SIST EN 13035-2:2008

(Main)Machines and plants for the manufacture, treatment and processing of flat glass - Safety requirements - Part 2: Storage, handling and transportation equipment outside the factory

Machines and plants for the manufacture, treatment and processing of flat glass - Safety requirements - Part 2: Storage, handling and transportation equipment outside the factory

1.1 This standard contains the requirements for safety for the design and installation of equipment intended for the storage (as defined in 3.2.1), handling (as defined in 3.2.2) and transportation (as defined in 3.2.3) of flat glass outside the factory (as defined in 3.1.1) and including stillages, pallets, frails fixed to vehicles, in-loader vehicles, specific glass-securing devices, stanchions and vacuum-lifting devices which are used for road transport and on building sites.

1.2 Specific hazards due to the use inside the factory are dealt with in EN 13035-1.

1.3 This standard deals only with the devices which are directly in contact with the glass. This standard does not apply to manual handling equipment such as carrying straps and vacuum pads. Tractors, cranes, hoists and fork lifts are out of the scope as well as parts of other powered vehicles that are not in contact with the glass. This European Standard does not apply to equipment for the transport by other ways than on road e.g. by ship or train, and the transportation of glazed windows/frames.

1.4 This standard deals with all significant hazards, hazardous situations and events relevant to equipment for the storage, handling and transportation of flat glass, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards during commissioning, the operation and maintenance. Noise has not been considered to be a significant hazard for any type of equipment in the scope of this standard.

1.5 This document is not applicable to storage, handling or transportation equipment for flat glass outside the factory, which is manufactured before the date of its publication as EN.

Maschinen und Anlagen für die Herstellung, Be- und Verarbeitung von Flachglas - Sicherheitsanforderungen - Teil 2: Einrichtungen zum Lagern, Handhaben und Transportieren außerhalb des Werks

1.1 Diese Norm enthält die Sicherheitsanforderungen für die Konstruktion und Installation von Einrichtungen zum Lagern (wie in 3.2.1 definiert), Handhaben (wie in 3.2.2 definiert) und Transportieren (wie in 3.2.3 definiert) von Flachglas außerhalb des Werks (wie in 3.1.1 definiert) und schließt Gestelle, Paletten, an Fahrzeuge angebaute Reffs, Innenlader-Fahrzeuge, spezifische Einrichtungen zum Sichern des Glases, Feststellstangen und Vakuum-Hebeeinrichtungen, die für den Straßentransport und auf Baustellen verwendet werden, ein.

1.2 Spezifische Gefährdungen, die auf die Verwendung innerhalb des Werks zurückzuführen sind, werden in EN 13035-1 behandelt.

1.3 Diese Norm befasst sich nur mit Einrichtungen, die in unmittelbarer Berührung mit Glas stehen. Diese Norm gilt nicht für manuelle Einrichtungen wie Tragschlaufen und Handsauger. Zugmaschinen, Krane, Windenzüge und Gabelstapler gehören nicht zum Anwendungsbereich wie auch Teile anderer kraftbetriebener Fahrzeuge, die nicht mit dem Glas in Berührung kommen. Diese Europäische Norm gilt nicht für Einrichtungen zum Transport auf andere Weise als auf der Straße z. B. auf Schiffen, Eisenbahnen und den Transport von bereits verglasten Fenstern/Rahmen.

1.4 Diese Norm behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die auf Einrichtungen zum Lagern, Handhaben und Transportieren von Flachglas zutreffen, wenn sie bestimmungsgemäß und unter Bedingungen des Missbrauchs, die vernünftigerweise vom Hersteller vorhersehbar sind, verwendet werden (siehe Abschnitt 4). Diese Norm spezifiziert die entsprechenden technischen Maßnahmen zur Beseitigung oder Verminderung der Risiken, die von den signifikanten Gefährdungen während der Inbetriebnahme, Bedienung und Wartung ausgehen. Gefährdungen durch Lärm werden für die Arten von Einrichtungen im Anwendungsbereich dieser Norm nicht als signifikant betrachtet.

