SIST EN 1127-2:2014

(Main)Explosive atmospheres - Explosion prevention and protection - Part 2: Basic concepts and methodology for mining

Explosive atmospheres - Explosion prevention and protection - Part 2: Basic concepts and methodology for mining

This European Standard specifies methods for explosion prevention and protection in mining by outlining the basic concepts and methodology for the design and construction of equipment, protective systems and components.

This European Standard applies to Group I equipment, protective systems and components intended for use in underground parts of mines and those parts of their surface installations at risk from firedamp and/or flammable dust.

NOTE Detailed information on specific equipment, protective systems and components is contained in the relevant individual standards. Safety-relevant data regarding flammable materials and explosive atmospheres are required for the design and construction of the explosion protection measures.

This European Standard specifies methods for the identification and assessment of hazardous situations that may lead to explosions and describes the design and construction measures appropriate for the required safety. This is achieved by

- risk assessment;

- risk reduction.

The safety of equipment, protective systems, and components can be achieved by eliminating hazards and/or limiting the risk, i.e.

a) by appropriate design (without using safeguarding);

b) by safeguarding;

c) by information for use;

d) by any other preventive measures.

Measures in accordance with a) (prevention) and b) (protection) against explosions are dealt with in clause 6 of this standard, measures according to c) against explosions are dealt with in clause 7 of this standard. Mea¬sures in accordance with d) are not described in this European Standard. They are dealt with in EN ISO 12100:2010, clause 6.

The preventive and protective measures described in this European Standard will not provide the required level of safety unless the equipment, protective systems and components are operated in line with their intended use and are installed and maintained according to the relevant codes of practice or requirements.

This standard is applicable to any equipment, protective systems and components intended to be used in potentially explosive atmospheres. These atmospheres can arise from flammable materials processed, used or released by the equipment, protective systems and components or from materials in the vicinity of the equipment, protective systems and components and/or from the materials of construction of the equipment, protective systems and components.

As shot firing can release potentially explosive atmospheres, this standard is also applicable to the equipment used for shot firing, apart from the explosives and detonators.

This standard is applicable to equipment, protective systems and components at all stages of use.

This standard is not applicable to:

- medical devices intended for use in a medical environment;

- equipment, protective systems and components where the explosion hazard results exclusively from the presence of explosives or unstable chemical substances;

- equipment, protective systems and components where the explosion can result from reaction of substances with oxidising agents other than atmospheric oxygen or by other hazardous reactions or conditions other than atmospheric conditions;

- equipment intended for use in domestic and non-commercial environments where explosive atmospheres may only rarely be created and solely as a result of the accidental leakage of fuel gas;

- personal protective equipment covered by Directive 89/686/EEC; the design and construction of systems containing desired, controlled combustion processes, unless they can act as ignition sources in potentially explosive atmospheres;

- mines where firedamp and/or flammable dust are not naturally present and surface installations such as coal preparation plants, power plants, coke oven plants etc. in which an explosive atmosphere can be present, but which are not part of a coal mine. These are covered by EN 1127-1:2011.

Explosionsfähige Atmosphären - Explosionsschutz - Teil 2: Grundlagen und Methodik in Bergwerken

Diese Europäische Norm legt allgemeine Verfahrensweisen für den Explosionsschutz im Bergbau fest, indem grundlegende Konzepte und Verfahren für die Konstruktion und den Bau von Geräten, Schutzsystemen und Komponenten dargelegt werden.

Diese Europäische Norm gilt für Geräte, Schutzsysteme und Komponenten der Gruppe I zur Verwendung in Untertagebetrieben von Bergwerken sowie deren Übertageanlagen, die durch Grubengas und/oder brennbare Stäube gefährdet werden können.

ANMERKUNG Detaillierte Informationen über spezielle Geräte, Schutzsysteme und Komponenten sind in entsprechenden Einzelnormen zusammengefasst. Für Konstruktion und Bau von Explosionsschutzmaßnahmen müssen die sicherheitsrelevanten Daten der brennbaren Stoffe und explosionsfähigen Atmosphären bekannt sein.

Diese Europäische Norm legt Verfahren zum Erkennen und Beurteilen von gefährlichen Situationen, die zu Explosionen führen können, fest und beschreibt geeignete Planungs- und Fertigungsmaßnahmen, um die erforderliche Sicherheit zu erreichen. Dies wird erreicht durch

- Risikobewertung;

- Risikoverringerung.

Die Sicherheit von Geräten, Schutzsystemen und Komponenten kann durch das Beseitigen von Gefährdungen und/oder die Begrenzung des Risikos erreicht werden durch

a) geeignete konstruktive Auslegung (ohne Anwendung von technischen Schutzmaßnahmen);

b) technische Schutzmaßnahmen;

c) Benutzerinformation;

d) sonstige Vorsichtsmaßnahmen.

Explosionsschutzmaßnahmen nach a) (Vorbeugung) und b) (Schutz) werden in Abschnitt 6 dieser Norm behandelt, Maßnahmen nach c) in Abschnitt 7. Maßnahmen nach d) sind in dieser Europäischen Norm nicht beschrieben. Sie werden in EN ISO 12100:2010, Abschnitt 6, behandelt.

Die in dieser Europäischen Norm beschriebenen Schutzmaßnahmen führen nur dann zum erforderlichen Maß an Sicherheit, wenn die Geräte, Schutzsysteme und Komponenten bestimmungsgemäß betrieben und entsprechend den für sie geltenden Regeln oder Vorschriften installiert und gewartet werden.

