SIST EN 17860-5:2025

(Main)Carrier cycles - Part 5: Electrical aspects

Carrier cycles - Part 5: Electrical aspects

This document applies to:

- functional and electrical safety aspects of carrier cycles covered in all parts of EN 17860;

- electrical aspects of electrically power assisted cycle trailers (EPACT) covered in prEN 17860-7;

- electrical aspects of batteries used for carrier cycles;

- electrical aspects of chargers used for carrier cycles.

This document does not apply to charging stations.

This document specifies requirements and test methods for motor power management systems, electrical circuits including the charger for the assessment of the design and assembly of carrier cycles and subassemblies for systems having a Safety Extra Low Voltage (SELV) maximum working voltage ≤ 60 V d.c. disregarding transients.

Lastenfahrräder - Teil 5: Elektrische Aspekte

Dieses Dokument gilt für:

funktionale und elektrische Sicherheitsaspekte von Lastenfahrrädern, die in allen Teilen von EN 17860 behandelt werden;

elektrische Aspekte von elektromotorisch unterstützten Anhängern (EPACT, en: electrically power assisted cycle trailers), die in prEN 17860 7 behandelt werden;

elektrische Aspekte von Batterien, die für Lastenfahrräder verwendet werden;

elektrische Aspekte von Ladegeräten, die für Lastenfahrräder verwendet werden.

Dieses Dokument gilt nicht für Ladestationen.

Dieses Dokument legt Anforderungen und Prüfverfahren für Motormanagement-Systeme und elektrische Stromkreise einschließlich des Ladegeräts für die Beurteilung des Designs und der Bauart von Lastenfahrrädern und Unterbaugruppen für Systeme mit einer maximalen Betriebsspannung entsprechend der Sicherheitskleinspannung (SELV, en: safety extra low voltage) ≤ 60 V Gleichstrom ohne Berücksichtigung von vorübergehenden Spannungsspitzen fest.

Cycles utilitaires - Partie 5: Aspects électriques

Le présent document s’applique :

aux aspects de sécurité fonctionnelle et électrique des cycles utilitaires couverts par toutes les parties de l’EN 17860 ;

aux aspects électriques des remorques pour cycles à assistance électrique (EPACT) couverts par le prEN 17860 7 ;

aux aspects électriques des batteries utilisées pour les cycles utilitaires ;

aux aspects électriques des chargeurs utilisés pour les cycles utilitaires.

Le présent document ne s’applique pas aux stations de charge.

Le présent document spécifie les exigences et les méthodes d’essai pour les systèmes de gestion de la puissance des moteurs et les circuits électriques, y compris le chargeur, afin d’évaluer la conception et l’assemblage des cycles utilitaires et des sous ensembles pour les systèmes ayant une très basse tension de sécurité (SELV) maximale ≤ 60 V c.c., sans tenir compte des transitoires.

Tovorna kolesa - 5. del: Električni vidiki

Ta dokument se uporablja za:

– funkcionalne in električne vidike v zvezi z varnostjo tovornih koles, zajetih v vseh delih standarda EN 17860;

– električne vidike kolesarskih prikolic z električnim pomožnim pogonom (EPACT), zajete v standardu prEN 17860-7;

– električne vidike akumulatorjev, ki se uporabljajo za tovorna kolesa;

– električne vidike polnilnikov, ki se uporabljajo za tovorna kolesa.

Ta dokument se ne uporablja za polnilne postaje.

Ta dokument določa zahteve in preskusne metode za sisteme upravljanja porabe motorja, električne tokokroge, vključno s polnilnikom, za oceno načrtovanja in montaže tovornih koles, ter podsklope za sisteme z največjo enosmerno delovno napetostjo ≤ 60 V v okviru varnostno nizke napetosti (SELV) brez upoštevanja prehodnih pojavov.

General Information

- Status

- Published

- Public Enquiry End Date

- 23-Oct-2023

- Publication Date

- 04-Feb-2025

- Technical Committee

- SPO - Sports

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 30-Jan-2025

- Due Date

- 06-Apr-2025

- Completion Date

- 05-Feb-2025

Overview

EN 17860-5:2024 - Carrier cycles: Part 5 - Electrical aspects defines electrical and functional safety requirements, test methods and assessment criteria for carrier cycles and related electrical subassemblies. It covers electrical systems, motor power management, batteries and chargers used on carrier electrically power assisted cycles (EPAC) and electrically power assisted cycle trailers (EPACT), for systems with a Safety Extra Low Voltage (SELV) maximum working voltage ≤ 60 V d.c. (transients excluded). This part of the EN 17860 series does not apply to charging stations.

Key topics and requirements

- Scope and risk assessment: Requires design per EN ISO 12100 principles and evaluation of electrical, mechanical, thermal and ergonomic hazards.

- Electric system architecture: Requirements for motor power management systems, wiring, power cables, conduits and electrical circuits including the onboard charger.

- Batteries and chargers: Safety aspects for secondary batteries and external chargers used on carrier cycles; references include EN 50604‑1 and EN 60335‑2‑29.

- Controls, symbols and anti‑tampering: Standardised controls and graphical symbols, prevention of unauthorised use and anti‑tampering measures.

