SIST EN 50617-2:2015

(Main)Railways applications - Basic parameters of train detection systems - Part 2: Axle counters

Railways applications - Basic parameters of train detection systems - Part 2: Axle counters

This European Standard specifies parameters for the design and usage of Axle counter systems.

For this, the standard specifies the technical parameters of Axle Counter systems associated with the magnetic field limits for RST in the context of interoperability. In addition test methods are defined for establishing the conformity and the performance of axle counter products.

The specified parameters are structured and allocated according to their basic references as follows:

- Axle counter system parameters

- Train based parameters

- Track based parameters

- Environmental and other parameters

Each parameter is defined by a short general description, the definition of the requirement, the relation to other standards and a procedure to show the fulfilment of the requirement as far as necessary. An overview on the safety relevance of each parameter is given in the context of this European Standard in a separate table.

This European Standard is intended to be used to assess compliance of axle counter systems and other forms of Wheel Sensors used for train detection, in the context of the Interoperability Directive and the associated technical specification for interoperability relating to the control-command and signalling track-side subsystems.

The bands and rolling stock emission limits are currently defined in the Axle Counter FRM as specified in the CCS TSI Index 77.

Bahnanwendungen - Basic Parameters der Gleisfreimeldesystemen - Teil 2: Achszähler

Applications ferroviaires - Paramètres de base des systèmes de détection des trains - Partie 2 : Compteurs d'essieux

Železniške naprave - Osnovni parametri sistemov za detekcijo vlakov - 2. del: Števci osi

Ta evropski standard določa parametre za zasnovo in uporabo sistemov števcev osi. V ta namen standard določa tehnične parametre sistemov števcev osi, povezanih z omejitvami magnetnih polj za RST v okviru interoperabilnosti. Poleg tega so določene preskusne metode za ugotavljanje skladnosti in delovanja proizvodov, povezanih s števci osi.

Opredeljeni parametri so strukturirani in dodeljeni v skladu z njihovimi osnovnimi sklicevanji, kot sledi:

– parametri sistemov števcev osi;

– parametri na podlagi vlaka;

– parametri na podlagi tirov;

– okoljski in drugi parametri.

Vsak parameter je opredeljen s kratkim splošnim opisom, definicijo zahteve, povezavo z drugimi standardi in postopkom za prikaz izpolnitve zahteve, kolikor je potrebno. Pregled varnostnega pomena vsakega parametra je v okviru tega evropskega standarda podan v ločeni tabeli.

Ta evropski standard je namenjen uporabi za oceno skladnosti sistemov števcev osi in drugih oblik senzorjev na kolesih, ki se uporabljajo za detekcijo vlakov, v okviru evropske direktive o interoperabilnosti vseevropskega železniškega sistema in povezane tehnične specifikacije za interoperabilnost, ki se nanaša na podsistema za upravljanje-vodenje in signaliziranje ob progi.

Frekvenčni pasovi in omejitve emisij železniških vozil so trenutno opredeljeni v okviru upravljanja s frekvencami, kot je določeno v indeksu 77 CCS TSI.

General Information

- Status

- Published

- Public Enquiry End Date

- 12-Dec-2013

- Publication Date

- 28-Jul-2015

- Technical Committee

- ŽEN - Electrical applications for railways

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 15-Jun-2015

- Due Date

- 20-Aug-2015

- Completion Date

- 29-Jul-2015

Relations

- Effective Date

- 08-Dec-2015

- Effective Date

- 01-Feb-2025

Overview

EN 50617-2:2015 - Railway Applications: Technical parameters of train detection systems - Part 2: Axle counters - is a CENELEC (CLC) European Standard that defines technical parameters, test methods and conformity criteria for axle counter systems used in the trans‑European railway system. The standard establishes design and usage requirements in the context of the Interoperability Directive and the CCS TSI (Index 77) frequency/EMC framework, with particular emphasis on magnetic field limits, immunity and performance validation.

Key topics and requirements

- Scope and structure: parameters are organised as Axle counter system parameters, Train‑based parameters, Track‑based parameters, and Environmental & other parameters.

- RAMS considerations: Reliability, Availability, Maintainability, Safety and specific indicators such as rate of miscounts and availability requirements.

- Immunity to magnetic fields: in‑band and out‑of‑band immunity levels, derivation of requirements and compatibility margins relative to rolling stock emissions.

