SIST EN 14705:2005

(Main)Heat exchangers - Method of measurement and evaluation of thermal performances of wet cooling towers

Heat exchangers - Method of measurement and evaluation of thermal performances of wet cooling towers

This European Standard specifies requirements, test methods and acceptance tests for thermal performances pumping head verification of wet cooling towers and plume abatement for wet/dry cooling towers.

This European Standard is applicable to natural draught wet cooling towers (see in 3.1.2.2) fan assisted natural draught cooling tower (see 3.1.2.3), wet/dry cooling towers (see 3.1.2.4) and "Mechanical draught cooling towers", except series ones.

It specifies the test methods, the apparatus required, the limitation of errors and the method for results examination.

The acceptance testing covers the verification of the thermal performance data and pumping head of the cooling tower as specified in the contract between the supplier and the purchaser. If these tests are required then this should be recognized at the time of the contract, as additional fittings, and preparations for the test may be required.

Deviations from the rules laid down below as well as additions need special agreement between purchaser and supplier and should be documented.

This standard does not apply to mechanical draught series wet cooling towers which are dealt with in prEN 13741.

NOTE Terms like "design", "values", "guarantee" and "acceptance" used in this standard should be understood in a technical but not in a legal or commercial sense.

Wärmeaustauscher - Verfahren zur Messung und Bewertung der wärmetechnischen Leistungskenndaten von Nasskühltürmen

Diese Europäische Norm legt Anforderungen, Prüfverfahren und Abnahmeprüfungen zum Nachweis wärmetechnischer

Leistungskenndaten, der Pumpförderhöhe für Nasskühltürme sowie zur Verminderung von

sichtbaren Schwaden für Nass-/Trockenkühltürme fest.

Diese Europäische Norm gilt für Naturzug-Nasskühltürme (siehe 3.1.2.2), für Naturzugkühltürme mit

Ventilatorunterstützung (siehe 3.1.2.3), Nass-/Trockenkühltürme (siehe 3.1.2.4) und mit Ausnahme von

Serienkühltürmen auch für zwangsbelüftete Kühltürme.

Es werden Prüfverfahren, die erforderlichen Prüfgeräte, Fehlergrenzen und das Verfahren zur Auswertung der

Ergebnisse festgelegt.

Die Abnahmeprüfung umfasst den Nachweis wärmetechnischer Kenndaten und der Pumpförderhöhe für

Kühltürme, die im Vertrag zwischen Lieferant und Käufer festgelegt sind. Falls Abnahmeprüfungen gefordert

werden, sollten sie bereits im Vertrag festgelegt werden, da zusätzliche Prüfausrüstungen und -vorbereitungen

erforderlich werden können.

Abweichungen von und Zusätze zu den nachfolgend festgelegten Regeln bedürfen einer besonderen

Vereinbarung zwischen Käufer und Lieferant und sollten dokumentiert werden.

Die vorliegende Norm gilt nicht für zwangsbelüftete Serien-Nasskühltürme, die in EN 13741 erfasst werden.

ANMERKUNG Ausdrücke wie Auslegung, Werte� Garantie und Abnahme werden in dieser Norm im technischen

und nicht im juristischen oder kaufmännischen Sinne gebraucht.

Echangeurs de chaleur - Méthode de mesure et évaluation des performances thermiques des aéroréfrigérants humides

La présente Norme européenne spécifie les exigences, les méthodes d'essai et les essais de des performances thermiques, de la vérification de la hauteur de refoulement des aéroréfrigérants humides et de la réduction du panache des aéroréfrigérants humides/secs.

La présente Norme européenne est appliquée aux aéroréfrigérants humides à tirage naturel (voir 3.1.2.2), aux aéroréfrigérants à tirage naturel assisté par ventilateur (voir 3.1.2.3), aux aéroréfrigérants humides/secs (voir 3.1.2.4) et aux " aéroréfrigérants à tirage mécanique ", à l'exception des aéroréfrigérants à tirage mécanique réalisés de série.

Elle précise les méthodes d'essai, les appareillages nécessaires, la limitation des erreurs et la méthode d'évaluation des résultats.

Les essais de réception couvrent la vérification des données de performances thermiques et de la hauteur de refoulement de l'aéroréfrigérant telle que spécifiée dans le contrat entre le fournisseur et le client. Lorsque ces essais sont exigé, cela doit être précisé lors du contrat, comme des équipements complémentaires et la préparatoire des essais peut être nécessaire.

Des divergences par rapport aux règles décrites ci-dessous ainsi que des additions nécessitent un accord spécial entre le fournisseur et le client et il convient qu'elles soient consignées par écrit.

La présente norme ne s'applique pas aux aéroréfrigérants humides à tirage mécanique réalisés en série qui sont traités dans le prEN 13741.

NOTE Il convient de comprendre les termes tels que "utile", "valeurs", "garantie" et "réception" utilisés dans la présente norme dans un sens technique mais non pas dans un sens juridique ou commercial.

Prenosniki toplote – Merilna metoda in ocenjevanje toplotnih lastnosti mokrih hladilnih stolpov

General Information

- Status

- Published

- Publication Date

- 30-Sep-2005

- Technical Committee

- OGS - Heating for buildings

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Oct-2005

- Due Date

- 01-Oct-2005

- Completion Date

- 01-Oct-2005

Overview

EN 14705:2005 - published by CEN - defines a standardized method of measurement and evaluation of the thermal performance of wet cooling towers. The standard covers requirements, test methods, measurement apparatus, limitations of error and result examination for performance testing, pumping head verification and plume abatement for wet/dry towers. It applies to natural-draught, fan-assisted natural-draught, wet/dry (reduced-plume and water-conservation) and non‑series mechanical-draught cooling towers (series mechanical-draught towers are excluded).

