SIST EN 15682-1:2013

(Main)Glass in building - Heat soaked thermally toughened alkaline earth silicate safety glass - Part 1: Definition and description

Glass in building - Heat soaked thermally toughened alkaline earth silicate safety glass - Part 1: Definition and description

This European Standard specifies the heat soak process system together with tolerances flatness, edgework, fragmentation and physical and mechanical characteristics of monolithic flat heat soaked thermally toughened alkaline earth silicate safety glass for use in buildings. Information on curved heat soak thermally toughened alkaline earth silicate safety glass is given in Annex B, but this product does not form part of this document.

Other requirements, not specified in this document, can apply to heat soaked thermally toughened alkaline earth silicate safety glass which is incorporated into assemblies, e.g. laminated glass or insulating units, or undergo an additional treatment, e.g. coating. The additional requirements are specified in the appropriate product standard EN 15682-2. In this case, heat soaked thermally toughened alkaline earth silicate glass does not lose its mechanical or thermal characteristics.

Glas im Bauwesen - Heißgelagertes thermisch vorgespanntes Erdalkali-Silicat-Einscheibensicherheitsglas - Teil 1: Definition und Beschreibung

Diese Europäische Norm legt das Heißlagerungsprozess-System sowie die Toleranzen der Geradheit, Kanten-bearbeitung, das Bruchverhalten und physikalische und mechanische Eigenschaften von flachem heißgelagertem thermisch vorgespanntem Erdalkali-Silicat-Einscheiben¬sicherheitsglas für die Verwendung im Bauwesen fest. Anhang B enthält Angaben zu gebogenem heißgelagertem thermisch vorgespanntem Erdalkali-Silicat-Einscheiben¬sicherheitsglas, dieses Produkt ist jedoch nicht Bestandteil dieses Dokuments.

An heißgelagerte thermisch vorgespannte Erdalkali-Silicat-Einscheibensicherheitsgläser können andere Anforderungen, die in diesem Dokument nicht beschrieben sind, gestellt werden, wenn sie Bestandteil von Kombinationen sind, wie z. B. Verbundglas oder Isolierglas, sind oder wenn sie weiterverarbeitet, z. B. beschichtet werden. Die zusätzlichen Anforderungen sind in der zutreffenden Produktnorm, EN 15682 2, festgelegt. In diesem Fall wird heißgelagertes thermisch vor¬gespanntes Erdalkali-Silicat-Einscheibensicherheitsglas seine mechanischen oder thermischen Eigenschaften nicht verlieren.

Verre dans la construction - Verre de silicate alcalinoterreux de sécurité trempé et traité Heat Soak - Partie 1 : Définition et description

La présente Norme européenne spécifie le système fonctionnel de stabilisation thermique ainsi que les tolérances, la planéité, la finition des chants, la fragmentation et les caractéristiques physiques et mécaniques du verre plat monolithique de silicate alcalino-terreux de sécurité trempé et traité Heat Soak dans la construction. L'Annexe B fournit des informations relatives au verre bombé de silicate alcalino-terreux de sécurité trempé et traité Heat Soak, mais ce produit ne fait pas partie de la présente norme.

D'autres exigences, non spécifiées dans le présent document, peuvent s'appliquer au verre de silicate alcalino-terreux de sécurité trempé et traité Heat Soak intégré dans des ensembles, par exemple du verre feuilleté ou des ensembles isolants préfabriqués scellés ou qui subit un traitement supplémentaire, par exemple une couche. Les exigences additionnelles sont spécifiées dans la norme de produit correspondante, EN 15682-2. Dans ce cas, le verre de silicate alcalino-terreux trempé et traité Heat Soak ne perd pas ses caractéristiques mécaniques ou thermiques.

Steklo v gradbeništvu - HS-preskus kaljenega zemljoalkalijskega silikatnega varnostnega stekla - 1. del: Definicije in opis

Ta evropski standard določa sistem vročinske obdelave (HS) s toleranco, ploskostjo, obdelavo robov, drobljenjem ter fizičnimi in mehanskimi lastnostmi monolitnega ploskega HS-preskušenega kaljenega zemljoalkalijskega silikatnega varnostnega stekla, ki se uporablja v gradbeništvu. Informacije o ukrivljenem HS-preskušenem kaljenem zemljoalkalijskem silikatnem varnostnem steklu so podane v dodatku B, vendar ta izdelek ni del tega dokumenta. Druge zahteve, ki niso določene v tem dokumentu, se lahko uporabljajo za HS-preskušeno kaljeno zemljoalkalijsko silikatno varnostno steklo, ki je vgrajeno v sestave, npr. lepljeno steklo ali izolacijsko steklo, ali pa ga je treba dodatno obdelati, npr. z nanosi. Dodatne zahteve so določene v ustreznem standardu za izdelek EN 15682-2. HS-preskušeno kaljeno zemljoalkalijsko silikatno steklo v tem primeru ne izgubi mehanskih ali toplotnih lastnosti.