- Immunity to traction and short‑circuit currents, harmonics and ETCS telepowering fields; procedures to check susceptibility caused by currents in the rails.

- Sensor and signal requirements: sensor position integrity control, integration time and filter bandwidth considerations for axle counter detectors (ACD).

- Track & vehicle influences: wheel and vehicle parameters, material properties in detection area (metal‑free space), rail fittings, sleeper materials, slab track effects, and magnetic brakes/eddy‑current brakes.

- Environmental and mechanical limits: temperature, humidity, vibration/shock, contamination, sealing, solar radiation, overvoltage and EMC validation.

- Test methods and equipment: Annex C defines antennas, test setups, measurement accuracy, homogeneous/inhomogeneous field tests, transient/intermittent immunity tests and required test reporting.

- Frequency management: Annex B reproduces CCS TSI frequency/band allocation and rolling stock emission references.

Applications and users

Who uses EN 50617-2:2015:

- Railway signalling and control engineers specifying axle counter systems for interoperable networks

- Manufacturers and designers of axle counters and wheel sensors for design verification

- Test laboratories and certification bodies performing immunity, EMC and performance tests

- Infrastructure managers and systems integrators assessing product compliance with CCS TSI and the Interoperability Directive Practical uses include system design, procurement specifications, conformity assessment, EMC test planning, and acceptance testing of trackside detection equipment.

Related standards

- CCS TSI (Index 77) - frequency management and rolling stock emission references

- Other parts of EN 50617 (basic parameters for train detection systems) and applicable EMC, signalling and interoperability standards referenced in the normative section

Keywords: EN 50617-2:2015, axle counters, train detection systems, interoperability, CCS TSI, magnetic field immunity, railway signalling, RAMS, EMC testing.

Frequently Asked Questions

SIST EN 50617-2:2015 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Railways applications - Basic parameters of train detection systems - Part 2: Axle counters". This standard covers: This European Standard specifies parameters for the design and usage of Axle counter systems. For this, the standard specifies the technical parameters of Axle Counter systems associated with the magnetic field limits for RST in the context of interoperability. In addition test methods are defined for establishing the conformity and the performance of axle counter products. The specified parameters are structured and allocated according to their basic references as follows: - Axle counter system parameters - Train based parameters - Track based parameters - Environmental and other parameters Each parameter is defined by a short general description, the definition of the requirement, the relation to other standards and a procedure to show the fulfilment of the requirement as far as necessary. An overview on the safety relevance of each parameter is given in the context of this European Standard in a separate table. This European Standard is intended to be used to assess compliance of axle counter systems and other forms of Wheel Sensors used for train detection, in the context of the Interoperability Directive and the associated technical specification for interoperability relating to the control-command and signalling track-side subsystems. The bands and rolling stock emission limits are currently defined in the Axle Counter FRM as specified in the CCS TSI Index 77.

This European Standard specifies parameters for the design and usage of Axle counter systems. For this, the standard specifies the technical parameters of Axle Counter systems associated with the magnetic field limits for RST in the context of interoperability. In addition test methods are defined for establishing the conformity and the performance of axle counter products. The specified parameters are structured and allocated according to their basic references as follows: - Axle counter system parameters - Train based parameters - Track based parameters - Environmental and other parameters Each parameter is defined by a short general description, the definition of the requirement, the relation to other standards and a procedure to show the fulfilment of the requirement as far as necessary. An overview on the safety relevance of each parameter is given in the context of this European Standard in a separate table. This European Standard is intended to be used to assess compliance of axle counter systems and other forms of Wheel Sensors used for train detection, in the context of the Interoperability Directive and the associated technical specification for interoperability relating to the control-command and signalling track-side subsystems. The bands and rolling stock emission limits are currently defined in the Axle Counter FRM as specified in the CCS TSI Index 77.