EN 14705:2005 is intended to ensure reproducible, contract‑recognised performance data and to harmonize how thermal performance and related parameters are measured and reported across Europe.

Key Topics

- Scope and applicability: types of cooling towers covered (natural draught, fan‑assisted, wet/dry, mechanical draught - except series types).

- Terms, definitions and symbols: standardized terminology (approach, range, drift loss, pumping head, etc.), and symbol tables used in calculations.

- Test procedures: parameters to control, quantities to measure (temperatures, flows, pressures), measurement arrangements and required apparatus.

- Acceptance testing: how to verify thermal performance and tower pumping head as specified in supplier–purchaser contracts; contractual recognition of tests and preparatory requirements.

- Measurement accuracy and test tolerance: limits of errors, handling of systematic deviations, and guidance on error calculation.

- Calculation and evaluation methods: methods for converting measured data into performance metrics, basic and extended evaluation procedures and performance curves (Merkel number concepts referenced).

- Annexes and normative references: requirements for measuring equipment, evaporation and blow‑down calculations, pump heat corrections and bibliographic references.

Applications

EN 14705:2005 is used by:

- Cooling tower manufacturers for performance guarantees and factory/field testing.

- Plant owners and operators (power plants, HVAC systems, chemical/process plants) to validate installed tower performance and compliance.

- Testing laboratories and third‑party inspectors performing acceptance or warranty tests.

- Consulting engineers and system integrators specifying performance, plume abatement, and pumping head requirements in procurement documents and contracts.

Practical benefits include consistent, comparable thermal performance data, clearer contractual acceptance criteria, and traceable methods for plume mitigation and water management testing.

Related Standards

- EN 13741 (mechanical draught series wet cooling towers) - exclusion referenced in EN 14705.

- Normative references cited within EN 14705: EN 306, EN 872, EN 60751; ISO 5167‑1, ISO 1438‑1, ISO 2975‑3, ISO/TR 3313.

Keywords: EN 14705:2005, wet cooling towers, thermal performance testing, plume abatement, pumping head, CEN, test methods.

Frequently Asked Questions

SIST EN 14705:2005 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Heat exchangers - Method of measurement and evaluation of thermal performances of wet cooling towers". This standard covers: This European Standard specifies requirements, test methods and acceptance tests for thermal performances pumping head verification of wet cooling towers and plume abatement for wet/dry cooling towers. This European Standard is applicable to natural draught wet cooling towers (see in 3.1.2.2) fan assisted natural draught cooling tower (see 3.1.2.3), wet/dry cooling towers (see 3.1.2.4) and "Mechanical draught cooling towers", except series ones. It specifies the test methods, the apparatus required, the limitation of errors and the method for results examination. The acceptance testing covers the verification of the thermal performance data and pumping head of the cooling tower as specified in the contract between the supplier and the purchaser. If these tests are required then this should be recognized at the time of the contract, as additional fittings, and preparations for the test may be required. Deviations from the rules laid down below as well as additions need special agreement between purchaser and supplier and should be documented. This standard does not apply to mechanical draught series wet cooling towers which are dealt with in prEN 13741. NOTE Terms like "design", "values", "guarantee" and "acceptance" used in this standard should be understood in a technical but not in a legal or commercial sense.

This European Standard specifies requirements, test methods and acceptance tests for thermal performances pumping head verification of wet cooling towers and plume abatement for wet/dry cooling towers. This European Standard is applicable to natural draught wet cooling towers (see in 3.1.2.2) fan assisted natural draught cooling tower (see 3.1.2.3), wet/dry cooling towers (see 3.1.2.4) and "Mechanical draught cooling towers", except series ones. It specifies the test methods, the apparatus required, the limitation of errors and the method for results examination. The acceptance testing covers the verification of the thermal performance data and pumping head of the cooling tower as specified in the contract between the supplier and the purchaser. If these tests are required then this should be recognized at the time of the contract, as additional fittings, and preparations for the test may be required. Deviations from the rules laid down below as well as additions need special agreement between purchaser and supplier and should be documented. This standard does not apply to mechanical draught series wet cooling towers which are dealt with in prEN 13741. NOTE Terms like "design", "values", "guarantee" and "acceptance" used in this standard should be understood in a technical but not in a legal or commercial sense.

SIST EN 14705:2005 is classified under the following ICS (International Classification for Standards) categories: 27.060.30 - Boilers and heat exchangers; 27.200 - Refrigerating technology. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14705:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2005

Prenosniki toplote – Merilna metoda in ocenjevanje toplotnih lastnosti mokrih

hladilnih stolpov

Heat exchangers - Method of measurement and evaluation of thermal performances of

wet cooling towers

Wärmeaustauscher - Verfahren zur Messung und Bewertung der wärmetechnischen

Leistungskenndaten von Nasskühltürmen

Echangeurs de chaleur - Méthode de mesure et évaluation des performances

thermiques des aéroréfrigérants humides

Ta slovenski standard je istoveten z: EN 14705:2005

ICS:

27.060.30 Grelniki vode in prenosniki Boilers and heat exchangers

toplote

27.200 Hladilna tehnologija Refrigerating technology

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 14705

NORME EUROPÉENNE

EUROPÄISCHE NORM

June 2005

ICS 27.060.30; 27.200

English version

Heat exchangers - Method of measurement and evaluation of

thermal performances of wet cooling towers

Echangeurs de chaleur - Méthode de mesure et évaluation Wärmeaustauscher - Verfahren zur Messung und

des performances thermiques des aéroréfrigérants Bewertung der wärmetechnischen Leistungskenndaten von

humides Nasskühltürmen

This European Standard was approved by CEN on 24 March 2005.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2005 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14705:2005: E

worldwide for CEN national Members.

