SIST EN 15629:2009

(Main)Steel static storage systems - Specification of storage equipment

Steel static storage systems - Specification of storage equipment

This European Standard supplies guidelines for the technical specification to allow the design of racking and shelving in its various forms such as adjustable pallet racking (APR), crane serviced racking, drive-in racking (DIR), cantilever racking and shelving systems, including their various forms of construction, using manually operated and controlled mechanical handling systems. Some other forms of storage equipments are only partially covered and further consideration, beyond the scope of this document, may be required.

This European Standard gives guidance for the specifier of storage systems to coordinate suppliers of all equipment including individual responsibilities.

This European Standard does not cover storage equipments manufactured from materials other than steel (except for certain accessories) and equipment intended to be used for domestic storage purposes.

Ortsfeste Regalsysteme aus Stahl - Spezifikation von Lagereinrichtungen

Diese Europäische Norm legt die Leitlinien für die technische Spezifikation fest, welche die Konstruktion von

Regalen verschiedener Art ermöglicht, wie z. B. verstellbare Palettenregale, regalförderzeugbediente (RFZbediente)

Regale, Einfahrregale, Kragarmregale, einschließlich deren verschiedene Ausführungsvarianten,

mit manuell bedienten bzw. gesteuerten Fördersystemen. Einige andere Lagersysteme sind nur zum

Teil abgedeckt und weitere Überlegungen außerhalb des Anwendungsbereichs dieses Dokuments sind evtl.

erforderlich.

Diese Europäische Norm bietet dem Verfasser von Lagersystemspezifikationen eine Leitlinie zur Koordination

von sämtlichen Einrichtungslieferanten, einschließlich individueller Zuständigkeiten.

Diese Europäische Norm gilt weder für Lagersysteme aus anderen Werkstoffen als Stahl (mit Ausnahme

einiger Zubehörteile) noch für Lagereinrichtungen im Haushaltsbereich.

Systèmes de stockage en acier - Spécification du système de stockage

La présente Norme européenne fournit des lignes directrices relatives aux spécifications techniques permettant le calcul de systèmes de rayonnage à palettes et à tablettes sous leurs différentes formes, telles que les rayonnages à palettes réglables (APR), les rayonnages à pont roulant, les rayonnages à accumulation statique ouvert sur une face (DIR) ou les rayonnages à palettes et à tablettes en porte-à-faux, comprenant ses différentes formes de construction, équipés de systèmes de manutention mécaniques actionnés et commandés manuellement. D'autres formes de systèmes de stockage ne sont que partiellement abordées et un traitement plus en profondeur, qui ne relève pas du domaine d’application de la présente norme, peut s’avérer nécessaire.

La présente Norme européenne fournit les lignes directrices permettant au rédacteur de spécifications relatives aux systèmes de stockage de coordonner les fournisseurs de l’ensemble des appareils, ainsi que leurs responsabilités individuelles.

La présente Norme européenne ne couvre ni les systèmes de stockage fabriqués à partir de matériaux autres que de l'acier (à l'exception de certains accessoires) ni les équipements de stockage destinés aux particuliers.

Stabilni jekleni sistemi za skladiščenje - Specifikacija opreme za skladiščenje

General Information

- Status

- Published

- Publication Date

- 03-Dec-2008

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 02-Dec-2008

- Due Date

- 06-Feb-2009

- Completion Date

- 04-Dec-2008

Overview

EN 15629:2008 - Steel static storage systems - Specification of storage equipment (CEN) provides guidance for preparing technical specifications used to design, supply and coordinate steel racking and shelving systems. The standard covers common storage types such as adjustable pallet racking (APR), drive‑in racking (DIR), crane‑served racking, cantilever racking and shelving systems used with manual and mechanically controlled handling equipment. It clarifies roles and responsibilities between specifiers, suppliers, designers and users and excludes non‑steel and domestic storage equipment.