- Mechanical and environmental robustness: Tests for moisture resistance, mechanical strength, shock and impact (including lateral overturning tests) and IP requirements.

- Performance limits and measurements: Procedures for measuring maximum continuous rated power, motor assistance cut‑off speed and walk/manoeuvring assistance modes.

- Power management and recuperation: Requirements and test methods for auxiliary motor management and recuperative braking (including brake light activation).

- Electromagnetic compatibility (EMC): Emission and immunity criteria for carrier EPACs in normal use and during mains charging (see normative Annex A).

- Safety functions and failure modes: Specification of safety functions, warning requirements and thermal hazard limits for contact surfaces and ambient temperatures.

Practical applications and users

This standard is essential for:

- Manufacturers and designers of carrier cycles, electric cargo bikes and electrically assisted trailers (EPACT) - to ensure safe electrical design and EMC compliance.

- Component suppliers (motors, batteries, chargers, connectors) - for specifying requirements and test acceptance.

- Testing laboratories and conformity assessors - to apply the referenced test methods and measure power/EMC performance.

- Fleet operators and safety engineers - to understand operational limits, charging/maintenance implications and anti‑tampering guidance.

- Regulators and procurement teams - when specifying safety and performance criteria for cargo e‑bikes.

Related standards

- EN 17860 series (Parts 1–4, 6–7) - terminology, mechanical and functional aspects, trailers and passenger transport.

- Normative references cited: EN 17860‑1:2024, EN 15194:2017+A1:2023, EN 50604‑1, EN 60335‑2‑29, IEC/EN EMC and IP standards (e.g., EN IEC 61000‑6‑1/6‑3, EN 60529).

Keywords: EN 17860-5:2024, carrier cycles electrical aspects, EPAC, EPACT, battery safety, charger requirements, SELV ≤ 60 V, motor power management, EMC, anti‑tampering.

Frequently Asked Questions

SIST EN 17860-5:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Carrier cycles - Part 5: Electrical aspects". This standard covers: This document applies to: - functional and electrical safety aspects of carrier cycles covered in all parts of EN 17860; - electrical aspects of electrically power assisted cycle trailers (EPACT) covered in prEN 17860-7; - electrical aspects of batteries used for carrier cycles; - electrical aspects of chargers used for carrier cycles. This document does not apply to charging stations. This document specifies requirements and test methods for motor power management systems, electrical circuits including the charger for the assessment of the design and assembly of carrier cycles and subassemblies for systems having a Safety Extra Low Voltage (SELV) maximum working voltage ≤ 60 V d.c. disregarding transients.

This document applies to: - functional and electrical safety aspects of carrier cycles covered in all parts of EN 17860; - electrical aspects of electrically power assisted cycle trailers (EPACT) covered in prEN 17860-7; - electrical aspects of batteries used for carrier cycles; - electrical aspects of chargers used for carrier cycles. This document does not apply to charging stations. This document specifies requirements and test methods for motor power management systems, electrical circuits including the charger for the assessment of the design and assembly of carrier cycles and subassemblies for systems having a Safety Extra Low Voltage (SELV) maximum working voltage ≤ 60 V d.c. disregarding transients.

SIST EN 17860-5:2025 is classified under the following ICS (International Classification for Standards) categories: 43.150 - Cycles. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 17860-5:2025 is associated with the following European legislation: EU Directives/Regulations: 2001/95/EC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 17860-5:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2025

Tovorna kolesa - 5. del: Električni vidiki

Carrier cycles - Part 5: Electrical aspects

Lastenfahrräder - Teil 5: Elektrische Aspekte

Cycles utilitaires - Partie 5: Aspects électriques

Ta slovenski standard je istoveten z: EN 17860-5:2024

ICS:

43.150 Kolesa Cycles

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17860-5

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2024

EUROPÄISCHE NORM

ICS 43.150

English Version

Carrier cycles - Part 5: Electrical aspects

Cycles utilitaires - Partie 5: Aspects électriques Lastenfahrräder - Teil 5: Elektrische Aspekte

This European Standard was approved by CEN on 4 November 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17860-5:2024 E

worldwide for CEN national Members.