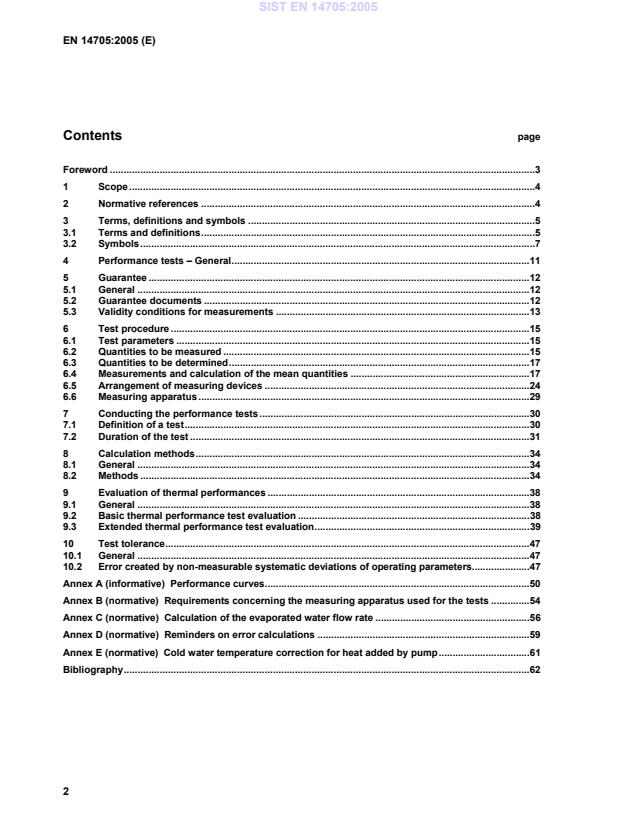

Contents page

Foreword .3

1 Scope .4

2 Normative references .4

3 Terms, definitions and symbols .5

3.1 Terms and definitions.5

3.2 Symbols.7

4 Performance tests – General.11

5 Guarantee .12

5.1 General .12

5.2 Guarantee documents .12

5.3 Validity conditions for measurements .13

6 Test procedure .15

6.1 Test parameters .15

6.2 Quantities to be measured .15

6.3 Quantities to be determined.17

6.4 Measurements and calculation of the mean quantities .17

6.5 Arrangement of measuring devices .24

6.6 Measuring apparatus .29

7 Conducting the performance tests.30

7.1 Definition of a test.30

7.2 Duration of the test .31

8 Calculation methods.34

8.1 General .34

8.2 Methods .34

9 Evaluation of thermal performances .38

9.1 General .38

9.2 Basic thermal performance test evaluation .38

9.3 Extended thermal performance test evaluation.39

10 Test tolerance.47

10.1 General .47

10.2 Error created by non-measurable systematic deviations of operating parameters.47

Annex A (informative) Performance curves.50

Annex B (normative) Requirements concerning the measuring apparatus used for the tests .54

Annex C (normative) Calculation of the evaporated water flow rate .56

Annex D (normative) Reminders on error calculations .59

Annex E (normative) Cold water temperature correction for heat added by pump.61

Bibliography.62

Foreword

This European Standard (EN 14705:2005) has been prepared by Technical Committee CEN/TC 110 “Heat

exchangers”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by December 2005, and conflicting national standards shall be withdrawn

at the latest by December 2005.

This document includes a Bibliography.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic,

Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland

and United Kingdom.

1 Scope

This European Standard specifies requirements, test methods and acceptance tests for thermal performances

pumping head verification of wet cooling towers and plume abatement for wet/dry cooling towers.

This European Standard is applicable to natural draught wet cooling towers (see in 3.1.2.2) fan assisted

natural draught cooling tower (see 3.1.2.3), wet/dry cooling towers (see 3.1.2.4) and "Mechanical draught

cooling towers", except series ones.

It specifies the test methods, the apparatus required, the limitation of errors and the method for results

examination.

The acceptance testing covers the verification of the thermal performance data and pumping head of the

cooling tower as specified in the contract between the supplier and the purchaser. If these tests are required

then this should be recognized at the time of the contract, as additional fittings, and preparations for the test

may be required.

Deviations from the rules laid down below as well as additions need special agreement between purchaser

and supplier and should be documented.

This standard does not apply to mechanical draught series wet cooling towers which are dealt with in

EN 13741.

NOTE Terms like "design", "values", "guarantee" and "acceptance" used in this standard should be understood in a

technical but not in a legal or commercial sense.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 306, Heat exchangers - Methods of measuring the parameters necessary for establishing the performance

EN 872, Water quality - Determination of suspended solids - Method by filtration through glass fibre filters

EN 60751, Industrial platinum resistance thermometer sensors (IEC 60751:1983 + A1:1986)

EN ISO 5167-1, Measurement of fluid flow by means of pressure differential devices inserted in circular cross-

section conduits running full - Part 1: General principles and requirements (ISO 5167-1:2003)

ISO 1438-1, Water flow measurement in open channels using weirs and Venturi flumes - Part 1: Thin-plate

weirs

ISO 2975-3, Measurement of water flow in closed conduits - Tracer methods - Part 3: Constant rate injection

method using radioactive tracers

ISO/TR 3313, Measurement of fluid flow in closed conduits - Guidelines on the effects of flow pulsations on

flow-measurement instruments

3 Terms, definitions and symbols

3.1 Terms and definitions

For the purposes of this European Standard, the following terms and definitions apply.