General Information

- Status

- Published

- Public Enquiry End Date

- 27-Feb-2013

- Publication Date

- 22-Sep-2013

- Technical Committee

- STV - Steklo, svetloba in razsvetljava v gradbeništvu

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 30-Aug-2013

- Due Date

- 04-Nov-2013

- Completion Date

- 23-Sep-2013

- Directive

- 88/609/EEC - Limitation of emissions of certain pollutants into the air from large combustion plants

- Directive

- 89/106/EEC - Construction products

Overview

EN 15682-1:2013 is the CEN European standard that defines and describes heat soaked thermally toughened alkaline earth silicate safety glass for use in buildings. It specifies the heat soak process system and the essential tolerances and characteristics for monolithic flat products - including flatness, edgework, fragmentation behavior and key physical/mechanical properties. Annex B provides information on curved products but curved glass is not within the main scope.

Key SEO keywords: EN 15682-1:2013, heat soaked thermally toughened alkaline earth silicate safety glass, heat soak process, NiS, fragmentation, glass in building.

Key topics and technical requirements

- Definition and scope: Clear definition of heat soaked thermally toughened alkaline earth silicate safety glass and the concept of residual risk from nickel sulphide (NiS) inclusions.

- Heat soak process: Requirements for the heating, holding and cooling phases of the heat soak cycle and the heat soak process system (oven, supports, separation and calibration).

- Calibration and performance: Procedures for heat soak system calibration and criteria to validate oven performance and glass surface temperatures.

- Dimensional tolerances: Nominal thickness, size limits, squareness, edge deformation and flatness measurement methods (overall and local bow).

- Edgework and openings: Rules and warnings for edge finishing, profiled edges, holes, notches and cut-outs including position and tolerance considerations.

- Fragmentation: Fragmentation test methods, particle count assessment and limits on longest fragment length to ensure safe post-breakage behavior.

- Physical properties: Statements on thermal durability, mechanical strength and optical characteristics (anisotropy/iridescence) without changing fundamental mechanical properties after incorporation into assemblies or coatings.

- Residual risk benchmark: The heat soak process aims, on average, to limit NiS-related breakage to about one break per 400 tonnes of heat soaked glass.

Applications and who uses this standard

EN 15682-1:2013 is intended for manufacturers, quality managers, glazing fabricators, façade engineers, architects, test laboratories and specifiers involved in building glass production and installation. Typical applications include safety glazing for windows, doors, façades, balustrades and other architectural uses where thermally toughened safety glass and predictable breakage behavior are required.

Related standards

- EN 15682-2 - Evaluation of conformity / Product standard (complements Part 1)

- EN 14178-1 - Basic alkaline earth silicate glass products (referenced)

- EN 12600 - Classification for impact performance (referenced for accidental human impact)

EN 15682-1:2013 ensures consistent manufacture, testing and documentation of heat soaked thermally toughened alkaline earth silicate safety glass across CEN member states, helping reduce the risk of spontaneous NiS-related breakage while retaining mechanical and thermal performance.

Frequently Asked Questions

SIST EN 15682-1:2013 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Glass in building - Heat soaked thermally toughened alkaline earth silicate safety glass - Part 1: Definition and description". This standard covers: This European Standard specifies the heat soak process system together with tolerances flatness, edgework, fragmentation and physical and mechanical characteristics of monolithic flat heat soaked thermally toughened alkaline earth silicate safety glass for use in buildings. Information on curved heat soak thermally toughened alkaline earth silicate safety glass is given in Annex B, but this product does not form part of this document. Other requirements, not specified in this document, can apply to heat soaked thermally toughened alkaline earth silicate safety glass which is incorporated into assemblies, e.g. laminated glass or insulating units, or undergo an additional treatment, e.g. coating. The additional requirements are specified in the appropriate product standard EN 15682-2. In this case, heat soaked thermally toughened alkaline earth silicate glass does not lose its mechanical or thermal characteristics.

This European Standard specifies the heat soak process system together with tolerances flatness, edgework, fragmentation and physical and mechanical characteristics of monolithic flat heat soaked thermally toughened alkaline earth silicate safety glass for use in buildings. Information on curved heat soak thermally toughened alkaline earth silicate safety glass is given in Annex B, but this product does not form part of this document. Other requirements, not specified in this document, can apply to heat soaked thermally toughened alkaline earth silicate safety glass which is incorporated into assemblies, e.g. laminated glass or insulating units, or undergo an additional treatment, e.g. coating. The additional requirements are specified in the appropriate product standard EN 15682-2. In this case, heat soaked thermally toughened alkaline earth silicate glass does not lose its mechanical or thermal characteristics.