Diese Norm gilt für alle Geräte, Schutzsysteme und Komponenten, die bestimmungsgemäß in explosionsgefährdeten Bereichen eingesetzt werden. Solche Bereiche können vorliegen, wenn brennbare Stoffe verarbeitet, verwendet oder von den Geräten, Schutzsystemen und Komponenten freigesetzt werden. Sie können auch auftreten in der Umgebung von Geräten, Schutzsystemen und Komponenten sowie durch die Konstruktionsmaterialien der Geräte, Schutzsysteme und Komponenten.

Da durch Sprengarbeiten möglicherweise explosionsfähige Atmosphären freigesetzt werden können, gilt diese Norm auch für Geräte zur Sprengarbeit, nicht aber für Sprengstoffe und Zünder.

Diese Norm gilt für Geräte, Schutzsysteme und Komponenten in allen Anwendungsstadien.

Diese Norm ist nicht anwendbar auf:

- medizinische Geräte zur bestimmungsgemäßen Verwendung in medizinischen Bereichen;

- Geräte, Schutzsysteme und Komponenten, bei denen die Explosionsgefahr ausschließlich durch die Anwesenheit von Sprengstoffen oder chemisch instabilen Stoffen hervorgerufen wird;

- Geräte, Schutzsysteme und Komponenten, bei denen die Explosion durch Reaktion von Stoffen mit anderen Oxidationsmitteln als Luftsauerstoff oder durch andere gefährliche Reaktionen oder andere als atmosphärische Bedingungen erfolgen kann;

- Geräte, die zur Verwendung in häuslicher und nichtkommerzieller Umgebung vorgesehen sind, in der eine explosionsfähige Atmosphäre nur selten und lediglich infolge eines unbeabsichtigten Brennstoffaustritts gebildet werden kann;

Atmosphères explosives - Prévention de l'explosion et protection contre l'explosion - Partie 2: Notions fondamentales et méthodologie dans l'exploitation des mines

La présente Norme européenne définit des méthodes pour la prévention de l’explosion et la protection contre l’explosion dans l’industrie minière, en précisant les notions fondamentales et la méthodologie relatives à la conception et à la construction des appareils, systèmes de protection et composants.

La présente Norme européenne s’applique aux appareils, systèmes de protection et composants du groupe I destinés aux travaux souterrains des mines et aux parties de leurs installations de surface susceptibles d’être mis en danger par le grisou et/ou des poussières combustibles.

NOTE Des informations détaillées sur les appareils, les systèmes de protection et les composants spécifiques sont données dans des normes séparées appropriées. La conception et l’élaboration des mesures de protection contre l’explosion nécessitent la détermination des données relatives à la sécurité des substances inflammables et des atmosphères explosives.

La présente Norme européenne spécifie des méthodes d’identification et d’appréciation des situations dangereuses pouvant conduire à l’explosion ainsi que les mesures de conception et de construction appropriées pour assurer la sécurité requise. Celle-ci est obtenue par :

- l’appréciation du risque ;

- la réduction du risque.

La sécurité des appareils, systèmes de protection et composants peut être obtenue par l’élimination des phénomènes dangereux et/ou la limitation du risque, c’est-à-dire :

a) par une conception appropriée (sans utiliser de dispositifs de protection) ;

b) à l’aide de dispositifs de protection ;

c) au moyen d’informations pour l’utilisation ;

d) par toute autre mesure de prévention.

Les mesures contre les explosions correspondant à l’alinéa a) (prévention) et à l’alinéa b) (protection) sont traitées dans l’Article 6 de la présente norme. Les mesures contre l’explosion correspondant à l’alinéa c) sont traitées dans l’Article 7 de la présente norme. Les mesures correspondant à l’alinéa d) ne sont pas décrites dans la présente Norme européenne. Elles sont traitées dans l’Article 6 de l’EN ISO 12100:2010.

Les mesures de prévention et de protection décrites dans la présente Norme européenne ne procurent le niveau de protection requis que si les appareils, systèmes de protection et composants sont employés conformément à leur utilisation prévue et sont installés et entretenus conformément aux codes de bonnes pratiques ou exigences approprié(e)s.

La présente norme est applicable à tout type d’appareil, système de protection et composant destiné à être utilisé dans des atmosphères explosibles. Ces atmosphères peuvent être générées par les substances inflammables traitées et manipulées dans les appareils, systèmes de protection et composants ou évacuées par ceux-ci, par les substances se trouvant à proximité des appareils, systèmes de protection et composants et/ou par les matériaux constitutifs des appareils, systèmes de protection et composants.

Dans la mesure où l’abattage à l’explosif peut créer une atmosphère explosible, la présente norme s’applique également aux appareils utilisés pour l’abattage à l’explosif, à l’exception des explosifs et détonateurs.

Cette norme est applicable aux appareils, systèmes de protection et composants à tous les stades de leur utilisation.