3.1.1

cooling tower

apparatus in which water is cooled down by heat exchange with ambient air

3.1.2

wet cooling tower

cooling tower in which the heat exchange between the water and the air is achieved by a direct contact

3.1.2.1

mechanical draught wet cooling tower

wet cooling tower where the air circulation is produced by a fan

3.1.2.1.1

series type mechanical draught wet cooling tower

mechanical draught wet cooling tower, the design of which is fixed and described in the manufacturer's

catalogue and for which the performance data are available, which allows tests evaluation over the defined

range of operating conditions

3.1.2.1.2

non series type mechanical draught wet cooling tower

mechanical draught wet cooling tower, the design of which is project dependent and for which the

performance data and test evaluation at specific operating conditions may be subject to agreement

3.1.2.2

natural draught cooling tower

wet cooling tower where the air circulation is produced only by a density difference between the cold air

outside the cooling tower and the hot air inside

3.1.2.3

fan assisted natural draught cooling tower

natural draught cooling tower with the addition of fan to boost the draught

3.1.2.4

wet/dry cooling tower (reduced plume cooling tower)

cooling tower comprising two parts. In the first part, the heat exchange between the water and the air is

achieved by direct contact and through a tight wall in the second part

3.1.2.4.1

reduced plume wet/dry cooling tower

wet/dry cooling tower designed for plume abatement

3.1.2.4.2

water conservation wet/dry cooling tower

wet/dry cooling tower designed for water conservation

3.1.3

air flow

total quantity of air, including associated water vapour flowing through the tower

3.1.3.1

counterflow

where air and water flows are in opposite direction in the filling

3.1.3.2

cross flow

where air flows perpendicular to the water in the filling

3.1.4

ambient wet (dry) bulb temperature

wet (dry) bulb temperature of air measured windward of the tower and free from the influence of the tower

3.1.5

approach

difference between recooled water temperature and inlet air wet bulb temperature

3.1.6

inlet water flow

quantity of hot water flowing into the tower

3.1.7

cold water basin

device underlying the tower to receive the recooled water from the tower and direct its flow to the suction line

or sump

3.1.8

cooling range

difference between the hot water temperature and the recooled water temperature

NOTE The term "range" is also applied to this definition, but is regarded as a non-preferred term.

3.1.9

drift loss

water lost from the tower as liquid droplets with the same chemical characteristics as the circulating water,

entrained in the outlet air

3.1.10

heat load

rate of heat to be removed from the water within the tower

3.1.11

hot water temperature

temperature of inlet water

3.1.12

inlet air wet (dry) bulb temperatures

average wet (dry) bulb temperatures of the inlet air; including any recirculation effect

3.1.13

make-up

water added to the circulating water system to compensate for water loss from the system by evaporation, drift,

purge and leakage

3.1.14

purge (blow down)

water discharged from the system to control concentration of salts or other impurities in the circulating water

3.1.15

recooled water temperature

average temperature of the water at the cold water basin discharge excluding the effect of any make-up

entering the basin or at the exhaust of the exchanger for wet/dry cooling tower

3.1.16

recirculation

portion of the outlet air that re-enters the tower

3.1.17

interference

intake of outlet air of adjacent cooling towers

3.1.18

tower pumping head

total head of water required at the inlet to the tower, to deliver the inlet water through the distribution system

3.1.19

surfacic flow

inlet water flow expressed in quantity per unit of plan packing area of the tower

3.1.20

wet (dry) bulb temperature

the temperature indicated by an adequately ventilated and wetted (non-wetted) thermometer in the shade and

(where applicable) protected from any radiation effect

3.1.21

atmospheric gradient

air dry bulb temperature variation with altitude expressed in degree Celsius per 100 m

3.2 Symbols

For the purposes of this European Standard, the symbols of Table 1 shall apply.

Table 1

Symbols Designated parameters Units

-1

A Transfer surface per unit of volume m

a Angle of an elbow degree

ap Approach (t - t ) K

c w

C Heat coefficient -

-2 -1

CEV Evaporation coefficient related to the difference in water content

kg⋅m ⋅s

C Load loss coefficient -

F

-2 -1

CFV Evaporation coefficient related to the difference in water content

kg⋅m ⋅s

-1

C Specific water consumption

kg⋅J

S

-1 -1

c Mass heat capacity of the air at constant pressure

J⋅kg ⋅K

pa

-1 -1

c

Mass heat capacity of the water J⋅kg ⋅K

pe

-1 -1

c Mass heat capacity of the vapour at constant pressure

J⋅kg ⋅K

pv

D Direction of the reference wind in relation to the north degree

d Hydraulic diameter m

F Fan motor power kW

p

F Guaranteed fan motor power kW

pG

-2

g Gravity acceleration m⋅s

H Draught height m

-1

h Mass enthalpy of the air

J⋅kg

-1

h

1 Mass enthalpy of the air at the air inlet calculated from p , t and ϕ J⋅kg

a s

-1

h Mass enthalpy of the saturated hot air at the air outlet downstream

2 J⋅kg

from the drift eliminators

-1

h Mass enthalpy of the saturated moist air at the water temperature

J⋅kg

s

-1

h , h Mass enthalpy of the saturated moist air at the water temperature

J⋅kg

s1 s2

with 1 = inlet, 2 = outlet

k Number of tests

Merkel number -

KAV

q

me

-1

L Water vaporization latent heat at temperature t

vt J⋅kg

3 -1

m Circulating water volume flow rate at the cooling tower inlet

m ⋅s

3 -1

m Calculated blow-down water volume flow rate

m ⋅s

b

3 -1

m Measured blow-down water volume flow rate

m ⋅s

bm

(to be continued)