SIST EN 50617-2:2015 is classified under the following ICS (International Classification for Standards) categories: 45.020 - Railway engineering in general. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 50617-2:2015 has the following relationships with other standards: It is inter standard links to SIST EN 50617-2:2015/AC:2016, SIST EN 50617-2:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 50617-2:2015 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC, 2016/797/EU; Standardization Mandates: M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 50617-2:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2015

Železniške naprave - Osnovni parametri sistemov za detekcijo vlakov - 2. del:

Števci osi

Railways applications - Basic parameters of train detection systems - Part 2: Axle

counters

Bahnanwendungen - Basic Parameters der Gleisfreimeldesystemen - Teil 2: Achszähler

Applications ferroviaires - Paramètres de base des systèmes de détection des trains -

Partie 2 : Compteurs d'essieux

Ta slovenski standard je istoveten z: EN 50617-2:2015

ICS:

45.020 Železniška tehnika na Railway engineering in

splošno general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD EN 50617-2

NORME EUROPÉENNE

EUROPÄISCHE NORM

April 2015

ICS 29.280

English Version

Railway Applications - Technical parameters of train detection

systems for the interoperability of the trans-European railway

system - Part 2: Axle counters

Applications ferroviaires - Paramètres techniques des Bahnanwendungen - Technische Parameter von

systèmes de détection des trains - Partie 2: Compteurs Gleisfreimeldesystemen - Teil 2: Achszähler

d'essieux

This European Standard was approved by CENELEC on 2015-03-09. CENELEC members are bound to comply with the CEN/CENELEC

Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC

Management Centre or to any CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CENELEC member into its own language and notified to the CEN-CENELEC Management Centre has the

same status as the official versions.

CENELEC members are the national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, the Czech Republic,

Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia,

Lithuania, Luxembourg, Malta, the Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

European Committee for Electrotechnical Standardization

Comité Européen de Normalisation Electrotechnique

Europäisches Komitee für Elektrotechnische Normung

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2015 CENELEC All rights of exploitation in any form and by any means reserved worldwide for CENELEC Members.