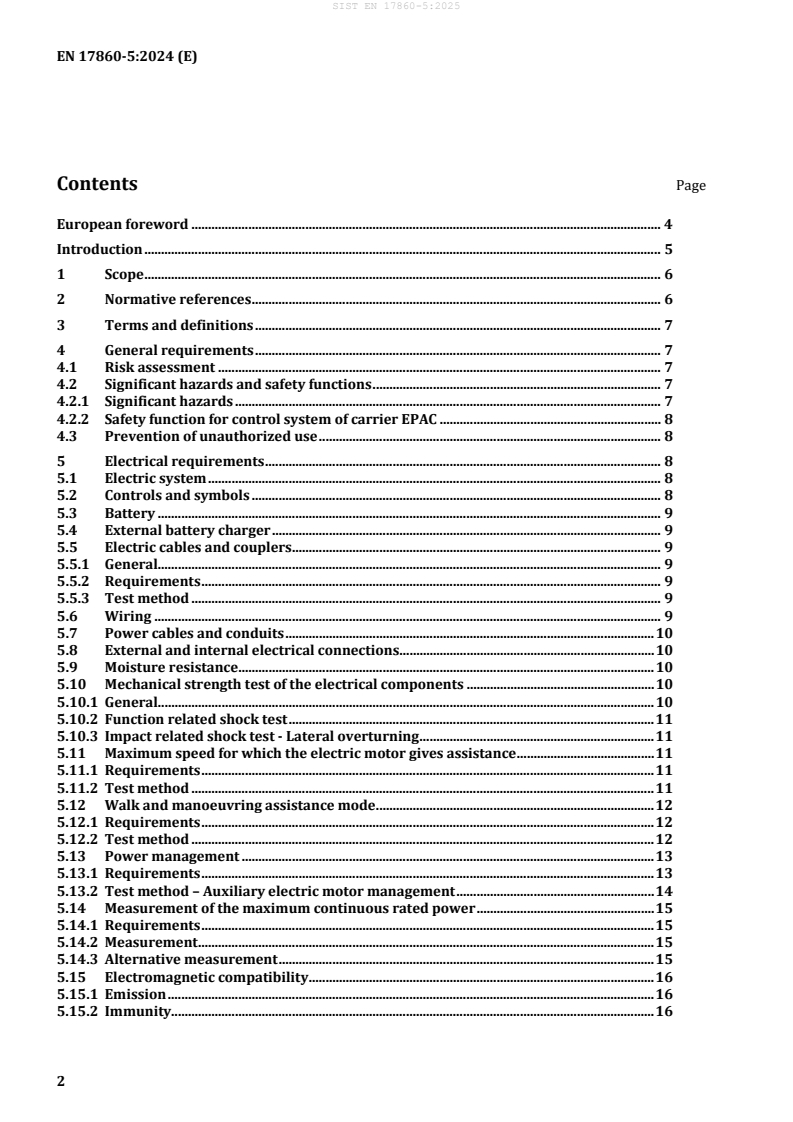

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 General requirements . 7

4.1 Risk assessment . 7

4.2 Significant hazards and safety functions . 7

4.2.1 Significant hazards . 7

4.2.2 Safety function for control system of carrier EPAC . 8

4.3 Prevention of unauthorized use . 8

5 Electrical requirements . 8

5.1 Electric system . 8

5.2 Controls and symbols . 8

5.3 Battery . 9

5.4 External battery charger . 9

5.5 Electric cables and couplers . 9

5.5.1 General. 9

5.5.2 Requirements . 9

5.5.3 Test method . 9

5.6 Wiring . 9

5.7 Power cables and conduits . 10

5.8 External and internal electrical connections . 10

5.9 Moisture resistance . 10

5.10 Mechanical strength test of the electrical components . 10

5.10.1 General. 10

5.10.2 Function related shock test . 11

5.10.3 Impact related shock test - Lateral overturning . 11

5.11 Maximum speed for which the electric motor gives assistance . 11

5.11.1 Requirements . 11

5.11.2 Test method . 11

5.12 Walk and manoeuvring assistance mode . 12

5.12.1 Requirements . 12

5.12.2 Test method . 12

5.13 Power management . 13

5.13.1 Requirements . 13

5.13.2 Test method – Auxiliary electric motor management . 14

5.14 Measurement of the maximum continuous rated power . 15

5.14.1 Requirements . 15

5.14.2 Measurement . 15

5.14.3 Alternative measurement . 15

5.15 Electromagnetic compatibility . 16

5.15.1 Emission . 16

5.15.2 Immunity. 16

5.15.3 Carrier EPAC in mains charging mode . 16

5.16 Failure mode . 17

5.16.1 Acoustical and / or visual warning . 17

5.17 Anti-tampering measures . 17

5.18 Thermal hazards . 17

5.18.1 Non-continuous contact surface . 17

5.18.2 Continuous contact surface . 17

5.18.3 Ambient temperature . 17

5.19 Recuperative braking . 18

5.19.1 Braking . 18

5.19.2 Brake light activation by recuperative braking . 18

5.20 Electrical requirements for electric cargo trailers . 18

5.20.1 Control for electric cargo trailers . 18

5.20.2 Handcart mode for electric cargo trailers - Handcart mode speed test. 18

5.20.3 Maximum speed test . 18

5.20.4 Assistance power for electric cargo trailer . 18

5.20.5 Activating the trailer mode . 23

5.20.6 Plug connections for electric cargo trailers . 23

5.20.7 Performance levels (PLrs) for control system of electric cargo trailers . 24

Annex A (normative) Electromagnetic compatibility of carrier EPAC and ESA . 26

Annex B (normative) Light, warning device, on/off symbols . 27

Annex C (informative) Walk and manoeuvring assistance mode symbols . 28

Annex D (informative) Measurement of the maximum continuous rated power —

Alternative measurement. 29

Bibliography . 31

European foreword

This document (EN 17860-5:2024) has been prepared by Technical Committee CEN/TC 333 “Cycles”, the

secretariat of which is held by UNI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2025, and conflicting national standards shall be

withdrawn at the latest by June 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document is part of standard series consisting of the following parts:

— EN 17860-1:2024, Carrier cycles — Part 1: Terms and definitions

— EN 17860-2:2024, Carrier cycles — Part 2: Lightweight single track carrier cycles — Mechanical

aspects

— EN 17860-3:2024, Carrier Cycles — Part 3: Lightweight multi track carrier cycles — Mechanical

aspects

— prEN 17860-4:2024, Carrier Cycles — Part 4: Heavy weight carrier cycles — Mechanical and

functional aspects

— FprEN 17860-5:2024, Carrier cycles — Part 5: Electrical aspects

— prEN 17860-6:2024, Carrier Cycles — Part 6: Passenger transport

— FprEN 17860-7:2024, Carrier cycles — Cargo trailers

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document has been developed in response to an increased demand throughout Europe for carrier

cycles of a type which are excluded from the scope of Regulation (EU) No 168/2013. Electrical aspects of

electric trailers and other peripherals such as chargers are also part of this document.

1 Scope

This document applies to:

— functional and electrical safety aspects of carrier cycles covered in all parts of EN 17860;

— electrical aspects of electrically power assisted cycle trailers (EPACT) covered in prEN 17860-7;

— electrical aspects of batteries used for carrier cycles;

— electrical aspects of chargers used for carrier cycles.

This document does not apply to charging stations.

This document specifies requirements and test methods for motor power management systems,

electrical circuits including the charger for the assessment of the design and assembly of carrier cycles

and subassemblies for systems having a Safety Extra Low Voltage (SELV) maximum working

voltage ≤ 60 V d.c. disregarding transients.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 17860-1:2024, Carrier cycles — Part 1: Terms and definitions

EN 17860-2:2024, Carrier cycles — Part 2: Lightweight single track carrier cycles — Mechanical aspects

EN 15194:2017+A1:2023, Cycles — Electrically power assisted cycles — EPAC Bicycles

EN ISO 7010, Graphical symbols — Safety colours and safety signs — Registered safety signs (ISO 7010)

EN ISO 12100, Safety of machinery — General principles for design — Risk assessment and risk reduction

(ISO 12100)

EN ISO 13849 (all parts), Safety of machinery — Safety-related parts of control systems

CEN/TS 17831:2023, Cycles — Electrically power assisted cycles — Anti-tampering measures

EN 50604-1:2016, Secondary lithium batteries for light EV (electric vehicle) applications — Part 1: General

safety requirements and test methods

EN 50604-1:2016/A1:2021, Secondary lithium batteries for light EV (electric vehicle) applications —

Part 1: General safety requirements and test methods

IEC 60034-1, Rotating electrical machines — Part 1: Rating and performance

EN 60068-2-27, Environmental testing — Part 2-27: Tests — Test Ea and guidance: Shock (IEC 60068-2-

27)

IEC 60335-1:2020, Household and similar electrical appliances — Safety — Part 1: General requirements

EN 60335-2-29, Household and similar electrical appliances — Safety — Part 2-29: Particular

requirements for battery chargers (IEC 60335-2-29)

HD 60364-5-52:2011, Low-voltage electrical installations — Part 5-52: Selection and erection of electrical

equipment — Wiring systems

IEC 60417, Graphical symbols for use on equipment

EN 60529, Degrees of protection provided by enclosures (IP Code) (IEC 60529)

EN IEC 61000-6-1, Electromagnetic compatibility (EMC) — Part 6-1: Generic standards — Immunity

standard for residential, commercial and light-industrial environments

EN IEC 61000-6-3, Electromagnetic compatibility (EMC) — Part 6-3: Generic standards — Emission

standard for equipment in residential environments

ISO 6742-1, Cycles — Lighting and retro-reflective devices —Part 1:Lighting and light signalling devices

ISO 13732-1, Ergonomics of the thermal environment — Methods for the assessment of human responses to

contact with surfaces — Part 1: Hot surfaces

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 17860-1:2024 apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

4 General requirements

4.1 Risk assessment

Carrier EPAC and electrically assisted cycle trailers (EPACT) shall be designed in accordance with the

principles of EN ISO 12100 for relevant hazards which are not dealt with by this document. This includes

evaluation of such risks for all relevant components.

4.2 Significant hazards and safety functions

4.2.1 Significant hazards

The following significant hazards of carrier EPAC have been considered in this document:

a) mechanical hazards: deceleration, acceleration, instability, kinetic energy, rotating elements and

moving elements, rough or slippery surfaces, sharp edges;

b) electrical hazards: electromagnetic phenomena, electrostatic phenomena, overload, short-circuit,

thermal radiation;

c) thermal hazards: explosion, flame, radiation from heat sources, objects or materials with a high or

low temperature;

d) ergonomic hazards: effort, local lighting, posture;

e) hazards associated with the environment in which the carrier EPAC is used: water (dust).

4.2.2 Safety function for control system of carrier EPAC

4.2.2.1 General

The carrier EPAC control system risk shall be assessed in accordance with EN ISO 13849 (all parts).

4.2.2.2 Requirements for the safety related parts of the electrical control systems

The safety requirements of Table 1 shall be necessary for a carrier EPAC. If necessary, the manufacturer

shall add more safety requirements and determine the necessary PL or safety level for each of these safety

requirements and the related safety functions.