Table 1 (continued)

Symbols Designated parameters Units

3 -1

m Evaporated water volume flow rate

m ⋅s

E

3 -1

m

Make-up water volume flow rate m ⋅s

m

m Number of a wind velocity class

3 -1

m Volume flow rate of water entrained by drift losses m ⋅s

p

N Characteristic index of nominal pattern

n Constant exponent of the exchange law

b

n 0

Number of tests per m class

b

n m

Number of recorded values for each test

P Thermal load kW

p Atmospheric pressure Pa

a

p

Saturating vapour pressure Pa

vs

p Static pressure Pa

s

p Partial pressure of vapour in the air Pa

v

-1

q Dry air mass flow rate

kg⋅s

mas

-1

q

Circulating water mass flow rate at cooling tower inlet kg⋅s

me

-1

q

Recooled water recuperation system leaking water volume flow rate 3

VF

m ⋅s

-1

q Local volume flow rate 3

Vi

m ⋅s

3 -1

q Volume flow rate of circulating pumps

VPC m ⋅s

S Flow section corresponding to the measurement point i m

i

S , S Cross sections perpendicular to the pressure taps on the water m

1 2

circuit

S Exchange body front surface m

F

T Test starting time h, min

t Temperature °C

t Dry temperature of the ambient air °C

a

t Blow-down water temperature °C

b

t Mean temperature of the recooled water immediately above the °C

c

plane of the cold water basin (rain water cooling tower) or

immediately above the plane of the water in the troughs (water

recuperator cooling tower)

t Mean temperature of the recooled water for the test i °C

c,i

(to be continued)

Table 1 (continued)

Symbols Designated parameters Units

T Guaranteed mean temperature of the recooled water for the test i °C

cG,i

t Mean temperature of the cold water at the cooling tower outlet °C

e

(mixture of cooled water and make-up water)

t Mean temperature of the hot water in the cooling tower inlet °C

h

t' , t'' Mean temperatures of the hot water in the inflows °C

h h

t Local temperature °C

k

t Make-up water temperature °C

m

t Wet bulb temperature at the air inlet °C

w

t Wet bulb temperature of ambient air °C

wa

t Dry bulb mean temperature at the air inlet °C

s

T Basin cold water renewal time min

V

V Total volume of the exchange body m

-1

v

Mean frontal velocity of the air at the exchange body inlet m⋅s

D

-1

v

Local flow velocity m⋅s

i

-1

v , v

Water velocities perpendicular to the measurement sections m⋅s

1 2

-1

v Reference wind velocity 10 m above ground level m⋅s

W10

x

Difference in level between the spray hole nozzle outlet and the m

water plane of the cold water basin

γ Coefficient of correction in the Merkel integral -

τ Student coefficient -

xϕ Absolute humidity of the ambient air

kg water

kg dryair

Absolute humidity of the air at air inlet

xϕ

kg water

kg dryair

xϕ Absolute humidity of the air at cooling tower outlet

kg water

kg dryair

ϕ Relative humidity of the ambient air %

ϕ Relative humidity of the ambient air at air inlet %

ϕ Relative humidity of the ambient air at cooling tower outlet %

Φ Fan power influence factor K/%

-3

ρ Density of the air kg⋅m

(to be continued)

Table 1 (concluded)

Symbols Designated parameters Units

-3

ρ (t) Density of the water of the circulating water circuit at temperature t kg⋅m

e

-3

ρ Density of the air entering the cooling tower kg⋅m

-3

ρ Density of the hot air at the outlet, downstream from the drift kg⋅m

eliminators

-1

σ Standard deviation of the wind velocity at 10 m (V ) during the m⋅s

w10

test

α Weighting coefficient of the class r reference wind velocity

r

∆p Circulating water pressure loss Pa

∆p Differential static pressure measured on the water circuit between Pa

s

sections s and s

1 2

∆t Weighted difference on the recooled water temperature K

z Difference in temperature on the water between the cooling tower K

inlet and outlet (Cooling range)

t - t Difference to the guarantee on the recooled water temperature for a K

cK cG

test

∆t Recooled water temperature difference for the class r reference K

r

wind velocity

θ Instantaneous temperature of the recooled water °C

λ Universal load loss coefficient for water conduits

µ

h − h

2 1

Coefficient µ =

h − h

s1 1

ν

h − h

s1 s2

Coefficient ν =

h − h

2 1

4 Performance tests – General

The performance tests forming the subject of this standard shall be carried out, unless otherwise specified, in

the contract at least after three months of continuous operation and definitely after commissioning. It concerns

the following performances:

pumping head - flow rates and pressure loss (see 6.4.5);

thermal performances - determination of the recooled water temperature at measured conditions

(see 6.4.4.4);

emission performances (drift losses);

plume characteristics at the outlet (only for wet/dry cooling towers).

The method described in this standard for the verification of thermal performances apply to all cooling towers

defined in the scope.

5 Guarantee

5.1 General

Prior to the contract the supplier shall have submitted performance documents available setting out the

guaranteed properties as a function of the admissible influence parameters in order to document the

guaranteed properties of the cooling tower supplied.

5.2 Guarantee documents

The supplier of a cooling tower shall guarantee:

a) the cooling tower pumping head;

b) the mean recooled water temperature (t ) as a function of;

c

. dry bulb temperature, t

s

. relative humidity, ϕ or wet bulb temperature t

w

. cooling range (z), or hot water temperature t

h

. water flow rate (m or q )

me

and where applicable as a function of other parameters such as

. fan power consumption, F

p

. interference factor

. recirculation factor

. ambient (atmospheric) pressure, P

a

. atmospheric (vertical) temperature gradient, G

However for natural draft cooling towers extended tests checking wind effect at site on tower performance

may be performed subject to the contract. If so, the supplier shall guarantee the average temperature of the

recooled water t as function of

c

. wind velocity, V

. wind direction, D

The guarantee documents can be in the form of spread sheets, curves, analytical expressions, computer

program etc.

