SIST EN 1999-1-1:2007

(Main)Eurocode 9 - Design of aluminium structures - Part 1-1: General structural rules

Eurocode 9 - Design of aluminium structures - Part 1-1: General structural rules

(1) EN 1999-1-1 gives basic design rules for structures made of wrought aluminium alloys and limited guidance for cast alloys (see section 3).

NOTE Minimum material thickness may be defined in the National Annex. The following limits are recommended – if not otherwise explicitly stated in this standard:

- components with material thickness not less than 0,6 mm;

- welded components with material thickness not less than 1,5 mm;

- connections with:

o steel bolts and pins with diameter not less than 5 mm;

o aluminium bolts and pins with diameter not less than 8 mm;

o rivets and thread forming screws with diameter not less than 4,2 mm

(2) The following subjects are dealt with in EN 1999-1-1:

Section 1: General

Section 2: Basis of design

Section 3: Materials

Section 4: Durability

Section 5: Structural analysis

Section 6: Ultimate limit states for members

Section 7: Serviceability limit states

Section 8: Design of joints

Annex A Execution classes

Annex B Equivalent T-stub in tension

Annex C Materials selection

Annex D Corrosion and surface protection

Annex E Analytical models for stress strain relationship

Annex F Behaviour of cross section beyond elastic limit

Annex G Rotation capacity

Annex H Plastic hinge method for continuous beams

Annex I Lateral torsional buckling of beams and torsional or flexural-torsional buckling of compression members

Annex J Properties of cross sections

Annex K Shear lag effects in member design

Annex L Classification of connections

Annex M Adhesive bonded connections

(3) Sections 1 to 2 provide additional clauses to those given in EN 1990 “Basis of structural design”.

(4) Section 3 deals with material properties of products made of structural aluminium alloys.

(5) Section 4 gives general rules for durability.

(6) Section 5 refers to the structural analysis of structures, in which the members can be modelled with sufficient accuracy as line elements for global analysis.

(7) Section 6 g

Eurocode 9 - Bemessung und Konstruktion von Aluminiumtragwerken - Teil 1-1: Allgemeine Bemessungsregeln

1.1.1 Anwendungsbereich von EN 1999

(1)P EN 1999 gilt für den Entwurf, die Berechnung und die Bemessung von Bauwerken und Tragwerken aus Aluminium. Sie entspricht den Grundsätzen und Anforderungen an die Tragfähigkeit und Gebrauchs¬tauglichkeit von Tragwerken, sowie den Grundlagen für ihre Bemessung und Nachweise, die in EN 1990 Grundlagen der Tragwerksplanung enthalten sind.

(2) EN 1999 behandelt ausschließlich Anforderungen an die Tragfähigkeit, die Gebrauchstauglichkeit, die Dauerhaftigkeit und den Feuerwiderstand von Tragwerken aus Aluminium. Andere Anforderungen, wie z. B. Wärmeschutz oder Schallschutz, werden nicht behandelt.

(3) EN 1999 gilt in Verbindung mit folgenden Regelwerken:

EN 1990 Grundlagen der Tragwerksplanung

EN 1991 Einwirkungen auf Tragwerke

Europäische Normen für Bauprodukte, die für Aluminiumtragwerke Verwendung finden

prEN 1090-1: Ausführung von Stahltragwerken und Aluminiumtragwerken Teil 1: Konformitäts¬nachweis für tragende Bauteile )

prEN 1090-3: Ausführung von Stahltragwerken und Aluminiumtragwerken Teil 3: Technische Anforderungen für Aluminiumtragwerke5)

(4) EN 1999 ist in fünf Teile gegliedert:

EN 1999-1-1 Bemessung und Konstruktion von Aluminiumtragwerken: Allgemeine Bemessungsregeln.

EN 1999-1-2 Bemessung und Konstruktion von Aluminiumtragwerken: Tragwerksbemessung für den Brandfall

EN 1999-1-3 Bemessung und Konstruktion von Aluminiumtragwerken: Ermüdungsbeanspruchte Tragwerke

EN 1999-1-4 Bemessung und Konstruktion von Aluminiumtragwerken: Kaltgeformte Profiltafeln

EN 1999-1-5 Bemessung und Konstruktion von Aluminiumtragwerken: Schalentragwerke

Eurocode 9 - Calcul des structures en aluminium - Partie 1-1: Regles générales

(1) L'EN 1999-1-1 donne les règles fondamentales de calcul des structures en alliage d'aluminium corroyé et des recommandations limitées pour les alliages de fonderie (voir la section 3).