Ref. No. EN 50617-2:2015 E

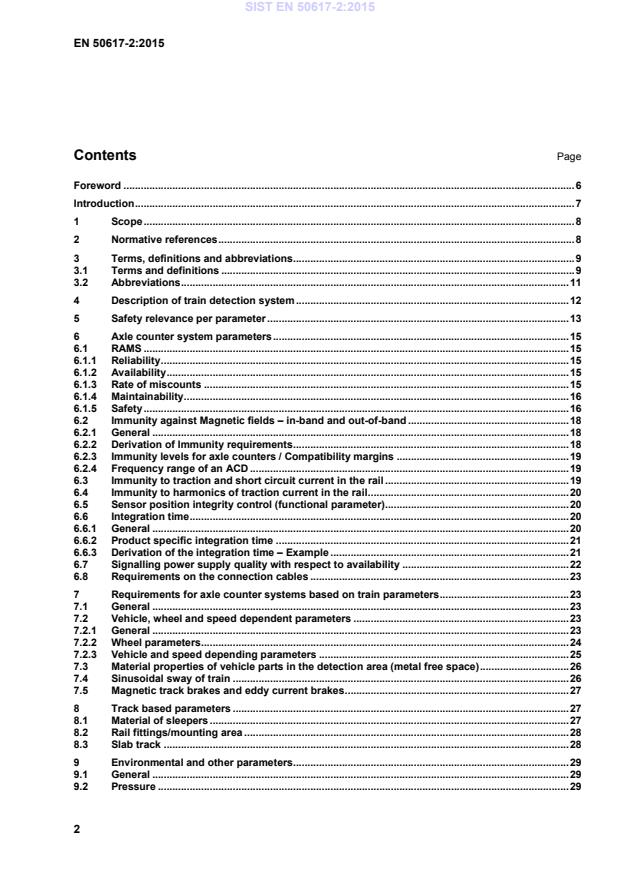

Contents Page

Foreword . 6

Introduction . 7

1 Scope . 8

2 Normative references . 8

3 Terms, definitions and abbreviations . 9

3.1 Terms and definitions . 9

3.2 Abbreviations . 11

4 Description of train detection system . 12

5 Safety relevance per parameter . 13

6 Axle counter system parameters . 15

6.1 RAMS . 15

6.1.1 Reliability . 15

6.1.2 Availability . 15

6.1.3 Rate of miscounts . 15

6.1.4 Maintainability . 16

6.1.5 Safety . 16

6.2 Immunity against Magnetic fields – in-band and out-of-band . 18

6.2.1 General . 18

6.2.2 Derivation of Immunity requirements . 18

6.2.3 Immunity levels for axle counters / Compatibility margins . 19

6.2.4 Frequency range of an ACD . 19

6.3 Immunity to traction and short circuit current in the rail . 19

6.4 Immunity to harmonics of traction current in the rail . 20

6.5 Sensor position integrity control (functional parameter). 20

6.6 Integration time . 20

6.6.1 General . 20

6.6.2 Product specific integration time . 21

6.6.3 Derivation of the integration time – Example . 21

6.7 Signalling power supply quality with respect to availability . 22

6.8 Requirements on the connection cables . 23

7 Requirements for axle counter systems based on train parameters . 23

7.1 General . 23

7.2 Vehicle, wheel and speed dependent parameters . 23

7.2.1 General . 23

7.2.2 Wheel parameters . 24

7.2.3 Vehicle and speed depending parameters . 25

7.3 Material properties of vehicle parts in the detection area (metal free space) . 26

7.4 Sinusoidal sway of train . 26

7.5 Magnetic track brakes and eddy current brakes . 27

8 Track based parameters . 27

8.1 Material of sleepers . 27

8.2 Rail fittings/mounting area . 28

8.3 Slab track . 28

9 Environmental and other parameters . 29

9.1 General . 29

9.2 Pressure . 29

9.3 Movement of surrounding air . 29

9.4 Ambient temperatures . 29

9.4.1 General . 29

9.4.2 Ambient temperature for axle counter evaluator equipment . 30

9.4.3 Ambient temperature for ACD (without axle counter sensor) . 30

9.4.4 Ambient temperature for axle counter sensor . 30

9.5 Humidity . 30

9.6 Precipitation . 31

9.7 Sealing of housing . 31

9.8 Solar radiation . 31

9.9 Overvoltage protection (incl. indirect lightning effects) . 32

9.10 Contamination . 32

9.10.1 General . 32

9.10.2 In the track, nearby the track . 32

9.10.3 Indoor. 32

9.11 Fire Protection . 32

9.12 Vibrations / shock . 33

9.13 EMC . 33

9.13.1 General . 33

9.13.2 Requirement and validation for EMC . 33

9.14 Definition of Influence from other components . 33

Annex A (informative) Design guide for measurement antennas . 34

A.1 Measurement antennas characteristics . 34

A.2 Termination impedance . 34

Annex B (normative) Frequency Management (reproduced from CCS TSI, Index 77) . 36

Annex C (normative) Test Equipment, test methodologies and reports to be performed . 38

C.1 Test equipment . 38

C.1.1 Antenna for generating magnetic fields (FGA) . 38

C.1.2 Reference antenna . 39

C.1.3 Test signal generator . 39

C.2 Test conditions . 39

C.2.1 Equipment under test (EUT) . 39

C.2.2 Susceptibility criteria . 39

C.3 Accuracy of magnetic field measurement . 40

C.4 Test methodology to determine immunity (susceptibility border of ACD) to homogenous

fields – in-band . 40

C.4.1 General . 40

C.4.2 Test set up for X-Z direction . 41

C.4.3 Test set up for Y-Z direction . 41

C.4.4 Test procedure to determine immunity to homogenous steady state fields . 42

C.4.5 Transient immunity test / Immunity to intermittent interference . 43

C.4.6 Immunity within the filter bandwidth of the EUT . 46

C.5 Test methodology to determine immunity to inhomogeneous fields – in band . 46

C.5.1 General . 46

C.5.2 Test set-up for the movement in X-direction . 47

C.5.3 Test set-up for the movement in Y-direction . 48

C.5.4 Test procedure . 49

C.6 Test methodology for establishing immunity to fields produced by in-band interference

currents in the rail . 50

C.6.1 General . 50

C.6.2 Test set-up . 51

C.6.3 Test procedure . 52

C.7 Test methodology for out of-band measurements . 52

C.8 Immunity to ETCS telepowering fields . 52

C.8.1 General . 52

C.8.2 Limits and requirements . 53

C.8.3 Test methodology to check immunity to ETCS telepowering fields . 53

C.9 Test report . 57

C.10 Test results according to CCS TSI Index 77 . 58

C.10.1 General . 58

C.10.2 In-band . 58

C.10.3 Out-band (10 kHz to 1,3 MHz) . 58

Annex ZZ (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 2008/57/EC . 59

Bibliography . 63

Figures

Figure 1 – System boundary of an axle counter system . 12

Figure 2 – Correlation between hazard rate and time between trains . 17

Figure 3 – Areas for evaluation . 19

Figure 4 – Immunity versus duration of interference field . 21

Figure 5 – ACD immunity as a function of time duration of in-band disturbance . 22