SIST EN 15682-1:2013 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15682-1:2013 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 88/609/EEC, 89/106/EEC; Standardization Mandates: M/135. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 15682-1:2013 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Steklo v gradbeništvu - HS-preskus kaljenega zemljoalkalijskega silikatnega varnostnega stekla - 1. del: Definicije in opisGlas im Bauwesen - Heißgelagertes thermisch vorgespanntes Erdalkali-Silicat-Einscheibensicherheitsglas - Teil 1: Definition und BeschreibungVerre dans la construction - Verre de silicate alcalinoterreux de sécurité trempé et traité Heat Soak - Partie 1 : Définition et descriptionGlass in building - Heat soaked thermally toughened alkaline earth silicate safety glass - Part 1: Definition and description81.040.20Steklo v gradbeništvuGlass in buildingICS:Ta slovenski standard je istoveten z:EN 15682-1:2013SIST EN 15682-1:2013en,fr,de01-november-2013SIST EN 15682-1:2013SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15682-1

July 2013 ICS 81.040.20 English Version

Glass in building - Heat soaked thermally toughened alkaline earth silicate safety glass - Part 1: Definition and description

Verre dans la construction - Verre de silicate alcalinoterreuxde sécurité trempé et traité Heat Soak - Partie 1 : Définition et description

Glas im Bauwesen - Heißgelagertes thermisch vorgespanntes Erdalkali-Silicat-Einscheibensicherheitsglas - Teil 1: Definition und Beschreibung This European Standard was approved by CEN on 30 May 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15682-1:2013: ESIST EN 15682-1:2013

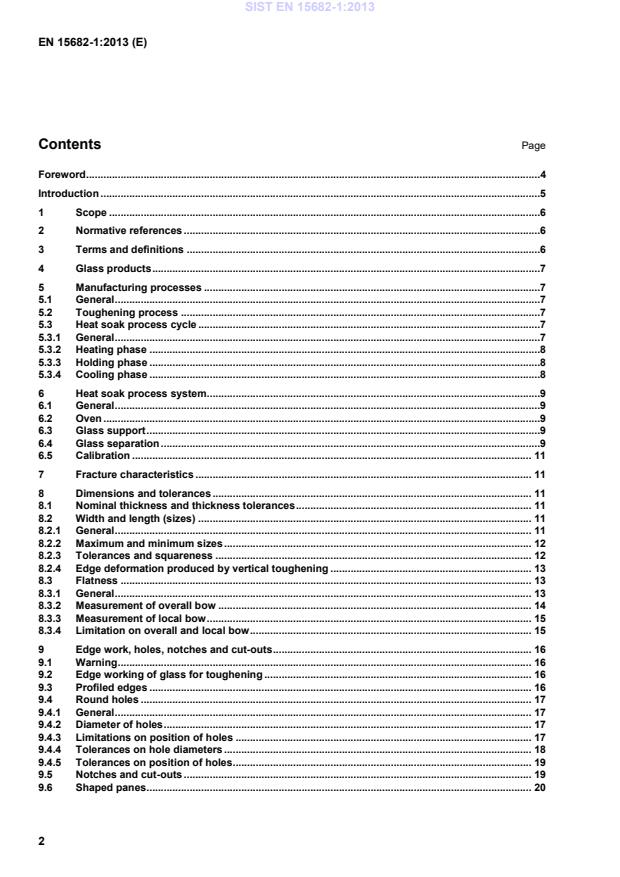

Foreword .4 Introduction .5 1 Scope .6 2 Normative references .6 3 Terms and definitions .6 4 Glass products .7 5 Manufacturing processes .7 5.1 General .7 5.2 Toughening process .7 5.3 Heat soak process cycle .7 5.3.1 General .7 5.3.2 Heating phase .8 5.3.3 Holding phase .8 5.3.4 Cooling phase .8 6 Heat soak process system .9 6.1 General .9 6.2 Oven .9 6.3 Glass support .9 6.4 Glass separation .9 6.5 Calibration . 11 7 Fracture characteristics . 11 8 Dimensions and tolerances . 11 8.1 Nominal thickness and thickness tolerances . 11 8.2 Width and length (sizes) . 11 8.2.1 General . 11 8.2.2 Maximum and minimum sizes . 12 8.2.3 Tolerances and squareness . 12 8.2.4 Edge deformation produced by vertical toughening . 13 8.3 Flatness . 13 8.3.1 General . 13 8.3.2 Measurement of overall bow . 14 8.3.3 Measurement of local bow . 15 8.3.4 Limitation on overall and local bow . 15 9 Edge work, holes, notches and cut-outs . 16 9.1 Warning . 16 9.2 Edge working of glass for toughening . 16 9.3 Profiled edges . 16 9.4 Round holes . 17 9.4.1 General . 17 9.4.2 Diameter of holes . 17 9.4.3 Limitations on position of holes . 17 9.4.4 Tolerances on hole diameters . 18 9.4.5 Tolerances on position of holes . 19 9.5 Notches and cut-outs . 19 9.6 Shaped panes . 20 SIST EN 15682-1:2013