NOTE L'épaisseur minimale du matériau peut être définie dans l'Annexe Nationale. Les limites ci-dessous sont recommandées – si elles ne sont pas explicitement établies dans la présente norme :

- - composants d'épaisseur supérieure ou égale à 0,6 mm ;

- - composants soudés d'épaisseur supérieure ou égale à 1,5 mm ;

- - liaisons à l'aide de :

· boulons et goupilles en acier de diamètre supérieur ou égal à 5 mm ;

· boulons et goupilles en aluminium de diamètre supérieur ou égal à 8 mm ;

· rivets et vis taraudeuses de diamètre supérieur ou égal à 4,2 mm.

(2) Les sujets ci-dessous sont traités dans l'EN 1999 1-1 :

Section 1 : Généralités

Section 2 : Base de calcul

Section 3 : Matériaux

Section 4 : Durabilité

Section 5 : Analyse structurale

Section 6 : Etats limites ultimes des barres

Section 7 : Etats limites de service

Section 8 : Calcul des assemblages

Annexe A Classes d'exécution

Annexe B Bout en T équivalent en tension

Annexe C Sélection des matériaux

Annexe D Corrosion et protection des surfaces

Annexe E Modèles analytiques pour le rapport contrainte-déformation

Annexe F Comportement de la section transversale au-delà de la limite d'élasticité

Annexe G Capacité de rotation

Annexe H Méthode d'analyse des rotules plastiques pour poutres continues

Annexe I Déversement des poutres et flambement par torsion et torsion-flexion des barres en compression

Annexe J Propriétés des sections transversales

Annexe K Effets de traînage de cisaillement dans le calcul des barres

Annexe L Classification des liaisons

Annexe M Liaisons collées par adhésif

(3) Les Sections 1 à 2 donnent des articles supplémentaires à ceux indiqués dans l’EN 1990 “Base du calcul des structures”.

Evrokod 9: Projektiranje konstrukcij iz aluminijevih zlitin - 1-1. del: Splošna pravila za konstrukcije

Standard EN 1999 se uporablja za projektiranje stavb ter inženirskih in konstrukcijskih objektov iz aluminija. Upošteva načela in zahteve glede varnosti in uporabnosti konstrukcij ter podlago za njihovo projektiranje in preverjanje, ki so podane v standardu EN 1990 – Osnove projektiranja. Standard EN 1999 se nanaša le na zahteve za odpornost, uporabnost, trajnost in požarno odpornost aluminijastih konstrukcij. Ostale zahteve, na primer glede toplotne in zvočne izolativnosti, niso obravnavane. Standard EN 1999 je namenjen za uporabo v povezavi z naslednjimi standardi: – EN 1990 »Osnove projektiranja« – EN 1991 »Vplivi na konstrukcije« – Evropski standardi za konstrukcijske izdelke v zvezi z aluminijastimi konstrukcijami – prEN 1090-1: Izvedba jeklenih konstrukcij in aluminijastih konstrukcij – 1. del: Zahteve za ugotavljanje skladnosti sestavnih delov konstrukcij5 – prEN 1090-3: Izvedba jeklenih konstrukcij in aluminijastih konstrukcij – 3. del: Tehnične zahteve za aluminijaste konstrukcije5 EN 1999 je razdeljen na pet delov: EN 1999-1-1 Projektiranje konstrukcij iz aluminijevih zlitin: Splošna pravila za konstrukcije. EN 1999-1-2 Projektiranje konstrukcij iz aluminijevih zlitin: Projektiranje požarnovarnih konstrukcij. EN 1999-1-3 Projektiranje konstrukcij iz aluminijevih zlitin: Konstrukcije, občutljive na utrujanje. EN 1999-1-4 Projektiranje konstrukcij iz aluminijevih zlitin: Hladno oblikovane konstrukcijske pločevine. EN 1999-1-5 Projektiranje konstrukcij iz aluminijevih zlitin: Lupinaste konstrukcije.