Key topics and technical requirements

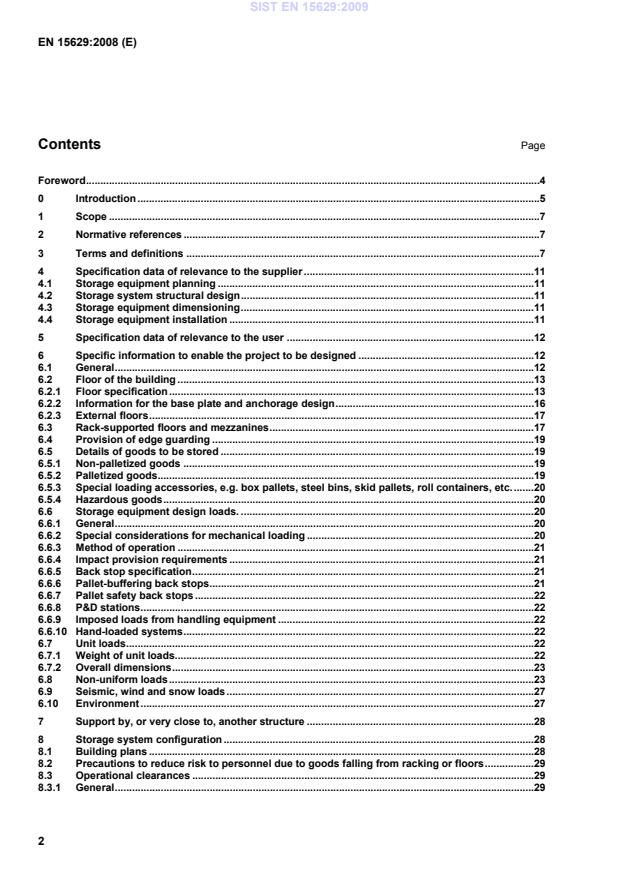

EN 15629:2008 focuses on specification rather than detailed structural calculation. Major technical topics include:

- Storage equipment planning and coordination of multiple suppliers

- Storage system structural design, dimensioning and installation data required by designers

- Floor requirements, base plate and anchorage information for safe fixing of racking to slab (including external floors)

- Rack‑supported floors and mezzanines and interactions with other structures

- Details of goods and unit loads (palletized and non‑palletized), special load carriers and loading accessories

- Design loads: bay/frame loads, imposed loads from handling equipment, impact provisions and back‑stop requirements

- Clearances and tolerances for pallet racking, aisle widths, horizontal/vertical clearances and intrusive stacking concerns

- Environmental and extreme actions: seismic, wind and snow considerations where relevant

- Safety aspects: edge guarding, safety colours, fire safety measures, means of escape and protection from falling goods

- Operational requirements: pedestrian/truck passageways, P&D (pick and deposit) stations, and maintenance/inspection regimes

- Informative annexes defining specifiers’ and suppliers’ responsibilities

EN 15629 references relevant structural codes (Eurocodes) and is intended to be used alongside EN 15512, EN 15620 and EN 15635.

Applications and who uses it

This standard is practical for:

- Specifiers and clients preparing procurement requirements for warehouse racking and shelving

- Designers and structural engineers who need specification data for safe design and coordination with Eurocodes

- Manufacturers and suppliers to understand client information needs and responsibilities

- Installers and facility managers for installation, anchorage and inspection criteria

- Warehouse operators, logistics planners and safety authorities implementing compliant storage systems

Use EN 15629:2008 when you need a comprehensive, supplier‑oriented specification framework for steel static storage systems to ensure safe, coordinated design, installation and operation.

Related standards

- EN 15512 - Adjustable pallet racking - Principles for structural design

- EN 15620 - Tolerances, deformations and clearances

- EN 15635 - Application and maintenance of storage equipment

- Eurocode EN 1993 series (steel structures) - for structural capacity and verification

Keywords: EN 15629:2008, steel static storage systems, specification of storage equipment, pallet racking, drive‑in racking, shelving systems, storage system design, racking specification.