Machines et installations pour la production, le façonnage et la transformation du verre plat - Prescriptions de sécurité - Partie 2 : Équipement de stockage, de manutention et de transport a l'extérieur de l'usine

1.1 La présente norme contient les prescriptions de sécurité relatives à la conception et à l’installation des

équipements, de stockage (tels que définis au 3.2.1), de manutention (tels que définis au 3.2.2) et de

transport (tels que définis au 3.2.3) du verre plat à l’extérieur de l’usine (tels que définis au 3.1.1). Cela inclut

le chevalet, les palettes, les pupitres fixés aux véhicules, les véhicules porte-verre, les dispositifs spécifiques

pour l’arrivage du verre, les étançons et les ventouses de levage qui sont utilisés sur route et sur chantier.

1.2 Les phénomènes dangereux spécifiques liés à l’utilisation à l’intérieur de l’usine sont traités dans

l’EN 13035-1.

1.3 La présente norme ne traite que des dispositifs qui sont uniquement en contact avec le verre. La

présente norme ne s’applique pas aux équipements de manutention manuelle telle que sangles et ventouses.

Les tracteurs, grues, treuils et chariots à fourche sont exclus du domaine d’application ainsi que les parties

d’autres véhicules motorisés qui ne sont pas en contact avec le verre. La présente Norme européenne ne

s’applique ni au transport autre que routier, par exemple naval ou ferroviaire, ni au transport des

fenêtres/baies vitrées.

1.4 La présente Norme européenne traite de tous les phénomènes dangereux, situations ou évènements

dangereux significatifs spécifiques aux équipements de stockage, de manutention et de transport du verre plat,

quand ces équipements sont utilisés normalement et dans des conditions anormales prévisibles prévues par

le fabricant (voir l’Article 4). La présente norme spécifie les mesures techniques appropriées pour éliminer ou

réduire les risques dus aux phénomènes dangereux significatifs durant la mise en service, le fonctionnement

et la maintenance.

Stroji in obrati za proizvodnjo, obdelavo in predelavo ravnega stekla - Varnostne zahteve - 2. del: Skladiščenje, rokovanje in prevozna oprema zunaj tovarne

General Information

- Status

- Published

- Publication Date

- 06-Apr-2008

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Apr-2008

- Due Date

- 06-Jun-2008

- Completion Date

- 07-Apr-2008

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 12-Jun-2019

Overview

EN 13035-2:2008 (CEN) specifies safety requirements for equipment used for the storage, handling and transportation of flat glass outside the factory - for example on road transport and building sites. The standard covers devices that are directly in contact with the glass such as stillages, pallets, frails fixed to vehicles, in‑loader vehicles, stanchions and vacuum‑lifting devices. It defines the significant hazards, required protective measures and information for use during commissioning, operation and maintenance. The document explicitly excludes equipment manufactured before its publication, manual handling aids (carrying straps, vacuum pads), general powered vehicles (tractors, cranes, forklifts) and transport modes other than road (ship, train). Noise is not considered a significant hazard in this part.

Key Topics

- Scope & exclusions - Clarifies which types of equipment and use-cases are inside/outside the standard’s scope (road transport, building sites; excludes glazed frames transport and maritime/rail transport).

- Definitions - Precise terms for storage, handling and transportation equipment, frails, in‑loader vehicles and thin glass frames.

- Hazard identification - Lists significant hazards during transportation, loading/unloading and in‑loader operations; includes wind/gust effects on vertical glass loads.

- Design & protective measures - Requirements for glass‑retention systems, bearers and cladding, angle of lean, in‑loader mechanisms, frail design and vacuum lifting devices to reduce risk of breakage and injuries.

- Verification & testing - Verification of safety measures and conformity checks during commissioning and maintenance.

- Information for use and marking - Required user instructions, warning signs and labels to ensure safe operation on sites and vehicles.

Applications and Who Uses It

- Manufacturers and designers of stillages, frails, pallets, in‑loader trailers, stanchions and dedicated glass‑securing devices use EN 13035-2:2008 to design compliant equipment.