General Information

- Status

- Published

- Publication Date

- 17-Apr-2007

- Technical Committee

- KON - Structures

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 12-Apr-2007

- Due Date

- 17-Jun-2007

- Completion Date

- 18-Apr-2007

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 01-May-2007

- Replaced By

kSIST FprEN 1999-1-1:2022 - Eurocode 9 - Design of aluminium structures - Part 1-1: General rules - Effective Date

- 01-Mar-2028

- Effective Date

- 01-May-2014

- Effective Date

- 01-Nov-2009

Frequently Asked Questions

SIST EN 1999-1-1:2007 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Eurocode 9 - Design of aluminium structures - Part 1-1: General structural rules". This standard covers: (1) EN 1999-1-1 gives basic design rules for structures made of wrought aluminium alloys and limited guidance for cast alloys (see section 3). NOTE Minimum material thickness may be defined in the National Annex. The following limits are recommended – if not otherwise explicitly stated in this standard: - components with material thickness not less than 0,6 mm; - welded components with material thickness not less than 1,5 mm; - connections with: o steel bolts and pins with diameter not less than 5 mm; o aluminium bolts and pins with diameter not less than 8 mm; o rivets and thread forming screws with diameter not less than 4,2 mm (2) The following subjects are dealt with in EN 1999-1-1: Section 1: General Section 2: Basis of design Section 3: Materials Section 4: Durability Section 5: Structural analysis Section 6: Ultimate limit states for members Section 7: Serviceability limit states Section 8: Design of joints Annex A Execution classes Annex B Equivalent T-stub in tension Annex C Materials selection Annex D Corrosion and surface protection Annex E Analytical models for stress strain relationship Annex F Behaviour of cross section beyond elastic limit Annex G Rotation capacity Annex H Plastic hinge method for continuous beams Annex I Lateral torsional buckling of beams and torsional or flexural-torsional buckling of compression members Annex J Properties of cross sections Annex K Shear lag effects in member design Annex L Classification of connections Annex M Adhesive bonded connections (3) Sections 1 to 2 provide additional clauses to those given in EN 1990 “Basis of structural design”. (4) Section 3 deals with material properties of products made of structural aluminium alloys. (5) Section 4 gives general rules for durability. (6) Section 5 refers to the structural analysis of structures, in which the members can be modelled with sufficient accuracy as line elements for global analysis. (7) Section 6 g

(1) EN 1999-1-1 gives basic design rules for structures made of wrought aluminium alloys and limited guidance for cast alloys (see section 3). NOTE Minimum material thickness may be defined in the National Annex. The following limits are recommended – if not otherwise explicitly stated in this standard: - components with material thickness not less than 0,6 mm; - welded components with material thickness not less than 1,5 mm; - connections with: o steel bolts and pins with diameter not less than 5 mm; o aluminium bolts and pins with diameter not less than 8 mm; o rivets and thread forming screws with diameter not less than 4,2 mm (2) The following subjects are dealt with in EN 1999-1-1: Section 1: General Section 2: Basis of design Section 3: Materials Section 4: Durability Section 5: Structural analysis Section 6: Ultimate limit states for members Section 7: Serviceability limit states Section 8: Design of joints Annex A Execution classes Annex B Equivalent T-stub in tension Annex C Materials selection Annex D Corrosion and surface protection Annex E Analytical models for stress strain relationship Annex F Behaviour of cross section beyond elastic limit Annex G Rotation capacity Annex H Plastic hinge method for continuous beams Annex I Lateral torsional buckling of beams and torsional or flexural-torsional buckling of compression members Annex J Properties of cross sections Annex K Shear lag effects in member design Annex L Classification of connections Annex M Adhesive bonded connections (3) Sections 1 to 2 provide additional clauses to those given in EN 1990 “Basis of structural design”. (4) Section 3 deals with material properties of products made of structural aluminium alloys. (5) Section 4 gives general rules for durability. (6) Section 5 refers to the structural analysis of structures, in which the members can be modelled with sufficient accuracy as line elements for global analysis. (7) Section 6 g

