nominal dimensions increased by the tolerance t, or smaller than the nominal dimensions reduced by the tolerance t. Limits are given in Table 2. The squareness of rectangular glass panes is expressed by the difference between its diagonals. The difference between the two diagonal lengths of the pane of glass shall not be larger than the deviation limit, v, as specified in Table 3. SIST EN 14179-1:2016

B or H Tolerance, t nominal glass thickness,

d

8 nominal glass thickness,

d > 8

2 000 ±2,0 ±3,0 2 000 < B or H

3 000 ±3,0 ±4,0 > 3 000 ±4,0 ±5,0 Table 3 — Limit deviations for the difference between diagonals Dimensions in millimetres Limit deviation v on the difference between diagonals Nominal dimension B or H nominal glass thickness,

d

8 nominal glass thickness,

d > 8

2 000

6 2 000 < B or H

3 000

8 > 3 000

10 8.2.4 Edge deformation produced by vertical toughening The tongs used to suspend the glass during toughening can result in surface depressions, known as tong marks (see Figure 5). The centres of the tong marks may be situated up to a maximum of 20 mm in from the edge. A deformation of the edge less than 2 mm can be produced in the region of the tong mark and there can also be an area of optical distortion. These deformations shall be included in the tolerances in Table 2.

Key 1 deformation 2 up to 20 mm 3 tong mark 4 100 mm radius maximum area of optical distortion Figure 5 — Tong mark deformation SIST EN 14179-1:2016

Key 1 deformation for calculating overall bow 2 B, or H, or diagonal length 3 thermally toughened soda lime silicate safety glass Figure 6 — Representation of overall bow

Key 1 thermally toughened soda lime silicate safety glass Figure 7 — Representation of roller wave distortion SIST EN 14179-1:2016

Key 1 straight edge 2 edge lift 3 thermally toughened soda lime silicate safety glass Figure 8 — Representation of edge lift

Key 1 local distortion 2 thermally toughened soda lime silicate safety glass Figure 9 — Representation of local distortion 8.3.2 Measurement of overall bow The pane of glass shall be placed in a vertical position and supported on its longer side by two load bearing blocks at the quarter points (see Figure 10). For glass thinner than 4 mm nominal thickness the support will have an angle between 3 and 7° from the vertical. The deformation shall be measured along the edges of the glass and along the diagonals, as the maximum distance between a straight metal ruler, or a stretched wire, and the concave surface of the glass (see Figure 6). The value for the bow is then expressed as the deformation, in millimetres, divided by the measured length of the edge of the glass, or diagonal, in millimetres, as appropriate. The measurement shall be carried out at room temperature. The maximum allowable values for overall bow are given in Table 4 and Table 6. NOTE Results from this this test method for glasses thinner than 4 mm may be inaccurate. SIST EN 14179-1:2016

Key 1 B or H 2 (B or H)/2 3 (B or H)/4 4 thermally toughened soda lime silicate safety glass 5 support Figure 10 — Support conditions for the measurement of overall distortion 8.3.3 Measurement of wave and roller wave 8.3.3.1 General The wave or roller wave is measured by means of a straight edge, or equivalent, being placed at right angles to the wave or roller wave and bridging from peak to peak of the waves (see Figure 11). NOTE This section deals with measurement using a straight edge and feeler gauges. An alternative method is described in Annex B. 8.3.3.2 Apparatus A straight edge: — length of between 300 mm and 400 mm. The minimal length of the straight edge has to bridge two peaks of the roller waves. Feeler gauges: — various thicknesses in units of 0,05 mm. 8.3.3.3 Method Place the straight edge so that it bridges across adjacent peaks. Insert the feeler gauge between the glass surface and the straight edge. Increase the thickness of the feeler gauges until they just fill the gap SIST EN 14179-1:2016

Key 1 straight edge 2 wave or roller wave distortion 3 thermally toughened soda lime silicate safety glass Figure 11 — Measurement of wave or roller wave distortion 8.3.4 Measurement of edge lift (for horizontally toughened glass only) The glass shall be placed on a flat support with the edge lift overhanging the edge of the support by between 50 mm and 100 mm. The straight edge is placed on the peaks of the roller waves and the gap between the ruler and the glass measured using a feeler gauge (see Figure 12). The maximum allowable values for edge lift are given in Table 5. The values in Table 5 only apply to thermally toughened soda lime silicate safety glass having edgework complying with Figures 15 to Figure 18. For profiled edges or other types of edgework contact the manufacturer. SIST EN 14179-1:2016

Key 1 straight edge 2 edge lift 3 thermally toughened soda lime silicate safety glass 4 flat support Figure 12 — Measurement of edge lift 8.3.5 Measurement of perimeter deformation of glass produced by air cushion toughening process Place the glass on a flat surface with the concave side facing upwards – see Figure 13. A 100 mm straight edge is laid on the pane at right angles to the edge. The gap between the ruler and the glass is measured using a feeler gauge (see Figure 13). The perimeter deformation is the maximum distance between the surface of the pane and the straight edge. The maximum allowable values for perimeter deformation are given in Table 7. Dimensions in millimetres

Key 1 straight edge 2 perimeter deformation 3 thermally toughened soda lime silicate safety glass Figure 13 — Measurement of perimeter deformation 8.3.6 Measurement of local distortion (for vertically toughened glass only) Local distortion can occur over relatively short distances on the edge of the vertically toughened glass that contains the tong marks (see Figure 5). SIST EN 14179-1:2016

Key 1 straight edge 2 local distortion 3 thermally toughened soda lime silicate safety glass Figure 14 — Measurement of local distortion 8.3.7 Limitation on overall bow, roller waves and edge lift for horizontally toughened glass The maximum allowable values for the overall bow, when measured according to 8.3.2, for roller waves, when measured according to 8.3.3 and edge lift, when measured according to 8.3.4 are given in Tables 4 and 5. These values only apply to thermally toughened soda lime silicate safety glass without holes and / or notches and / or cut-outs. Table 4 — Maximum allowable values of overall bow and roller wave distortion for horizontally toughened glass Glass Type Maximum allowable value for distortion Overall bow mm / m Roller Wave mm Uncoated float glass in accordance with EN 572–1 and EN 572–2 3,0 0,3 Others a 4,0 0,5 Dependent upon the wavelength of the roller wave an appropriate length of gauge has to be used a For enamelled glass which is not covered over the whole surface the manufacturer should be consulted. SIST EN 14179-1:2016

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...