Figure 6 – Filter curves measured and calculated . 22

Figure 7 – Definition of the parameters . 24

Figure 8 – Axle to axle distance . 26

Figure 9 – Definition of sinusoidal sway . 27

Figure A.1 – Side view (Y and Z coils, dimensions 50 mm to 150 mm) . 34

Figure B.1 – Areas for evaluation . 37

Figure C.1 – Homogenity of field generation antenna (FGA) . 39

Figure C.2 – ACD, schematic diagram . 40

Figure C.3 – Test set-up for homogeneous fields in X-Z-direction (front view for α = 0°) . 41

Figure C.4 – Test set-up for homogeneous fields in X-Z-direction (side view for α = 0°) . 41

Figure C.5 – Test set-up for homogeneous fields in Y-Z-direction (front view) . 42

Figure C.6 – Test set-up for homogeneous fields in Y-Z-direction (side view for α = 0°) . 42

Figure C.7 – ACD response to intermittent sinusoidal waves . 44

Figure C.8 – Test set-up for inhomogeneous field tests in X-direction (side view) . 47

Figure C.9 – Test set-up for inhomogeneous field tests in X-direction (front view) . 48

Figure C.10 – Test set-up for inhomogeneous field tests in Y-direction (side view) . 48

Figure C.11 – Test set-up for inhomogeneous field tests in Y-direction (front view) . 49

Figure C.12 – FGA movement / field distribution for inhomogeneous field tests . 50

Figure C.13 – Test set-up for rail current tests . 51

Figure C.14 – Frequency mask . 53

Figure C.15 – Influence zones of magnetic fields . 54

Figure C.16 – Test setup . 55

Figure C.17 – Test set-up for conducted immunity testing . 56

Tables

Table 1 – Overview of safety relevance in the subclauses . 14

Table B.1 – Emission limits and evaluation parameters (narrow band) . 36

Table B.2 – Increased magnetic field limits . 37

Foreword

This document (EN 50617-2:2015) has been prepared by CLC/SC 9XA "Communication, signalling and

processing systems" of CLC/TC 9X "Electrical and electronic applications for railways".

The following dates are fixed:

• latest date by which this document has to be (dop) 2016-03-09

implemented at national level by publication of

an identical national standard or by

endorsement

(dow) 2018-03-09

• latest date by which the national standards

conflicting with this document have to

be withdrawn

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CENELEC [and/or CEN] shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a mandate given to CENELEC by the European Commission and

the European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive 2008/57/EC amended by Commission Directive 2011/18/EU, see

informative Annex ZZ, which is an integral part of this document.

This document is Part 2 of the EN 50617 series, which consists of the following parts under the common title

"Railway Applications - Technical parameters of train detection systems”:

- Part 1: Track circuits;

- Part 2: Axle counters.

Introduction

The working group CENELEC/SC9XA WGA4-2 has developed the limits for electromagnetic compatibility

between rolling stock and train detection systems, specifically track circuits and axle counter systems, and

correspondingly published two technical specifications: CLC/TS 50238-2 and CLC/TS 50238-3. These limits

and associated measurement methods are based on characteristics of existing systems that are well

established and still put forward for signalling renewals by infrastructure managers.

To meet the requirements for compatibility between train detection systems and rolling stock in the future and

to achieve interoperability and free movement within the European Union, it is necessary to define a “FrM” and

a complete set of interface requirements.

Track circuits and axle counter systems, are an integral part of the CCS trackside subsystem in the context of

the Rail Interoperability Directive. The relevant basic parameters are enumerated in the CCS and LOC&PAS

TSI and specified in the mandatory Specification CCS TSI Index 77 “Interfaces between Control-Command

and Signalling Trackside and other Subsystems”. This standard refers whenever needed to the mandatory

specification.

The already published specifications CLC/TS 50238-2 and CLC/TS 50238-3 can be used to ascertain

conformity of individual train detection systems to the requirements of the TSIs and to the Notified National

Rules, which will be in place for the parameters still declared “open points” in CCS TSI Index 77.

The requirements defined in this standard are either compliant with those of CCS TSI Index 77 or can be used

as input information for the closure of open points of the CCS TSI Index 77. Where applicable, the standard

should refer to the rolling stock FrM in the TSI CCS and the parameter values defined in the CCS TSI Index

77.

1 Scope

This European Standard specifies parameters for the design and usage of axle counter systems.

For this, the standard specifies the technical parameters of axle counter systems associated with the magnetic

field limits for RST in the context of interoperability. In addition test methods are defined for establishing the

conformity and the performance of axle counter products.