SIST EN 1999-1-1:2007 is classified under the following ICS (International Classification for Standards) categories: 91.010.30 - Technical aspects; 91.080.17 - Aluminium structures. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1999-1-1:2007 has the following relationships with other standards: It is inter standard links to SIST ENV 1999-1-1:2002, kSIST FprEN 1999-1-1:2022, SIST EN 1999-1-1:2007/A2:2014, SIST EN 1999-1-1:2007/A1:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1999-1-1:2007 is associated with the following European legislation: EU Directives/Regulations: 2003-01-2705, 2005-01-4408, 305/2011, 89/106/EEC; Standardization Mandates: M/265, M/BC/CEN/89/11. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase SIST EN 1999-1-1:2007 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of SIST standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Eurocode 9 - Design of aluminium structures - Part 1-1: General structural rulesEvrokod 9: Projektiranje konstrukcij iz aluminijevih zlitin - 1-1. del: Splošna pravila za konstrukcijeEurocode 9 - Calcul des structures en aluminium - Partie 1-1: Regles généralesEurocode 9 - Bemessung und Konstruktion von Aluminiumtragwerken - Teil 1-1: Allgemeine BemessungsregelnTa slovenski standard je istoveten z:EN 1999-1-1:2007SIST EN 1999-1-1:2007en;fr;de91.080.10Kovinske konstrukcijeMetal structures91.010.30Technical aspectsICS:SIST ENV 1999-1-1:20021DGRPHãþDSLOVENSKI

STANDARDSIST EN 1999-1-1:200701-maj-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1999-1-1February 2007ICS 91.010.30; 91.080.10Supersedes ENV 1999-1-1:1998

English VersionEurocode 9 - Design of aluminium structures - Part 1-1: Generalstructural rulesEurocode 9 - Calcul des structures en aluminium - Partie 1-1: Règles généralesEurocode 9 - Bemessung und Konstruktion vonAluminiumtragwerken - Teil 1-1: AllgemeineBemessungsregelnThis European Standard was approved by CEN on 18 September 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1999-1-1:2007: E

EN 1999-1-1: 2007 (E)