Table 1 — Safety functions related to defined hazards

Safety function Performance Level

Prevention of electric motor assisted

propulsion without user request by pedalling or PL c

r

by activation of the walk assistance mode

Prevention of risk of fire in case of management

system failure for batteries with electric energy PL c

r

above 100 Wh

4.2.2.3 Verification of the safety functions

The whole procedure for achieving functional safety shall be in accordance with EN ISO 13849 (all parts).

System suppliers shall document this process and take measures to achieve the required performance

level (see Table 1).

The minimum set of safety related functions shall be implemented at least by both, system suppliers and

the manufacturer, to achieve conformity with this document.

4.3 Prevention of unauthorized use

Means shall be provided to the user to prevent an unauthorized use of the electric assistance/walk

assistance mode of the carrier EPAC e.g. key, locks, electronic control device.

5 Electrical requirements

5.1 Electric system

The electrical system shall be designed so that, should it malfunction in a hazardous manner, it shall

switch off power to the malfunctioning parts without increasing the hazard. It shall require user

interaction to switch on again.

NOTE The mechanical brakes provide fast and safe stopping in emergency situations.

5.2 Controls and symbols

A control device shall be fitted to switch on and off the assistance.

Two independent applying actions shall be required to start the electrical assistance mode (e.g. power

switch and forward pedalling activation); a traffic caused stop (e.g. traffic lights) is not subject to this

requirement.

The control device shall be apparent, easy to reach and unmistakable. This control device shall be

activated by voluntary action.

Designs of the on/off symbol, lighting symbol and audible warning device symbol shall be in accordance

with Annex B.

5.3 Battery

The battery shall comply with EN 50604-1:2016 and EN 50604-1:2016/A1:2021. At the moment of the

publication of this standard, EN 50604-1 is only applicable for secondary lithium batteries, and only risks

related to these batteries were taken into account.

5.4 External battery charger

External battery chargers with output voltage below 60V DC shall comply with EN 60335-2-29. The user

shall be informed if the charger is designed for indoor or both indoor and outdoor use. Battery chargers

for indoor use only shall be marked with symbol IEC 60417-5957 (2004-12). Chargers for outdoor use

shall be labelled accordingly. In case chargers are designed and labelled for outdoor use, they shall be

rated at at least IP X4. Chargers for carrier cycles are considered to be operated in a residential

(household) environment.

5.5 Electric cables and couplers

5.5.1 General

All couplers for cable and wire shall be selected to prevent corrosion of electrical contact conductance.

5.5.2 Requirements

Cable and plug temperature shall be lower than that specified by the manufacturer of the cables and plugs.

Damage to cable and plug insulation shall be prevented.

The cable cross sections shall be selected in accordance to IEC 60335-1:2020, Table 11. If these

requirements are not met, a temperature rise test shall be performed, in accordance to 5.5.3.

Cables used exclusively for communication lines are excluded.

5.5.3 Test method

At an ambient room temperature (20 ± 5) °C, discharge the fully charged carrier EPAC battery to the

discharging limit specified by the carrier EPAC or ESA manufacturer at the maximum current allowable

by the system and record it. Measure the cable and plug temperatures and ensure, by examination, that

there is no deterioration of the insulation on either assembly.

The increase of outer surface temperature of parts that can be touched shall be ≤ 60 K while in use on

performance test rig.

5.6 Wiring

Requirements on wiring shall be checked according to the following sequence at an ambient room

temperature (20 ± 5) °C.

a) Wire ways shall be smooth and free from sharp edges.

b) Wires shall be protected so that they do not come into contact with burrs, cooling fins or similar

sharp edges that may cause damage to their insulation. Holes in metal through which insulated wires

pass shall have smooth well-rounded surfaces or be provided with bushings.

c) Wiring shall be effectively prevented from coming into contact with moving parts.

Compliance with a), b) and c) shall be checked by inspection.

d) Separate parts of the carrier EPAC that can move in normal use or during user maintenance relative

to each other, shall not cause undue stress to electrical connections and internal conductors,

including those providing ground continuity.

If an open coil spring is used to protect wire, it shall be correctly installed and insulated. Flexible metallic

tubes shall not cause damage to the insulation of the conductors contained within them.

Compliance with d) shall be checked by inspection and by the following test method:

— if flexing occurs in normal use, the appliance is placed in its normal operational position and is

supplied at rated voltage under normal operation;

— the movable part is moved backwards and forwards through the largest angle permitted by its

construction;

— for conductors that are flexed in normal use, flex movable part for 10 000 cycles at a test frequency

of 0,5 Hz;

— for conductors that are flexed during user maintenance, flex the movable part for 100 cycles at the

same frequency.

5.7 Power cables and conduits

Conduit entries, cable entries and knockouts shall be constructed or located so that the introduction of

the conduit or cable does not reduce the protection measures adopted by the manufacturer.

Compliance shall be checked by inspection.

Guidance for power cables size selection is given in HD 60364-5-52:2011, 5.22.1.2, 523.1, 523.3 and

Table A.