The specified parameters are structured and allocated according to their basic references as follows:

- Axle counter system parameters

- Train based parameters

- Track based parameters

- Environmental and other parameters

Each parameter is defined by a short general description, the definition of the requirement, the relation to

other standards and a procedure to show the fulfilment of the requirement as far as necessary. An overview

on the safety relevance of each parameter is given – in the context of this European Standard – in a separate

table.

This European Standard is intended to be used to assess compliance of axle counter systems and other

forms of wheel sensors used for train detection, in the context of the European Directive on the interoperability

of the trans-European railway system and the associated technical specification for interoperability relating to

the control-command and signalling track-side subsystems.

The frequency bands and rolling stock emission limits are currently defined in the axle counter FrM as

specified in the CCS TSI Index 77.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

EN 50121-4, Railway applications — Electromagnetic compatibility — Part 4: Emission and immunity of the

signalling and telecommunications apparatus

EN 50124-2, Railway applications — Insulation coordination — Part 2: Overvoltages and related protection

EN 50125-3:2003, Railway applications — Environmental conditions for equipment — Part 3: Equipment for

signaling and telecommunications

EN 50126 (all parts), Railway applications — The specification and demonstration of Reliability, Availability,

Maintainability and Safety (RAMS)

EN 50128, Railway applications — Communication, signalling and processing systems — Software for railway

control and protection systems

EN 50129, Railway applications — Communications, signalling and processing systems — Safety related

electronic systems for signalling

EN 50238-1, Compatibility between rolling stock and train detection systems — Part 1: General

EN 60068-2-1, Environmental testing — Part 2-1: Tests — Tests A: Cold (IEC 60068-2-1)

EN 60068-2-2, Environmental testing — Part 2-2: Tests — Test B: Dry heat (IEC 60068-2-2)

EN 60068-2-30, Environmental testing — Part 2-30: Tests - Test Db: Damp heat, cyclic (12 h + 12 h cycle)

(IEC 60068-2-30)

EN 60529, Degrees of protection provided by enclosures (IP Code) (IEC 60529)

EN 61000 (all parts), Electromagnetic compatibility (EMC) (IEC 61000, all parts)

CCS TSI Index 77, ERTMS/ETCS UNIT — Interfaces between control-command and signalling trackside and

other subsystems

UNISIG SUBSET-023, Glossary of UNISIG Terms and Abbreviations

UNISIG SUBSET-036, FFFIS for Eurobalise

UNISIG SUBSET-085, Test Specification for Eurobalise FFFIS

3 Terms, definitions and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

antenna for generating magnetic fields

square loop antenna to generate the magnetic fields for testing of the immunity

3.1.2

axle counter detector (ACD)

detector consisting of the axle counter sensor and of the detection circuit, which includes in general filters and

rectifiers

3.1.3

axle counter sensor

sensor head mounted in the track

3.1.4

axle counter system

whole system including the axle counter detector ACD with its sensor, and the evaluation unit

3.1.5

bandwidth

difference between the upper and lower frequencies in a contiguous set of frequencies and is typically

measured in Hz

3.1.6

direct safety relevant

failure results in a wrong side failure

3.1.7

equipment under test

test object is the set of ACD connected to a rail

3.1.8

immunity level

maximum level of interfering signal at which the correct operation of the equipment is granted to be in line with

expectations

3.1.9

in-band

working frequency area of an ACD

3.1.10

indirect safety relevant

every not autocorrected fault count will lead to a reset of the section, which itself is a safety issue

Note 1 to entry: These faults are indirectly safety relevant.

3.1.11

inflection point

defines the transition between the static (continuous wave) and dynamic immunity (short duration) behaviour

of the ACD

3.1.12

integration time

parameter for evaluation defined as the window size over which the root mean square (rms) of the output of

the band-pass filter is calculated

3.1.13

measurement antenna

antenna, mounted on the rail to capture magnetic field

Note 1 to entry: The measurement covers the axes X, Y and Z.

3.1.14

out-of-band

frequency bands out of the working frequency area of an ACD

3.1.15

right side failure

failure of a signalling system which results in a more restrictive condition for the movement of traffic than is

appropriate

3.1.16

sinusoidal sway

maximum movement of a wheel in y-direction with the running of a train in relation to the inner flange of the

rail head

3.1.17

working frequency range

frequency area or field where the sensors are operating

3.1.18

wrong side failure

failure of a signalling system which results in a less restrictive condition for the movement of traffic than is

appropriate

3.2 Abbreviations

For the purposes of this document, the following abbreviations apply.