Heat soak process system calibration test . 25 A.1 Calibration criteria . 25 A.2 Loading of oven and position for glass surface temperature measurement . 25 A.3 Procedure . 26 A.4 Records . 27 A.5 Interpretation of the calibration test . 27 Annex B (informative)

Curved heat soaked thermally toughened alkaline earth silicate safety glass . 36 Annex C (informative)

Examples of particle count . 37 Bibliography . 40

Key T glass temperature at any point, °C d ambient temperature t time, h a heating phase 1 first glass to reach 280 °C b holding phase 2 last glass to reach 280 °C c cooling phase Figure 1 — Heat soak process cycle 5.3.2 Heating phase The heating phase commences with all the glasses at ambient temperature and concludes when the surface temperature of the last glass reaches 280 °C. The time to reach this temperature is defined in the calibration process. This time will be dependent on the size of the oven, the amount of glass to be treated, the separation between glasses and the heating system capacity. The glass separation and rate of heating should be controlled to minimise the risk of glass breakage as a result of thermal stress. To facilitate economic heating, the air temperature within the oven may exceed 320 °C. However, the glass surface temperature shall not be allowed to exceed 320 °C. The period of glass surface temperature in excess of 300 °C shall be minimised. When the temperature of the glass exceeds 300 °C, care should be taken to ensure that the properties of the heat soaked thermally toughened alkaline earth silicate safety glass are not significantly altered, i.e. they continue to meet Clause 10. 5.3.3 Holding phase The holding phase commences when the surface temperature of all the glasses has reached a temperature of 280 °C. The duration of the holding phase is minimum 2 h. Precise oven control is necessary in order to ensure that the glass surface temperature shall be maintained in the range of 290 °C ± 10 °C during the holding phase. 5.3.4 Cooling phase The cooling phase commences when the last glass to reach 280 °C has completed its holding phase, i.e. been held for two hours at 290 °C ± 10 °C. During this phase the glass temperature shall be brought down to ambient temperature. SIST EN 15682-1:2013

Figure 2 — Example of a vertical glass support The minimum separation of the glasses shall be determined during the calibration of the oven (see 6.5 and Annex A). Generally, a minimum separation of 20 mm is recommended. See Figure 3. NOTE If glasses of very different sizes are put on the same stillage, they will require greater separation in order to prevent glass breakage when the furnace is opened after the heat soak process. The same applies to glasses with holes, notches and cut-outs. Dimensions in millimetres

Figure 3 — Recommend separation between glass The positioning of the separators, material of the manufacture and their shape shall be specified during the calibration test of the oven and shall be reproduced during the manufacturing process. SIST EN 15682-1:2013

d Thickness tolerances

4 5 6 8 10 12 15 ±0,2 ±0,2 ±0,2 ±0,3 ±0,3 ±0,3 ±0,5 The thickness of a pane shall be determined as for the basic product. The measurement shall be taken at the centres of the four sides, and away from the area of any tong marks (see Figure 6), which may be present. 8.2 Width and length (sizes) 8.2.1 General When heat soaked thermally toughened alkaline earth silicate safety glass dimensions are quoted for rectangular panes, the first dimension shall be the width, B, and the second dimension the length, H, as shown in Figure 4. It shall be made clear which dimension is the width, B, and which is the length, H, when related to its installed position. SIST EN 15682-1:2013

Figure 4 — Examples of width, B, and length, H, relative to the pane shape 8.2.2 Maximum and minimum sizes For maximum and minimum sizes, the manufacturer shall be consulted. 8.2.3 Tolerances and squareness The nominal dimensions for width and length being given, the finished pane shall not be larger than a prescribed rectangle resulting from the nominal dimensions increased by the tolerance, t, or smaller than a prescribed rectangle reduced by the tolerance, t. The sides of the prescribed rectangles are parallel to one another and these rectangles shall have a common centre (see Figure 5). The limits of squareness shall be determined by the prescribed rectangles. Tolerances are given in Table 2.

Figure 5 — Tolerance limits for dimensions of rectangular panes SIST EN 15682-1:2013

B or H Tolerance, t nominal glass thickness,

d ≤ 12 nominal glass thickness,

d > 12 ≤ 2 000 ±2,5 (horizontal toughening)

± 3,0 (vertical toughening) ±3,0 > 2 000 to 3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...