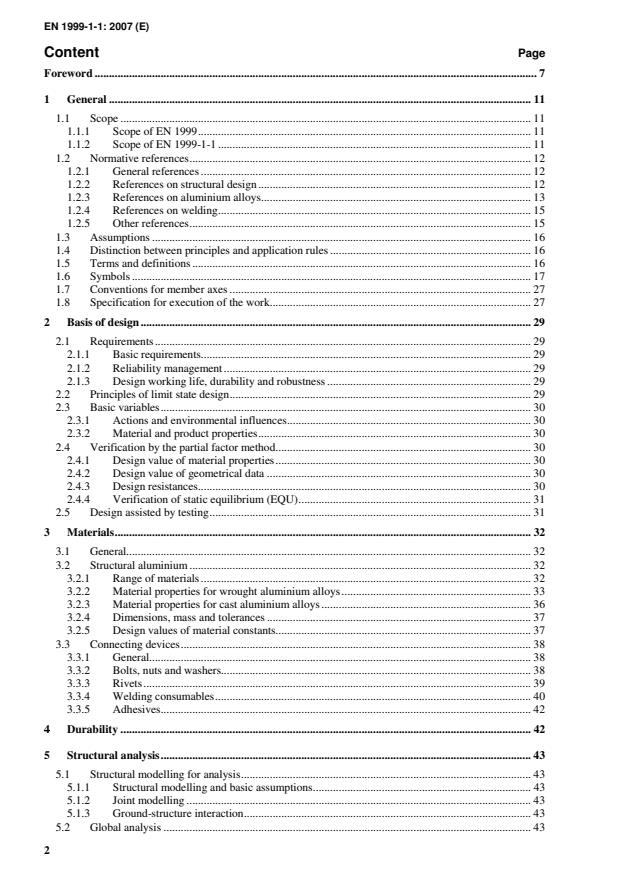

2 Content Page Foreword.7 1 General.11 1.1 Scope.11 1.1.1 Scope of EN 1999.11 1.1.2 Scope of EN 1999-1-1.11 1.2 Normative references.12 1.2.1 General references.12 1.2.2 References on structural design.12 1.2.3 References on aluminium alloys.13 1.2.4 References on welding.15 1.2.5 Other references.15 1.3 Assumptions.16 1.4 Distinction between principles and application rules.16 1.5 Terms and definitions.16 1.6 Symbols.17 1.7 Conventions for member axes.27 1.8 Specification for execution of the work.27 2 Basis of design.29 2.1 Requirements.29 2.1.1 Basic requirements.29 2.1.2 Reliability management.29 2.1.3 Design working life, durability and robustness.29 2.2 Principles of limit state design.29 2.3 Basic variables.30 2.3.1 Actions and environmental influences.30 2.3.2 Material and product properties.30 2.4 Verification by the partial factor method.30 2.4.1 Design value of material properties.30 2.4.2 Design value of geometrical data.30 2.4.3 Design resistances.30 2.4.4 Verification of static equilibrium (EQU).31 2.5 Design assisted by testing.31 3 Materials.32 3.1 General.32 3.2 Structural aluminium.32 3.2.1 Range of materials.32 3.2.2 Material properties for wrought aluminium alloys.33 3.2.3 Material properties for cast aluminium alloys.36 3.2.4 Dimensions, mass and tolerances.37 3.2.5 Design values of material constants.37 3.3 Connecting devices.38 3.3.1 General.38 3.3.2 Bolts, nuts and washers.38 3.3.3 Rivets.39 3.3.4 Welding consumables.40 3.3.5 Adhesives.42 4 Durability.42 5 Structural analysis.43 5.1 Structural modelling for analysis.43 5.1.1 Structural modelling and basic assumptions.43 5.1.2 Joint modelling.43 5.1.3 Ground-structure interaction.43 5.2 Global analysis.43

EN 1999-1-1: 2007 (E)

3 5.2.1 Effects of deformed geometry of the structure.43 5.2.2 Structural stability of frames.44 5.3 Imperfections.45 5.3.1 Basis.45 5.3.2 Imperfections for global analysis of frames.45 5.3.3 Imperfection for analysis of bracing systems.49 5.3.4 Member imperfections.52 5.4 Methods of analysis.52 5.4.1 General.52 5.4.2 Elastic global analysis.52 5.4.3 Plastic global analysis.52 6 Ultimate limit states for members.53 6.1 Basis.53 6.1.1 General.53 6.1.2 Characteristic value of strength.53 6.1.3 Partial safety factors.53 6.1.4 Classification of cross-sections.53 6.1.5 Local buckling resistance.58 6.1.6 HAZ softening adjacent to welds.59 6.2 Resistance of cross-sections.61 6.2.1 General.61 6.2.2 Section properties.62 6.2.3 Tension.63 6.2.4 Compression.64 6.2.5 Bending moment.64 6.2.6 Shear.66 6.2.7 Torsion.67 6.2.8 Bending and shear.69 6.2.9 Bending and axial force.69 6.2.10 Bending, shear and axial force.70 6.2.11 Web bearing.71 6.3 Buckling resistance of members.71 6.3.1 Members in compression.71 6.3.2 Members in bending.75 6.3.3 Members in bending and axial compression.77 6.4 Uniformed built-up members.80 6.4.1 General.80 6.4.2 Laced compression members.82 6.4.3 Battened compression members.83 6.4.4 Closely spaced built-up members.85 6.5 Un-stiffened plates under in-plane loading.85 6.5.1 General.85 6.5.2 Resistance under uniform compression.86 6.5.3 Resistance under in-plane moment.87 6.5.4 Resistance under transverse or longitudinal stress gradient.88 6.5.5 Resistance under shear.88 6.5.6 Resistance under combined action.89 6.6 Stiffened plates under in-plane loading.89 6.6.1 General.89 6.6.2 Stiffened plates under uniform compression.90 6.6.3 Stiffened plates under in-plane moment.92 6.6.4 Longitudinal stress gradient on multi-stiffened plates.92 6.6.5 Multi-stiffened plating in shear.93 6.6.6 Buckling load for orthotropic plates.93 6.7 Plate girders.96 6.7.1 General.96 6.7.2 Resistance of girders under in-plane bending.96 6.7.3 Resistance of girders with longitudinal web stiffeners.97

EN 1999-1-1: 2007 (E)