5.8 External and internal electrical connections

Electrical connection shall comply with HD 60364-5-52:2011, 526.1 and 526.2.

5.9 Moisture resistance

The electrical components of a fully assembled carrier EPAC and/or EPAC trailer shall be tested and shall

comply with at least IPX4 requirements according to EN 60529.

These requirements should be checked for each relevant component or unit of the carrier EPAC (e.g. the

handle assembly including the control switch, display, lamp and other electrical components, the drive

unit, the battery unit, etc.).

After the test no water shall be found in the components of the drive system

NOTE 1 The battery charger is not included in the electrical components of a fully assembled Carrier EPAC.

NOTE 2 If the carrier cycle is intended for specific wet conditions a higher IP degree may be necessary.

5.10 Mechanical strength test of the electrical components

5.10.1 General

The electrical components shall have adequate mechanical strength and be constructed to withstand such

rough handling that may be expected in normal use.

NOTE 1 For environmental test, see DIN SPEC 79009:2018-10.

5.10.2 Function related shock test

In accordance with EN 60068-2-27, half sine shocks shall be applied with a peak acceleration of 150 m/s

and a duration equal to the nominal impulse of 6 ms in both directions of each of the three perpendicular

axes. Number of shocks in each direction: (100 ± 3) shocks (a total of 600 shocks). After the test, the

performance of the components shall be fully maintained and no failure shall occur.

5.10.3 Impact related shock test - Lateral overturning

The impact related shock test shall be carried out on a fully assembled single track Carrier EPAC. The

Carrier EPAC shall be left to fall 5 times both to the left and to the right from its upright position. For this

purpose, the steering shall be aligned in the straightforward position, the ends of the handlebar shall be

fitted with handlebar grips or handlebar plugs, and cranks shall be aligned horizontally prior to each fall.

The test shall be carried out on a hard surface (concrete or sett).

After the test:

— electrical components shall not have any detachment, any tearing out or any breaking of fastening

elements;

— detachable electrical components shall not have any functional impairment (e.g. inserting and

removing the battery).

5.11 Maximum speed for which the electric motor gives assistance

5.11.1 Requirements

The electrical motor assistance shall stop when the carrier EPAC reaches a speed of 25 km/h or lower

speed if limited by design (design speed).

The maximum speed of the carrier EPAC for which the electric motor gives assistance shall not differ by

more than +10 % from the maximum assistance speed indicated in the marking required by

EN 17860-2:2024, Clause 19 “Marking” when determined according to the test method described in

5.11.2.

5.11.2 Test method

5.11.2.1 Test conditions

a) The test shall be performed either on a test track, a test bench or on a stand that keeps the motor

driven wheel free of the ground.

b) The speed-measuring device used for the test shall have the following characteristics:

1) accuracy: ± 2 %;

2) resolution: 0,1 km/h.

c) The ambient temperature shall be between 5 °C and 35 °C.

d) Maximum wind speed: 3 m/s.

e) The battery shall be fully charged according to the manufacturer instructions.

5.11.2.2 Test procedure

The cut-off speed shall be measured by measuring either the motor torque output or the motor current.

Other appropriate method the pertinence of which has been demonstrated shall be used.

The following example describes the cut-off speed test:

a) pre-condition the carrier EPAC by running it for 5 min at 80 % of the maximum assistance speed as

declared by the manufacturer;

b) record continuously the current and note the speed at which the current drops to a value equal to or

less than “no load current point”;

c) while pedalling, ride steadily to reach a speed equal to 1,25 times (if possible by design) the

maximum assistance speed as declared by the manufacturer;

d) verify that the noted value in b) is the no load current point;

e) instead of measuring the current, one may also measure the difference between the average road

power measured at the driven wheel(s) and the applied crank power. The cut off speed is reached

when the power applied to the wheel is less than or equal to the applied crank power.

5.12 Walk and manoeuvring assistance mode

5.12.1 Requirements

A carrier EPAC may be equipped with a walk and manoeuvring assistance mode.

Manoeuvring may include but is not limited to moving uphill, start-up and moving backwards.

This mode shall be activated by the voluntary and maintained action of the user. Conformity is checked

by the test described in 5.12.2.

A walk and manoeuvring assistance mode shall only operate up to a maximum speed of 6 km/h.

If there is a mechanical connection that forces the pedals to rotate backwards if the vehicle reverses and

the rider is not required to actively pedal backwards to activate the reverse mode an acoustical or visual

signal shall warn the user while the reverse mode is active and the maximum speed shall be limited to

3 km/h. Conformity is checked by the test described in 5.12.2.2.

5.12.2 Test method

5.12.2.1 Test conditions

a) The test may be performed either on a test track, a test bench or on a stand that keeps the motor

driven wheel free of the ground.

b) The speed-measuring device shall have the following characteristics:

1) accuracy: ± 2 %;

2) resolution: 0,1 km/h.

c) The ambient temperature shall be between 5 °C and 35 °C.

d) M-aximum wind speed: 3 m/s.

e) The battery shall be fully charged according to the manufacturer's instructions before starting the

test.