Performance curves should be presented in the format shown in Annex A, however other formats or

appropriate formulas as acceptable provided they give the same information.

Curves shall have reading accuracy of 0,1 K. The area in which acceptance tests are permitted shall be

indicated as per 5.3.2.

If correction curves are provided for the effect of other parameters (e.g. wind speed, atmospheric gradient,

plume abatement, atmospheric pressure, interference factor, recirculation factor), they shall be used subject to

contract.

c) For hybrid cooling towers the outlet air status has to be predicted for all specified boundary conditions:

. dry bulb temperature, t

s

. relative humidity, ϕ or wet bulb temperature t

w

Other parameters may be guaranteed subject to the contract.

5.3 Validity conditions for measurements

5.3.1 General

The measurement results obtained during the course of the tests shall only be taken into account if the

requirements mentioned below are met.

5.3.2 Acceptable operating conditions

a) During the tests:

The values of the following quantities may differ from the design values of the percentages shown below:

circulating water volume flow rate m: ± 10 % of the design volume flow rate m ,

N

cooling range t - t : ± 20 % of the design temperature rise t - t ,

h c h cN

thermal load P: ± 20 % of the design thermal load P ,

N

b) During the hour finishing at the end of the measuring period, the following gradient conditions shall be

fulfilled:

water flow rate ≤ ± 2 % per hour;

heat load ≤ ± 5 % per hour;

ambient wet bulb temperature ≤ 1 K/hour.

5.3.3 Water conditions

The quality of the circulating water flow as well as that of the make-up water shall be within the range of the

specification defined in the contract.

In particular dissolved and suspended solids, oil and organic components concentration shall be checked.

The total dissolved solid shall not exceed the greater of the following:

a) 5000 ppm;

b) 1,1 time the design concentration.

The circulating water shall contain not more than 10 ppm of oil, tar or fatty substances.

For measuring methods, see EN 872 for solids.

5.3.4 Other conditions

5.3.4.1 Equipment-related requirements

The whole cooling tower shall be in proper operating condition. In particular, the water distribution system, the

drift eliminators and the exchange body shall not contain a quantity of foreign bodies likely to interfere with the

normal flow of the water and air.

In order to establish that the cooling tower operates well, it shall be visited by both parts of the contract

together before testing.

5.3.4.2 Climatic conditions-related requirements

The climatic conditions shall be within the normal operating ranges, these being defined by agreement

between the customer and the manufacturer.

If the wind conditions are agreed by contract, the average wind velocity and peak wind velocity shall lie within

the design limits specified in the contract. In that case, wind effect shall be provided by the cooling tower

manufacturer, as mentioned in 9.3.2 or as shown in Annex A.

-1

If no limits are defined in the contract, the average wind velocity shall not exceed 3 m.s . The wind stability

-1

condition shall be that the standard deviation σ of the wind speed (m.s ) of the reference wind shall not

exceed a limit value during the half hour (30 min) preceding and during the measurements, whatever the

duration of the test period may be.

σ < 0,5 + 0,2 V for all cases

mean

Furthermore, during the test, the atmospheric conditions shall comply with the following conditions:

no rain, snow or hail;

no fog, the difference between the dry temperature t and the wet temperature t shall be greater than

a w

0,1 K;

in the event of high obstacles (other cooling tower, machine room, .) being in the vicinity of the cooling

tower, only those tests for which the wind does not come from the direction of these obstacles are taken

into account.

the wet bulb temperature of the ambient air averaged at the air inlet t shall be greater than or equal to

w

2 °C:

t ≥ 2 °C

w

Mainly for natural draught cooling towers it is essential to control the atmospheric gradient during the test

since it affects the inlet air density which is part of the driving force that makes the cooling tower perform. If

the atmospheric gradient is agreed by contract, the average gradient measured up to twice the cooling tower

height shall be in the range of specification. If the atmospheric gradient is not defined in the contract the

average gradient shall be negative and over -1 K per 100 m.

An indicator of the gradient may be the absolute difference between the dry mean temperature in the cooling

tower air inlet t and the dry temperature of the ambient air t . Between -1 K and 0 K corresponds in most

s a

cases to an atmospheric gradient between + 0 K per 100 m and -1 K per 100 m.

The difference between the dry temperature of the ambient air t and the dry mean temperature in the cooling

a

tower air inlet t shall be such that:

s

-1 < t – t < 0 K

s a

Another indicator of the cooling tower vertical dry bulb gradient shall be the difference in dry bulb between

ground level and the top of the air inlet. For an acceptable test, the average dry bulb at or near the top of the

air inlet shall be at least 0,15 °C less than the average dry bulb measured 1,5 m above grade level.

In suspicion of inversion (positive atmospheric gradient), whatever the indicator may be, performance tests

can only be continued by agreement between all parties involved.

5.3.4.3 Operating configuration-related requirements

The cooling tower shall be in its normal configuration, anti-freeze system out of service, by-passes closed.

5.3.4.4 Conditions concerning the instrumentation

Prior to conducting the tests, the measuring probes employed and the measuring devices in the case of the

use of an indirect method for determining a flow rate, shall be calibrated.

6 Test procedure

6.1 Test parameters

Table 2 summarises the parameters influencing the thermal test for each type of cooling tower within the

scope of this European Standard.