4 6.7.4 Resistance to shear.98 6.7.5 Resistance to transverse loads.102 6.7.6 Interaction.105 6.7.7 Flange induced buckling.106 6.7.8 Web stiffeners.106 6.8 Members with corrugated webs.108 6.8.1 Bending moment resistance.108 6.8.2 Shear force resistance.108 7 Serviceability Limit States.110 7.1 General.110 7.2 Serviceability limit states for buildings.110 7.2.1 Vertical deflections.110 7.2.2 Horizontal deflections.110 7.2.3 Dynamic effects.110 7.2.4 Calculation of elastic deflection.110 8 Design of joints.111 8.1 Basis of design.111 8.1.1 Introduction.111 8.1.2 Applied forces and moments.111 8.1.3 Resistance of joints.111 8.1.4 Design assumptions.112 8.1.5 Fabrication and execution.112 8.2 Intersections for bolted, riveted and welded joints.112 8.3 Joints loaded in shear subject to impact, vibration and/or load reversal.113 8.4 Classification of joints.113 8.5 Connections made with bolts, rivets and pins.113 8.5.1 Positioning of holes for bolts and rivets.113 8.5.2 Deductions for fastener holes.115 8.5.3 Categories of bolted connections.117 8.5.4 Distribution of forces between fasteners.119 8.5.5 Design resistances of bolts.120 8.5.6 Design resistance of rivets.122 8.5.7 Countersunk bolts and rivets.123 8.5.8 Hollow rivets and rivets with mandrel.123 8.5.9 High strength bolts in slip-resistant connections.123 8.5.10 Prying forces.125 8.5.11 Long joints.125 8.5.12 Single lap joints with fasteners in one row.126 8.5.13 Fasteners through packings.126 8.5.14 Pin connections.126 8.6 Welded connections.129 8.6.1 General.129 8.6.2 Heat-affected zone (HAZ).129 8.6.3 Design of welded connections.129 8.7 Hybrid connections.136 8.8 Adhesive bonded connections.136 8.9 Other joining methods.136 Annex A [normative] – Reliability differentiation.137 A.1 Introduction.137 A.2 Design provisions for reliability differentiation - Design supervision levels.137 A.3 Execution provisions for reliability differentiation – Execution classes.137 A.4 Governing factors for choice of execution class.137 A.5 Hazards connected with the execution and use of the structure.138 A.6 Determination of execution class.138 A.7 Utilization grades.139 Annex B [normative] - Equivalent T-stub in tension.140

EN 1999-1-1: 2007 (E)

5 B.1 General rules for evaluation of resistance.140 B.2 Individual bolt-row, bolt-groups and groups of bolt-rows.144 Annex C [informative] - Materials selection.146 C.1 General.146 C.2 Wrought products.146 C.2.1 Wrought heat treatable alloys.146 C.2.2 Wrought non-heat treatable alloys.149 C.3 Cast products.150 C.3.1 General

..................................................................................................150 C.3.2 Heat treatable casting alloys EN AC-42100, EN AC-42200, EN AC-43000 and..................150 EN AC-43300.........................................................................................................................................150 C.3.3 Non-heat treatable casting alloys EN AC-44200 and EN AC-51300.....................................150 C.3.4 Special design rules for castings.............................................................................................150 C.4 Connecting devices.........................................................................................................................152 C.4.1 Aluminium bolts.....................................................................................................................152 C.4.2 Aluminium rivets....................................................................................................................152 Annex D [informative] – Corrosion and surface protection.....................................................................153 D.1 Corrosion of aluminium under various exposure conditions..........................................................153 D.2 Durability ratings of aluminium alloys...........................................................................................153 D.3 Corrosion protection.......................................................................................................................154 D.3.1 General...................................................................................................................................154 D.3.2 Overall corrosion protection of structural aluminium............................................................154 D.3.3 Aluminium in contact with aluminium and other metals.......................................................155 D.3.4 Aluminium surfaces in contact with non-metallic materials..................................................155 Annex E

[informative] - Analytical models for stress strain relationship.160 E.1 Scope.160 E.2 Analytical models.160 E.2.1 Piecewise linear models.160 E.2.2 Continuous models.162 E.3 Approximate evaluation of eu.165 Annex F