- Safety engineers and compliance officers apply its requirements when assessing risk and preparing technical documentation for road transport of flat glass.

- Building contractors, glaziers and logistics operators use it to select appropriate storage and transport systems for on‑site handling.

- Fleet managers and maintenance teams use the verification and information-for-use clauses to implement safe procedures during loading, transport and unloading.

Related Standards

- EN 13035-1 - Safety requirements for storage/handling inside the factory (complements Part 2).

- EN ISO 12100-1 / -2 - General machine safety principles and terminology.

- EN 12195-1 - Load restraint assemblies on road vehicles (lashing calculations).

- EN 13155, EN ISO 13850, EN 60204-1 and other cited standards - provide related safety requirements for lifting attachments, emergency stops and machine electrical equipment.

EN 13035-2:2008 is essential for anyone specifying, manufacturing or operating equipment that directly contacts flat glass during exterior transport and site handling - ensuring safer glass logistics and reduced risk of breakage and injury.

Frequently Asked Questions

SIST EN 13035-2:2008 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Machines and plants for the manufacture, treatment and processing of flat glass - Safety requirements - Part 2: Storage, handling and transportation equipment outside the factory". This standard covers: 1.1 This standard contains the requirements for safety for the design and installation of equipment intended for the storage (as defined in 3.2.1), handling (as defined in 3.2.2) and transportation (as defined in 3.2.3) of flat glass outside the factory (as defined in 3.1.1) and including stillages, pallets, frails fixed to vehicles, in-loader vehicles, specific glass-securing devices, stanchions and vacuum-lifting devices which are used for road transport and on building sites. 1.2 Specific hazards due to the use inside the factory are dealt with in EN 13035-1. 1.3 This standard deals only with the devices which are directly in contact with the glass. This standard does not apply to manual handling equipment such as carrying straps and vacuum pads. Tractors, cranes, hoists and fork lifts are out of the scope as well as parts of other powered vehicles that are not in contact with the glass. This European Standard does not apply to equipment for the transport by other ways than on road e.g. by ship or train, and the transportation of glazed windows/frames. 1.4 This standard deals with all significant hazards, hazardous situations and events relevant to equipment for the storage, handling and transportation of flat glass, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards during commissioning, the operation and maintenance. Noise has not been considered to be a significant hazard for any type of equipment in the scope of this standard. 1.5 This document is not applicable to storage, handling or transportation equipment for flat glass outside the factory, which is manufactured before the date of its publication as EN.

1.1 This standard contains the requirements for safety for the design and installation of equipment intended for the storage (as defined in 3.2.1), handling (as defined in 3.2.2) and transportation (as defined in 3.2.3) of flat glass outside the factory (as defined in 3.1.1) and including stillages, pallets, frails fixed to vehicles, in-loader vehicles, specific glass-securing devices, stanchions and vacuum-lifting devices which are used for road transport and on building sites. 1.2 Specific hazards due to the use inside the factory are dealt with in EN 13035-1. 1.3 This standard deals only with the devices which are directly in contact with the glass. This standard does not apply to manual handling equipment such as carrying straps and vacuum pads. Tractors, cranes, hoists and fork lifts are out of the scope as well as parts of other powered vehicles that are not in contact with the glass. This European Standard does not apply to equipment for the transport by other ways than on road e.g. by ship or train, and the transportation of glazed windows/frames. 1.4 This standard deals with all significant hazards, hazardous situations and events relevant to equipment for the storage, handling and transportation of flat glass, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards during commissioning, the operation and maintenance. Noise has not been considered to be a significant hazard for any type of equipment in the scope of this standard. 1.5 This document is not applicable to storage, handling or transportation equipment for flat glass outside the factory, which is manufactured before the date of its publication as EN.