Elle ne s’applique pas :

- aux dispositifs médicaux destinés à être utilisés dans un environnement médical ;

- aux appareils, systèmes de protection et composants lorsque le phénomène dangereux d’explosion est exclusivement dû à la présence de matières explosives ou de substances chimiques instables ;

Eksplozivne atmosfere - Protieksplozijska zaščita - 2. del: Osnovni pojmi in metodologija za rudarstvo

EN 1127-2 določa metode za preprečevanje in zaščito pred eksplozijami v rudarstvu z opisom osnovnih konceptov in metodologij za načrtovanje in konstrukcijo opreme, zaščitnih sistemov in komponent. Ta evropski standard velja za opremo skupine I, zaščitne sisteme in sestavne dele za uporabo v podzemnih delih rudnikov in tiste dele površinskih naprav, ki jih ogroža jamski eksplozivni plin ali vnetljiv prah. Ta evropski standard določa metode za ugotavljanje in ocenjevanje nevarnih situacij, ki lahko povzročijo eksplozije, in opisuje strukturne in konstrukcijske ukrepe, primerne za zahtevano varnost. To je doseženo z - oceno tveganja; - zmanjšanjem tveganja. Varnost opreme, zaščitnih sistemov in komponent je mogoče doseči z odpravo nevarnosti in/ali omejevanjem tveganja, tj. a) z ustreznim načrtovanjem (brez uporabe zaščite); b) z zaščito; c) z informacijami za uporabo; d) s poljubnimi drugimi preventivnimi ukrepi. Ukrepi v skladu z a) (preprečevanje) in b) (zaščita) proti eksploziji so obravnavani v točki 6 tega standarda; ukrepi v skladu s c) proti eksploziji so obravnavani v točki 7 tega standarda. Ukrepi v skladu z d) niso opisani v tem evropskem standardu. Obravnavani so v točki 6 standarda EN ISO 12100:2010. Preventivni in zaščitni ukrepi, opisani v tem evropskem standardu, ne zagotavljajo zahtevane ravni zaščite, razen če se z opremo, zaščitnimi sistemi in komponentami ravna v skladu z njihovim namenom uporabe in so nameščeni in vzdrževani v skladu z ustreznimi kodeksi ravnanja ali zahtev. Ta standard velja za vso opremo, zaščitne sisteme in komponente, ki so namenjeni za uporabo v potencialno eksplozivnih atmosferah. Te atmosfere lahko nastanejo iz vnetljivih materialov, ki jih obdeluje, uporablja ali sprošča oprema, zaščitni sistemi in sestavni del ali materiali v bližini opreme, zaščitnih sistemov in sestavnih delov in/ali iz konstrukcijskih materialov opreme, zaščitnih sistemov in komponent. Ker lahko streljanje povzroči nastanek potencialno eksplozivnih atmosfer, se ta standard uporablja tudi za opremo, ki se uporablja za streljanje, razen eksplozivov in detonatorjev. Ta standard se uporablja za opremo, zaščitne sisteme in sestavne dele v vseh fazah uporabe. Ta standard se ne uporablja za: - medicinske pripomočke, namenjene uporabi v medicinskem okolju; - opremo, zaščitne sisteme in komponente, kjer je nevarnost eksplozije izključno posledica navzočnosti eksplozivov ali nestabilnih kemikalij; - opremo, zaščitne sisteme in komponente, kjer je eksplozija lahko posledica reakcije snovi z oksidacijsko snovjo, razen atmosferskega kisika ali drugih nevarnih reakcij ali pogojev, razen atmosferskih pogojev; - opremo, namenjeno za uporabo v domačem in nekomercialnem okolju, kjer eksplozivna atmosfera nastane zelo redko, in sicer izključno zaradi naključnega uhajanja kurilnega plina; - osebno zaščitno opremo, zajeto z Direktivo 89/686/EGS; - projektiranje in gradnjo sistemov, ki vsebujejo želene, nadzorovane procese zgorevanja, razen če lahko delujejo kot viri vžiga v potencialno eksplozivnih atmosferah; - rudnike, kjer jamski eksplozivni plin in/ali vnetljiv prah nista naravno prisotna in površinske naprave, kot so obrati za pripravo premoga, elektrarne, peči na koks itd., v katerih je lahko prisotna eksplozivna atmosfera, vendar niso del premogovnika. Te so zajete v standardu v EN 1127-1:2011.

General Information

- Status

- Published

- Public Enquiry End Date

- 07-Apr-2013

- Publication Date

- 04-Aug-2014

- Technical Committee

- EXP - Product for explosive atmospheres

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 27-Jun-2014

- Due Date

- 01-Sep-2014

- Completion Date

- 05-Aug-2014

Relations

- Effective Date

- 01-Sep-2014

Overview

EN 1127-2:2014 - "Explosive atmospheres - Explosion prevention and protection - Part 2: Basic concepts and methodology for mining" is a CEN European Standard that defines methods and a structured methodology for preventing and protecting against explosions in mining. It applies to Group I equipment, protective systems and components intended for use in underground mine workings and surface installations exposed to firedamp (methane) and/or flammable dust. The standard supersedes EN 1127-2:2002+A1:2008 and is intended to guide designers, manufacturers and users throughout the equipment lifecycle (design, construction, installation, operation, maintenance).

Key topics and requirements

- Risk assessment & risk reduction: systematic identification and assessment of hazardous situations that may lead to explosions, followed by measures to remove or limit risk.

- Identification of ignition sources (Clause 5): comprehensive listing of potential ignition sources including hot surfaces, flames/hot gases, mechanically generated sparks, electrical equipment, stray currents, static electricity, lightning, RF and optical electromagnetic waves, ionizing radiation, ultrasonics, shock/adiabatic compression, and exothermic reactions/self‑ignition of dusts.

- Design & construction measures (Clause 6): principles to avoid explosive atmospheres and to eliminate or limit ignition sources by appropriate design (prevention), safeguarding (protection) and construction of equipment and protective systems.

- Information for use (Clause 7): mandatory information for commissioning, maintenance, repair, and user training to ensure equipment remains safe in intended use.

- Classification of hazardous atmospheric conditions: guidance on assessing zones and conditions specific to mining environments (firedamp and combustible dust).