ACD axle counter detector

AM amplitude modulation

CCS control-command and signalling

DC direct current

EMC electromagnetic compatibility

ERTMS European Rail Traffic Management System

ETCS European Train Control System

EUT equipment under test

FFFIS form fit functional interface specification

FGA field generating antenna

FrM frequency management

FSK frequency shift key

HR hazard rate

IR Infrared (electromagnetic radiation)

IP(xx) ingress protection (rating)

LC inductor/capacitor resonant circuit

MA measurement antenna

MIZ metallic influencing zone

MTBF mean time between failure

MTTR mean time to repair

PS power supply

rms root mean square

RSF right side failure

RST rolling stock

TEU trackside electronic unit

THR tolerable hazard rate

TSI technical specification for interoperability

UV Ultraviolet (electromagnetic radiation)

WSF wrong side failure

4 Description of train detection system

Train detection systems for route proving as a fully automatic train detection system are integrated into railway

signalling and safety systems. The train detection is part of the route proving procedure contributing to a safe

and reliable railway operation.

The train detection equipment provides information about whether track sections are clear of or occupied by

rail vehicles.

Axle counting systems operate on the principle of difference calculation. The evaluation unit evaluates the

signals received from each counting head associated with a section, compares the number of axles which

have entered the train detection section with the number of axles which have left this section and generates a

"track clear" or "track occupied" indication.

The figure below defines the system boundaries of a train detection system using axle counter systems:

Figure 1 – System boundary of an axle counter system

5 Safety relevance per parameter

There are two degrees of safety relevance which may be assigned to the technical parameters of axle counter

systems:

NOTE The issue safety relevance is defined in general in EN 50126 and EN 50129 (see also 6.1.5). The information

below is given only with respect to the parameters defined in this document.

- Direct safety relevant parameters:

Failure to meet the direct safety relevant requirement can result directly in a wrong side failure.

- Indirect safety relevant parameters:

Failure to meet the indirect safety relevant requirement may cause a right side failure, but may result

in the occurrence of a second failure or human error which could subsequently lead to an accident.

Indirect safety relevant parameters are generally availability related. A deviation may result in a reset being

required. Human error may then lead to an accident.

The consequences of right side failures and errors shall therefore be evaluated in the context of risk analysis

and appropriately mitigated in the equipment and system design, and in the operational rules.

Table 1 – Overview of safety relevance in the subclauses

Direct

Subclause safety Explanation

relevance

6.1.2 Availability no Part of the fail-safe behaviour of axle counter system

Not following the established maintenance regime can

6.1.4 Maintainability no lead to RSF and potentially increase the risk of a WSF in

certain cases.

Safety criteria and safely level form determine the safety

6.1.5 Safety yes

concept and design of the axle counter system.

6.2 Immunity against Magnetic

no

fields – in-band and out-of-band

C.4.5.3 Immunity to multiple

no

transients

The parameter is safety related, as it influences the

6.1.5.2 Maximum time between

no reliability. Exceedances do not lead directly to a hazard,

trains

however, the probability of WSF increases with time.

6.3 Immunity to traction and short

no

circuit current in the rail

6.4 Immunity to harmonics of

no

traction current in the rail

A sensor position integrity control is required to detect if an

6.5 Sensor position integrity

yes axle counter sensor has become detached from the rail

control (functional parameter)

and is not able to detect wheels.

Exceedances may cause a reliability problem which will be

6.6 Integration time no

detected by the axle counter system.

6.7 Signalling power supply quality Exceedances may cause a reliability problem which will be

no

with respect to availability detected by the axle counter system.

6.8 Requirements on the Exceedances may cause a reliability problem which will be

no

connection cables detected by the axle counter system.

7.2 Vehicle, wheel and speed Wheel dimensions which do not meet these requirements

yes

dependent parameters may lead to the wheel not being detected.

7.3 Material properties of vehicle

Exceedances may cause a reliability problem which will be

parts in the detection area (metal no

detected by the axle counter system.

free space)

Exceedances may cause a reliability problem which will be

7.4 Sinusoidal sway of train no

detected by the axle counter system.

7.5 Magnetic track brakes and Exceedances may cause a reliability problem which will be

no

eddy current brakes detected by the axle counter system.