Frequently Asked Questions

SIST EN 15629:2009 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Steel static storage systems - Specification of storage equipment". This standard covers: This European Standard supplies guidelines for the technical specification to allow the design of racking and shelving in its various forms such as adjustable pallet racking (APR), crane serviced racking, drive-in racking (DIR), cantilever racking and shelving systems, including their various forms of construction, using manually operated and controlled mechanical handling systems. Some other forms of storage equipments are only partially covered and further consideration, beyond the scope of this document, may be required. This European Standard gives guidance for the specifier of storage systems to coordinate suppliers of all equipment including individual responsibilities. This European Standard does not cover storage equipments manufactured from materials other than steel (except for certain accessories) and equipment intended to be used for domestic storage purposes.

This European Standard supplies guidelines for the technical specification to allow the design of racking and shelving in its various forms such as adjustable pallet racking (APR), crane serviced racking, drive-in racking (DIR), cantilever racking and shelving systems, including their various forms of construction, using manually operated and controlled mechanical handling systems. Some other forms of storage equipments are only partially covered and further consideration, beyond the scope of this document, may be required. This European Standard gives guidance for the specifier of storage systems to coordinate suppliers of all equipment including individual responsibilities. This European Standard does not cover storage equipments manufactured from materials other than steel (except for certain accessories) and equipment intended to be used for domestic storage purposes.

SIST EN 15629:2009 is classified under the following ICS (International Classification for Standards) categories: 53.080 - Storage equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15629:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Ortsfeste Regalsysteme aus Stahl - Spezifikation von LagereinrichtungenSystèmes de stockage en acier - Spécification du système de stockageSteel static storage systems - Specification of storage equipment53.080Storage equipmentICS:Ta slovenski standard je istoveten z:EN 15629:2008SIST EN 15629:2009en,fr01-januar-2009SIST EN 15629:2009SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15629November 2008ICS 53.080 English VersionSteel static storage systems - Specification of storageequipmentSystèmes de stockage en acier - Spécification du systèmede stockageOrtsfeste Regalsysteme aus Stahl - Spezifikation vonLagereinrichtungenThis European Standard was approved by CEN on 5 October 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15629:2008: ESIST EN 15629:2009

Specifiers’ and users’ responsibilities.33 Annex B (informative)

Suppliers’ responsibilities.34 Bibliography.35

APR steelwork structure consisting of frames and beams adjustable in height, specifically designed to support pallets and unit loads 3.2 bay load total allowable weight of all the unit loads in a bay of racking not including any unit loads that may be stored on the floor of the bay 3.3 compartment load load which can be loaded into one compartment of a racking or shelving structure from one side 3.4 counterbalanced forklift truck rider-operated type of forklift truck that carries its load cantilevered forward of its front main wheel axle and is stabilized with a counter weight at the rear of the truck NOTE This type of truck is a general-purpose truck and may be used in wide-aisle pallet racking systems. SIST EN 15629:2009

drive-in racking DIR system of racking that provides blocks of storage where pallets are stored two or more deep and access is gained by driving a lift truck into a lane with pallets supported along their sides on beam rails supported from the uprights 3.8 drive-through racking system of racking that provides blocks of storage where pallets are stored two or more deep similar to DIR except that the truck can be driven into a lane on one side of the block and out of the other if there are no obstructions 3.9 frame load total allowable weight of all the unit loads transmitted to the frame by the members attached to the frame 3.10 hand pallet truck small hand-operated truck used for moving pallets around on level floors and the pallet is lifted clear of the floor by raising and lowering a tiller bar that operates a hydraulic lifting device 3.11 intrusive stacking placement or retrieval of a pallet where the turning radius or length of a lift truck is greater than the aisle width and part of the pallet storage location concerned is used by the truck forks and load when turning to place or retrieve a pallet 3.12 mechanical handling equipment MHE mechanical equipment used to transport the unit load to be stored 3.13 mezzanine floors RSA additional floor above the ground floor slab level used for storage which can be free standing or attached to the building structure 3.14 narrow-aisle racking pallet racking arranged in a similar way to wide aisle racking but having aisles of a reduced width for use with more specialist types of lift truck SIST EN 15629:2009