- Special provisions: emergency measures, measuring and control systems, and specific requirements for underground mining equipment; shot firing equipment is included except explosives/detonators.

- Annexes: tools for use in explosive atmospheres (Annex B), relations to EU Directives (Annex ZA/ZB) and changes from previous editions.

Practical applications and who uses it

EN 1127-2:2014 is used by:

- Equipment designers and manufacturers of mining machinery and protective systems to ensure explosion-robust design.

- Mine operators and safety engineers for selecting compliant equipment, conducting workplace risk assessments and implementing preventive measures.

- Maintenance personnel and trainers, since correct installation, maintenance and user information are essential for the standard’s effectiveness.

- Notified bodies and conformity assessors when verifying compliance with EU essential requirements (see Annex ZA/ZB).

Practical uses include safe design of electrical and mechanical equipment for gassy or dusty mines, evaluation of ignition risks at transfer points and conveyors, and preparing documentation and training for safe operation.

Related standards

- EN 1127-1:2011 - Explosive atmospheres - Part 1: Basic concepts and methodology (surface industries)

- EN ISO 12100:2010 - Safety of machinery - General principles for design (risk assessment and reduction)

Keywords: EN 1127-2:2014, explosive atmospheres, mining, explosion prevention, explosion protection, firedamp, flammable dust, risk assessment, Group I equipment.

Frequently Asked Questions

SIST EN 1127-2:2014 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Explosive atmospheres - Explosion prevention and protection - Part 2: Basic concepts and methodology for mining". This standard covers: This European Standard specifies methods for explosion prevention and protection in mining by outlining the basic concepts and methodology for the design and construction of equipment, protective systems and components. This European Standard applies to Group I equipment, protective systems and components intended for use in underground parts of mines and those parts of their surface installations at risk from firedamp and/or flammable dust. NOTE Detailed information on specific equipment, protective systems and components is contained in the relevant individual standards. Safety-relevant data regarding flammable materials and explosive atmospheres are required for the design and construction of the explosion protection measures. This European Standard specifies methods for the identification and assessment of hazardous situations that may lead to explosions and describes the design and construction measures appropriate for the required safety. This is achieved by - risk assessment; - risk reduction. The safety of equipment, protective systems, and components can be achieved by eliminating hazards and/or limiting the risk, i.e. a) by appropriate design (without using safeguarding); b) by safeguarding; c) by information for use; d) by any other preventive measures. Measures in accordance with a) (prevention) and b) (protection) against explosions are dealt with in clause 6 of this standard, measures according to c) against explosions are dealt with in clause 7 of this standard. Mea¬sures in accordance with d) are not described in this European Standard. They are dealt with in EN ISO 12100:2010, clause 6. The preventive and protective measures described in this European Standard will not provide the required level of safety unless the equipment, protective systems and components are operated in line with their intended use and are installed and maintained according to the relevant codes of practice or requirements. This standard is applicable to any equipment, protective systems and components intended to be used in potentially explosive atmospheres. These atmospheres can arise from flammable materials processed, used or released by the equipment, protective systems and components or from materials in the vicinity of the equipment, protective systems and components and/or from the materials of construction of the equipment, protective systems and components. As shot firing can release potentially explosive atmospheres, this standard is also applicable to the equipment used for shot firing, apart from the explosives and detonators. This standard is applicable to equipment, protective systems and components at all stages of use. This standard is not applicable to: - medical devices intended for use in a medical environment; - equipment, protective systems and components where the explosion hazard results exclusively from the presence of explosives or unstable chemical substances; - equipment, protective systems and components where the explosion can result from reaction of substances with oxidising agents other than atmospheric oxygen or by other hazardous reactions or conditions other than atmospheric conditions; - equipment intended for use in domestic and non-commercial environments where explosive atmospheres may only rarely be created and solely as a result of the accidental leakage of fuel gas; - personal protective equipment covered by Directive 89/686/EEC; the design and construction of systems containing desired, controlled combustion processes, unless they can act as ignition sources in potentially explosive atmospheres; - mines where firedamp and/or flammable dust are not naturally present and surface installations such as coal preparation plants, power plants, coke oven plants etc. in which an explosive atmosphere can be present, but which are not part of a coal mine. These are covered by EN 1127-1:2011.