[informative] - Behaviour of cross-sections beyond the elastic limit.166 F.1 General.166 F.2 Definition of cross-section limit states.166 F.3 Classification of cross-sections according to limit states.166 F.4 Evaluation of ultimate axial load.167 F.5 Evaluation of ultimate bending moment.168 Annex G

[informative] - Rotation capacity.170 Annex H

[informative] - Plastic hinge method for continuous beams.172 Annex I

[informative] - Lateral torsional buckling of beams and torsional or torsional-flexural buckling of compressed members.174 I.1 Elastic critical moment and slenderness.174 I.1.1 Basis

.....................................................................................................................174 I.1.2 General formula for beams with uniform cross-sections symmetrical about the minor or major axis

..............................................................................................................................174 I.1.3 Beams with uniform cross-sections symmetrical about major axis, centrally symmetric and doubly symmetric cross-sections............................................................................................................179 I.1.4 Cantilevers with uniform cross-sections symmetrical about the minor axis

.............180 I.2 Slenderness for lateral torsional buckling......................................................................................182 I.3 Elastic critical axial force for torsional and torsional-flexural buckling........................................184 I.4 Slenderness for torsional and torsional-flexural buckling..............................................................185 Annex J

[informative] - Properties of cross sections.190 J.1 Torsion constant It.190

EN 1999-1-1: 2007 (E)

6 J.2 Position of shear centre S.190 J.3 Warping constant Iw.190 J.4 Cross section constants for open thin-walled cross sections.194 J.5 Cross section constants for open cross section with branches.196 J.6 Torsion constant and shear center of cross section with closed part.196 Annex K

[informative] - Shear lag effects in member design.197 K.1 General.197 K.2 Effective width for elastic shear lag.197 K.2.1 Effective width factor for shear lag.197 K.2.2 Stress distribution for shear lag.198 K.2.3 In-plane load effects.199 K.3 Shear lag at ultimate limit states.200 Annex L [informative] - Classification of joints.201 L.1 General.201 L.2 Fully restoring connections.202 L.3 Partially restoring connections.202 L.4 Classification according to rigidity.202 L.5 Classification according to strength.203 L.6 Classification according to ductility.203 L.7 General design requirements for connections.203 L.8 Requirements for framing connections.203 L.8.1 General.203 L.8.2 Nominally pinned connections.204 L.8.3 Built-in connections.205 Annex M [informative] - Adhesive bonded connections.206 M.1 General.206 M.2 Adhesives.206 M.3 Design of adhesive bonded joints.207 M.3.1 General.207 M.3.2 Characteristic strength of adhesives.207 M.3.3 Design shear stress.208 M.4 Tests.208

EN 1999-1-1: 2007 (E)

7 Foreword This European Standard (EN 1999-1-1:2007) has been prepared by Technical Committee CEN/TC250 « Structural Eurocodes », the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by August 2007, and conflicting national standards shall be withdrawn at the latest by March 2010. This European Standard supersedes ENV 1999-1-1: 1998. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard:

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece,

Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxemburg, Malta, Netherlands, Norway, Poland,

Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

Background of the Eurocode programme

In 1975, the Commission of the European Community decided on an action programme in the field of construction, based on article 95 of the Treaty. The objective of the programme was the elimination of technical obstacles to trade and the harmonisation of technical specifications.

Within this action programme, the Commission took the initiative to establish a set of harmonised technical rules for the design of construction works, which in a first stage would serve as an alternative to the national rules in force in the Member States and, ultimately, would replace them.

For fifteen years, the Commission, with the help of a Steering Committee with Representatives of Member States, conducted the development of the Eurocodes programme, which led to the first generation of Euro-pean codes in the 1980s.

In 1989, the Commission and the Member States of the EU and EFTA decided, on the basis of an agreement1 between the Commission and CEN, to transfer the preparation and the publication of the Eurocodes to the CEN through a series of Mandates, in order to provide them with a future status of European Standard (EN). This links de facto the Eurocodes with the provisions of all the Council’s Directives and/or Commission’s Decisions dealing with European standards (e.g. the Council Directive 89/106/EEC on construction products – CPD – and Council Directives 93/37/EEC, 92/50/EEC and 89/440/EEC on public works and services and equivalent EFTA Directives initiated in pursuit of setting up the internal market).