Table 2 — Parameters influencing the thermal test for each type of cooling tower

Type of cooling tower Air temperature Atmospheric Wind Fan Other

gradient effect power

Natural draught Dry bulb (inlet)

X X -

Wet bulb (ambient)

Fan assisted natural Dry bulb (inlet)

X X X

draught

Wet bulb (ambient)

Mechanical draught Wet bulb (inlet)

a

- X X X

(except series)

Wet/dry plume

Extra-plume

abatement

verification

Natural draught Wet bulb (ambient or inlet)

X X

Dry bulb (inlet)

Mechanical draught Wet bulb (ambient or inlet)

X X

Dry bulb (inlet)

a

Recirculation is not part of the guarantee.

6.2 Quantities to be measured

The quantities to be measured for each of these performances shall be as follows:

a) Thermal performances:

reference wind velocity measured 10 m above the floor;

direction of the reference wind measured 10 m above the floor (only if certain sectors are to be taken

into account);

pluviometry (if necessary);

atmospheric pressure, p ;

a

wet bulb temperature of the ambient air, t , measured 10 m above the floor or alternatively relative

wa

humidity of the ambient air ϕ

;

dry bulb temperature of the ambient air, t , measured 10 m above the floor;

a

dry bulb mean temperature of the air in the cooling tower inlet, t ;

s1

wet bulb mean temperature of the air at tower inlet, t , or alternatively relative humidity of the air at

w

tower inlet ϕ ;

cold water temperature, t ;

e

hot water mean temperature of the circulating water (if applicable), t ;

h

1)

make-up water temperature, t

m (if necessary) ;

1)

blow-down water temperature, t

b (if necessary) ;

volume flow rate of the circulating water entering the cooling tower m

;

1)

volume flow rate of the make-up water, m (if necessary) ;

m

1)

volume flow rate of the blow-down water, m (if necessary) .

b

b) Cooling tower pumping head:

pressure in water intake of the refrigerant inlet (or the limit of supply).

c) Drift loss performance:

Volume flow rate of water with the same chemical characteristics as the circulating water entrained

by drift losses, m .

p

d) Plume abatement:

Wet bulb temperature at tower outlet t or relative humidity ϕ

w2 2;

dry bulb temperature at tower outlet t .

s2

e) Atmospheric vertical gradient G;

1) These temperatures and flow are only necessary if the corresponding auxiliary water flow rate enters or exits between

the hot and cold water temperature measurement section.

f) Fan power consumption.

6.3 Quantities to be determined

The quantities to be determined by calculation are as follows:

water mass flow rate in the cooling tower inlet;

cooling range t - t ;

h c

transferred thermal load P;

evaporated water volume flow rate m (can be measured);

E

recooled water mean temperature, t ,

c

6.4 Measurements and calculation of the mean quantities

Measurements of atmospheric parameters

6.4.1

6.4.1.1 Measurements of the reference wind velocity and direction

The measurements of the wind velocity v and wind direction D shall be conducted by means of cup-type

W10 10

anemometers and weather vanes or by means of anemometer/vane assemblies.

One measuring device is sufficient. However three measuring devices are required when extended tests

checking wind effect at site on tower performance are performed.

For open field the measuring device shall be at a height of 10 m above the mean level of the ground and the

location of the measurement support mast shall be defined as a function of wind sectors selected for the test

and shall be if possible in an open spot at a minimum distance of 300 m from any sizeable obstacle (cooling

tower, machine room relief, etc.). Should this be impossible an agreement shall be made between the

manufacturer and the customer.

6.4.1.2 Measurement of the dry bulb temperature of the ambient air t and wet bulb temperature t

w

a

or relative humidity and atmospheric pressure

If necessary, the dry bulb temperature and wet bulb temperature or relative humidity of the ambient air and the

atmospheric pressure shall be measured at 10 m above the ground, in the vicinity of the location where the

wind velocity and direction measurements were made using temperature probes and barometer.

Where necessary, the average vertical ambient dry bulb temperature gradient shall be measured in the

surrounding of the cooling tower between the elevation of the centre of air inlet and up to twice the height of

the cooling tower.

The probe(s) shall be protected from the sun's rays and from the rain.

6.4.1.3 Detection of rain

It may be carried out using a bucket-type pluviometer or indicate presence or rain (e.g. rain detector) or by

visual examination.

6.4.1.4 Measurements of the air inlet dry bulb temperature t and wet bulb temperature or relative

s

humidity

For undisturbed cooling tower's environment, air inlet dry bulb temperature t and air inlet wet bulb

s

temperature t (or relative humidity) shall be measured close to the air inlet, at a maximum distance of 1,5 m

w

of the air inlet.

The minimum number of probes shall be n × n , where n = number of probes around the circumference, n =

c v c v

number of probes along the height of air inlet (see Table 4).

Where several probes are used they shall be spread out at regulars intervals both in circumferential and

vertical directions.

If the probes are located at only one level, they shall be preferably installed at the middle of the air inlet.

The probes shall be protected from possible projections of water and from the sun's rays.

The undisturbed cooling tower is identified by the fact that there are no obstructing elements protruding in the

area limited by a circle the radius of which is the height of the air inlet and a line inclined at 45°, as shown on

Figure 1.

Key

1 Higher level of the air outlet

2 Zone without obstructing element

Figure 1 — Zone without obstructing element at the air inlet

If these conditions are not fulfilled special boundaries conditions are necessary and shall be agreed by the

parties involved. Where additional measuring points are used the results shall be weighted by the surface they

represent.