This European Standard specifies methods for explosion prevention and protection in mining by outlining the basic concepts and methodology for the design and construction of equipment, protective systems and components. This European Standard applies to Group I equipment, protective systems and components intended for use in underground parts of mines and those parts of their surface installations at risk from firedamp and/or flammable dust. NOTE Detailed information on specific equipment, protective systems and components is contained in the relevant individual standards. Safety-relevant data regarding flammable materials and explosive atmospheres are required for the design and construction of the explosion protection measures. This European Standard specifies methods for the identification and assessment of hazardous situations that may lead to explosions and describes the design and construction measures appropriate for the required safety. This is achieved by - risk assessment; - risk reduction. The safety of equipment, protective systems, and components can be achieved by eliminating hazards and/or limiting the risk, i.e. a) by appropriate design (without using safeguarding); b) by safeguarding; c) by information for use; d) by any other preventive measures. Measures in accordance with a) (prevention) and b) (protection) against explosions are dealt with in clause 6 of this standard, measures according to c) against explosions are dealt with in clause 7 of this standard. Mea¬sures in accordance with d) are not described in this European Standard. They are dealt with in EN ISO 12100:2010, clause 6. The preventive and protective measures described in this European Standard will not provide the required level of safety unless the equipment, protective systems and components are operated in line with their intended use and are installed and maintained according to the relevant codes of practice or requirements. This standard is applicable to any equipment, protective systems and components intended to be used in potentially explosive atmospheres. These atmospheres can arise from flammable materials processed, used or released by the equipment, protective systems and components or from materials in the vicinity of the equipment, protective systems and components and/or from the materials of construction of the equipment, protective systems and components. As shot firing can release potentially explosive atmospheres, this standard is also applicable to the equipment used for shot firing, apart from the explosives and detonators. This standard is applicable to equipment, protective systems and components at all stages of use. This standard is not applicable to: - medical devices intended for use in a medical environment; - equipment, protective systems and components where the explosion hazard results exclusively from the presence of explosives or unstable chemical substances; - equipment, protective systems and components where the explosion can result from reaction of substances with oxidising agents other than atmospheric oxygen or by other hazardous reactions or conditions other than atmospheric conditions; - equipment intended for use in domestic and non-commercial environments where explosive atmospheres may only rarely be created and solely as a result of the accidental leakage of fuel gas; - personal protective equipment covered by Directive 89/686/EEC; the design and construction of systems containing desired, controlled combustion processes, unless they can act as ignition sources in potentially explosive atmospheres; - mines where firedamp and/or flammable dust are not naturally present and surface installations such as coal preparation plants, power plants, coke oven plants etc. in which an explosive atmosphere can be present, but which are not part of a coal mine. These are covered by EN 1127-1:2011.

SIST EN 1127-2:2014 is classified under the following ICS (International Classification for Standards) categories: 13.230 - Explosion protection; 73.020 - Mining and quarrying. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1127-2:2014 has the following relationships with other standards: It is inter standard links to SIST EN 1127-2:2002+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1127-2:2014 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2014/34/EU, 94/9/EC, EUR-PUB; Standardization Mandates: M/396, M/BC/CEN/92/45. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1127-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Explosionsfähige Atmosphären - Explosionsschutz - Teil 2: Grundlagen und Methodik in BergwerkenAtmosphères explosives - Prévention de l'explosion et protection contre l'explosion - Partie 2: Notions fondamentales et méthodologie dans l'exploitation des minesExplosive atmospheres - Explosion prevention and protection - Part 2: Basic concepts and methodology for mining73.020Rudarstvo in kamnolomsko izkopavanjeMining and quarrying13.230Varstvo pred eksplozijoExplosion protectionICS:Ta slovenski standard je istoveten z:EN 1127-2:2014SIST EN 1127-2:2014en01-september-2014SIST EN 1127-2:2014SLOVENSKI

STANDARDSIST EN 1127-2:2002+A1:20081DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1127-2

June 2014 ICS 13.230; 73.100.01 Supersedes EN 1127-2:2002+A1:2008English Version

Explosive atmospheres - Explosion prevention and protection - Part 2: Basic concepts and methodology for mining

Atmosphères explosives - Prévention de l'explosion et protection contre l'explosion - Partie 2: Notions fondamentales et méthodologie dans l'exploitation des mines

Explosionsfähige Atmosphären - Explosionsschutz - Teil 2: Grundlagen und Methodik in Bergwerken This European Standard was approved by CEN on 7 May 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1127-2:2014 ESIST EN 1127-2:2014