SIST EN 13035-2:2008 is classified under the following ICS (International Classification for Standards) categories: 81.100 - Equipment for the glass and ceramics industries. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13035-2:2008 has the following relationships with other standards: It is inter standard links to kSIST FprEN 13035-2:2022, kSIST FprEN 13035-2:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13035-2:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/396, M/BC/CEN/88/13. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 13035-2:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Machines and plants for the manufacture, treatment and processing of flat glass - Safety requirements - Part 2: Storage, handling and transportation equipment outside the factoryMachines et installations pour la production, le façonnage et la transformation du verre plat - Prescriptions de sécurité - Partie 2 : Équipement de stockage, de manutention et de transport a l'extérieur de l'usineMaschinen und Anlagen für die Herstellung, Be- und Verarbeitung von Flachglas - Sicherheitsanforderungen - Teil 2: Einrichtungen zum Lagern, Handhaben und Transportieren außerhalb des WerksTa slovenski standard je istoveten z:EN 13035-2:2008SIST EN 13035-2:2008en,fr81.100ICS:SLOVENSKI

STANDARDSIST EN 13035-2:200801-junij-2008

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13035-2March 2008ICS 81.100 English VersionMachines and plants for the manufacture, treatment andprocessing of flat glass - Safety requirements - Part 2: Storage,handling and transportation equipment outside the factoryMachines et installations pour la production, le façonnageet la transformation du verre plat - Prescriptions de sécurité- Partie 2: Équipement de stockage, de manutention et detransport à l'extérieur de l'usineMaschinen und Anlagen für die Herstellung, Be- undVerarbeitung von Flachglas - Sicherheitsanforderungen -Teil 2: Einrichtungen zum Lagern, Handhaben undTransportieren außerhalb des WerksThis European Standard was approved by CEN on 5 January 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13035-2:2008: E

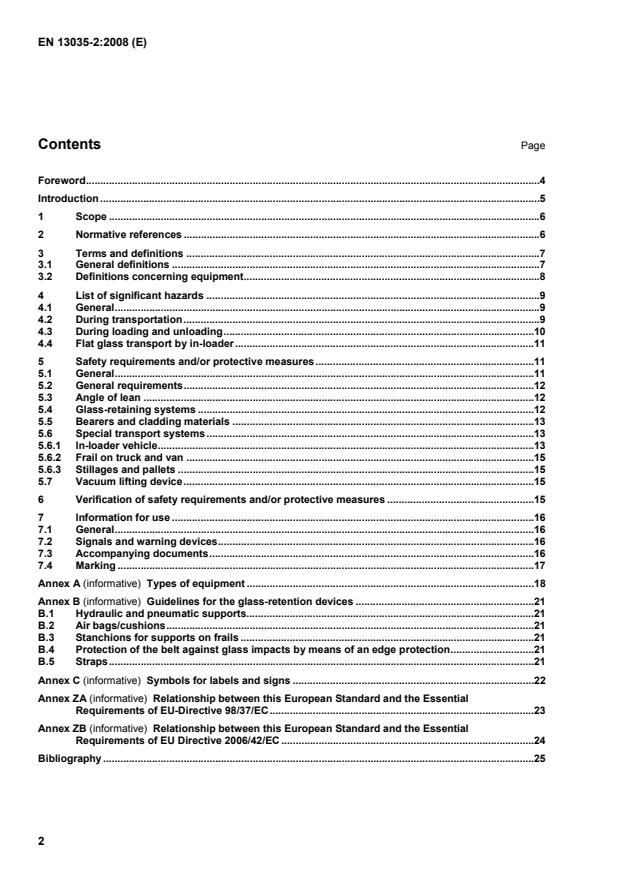

Types of equipment.18 Annex B (informative)

Guidelines for the glass-retention devices.21 B.1 Hydraulic and pneumatic supports.21 B.2 Air bags/cushions.21 B.3 Stanchions for supports on frails.21 B.4 Protection of the belt against glass impacts by means of an edge protection.21 B.5 Straps.21 Annex C (informative)

Symbols for labels and signs.22 Annex ZA (informative)

Relationship between this European Standard and the Essential

Requirements of EU-Directive 98/37/EC.23 Annex ZB (informative)