5.12.2.2 Test procedure walk and manoeuvring assistance mode

a) Activate the walk assistance mode and verify that the speed increases up to 6 km/h maximum

designed speed or lower value.

b) Verify that the speed reduces progressively to 0 km/h when the walk assistance mode is deactivated.

c) Activate the walk assistance mode and maintain it for 1 min.

d) Verify that speed is equal to or less than 6 km/h.

e) Verify that the walk assistance mode is activated only when the actuation of the device to initiate it

is maintained.

5.12.2.3 Test procedure reverse manoeuvring mode with backwards rotating pedals

a) Activate the walk assistance mode and verify that the speed increases up to 3 km/h maximum

designed speed or lower value.

b) Verify that the speed reduces progressively to 0 km/h when the walk assistance mode is deactivated.

c) Activate the walk assistance mode and maintain it for 30 s.

d) Verify that speed is equal to or less than 3 km/h.

e) Verify that the walk assistance mode is activated only when the actuation of the device to initiate it

is maintained.

f) Verify that the acoustic or visual warning signal is active while the reverse manoeuvring mode is

active.

5.13 Power management

5.13.1 Requirements

a) When tested by the method described in 5.13.2 the recordings shall show that pedal assistance shall

be provided only when the cyclist pedals forward. This requirement shall be checked according to

the test methods described in 5.13.2.3.

b) Pedal assistance shall be cut off when the cyclist stops pedalling forward and the cut-off distance

shall not exceed 2 m.

c) If all braking devices (e.g. levers, back pedal) are equipped with cut-off switches, the cut off distance

shall not exceed 5 m.

d) The power output shall be progressively reduced and finally cut off before the carrier EPAC reaches

the maximum assistance speed. This requirement shall be checked according to the test methods

described in 5.13.2.

e) The assistance shall be progressively and smoothly managed (e.g. no hunting). This also applies to

recuperation, if applicable.

f) Two independent applying actions shall be required to start the pedal assistance mode (e.g. power

switch and forward pedalling activation). A traffic caused stop (e.g. traffic lights) is not subject to this

requirement.

g) After a deactivation of the electrical assistance mode due to any hazardous electric drive malfunction,

the electric drive shall not start automatically without rider intervention (pedalling is not considered

as rider intervention).

5.13.2 Test method – Auxiliary electric motor management

5.13.2.1 Test conditions

a) The test may be performed either on a test track, a test bench or on a stand which keeps the wheel

driven by the auxiliary electric motor free of the ground.

b) The test track shall be according to 5.13.2.2.

c) The time-measuring device shall have an accuracy of ± 2 %.

d) The ambient temperature shall be between 5 °C and 35 °C.

e) Maximum wind speed shall not exceed 3 m/s.

f) The battery shall be fully charged according to the manufacturer's instructions.

g) Speed measurement shall have an accuracy of ± 2 %.

The test to ensure the compliance to this clause shall be adapted to the technology used; for example:

— pedal backwards and check the no load current point;

or

— pedal backwards and check that no torque is delivered on the driving wheel.

For the test, the worst case conditions of gear ratio and speed shall be applied. The worst condition for

speed is defined as 90 % of cut off speed.

Pedalling backwards for reverse manoeuvring in accordance with 5.12 is accepted.

5.13.2.2 Test track

The gradient of the track shall not exceed 0,5 %. If the gradient is less than 0,2 %, all runs shall be done

in the same direction. If the gradient lies between 0,2 % and 0,5 %, alternate runs shall be done in

opposite directions.

The surface shall be hard, of concrete or fine asphalt free from loose dirt or gravel. The minimum

coefficient of friction between the dry surface and the cycle tyre shall be 0,75.

5.13.2.3 Test procedure

a) Pedal backwards and check that no auxiliary electric motor assistance is provided. The test to ensure

the compliance to this clause shall be adapted to the technology used. Pedalling backwards for reverse

manoeuvring in accordance with 5.12 is accepted.

b) Check the cut off distance of 2 m when the cyclist stop pedalling:

1) pedal so that the carrier EPAC reach 90 % of the cut off speed;

2) stop pedalling without braking;

3) measure the cut off distance;

4) carry out the test 3 times; the result is the average of this measurement after rejection of invalid

points.

c) If braking device cut-off switches are fitted, actuate each brake device separately and check the cut off

distance of 5 m:

1) pedal so that the carrier EPAC reach 90 % of the cut off speed;

2) actuate the brake and then stop pedalling;

3) measure the cut off distance;

4) carry out the test 3 times; the result is the average of this measurement after rejection of invalid

point

5.14 Measurement of the maximum continuous rated power

5.14.1 Requirements

The maximum continuous rated power of the auxiliary electric motor shall not exceed 0,25 kW when the

auxiliary electric motor reaches its thermal equilibrium.

In case the carrier EPAC is equipped with several motors, the sum power of all motors shall not exceed

the maximum continuous rated power of the auxiliary electric motor of 0,25 kW. The thermal equilibrium

is always determined separately for each motor.

NOTE Thermal equilibrium: temperatures of motor parts do not vary more than 2 K per hour.

The measurement of the maximum continuous rated power shall be performed either by the

measurement in 5.14.2 or the alternative measurement in 5.14.3 and Annex D.