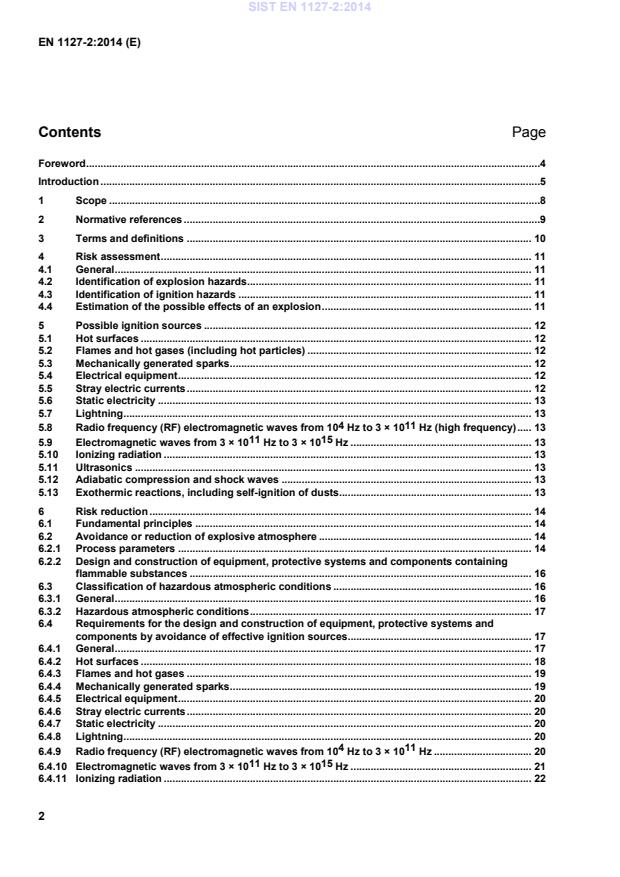

Contents Page Foreword .4 Introduction .5 1 Scope .8 2 Normative references .9 3 Terms and definitions . 10 4 Risk assessment . 11 4.1 General . 11 4.2 Identification of explosion hazards. 11 4.3 Identification of ignition hazards . 11 4.4 Estimation of the possible effects of an explosion . 11 5 Possible ignition sources . 12 5.1 Hot surfaces . 12 5.2 Flames and hot gases (including hot particles) . 12 5.3 Mechanically generated sparks . 12 5.4 Electrical equipment . 12 5.5 Stray electric currents . 12 5.6 Static electricity . 13 5.7 Lightning . 13 5.8 Radio frequency (RF) electromagnetic waves from 104 Hz to 3 × 1011 Hz (high frequency) . 13 5.9 Electromagnetic waves from 3 × 1011 Hz to 3 × 1015 Hz . 13 5.10 Ionizing radiation . 13 5.11 Ultrasonics . 13 5.12 Adiabatic compression and shock waves . 13 5.13 Exothermic reactions, including self-ignition of dusts . 13 6 Risk reduction . 14 6.1 Fundamental principles . 14 6.2 Avoidance or reduction of explosive atmosphere . 14 6.2.1 Process parameters . 14 6.2.2 Design and construction of equipment, protective systems and components containing flammable substances . 16 6.3 Classification of hazardous atmospheric conditions . 16 6.3.1 General . 16 6.3.2 Hazardous atmospheric conditions . 17 6.4 Requirements for the design and construction of equipment, protective systems and components by avoidance of effective ignition sources. 17 6.4.1 General . 17 6.4.2 Hot surfaces . 18 6.4.3 Flames and hot gases . 19 6.4.4 Mechanically generated sparks . 19 6.4.5 Electrical equipment . 20 6.4.6 Stray electric currents . 20 6.4.7 Static electricity . 20 6.4.8 Lightning . 20 6.4.9 Radio frequency (RF) electromagnetic waves from 104 Hz to 3 × 1011 Hz . 20 6.4.10 Electromagnetic waves from 3 × 1011 Hz to 3 × 1015 Hz . 21 6.4.11 Ionizing radiation . 22 SIST EN 1127-2:2014

Relation between categories and hazardous atmospheric conditions . 27 Annex B (normative)

Tools for use in potentially explosive atmospheres . 28 Annex C (informative)

Significant technical changes between this document and the previous edition of this European Standard . 29 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 94/9/EC . 30 Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 31 Bibliography . 32

Foreword This document (EN 1127-2:2014) has been prepared by Technical Committee CEN/TC 305 “Potentially explosive atmospheres - Explosion prevention and protection”, the secretariat of which is held by DIN. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by December 2014 and conflicting national standards shall be withdrawn at the latest by December 2014. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document supersedes EN 1127-2:2002+A1:2008. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directives. For relationship with EU Directives, see informative Annexes ZA and ZB, which are an integral part of this document. EN 1127, Explosive atmospheres — Explosion prevention and protection is composed of the following parts: — Part 1: Basic concepts and methodology — Part 2: Basic concepts and methodology for mining (the present document) Annex C provides details of significant changes between this document and the previous edition. According to the CEN-CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 1127-2:2014

firedamp explosion. In the latter case, the explosive violence can increase many times as more and more fuel in the form of combustible dust is raised by a blast wave and added to the flame as it travels along the roadways. The risk of an explosive atmosphere occurring and its consequences will therefore vary from mine to mine, depending on the type of mine, its layout, the mineral being extracted and the likelihood of firedamp and/or combustible dust occurring. In coal mining, firedamp and coal dust naturally associated with the coal is released by the activity of the miners. Therefore, the potential explosion risk is greater as a result of explosive air/gas or air/dust mixtures forming that cannot be totally excluded by the preventive measures taken. Firedamp/air mixtures are usually diluted by the ventilation and evacuated to the surface via the mine workings so that the gas content in normal operation is kept far below the lower explosion limit. However, as a result of system malfunction (e.g. fan failure), sudden release of large gas quantities (gas outbursts) or intensified gas release caused by decreasing air pressure or by increased coal production, the permissible gas concentration thresholds may be exceeded. The explosive atmosphere caused in this way, even though limited in space and/or time, may cause a hazard not just at its point of origin but also in the escape roads, waste air paths and other connected mine structures in the mine layout. Coal dust/air mixtures are usually neutralized at the dust source by water sprays, dust removal systems on heading machines and/or treating with inert dust in order to reduce the explosive potential. However, an explosion hazard can exist if explosive dust can become airborne, e.g. at transfer points, in bunkers and other conveying systems. In contrast to surface industries, in gassy mines electrical and non-electrical equipment and mining personnel are in permanent contact with gas and/or dust/air mixtures which, under unfavourable conditions, may constitute explosive atmospheres. Accordingly, particularly stringent safety requirements are in force for explosion protection and escape possibilities in the event of a hazard. Due to the possibly devastating effects of underground gas/dust explosions, underground mining is permitted only well outside the explosion range. In gassy mines, the decision as to whether or not mine workers can operate in a particular workplace depends upon the atmospheric conditions prevailing at the time. Traditionally, a factor of safety is also introduced so that it is common practice throughout the European member states for equipment to be de-energized or made safe and for miners to be withdrawn from their workplace if the atmospheric conditions attain a specific percentage of the lower explosion limit (LEL) of methane (firedamp) in air as defined by the relevant national legislation of the member states. NOTE 2 The current limit values for disconnecting equipment and withdrawing personnel are different in each member state. Two different ranges of explosive atmospheres originating from the intended installation and use of the equipment are taken into account when dealing with requirements for Equipment Groups M 2 and M 1: — potentially explosive atmosphere — range between 0 % and below LEL or above UEL up to 100 % of firedamp in air; — explosive atmosphere — range between LEL and UEL of firedamp in air. In mine workings with explosive atmospheres, only M 1 equipment is acceptable as it has a very high level of protection. M 1 equipment, e.g. telephones or gas measuring equipment may continue to be operated in explosive atmospheres, because they are safe even in the event of rare equipment faults. This is ensured by the existence of two independent protective measures or double fail-safe systems. In mine workings with potentially explosive atmospheres, both M 1 and M 2 equipment may be used. M 2 equipment may be used as it has a high level of protection and is suitable for the severe conditions in mining. In an explosive atmospheres, M 2 equipment needs to be capable of being disconnected or made safe. SIST EN 1127-2:2014