6.4.2 Measurement and calculation of the absolute and relative humidities of the ambient air (xϕϕ and

ϕϕ

ϕϕ)

ϕϕ

Measurements

The measurement of the ambient humidity shall be conducted either using three suction psychrometers or

three hygrometers (for example dew point). This apparatus, protected from the sun's rays and the rain, is

placed at a height of 10 m above ground level in the vicinity of the wind velocity and direction measurement

points.

The psychrometer measurements of the dry and moist temperatures allow to determine the relative humidity

of the ambient air as well as the absolute humidity for which one uses the formulae given in 8.2.3.

In the case of the use of hygrometers, the combined measurements of the relative humidity and dry

temperature allow to calculate the wet bulb temperature, then the value of the absolute humidity of the

ambient air using these same formulae.

6.4.3 Measurement of the atmospheric pressure (P )

a

The atmospheric pressure shall be measured using an absolute pressure sensor protected against the effects

of the wind.

6.4.4 Water temperature

6.4.4.1 Determination of the hot water temperature t

h

Where possible the test shall be conducted with make-up and blow-down water circuits shut off.

If it is not possible temperatures shall be measured as in 6.4.4.2 and 6.4.4.3.

a) Measurement of the circulating water temperature on reaching the cooling tower:

the hot water temperature shall be measured in the riser or in the water distribution of the cooling

tower;

in the case of two water inlets, the temperature shall be measured in each riser or in the water

distribution;

the measuring device shall comprise at least 3 probes per riser or water distribution.

b) Calculation of the mean temperature of the hot water:

hot water intake: the mean temperature t is equal to the arithmetical mean of the temperatures

h

measured at each point;

two hot water intakes: the mean temperature of the hot water shall be calculated by weighing the

temperatures by the corresponding flows

6.4.4.2 Determination of the make-up water temperature t

m

The make-up water temperature shall be measured at the entry into the cooling water circle.

The measuring device comprises three probes.

The mean temperature of the make-up water is equal to the arithmetical mean of the measured temperatures.

6.4.4.3 Determination of the blow-down water temperature t

b

The blow-down water temperature shall be measured in the blow-down discharge structure, at the boundary

of the cooling tower.

The measuring device shall comprise three probes.

The mean temperature of the blow down water is equal to the arithmetical mean of the measured

temperatures.

6.4.4.4 Determination of the recooled water temperature t

c

6.4.4.4.1 Measurement of the temperature of the circulating water leaving the cold water basin

6.4.4.4.1.1 General

The circulating water temperature shall preferably be measured inside the pipes, at cooling tower outlet

structure and upstream the (cold water) pump (s) or directly in the water discharge structure. Measurements

may also be performed down stream the pump but in that case correction of recooled water measured

temperature shall be made to take account of heat input from the pump and precautions are needed to

prevent damage (e.g. thermometer break).

6.4.4.4.1.2 Measurements inside the pipes

In the case of several outflows, the temperature shall be measured in each of them.

-1

1/2

-3

The minimum number of probes at one outflow shall be 2,5 (q .10 ) where q is expressed in kg⋅s . They

me me

shall be located as indicated in EN 306.

6.4.4.4.1.3 Measurements in the water discharge structure

-3 1/2 -1

The minimum number of probes shall be 2,5 (q .10 ) , where q is expressed in kg⋅s .

me me

Where the depth of water exceeds 1,5 m, two levels of probes shall be used.

NOTE If the temperature at at one or more measuring points differs by more than 1 K from the average, a first step to

reduce the uncertainty should be to double the number of sensors installed.

In the case the uncertainty remains unacceptable, it should be necessary to weight the temperature by local velocity (to be

measured).

In this case, it is necessary to draw up velocity charts for the water perpendicular to the measurement section

if the average temperature at one or more measuring point varies by more than 1 K during measuring period

per outlet. These charts enable one on the one hand to define the minimum number of probes to be installed

and their location and furthermore to carry out, if necessary, on the basis of the conditions described, the

weighting of the temperatures by the velocities.

Where make-up circuit is not shut off precautions shall be taken e.g. measures of the velocity field to prevent

heterogeneous flows to be undetected.

6.4.5 Water flow rates

6.4.5.1 General

There exist two types of water flow rates which enter and leave the cooling tower:

a) Time-invariant flow rates (flow rates produced by pumps, without adjusting mechanisms on the circuit).

NOTE 1 Precautions should be taken to ensure that pressure losses are constant during the test (clean lines).

b) Flow rates which are variable as a function of the settings (water level, valves, thresholds,.).

NOTE 2 The measurements of such flow rates are conducted on a continuous basis during the performance tests.

6.4.5.2 Measurement of the circulating water volume flow rate at the cooling tower inlet m

Depending on the type of cooling circuit, this flow rate is invariant or variable.

In the first case, the measurement shall be conducted for each configuration of the pumps to be tested in

operation using the velocity area method, the constant flow injection method using radioactive tracers

(ISO 2975-3), or any other equivalent method.

When conducting thermal performance tests, the configuration of the pumps in operation shall be checked in

order to determine the total flow rate.

In the second case, one shall use either an absolute method by standardized pressure-reducing appliances

(see EN ISO 5167-1 and ISO/TR 3313) or by a standardised overflow (see ISO 1438-1), or an indirect method

which requires preliminary calibration.

6.4.5.3 Measurements of the make-up water volume flow rate m

m

If the make-up circuit is not shut off during the test, m shall be measured.

m

The measurement shall be conducted either by an absolute method by standardised pressure-reducing

appliances (EN ISO 5167-1 and ISO/TR 3313) or by a standardised overflow (see ISO 1438-1), or an indirect

method which requires preliminary calibration.

6.4.5.4 Measurement of the blow-down water volume flow rate m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...