The acceptable tolerance shall be 10% of the maximum continuous rated power.

5.14.2 Measurement

The maximum continuous rated power of the auxiliary electric motor shall be determined by deducting

the applied crank power from the measured output power at the driven wheel(s) of the carrier EPAC in

accordance with IEC 60034-1 when the auxiliary electric motor reaches its thermal equilibrium as

specified by the manufacturer.

5.14.3 Alternative measurement

When the power is measured at the wheel, the result of the measurement is the reading value.

Example of a verification method is given in, but not limited to informative Annex D.

5.15 Electromagnetic compatibility

5.15.1 Emission

The carrier EPAC shall fulfil the EPAC requirements of Annex A. The ESA may fulfil the EPAC requirements

of Annex A when mounted on a representative Carrier EPAC. The ESA tests in Annex A serve as single

ESA characterization tests, only.

The requirements shall be met in all kinds of operating mode (e.g. cycling mode, standstill mode, walk

assistance mode, charging mode). Regardless of the primary power supply technology used for traction

purposes, at least one of these operation modes shall include the simultaneous operation of all power

technologies (or a combination of supplies as specified by the manufacturer, but covering the use of all

power supply technologies), unless they are designed to be used not simultaneously. In those cases, the

EPAC requirements of Annex A extend for each primary supply mode separately.

The carrier EPAC requirements when the carrier EPAC is connected to the mains grid are covered in

5.15.3.

For some carrier EPACs, additional operating modes could be riding above 25 km/h or riding with an

empty battery.

5.15.2 Immunity

The carrier EPAC shall fulfil the EPAC requirements of Annex A. The ESA may fulfil the EPAC requirements

of Annex A when mounted on a representative carrier EPAC. The ESA tests in Annex A serve as single ESA

characterization tests, only.

The requirements shall be met in all kinds of operating mode (e.g. cycling mode, standstill mode, walk

assistance mode, charging mode). Regardless of the primary power supply technology used for traction

purposes, at least one of these operation modes shall include the simultaneous operation of all power

technologies (or a combination of supplies as specified by the manufacturer, but covering the use of all

power supply technologies), unless they are designed to be used not simultaneously. In those cases, the

EPAC requirements of Annex A extend for each primary supply mode separately.

The carrier EPAC requirements when the carrier EPAC is connected to the mains grid are covered in

5.15.3.

5.15.3 Carrier EPAC in mains charging mode

Carrier EPAC in mains charging mode (mains charger connected to the carrier EPAC) shall comply with

the requirements of EN IEC 61000-6-1 and EN IEC 61000-6-3.

In case the carrier EPAC has a separate mains charger, this configuration shall be tested as combination

of table top equipment (mains charger) and ungrounded floor standing equipment (carrier EPAC).

Integrated mains chargers shall be tested as ungrounded floor standing equipment.

When testing a combination of table top (mains charger) and ungrounded floor standing equipment

(carrier EPAC) any excess cable shall be routed to the ground-plane, insulated from it, and z-folded to a

maximum width of 0,5 m. The horizontal projection distance between the carrier EPAC socket and the

mains network shall be between 0,8 m and 1 m. The general requirements of cabling on the mains side of

the mains charger apply.

For constructions allowing to mains charge the battery removed from the carrier EPAC, this set up should

also comply with the requirements of EN IEC 61000-6-1 and EN IEC 61000-6-3.

5.16 Failure mode

5.16.1 Acoustical and / or visual warning

5.16.1.1 Requirements

The carrier EPAC shall be equipped with a dedicated system that warns the user acoustically and / or

visually before and when the assistance is cut off due to discharge. Before complete battery discharge,

acoustic and/or visual warning signals shall indicate the decreasing state of charge (SOC) and the

assistance power shall be reduced gradually (not abruptly).

The level of battery SOC at which an audible and/or visual warning is given and subsequently the

assistance is reduced or switched off due to discharge shall be determined according to the principles of

EN ISO 12100. The value shall be declared by the manufacturer.

The audible signals may be temporarily deactivated by the user at any time after they occur by a

deliberate action. As soon as the next escalation level has been reached, the acoustic signals shall

reactivate automatically without any action by the user.

5.17 Anti-tampering measures

CEN/TS 17831:2023 applies, with the following additions

a) The provisions in the CEN/TS 17831:2023 also apply to carrier EPAC and EPACT

b) for EPACT the following is added to 4.2 (Requirements for powertrain anti-tampering)

1) maximum speed for handcart mode of trailers;

2) the requirement that motor assistance shall be provided only when the trailer is moved

forward by the towing cycle, except when in handcart mode.

5.18 Thermal hazards

5.18.1 Non-continuous contact surface

Warning symbol W017 in accordance with EN ISO 7010 shall be placed on the surface, if the temperature

of the non-continuous contact surface can be above the limits of 1 s contact period defined in

ISO 13732-1. Brake systems are excluded from this requirement.

NOTE A non-continuous contact surface is a surface on a carrier EPAC which has a possibility of touching the

rider’s hands, legs etc. during normal use and maintenance.

5.18.2 Continuous contact surface

Continuous contact surface of at least 10 min contact period shall not exceed the temperature lim

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...