1 Scope This European Standard specifies methods for explosion prevention and protection in mining by outlining the basic concepts and methodology for the design and construction of equipment, protective systems and components. This European Standard applies to Group I equipment, protective systems and components intended for use in underground parts of mines and those parts of their surface installations at risk from firedamp and/or combustible dust. NOTE Detailed information on specific equipment, protective systems and components is contained in the relevant individual standards. Safety-relevant data regarding flammable materials and explosive atmospheres are required for the design and construction of the explosion protection measures. This European Standard specifies methods for the identification and assessment of hazardous situations that may lead to explosions and describes the design and construction measures appropriate for the required safety. This is achieved by — risk assessment; — risk reduction. The safety of equipment, protective systems, and components can be achieved by eliminating hazards and/or limiting the risk, i.e. a) by appropriate design (without using safeguarding); b) by safeguarding; c) by information for use; d) by any other preventive measures. Measures in accordance with a) (prevention) and b) (protection) against explosions are dealt with in Clause 6 of this standard; measures according to c) against explosions are dealt with in Clause 7 of this standard. Measures in accordance with d) are not described in this European Standard. They are dealt with in EN ISO 12100:2010, Clause 6. The preventive and protective measures described in this European Standard will not provide the required level of protection unless the equipment, protective systems and components are operated in line with their intended use and are installed and maintained according to the relevant codes of practice or requirements. This standard is applicable to any equipment, protective systems and components intended to be used in potentially explosive atmospheres. These atmospheres can arise from flammable materials processed, used or released by the equipment, protective systems and components or from materials in the vicinity of the equipment, protective systems and components and/or from the materials of construction of the equipment, protective systems and components. As shot firing can release potentially explosive atmospheres, this standard is also applicable to the equipment used for shot firing, apart from the explosives and detonators. This standard is applicable to equipment, protective systems and components at all stages of use. This standard is not applicable to: — medical devices intended for use in a medical environment; SIST EN 1127-2:2014

EN ISO 13849-1, Safety of machinery — Safety-related parts of control systems — Part 1: General principles for design (ISO 13849-1) 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN 13237:2012 and the following apply. 3.1 firedamp any potentially explosive mixture of gases or any flammable gas naturally occurring in a mine Note 1 to entry: As firedamp consists mainly of methane, the terms firedamp and methane are used frequently in mining practice as synonyms. 3.2 protection against firedamp explosions explosion prevention and protection in underground parts of mines and those parts of surface installations of such mines liable to be endangered by firedamp and or combustible dust 3.3 component any item essential to the safe functioning of equipment and protective systems but with no autonomous function [SOURCE: Directive 94/9/EC, Chapter I, Article 1, modified] 3.4 equipment machines, apparatus, fixed or mobile devices, control components and instrumentation thereof and detection and prevention systems which, separately or jointly, are intended for the generation, transfer, storage, measurement, control and conversion of energy, for the processing of material, and which are capable of causing an explosion through their own potential sources of ignition [SOURCE: Directive 94/9/EC, Chapter I, Article 1, modified] 3.5 machinery — an assembly, fitted with or intended to be fitted with a drive system other than directly applied human or animal effort, consisting of linked parts or components, at least one of which moves, and which are joined together for a specific application; — an assembly referred to in the first indent, missing only the components to connect it on site or to sources of energy and motion; — an assembly referred to in the first and second indents, ready to be installed and able to function as it stands only if mounted on a means of transport, or installed in a building or a structure; — assemblies of machinery referred to in the first, second and third indents or partly completed machinery which, in order to achieve the same end, are arranged and controlled so that they function as an integral whole; — an assembly of linked parts or components, at least one of which moves and which are joined together, intended for lifting loads and whose only power source is directly applied human effort [SOURCE: Directive 2006/42/EC, modified] SIST EN 1127-2:2014

Note 1 to entry: Protective systems are separately placed on the market for use as autonomous systems. [SOURCE: Directive 94/9/EC, Chapter I, Article 1, modified] 3.9 self-ignition of dust in bulk ignition of dusts caused by the rate of heat generation from oxidation and/or decomposition reactions of the dust being greater than the rate of heat loss to the surroundings 4 Risk assessment 4.1 General In addition to EN 1127-1:2011, 4.1 the following shall apply: In assessment of the likelihood of occurrence of a hazardous explosive atmosphere in mines, the main factors are: — the properties of the mineral being worked; — the manner of working it; — the presence of firedamp in the immediate strata; — the effects of human action on the strata in the vicinity of the mine workings; — the degree of dilution by the ventilation system. NOTE For further information see EN 13478. 4.2 Identification of explosion hazards EN 1127-1:2011, 4.2 shall apply. 4.3 Identification of ignition hazards EN 1127-1:2011, 4.3 shall apply. 4.4 Estimation of the possible effects of an explosion In addition to EN 1127-1:2011, 4.4 the following shall apply: SIST EN 1127-2:2014