Relationship between this European Standard and the Essential

Requirements of EU Directive 2006/42/EC.24 Bibliography.25

Tables Table 1.9 Table 2.10 Table 3.11 Table 4.16

and the following apply. 3.1 General definitions 3.1.1 outside the factory all areas, such as building sites, in which the glass is stored and moved, with the exception of enclosed buildings and company premises for glass manufacturing and processing 3.1.2 gust sudden wind-speed increase

also used for transportation 3.2.2 handling equipment devices which are specifically designed to support and retain a single plate or pack of glass during transportation from one position to another 3.2.3 transportation equipment equipment for the movement of glass-laden storage or handling devices 3.2.4 frail device for transportation, in a position close to the vertical, of glass plates, fixed or mounted outside of a vehicle (see Figures A.1, A.2 and A.3) 3.2.5 in-loader transportation device (usually a trailer or semi-trailer) with a self-loading mechanism for stillages with or without glass plates/packs (see Figure A.4) 3.2.6 thin glass frames devices for storing and transporting packs of glass in sizes of 4,5 m to 6,0 m ✕ 3,21 m and thickness less than or equal to 2,5 mm

4 List of significant hazards 4.1 General This clause contains the significant hazards, hazardous situations and events, as far as they are dealt with in this standard, identified by risk assessment as significant for this type of machinery and which require action to eliminate or reduce the risk. 4.2 During transportation Table 1 Hazards Dangerous items Preventive measures

Tilting of load and/or falling from the transport device because of:

a) missing or using an insufficient safety device 5.4; 7.3 b) incorrect unloading of movable equipment (e.g. from platforms, forklifts) 7.3 c) insufficiently secured in the crane hook

7.3 d) use of excessive speed 5.2; 7.3 e) pressure gust of wind/high side wind

5.3; 5.4; 5.6; 7.3 f) unsecured stillage 5.2; 5.4; 5.6 i) overloading 7 l) impact by impulse from outside to the transportation system 5.6; 7.3 Crushing of the body

m) movement of the frail 5.3; 5.4; 7.3

n) break-up of the device by insufficient strength 5.2 Crushing of the feet

wheels of movable equipment 7.3

Single plates or glass pieces fall from transport device because of:

a) glass is not secured 5.3; 5.4; 5.6; 5.7; 7.3 b) glass is not correctly placed 7.3 d) damage of glass because of impact on fixed parts in the environment 7.3 Cutting, severing or puncturing

e) damage of glass because of impact with the frail 5.5 Neglected use of personal protective equipment

injury from glass 7.3

Tilting of load and/or falling from the transport device because of:

a) insufficient angle of lean 5.3 b) uneven area of work 5.3; 5.6.2 c) unexpected gust of wind 5.4; 7.3 d) impact of transportation stillage 7.3 e) incorrect positioning of safety equipment when unloading is interrupted 5.4; 5.6.2; 7.3 f) opening safety equipment before checking the load position 5.3; 5.4; 5.6.2; 7.3 g) insufficient restricted area of work 7.3 Crushing of the body

h) overloading 7.4

i) break-up of the device by insufficient strength 5.2 Crushing of the feet

wheels of movable equipment 7.3

Single plates or glass pieces falling from stillages because of:

a) insufficient angle of lean 5.3; 5.4; 5.6.2; 7.3 b) glass is not correctly placed 7.3 c) impact of transportation stillage 7.3 d) damage of glass because of impact of the construction 5.3; 5.4; 5.6.2; 7.3 e) incorrect positioning of safety equipment when loading is interrupted 5.4; 7.3 Cutting, severing or puncturing

f) unexpected gust of wind 7.3 a) tripping over the base bearer 7.3 Slip, trip and fall of persons

b) falling from height 5.6.1; 5.6.2; 7 Neglected use of personal protective equipment

injury from glass 7.3 a) composition of area, uneven working area5.3; 5.4; 5.6; 7.3 Unexpected start or movement

b) moveable frail (“tilting frail”) 5.6.2; 7.3

Tilting of load and injuries because of:

a) during driving backward

5.6.1; 7.3 b) during load securing 5.6.1; 7.3 c) falling over of the glass inside the in-loader during lifting of the load 5.6.1 d) closing the backward gate by wind 5.6.1 Crushing, impact knocked over of the body

e) inside the loading area by load-securing d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...