Exceedances maycause a reliability problem which will be

8.1 Material of sleepers no

detected by the axle counter system.

Exceedances may cause a reliability problem which will be

8.2 Rail fittings/mounting area no

detected by the axle counter system.

Exceedances may cause a reliability problem which will be

8.3 Slab track no

detected by the axle counter system.

Direct

Subclause safety Explanation

relevance

9 Environmental and other

no

parameters

6 Axle counter system parameters

6.1 RAMS

6.1.1 Reliability

Reliability is defined in EN 50126. A single reliability figure cannot be harmonized because it is a combination

of qualitative and quantitative aspects.

6.1.2 Availability

The following information and definitions are derived from EN 50126.

The availability is one of the most significant parameters of an axle counter system. It is dependent on the

sufficient immunity margin (compatibility margin between susceptibility threshold and the radiated emission

level from RST). To ensure an adequate operational availability, a margin of 9 dB between the established

immunity and the limit for rolling stock has to be applied. The value of 9 dB ensures a correct count.

NOTE Concerning the margin 9 dB see also 6.2.3

For a standardised (typical) axle counter system section the following example of parameters may be used to

determine an acceptable availability in terms of failures per train:

Axles per train: 25 (average)

Train movements per day per track: 100

MTBF

Availability = 100%⋅

(MTBF+ MTTR)

Mean Time to repair (MTTR): 30 min (best case) - 300 min (worst case)

MTBF is calculated on the basis of component data and is for this reason product specific. The rate of

miscounts is a separate parameter which may be affected by the geometry of wheels and other mechanical

subsystems and EMC characteristics of rolling stock.

MTBF is a parameter of the equipment of the train detection system required for a single detection section.

The integrity of the trackside cables and tracks/rails are excluded from the MTBF requirement calculations.

6.1.3 Rate of miscounts

-7

The counting error rate shall be equal or better than 10 .

For example:

Minimum time between miscounts using the operational parameter values shown above

Validation of parameters and performance during the development process is permissible. The rate of

miscounts in the field shall be demonstrated in an adequate field test.

6.1.4 Maintainability

The following information and definitions are derived from EN 50126 and EN 50129.

The proper function of the axle counter system depends on correct installation, initial adjustment, preventive

and corrective maintenance of the cabling, connections to the rail and position of the sensors.

The maintainability of the axle counter system shall be seen in the context of the complete integrated system

including the ACD, the communication links, the evaluator unit and the power supplies.

The maintenance cycle shall have a frequency lower than or equal to once a year per ACD. The cycle for

indoor equipment shall be described in the product specific user's guide. This guide shall be checked for

validation.

The scope and frequency of the maintenance cycle of the axle counter shall be described in the product

specific user’s guide. A validation of these documents shall be done.

The supplier shall provide the information related to equipment failure modes and their rates of occurrence.

This will enable infrastructure managers to estimate the corresponding MTTR and clarify the implications for

their maintenance specification. Aspects to be taken into consideration on the trackside maintenance:

- Axle counter sensor has been damaged or knocked off the rail,

- Sensor sensitivity requires readjustment due to a deterioration of rail conditions (e.g. worn rail

surface),

- Train wheel conditions changed (introduction of a new type of vehicle),

- Cabling is incorrectly connected to the sensor and or the connection box,

- Short circuit of two or more wires in the outdoor cable.

Other aspects

- In-House equipment If there are any then they have to be described in the product specific user’s

guide,

- Cabling/wiring/connection boxes,

- Time without train runs (refer to 6.1.5.2).

6.1.5 Safety

6.1.5.1 General

The following information and definitions are derived from EN 50126, EN 50128 and EN 50129.

The safe movement of the trains on railways relies on the train detection equipment. The following levels of

safety integrity may be assigned.

NOTE THR is a term used in evolving safety related standards and means a specific calculable failure rate, which can

be converted to a defined SIL level.

The safety integrity shall be validated based on the safety case of the axle counter system. It shall be shown

in the safety case that the safety integrity level required is achieved. Requirements are described in

EN 50126, EN 50128 and EN 50129.

Examples of applications with different safety requirements:

• Lower safety integrity levels

For systems designed with the lowest level of safety integrity, the equipment is not safety relevant. There is no

level of automatic train protection that can be achieved with these systems. In such circumstances, the train

driver is responsible for the safe train movement. Based on the reaction time of drivers, the train spe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...