The expected injury to persons or damage to objects and the size of the endangered place can thus be estimated only for each individual case. The risk of an explosive atmosphere occurring and its consequences will therefore vary from mine to mine, depending on the type of mine, its layout, the mineral being extracted and the likelihood of firedamp and/or combustible dust occurring. 5 Possible ignition sources 5.1 Hot surfaces The requirements of 5.1 of EN 1127-1:2011 apply, but special consideration shall be given to hot surfaces of internal combustion engines. For protective measures against ignition hazards from hot surfaces, see 6.4.2. 5.2 Flames and hot gases (including hot particles) The requirements of 5.2 of EN 1127-1:2011 apply. For protective measures against ignition hazards due to flames and hot gases, see 6.4.3. 5.3 Mechanically generated sparks The requirements of 5.3 of EN 1127-1:2011 apply. During the cutting of mineral, sparks can be generated and are very often a source of ignition. For protective measures against ignition hazards due to mechanically generated sparks, see 6.4.4. 5.4 Electrical equipment The requirements of 5.4 of EN 1127-1:2011 apply. During shot firing, electrical sparks can be generated by the blasting machine and/or detached cables and leads at the time of ignition. For protective measures against ignition hazards due to electrical equipment, see 6.4.5. 5.5 Stray electric currents Stray currents can flow in electrically conductive systems or parts of systems — as return currents in power generating systems; — as a result of a short-circuit or of a short-circuit to earth owing to faults in the electrical installations; — as a result of magnetic induction (e.g. near electrical installations with high currents or radio frequencies, see also 5.8); — as a result of lightning (see 5.7) and — as a result of induction from surface overhead lines. If parts of a system able to carry stray currents are disconnected, connected or bridged - even in the case of slight potential differences - an explosive atmosphere can be ignited as a result of electric sparks and/or arcs. Moreover, ignition can also occur due to the heating up of these current paths (see 5.1). For protective measures against ignition hazards due to stray electric currents, see 6.4.6. SIST EN 1127-2:2014

6 Risk reduction 6.1 Fundamental principles The necessity for the simultaneous presence of an explosive atmosphere and effective ignition source and the anticipated effects of an explosion as described in Clause 4 lead immediately to the three basic principles of explosion prevention and protection in the following order: a) Prevention: 1) avoid or reduce explosive atmospheres. This objective can mainly be achieved by modifying either the concentration of the flammable substance to a value outside the explosion range or the concentration of oxygen to a value below the limiting oxygen concentration (LOC); 2) avoid any possible effective ignition source. This is achieved by a suitable design of the equipment, protective systems and components; 3) de-energize equipment containing an ignition source when there is an explosive concentration. b) Protection: limiting the effects of explosions to an acceptable degree. This can be done to a certain extent by constructional protective measures. In contrast to the measures described above, here the occurrence of a starting explosion is taken into account. The elimination or minimization of risk can be achieved by applying one or more of the above prevention or protection principles. The avoidance of an explosive atmosphere shall always be the first choice. The more likely the occurrence of an explosive atmosphere is, the higher the extent of measures against effective ignition sources shall be and vice versa. To allow selection of the appropriate measures, an explosion safety concept shall be developed for each individual case. In the planning of explosion prevention and protection measures, consideration shall be given to normal operation, which includes start-up and shut-down. Moreover, possible technical malfunctions as well as foreseeable misuse (see EN ISO 12100) shall be taken into account. Application of explosion prevention and protection measures requires a thorough knowledge of the facts and sufficient experience. It is thus highly advisable to seek expert guidance. 6.2 Avoidance or reduction of explosive atmosphere 6.2.1 Process parameters 6.2.1.1 Substitution or reduction of the amount of substances capable of forming explosive atmospheres Wherever possible flammable substances, e.g. mineral oil for lubricating machines, shall be replaced by non-flammable substances or by substances not capable of forming explosive atmospheres, e.g. use of “water-in-oil emulsions” for hydraulic roof supports instead of mineral oil. As far as reasonably practicable, the amount of flammable material shall be reduced to the minimum, e.g. by firedamp drainage or by dust control measures. The content of firedamp in the air can be substantially reduced by firedamp drainage before and during winning operations. SIST EN 1127-2:2014

6.2.2 Design and construction of equipment, protective systems and components containing flammable substances 6.2.2.1 General In the planning stage of equipment, protective systems and components which will contain flammable substances, efforts shall be made to keep the substances in closed systems at all times, e.g. firedamp drainage systems, dust extraction systems and diesel fuel tanks. Non-flammable or fire-resistant materials shall be used wherever possible (see EN 13478). 6.2.2.2 Minimization of releases of flammable substances To minimize the explosion risk outside the equipment, protective systems and components due to leakage of flammable substances, such equipment, protective systems and components shall be designed, constructed and operated so that they are and remain leak-free. However, experience shows that small leaks are likely to occur in certain cases, e.g. at some pump glands and sampling points. This shall be taken into account in the design of the equipment, protective systems and components. Arrangements shall be made to limit leak rates and to prevent the flammable substances from spreading. Where necessary, a leak detector shall be fitted. 6.2.2.3 Dilution by ventilation Ventilation is of paramount importance in the control of the effects of releases of flammable gases and vapours. It can be used inside and outside equipment, protective systems and components. For dusts, ventilation generally provides sufficient protection only when the dust is extracted from the place of origin (local extraction) and hazardous deposits of combustible dust are reliably prevented. 6.3 Classification of hazardous atmospheric conditions 6.3.1 General Large parts of mines can be endangered at the same time by both firedamp and combustible dust and so it is inadvisable to subdivide the hazards into those which are caused by the gas atmosphere and those by the dust atmosphere. Therefore, measures for explosion prevention

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...