The Structural Eurocode programme comprises the following standards generally consisting of a number of Parts: EN 1990 Eurocode 0: Basis of structural design EN 1991 Eurocode 1: Actions on structures EN 1992 Eurocode 2: Design of concrete structures EN 1993 Eurocode 3: Design of steel structures EN 1994 Eurocode 4: Design of composite steel and concrete structures EN 1995 Eurocode 5: Design of timber structures EN 1996 Eurocode 6: Design of masonry structures EN 1997 Eurocode 7: Geotechnical design EN 1998 Eurocode 8: Design of structures for earthquake resistance EN 1999 Eurocode 9: Design of aluminium structures

1 Agreement between the Commission of the European Communities and the European Committee for Standardisation (CEN) concerning the work on EUROCODES for the design of building and civil engineering works (BC/CEN/03/89).

EN 1999-1-1: 2007 (E)

8 Eurocode standards recognise the responsibility of regulatory authorities in each Member State and have safeguarded their right to determine values related to regulatory safety matters at national level where these continue to vary from State to State. Status and field of application of Eurocodes

The Member States of the EU and EFTA recognise that Eurocodes serve as reference documents for the following purposes: – as a means to prove compliance of building and civil engineering works with the essential requirements of Council Directive 89/106/EEC, particularly Essential Requirement N°1 - Mechanical resistance and stability - and Essential Requirement N°2 - Safety in case of fire; – as a basis for specifying contracts for construction works and related engineering services; – as a framework for drawing up harmonised technical specifications for construction products (ENs and ETAs)

The Eurocodes, as far as they concern the construction works themselves, have a direct relationship with the Interpretative Documents2

referred to in Article 12 of the CPD, although they are of a different nature from harmonised product standard3. Therefore, technical aspects, arising from the Eurocodes work, need to be adequately considered by CEN Technical Committees and/or EOTA Working Groups working on product standards with a view to achieving a full compatibility of these technical specifications with the Eurocodes.

The Eurocode standards provide common structural design rules for everyday use for the design of whole structures and component products of both a traditional and an innovative nature. Unusual forms of construction or design conditions are not specifically covered and additional expert consideration will be required by the designer in such cases. National Standards implementing Eurocodes

The National Standards implementing Eurocodes will comprise the full text of the Eurocode (including any annexes), as published by CEN, which may be preceded by a National title page and National foreword, and may be followed by a National annex (informative). The National Annex (informative) may only contain information on those parameters which are left open in the Eurocode for national choice, known as Nationally Determined Parameters, to be used for the design of buildings and civil engineering works to be constructed in the country concerned, i.e. : – values for partial factors and/or classes where alternatives are given in the Eurocode, – values to be used where a symbol only is given in the Eurocode, – geographical and climatic data specific to the Member State, e.g. snow map, – the procedure to be used where alternative procedures are given in the Eurocode, – references to non-contradictory complementary information to assist the user to apply the Eurocode.

Links between Eurocodes and product harmonised technical specifications (ENs and ETAs)

There is a need for consistency between the harmonised technical specifications for construction products and the technical rules for works4. Furthermore, all the information accompanying the CE Marking of the

2 According to Art. 3.3 of the CPD, the essential requirements (ERs) should be given concrete form in interpretative documents for the creation of the necessary links between the essential requirements and the mandates for hENs and ETAGs/ETAs.

3 According to Art. 12 of the CPD the interpretative documents should : a) give concrete form to the essential requirements by harmonising the terminology and the technical bases and indicating classes or levels for each requirement where necessary ; b) indicate methods of correlating these classes or levels of requirement with the technical specifications, e.g. methods of calculation and of proof, technical rules for project design, etc. ; c) serve as a reference for the establishment of harmonised standards and guidelines for European technical approvals. The Eurocodes, de facto, play a similar role in the field of the ER 1 and a part of ER 2.

See Art.3.3 and Art.12 of the CPD, as well as clauses 4.2, 4.3.1, 4.3.2 and 5.2 of ID 1.

EN 1999-1-1: 2007 (E)

9 construction products which refer to Eurocodes should clearly mention which Nationally Determined Parameters have been taken into account. Additional information specific to EN 1999-1-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...