3.16 pallet buffer back stop buffering back stop, which is specified as an aid for use by forklift truck drivers to deposit a unit load in the correct position in the racking 3.17 pallet safety back stop safety back stop to prevent accidental collision of a pallet or its load with other unit loads or equipment, when that load is placed in the storage compartment

type (a) safety device, which protects against unintentional load movement within the racking and prevents loads from protruding or from falling into an aisle or into an area accessible to people

type (b) backstop to prevent accidental damage, usually placed at the back of a storage compartment, to prevent the accidental collision of a pallet or its load with other equipment, such as sprinklers, when a load is placed in the storage compartment 3.18 pick up and deposit stations P and D stations storage locations at the end of an aisle used as an interface between different types of mechanical handling equipment NOTE The P and D stations can be used as an interface between the unit load and handling equipment that is dedicated to the rack aisle (such as very narrow aisle (VNA) trucks or cranes) and the conveyors or free movement trucks which service the installation. The P and D stations can also be used to accurately fix the location of the unit load relative to the racking. This is often used by trucks or cranes having a fixed length of fork stroke and ensures accuracy in the X and Z directions when placing the unit load onto the racking beams. 3.19 powered hand pallet truck

small hand-operated truck used for moving pallets around on level floors where the power for lifting and moving the pallet loads is provided by a battery and electric motor. 3.20 reach truck stacking lift truck with outriggers where the load can be repositioned by moving the mast or fork arm carriage NOTE These trucks are generally used in narrow aisle racking because their overall length is less than a counterbalanced lift truck of the same lifting capacity. 3.21 shelving hand-loaded supporting surfaces supported by upright frames 3.22 specified allowable unit load unit load allowed in the storage equipment 3.23 specifier person or company that provides the supplier with a specification based on the user’s requirements NOTE The specifier can be a consultant or other specialist, the end user or the equipment supplier acting as the specifier. SIST EN 15629:2009

NOTE This may be the total load from beams or shelves in a defined area of racking or shelving. 3.28 unit load weight of an individual stored item that can be placed or retrieved in one operation 3.29 user company or person who manages and operates the installation on a daily basis and is responsible for the continuing safety of the installation 3.30 very narrow aisle racking VNA racking pallet racking arranged with aisles of a width to cater only for the truck and the unit load width plus an operational clearance where the truck cannot make 90° turns into the rack face for loading and off loading 3.31 very narrow aisle truck VNA truck rider operated fork lift truck which can work in aisles only slightly wider than the truck or the unit load carried and is fitted with a fork mechanism permitting access on either side of the aisle without turning the main body of the truck. NOTE 1 VNA trucks are normally guided within the aisles. Because of the accuracy required in placing pallets into the racking, these trucks usually pick the pallet loads up from a specially designed P&D station at the entrance to each aisle. NOTE 2 A VNA truck is sometimes known as a Turret Truck. 3.32 wide-aisle racking pallet racking arranged to leave aisles of sufficient width to allow the forklift truck equipment to traverse the length of the aisle and to make 90° turns into the rack face for loading and off loading. 3.33 90° stacking placement or retrieval of a pallet where the forklift truck makes a 90° turn to face the rack during the placement or retrieval process. NOTE In making this turn no part of the truck or load intrudes into the racking. SIST EN 15629:2009

NOTE This is to allow sufficient design clearances to be provided for the safe depositing and retrieval of goods. f) specification of the handling equipment to be used, e.g. type of truck etc., in relation to the storage equipment (see EN 15620 for information on truck turning radius and effective aisle width requirements); g) specify if the user shall carry out the installation of the storage equipment; h) all known information about planned future changes to storage requirements; The specifiers' and users' responsibilities are further clarified in Annex A. 4.2 Storage system structural design The supplier, provided with the relevant specification information, shall design the storage equipment in accordance with the relevant European Standards or, if not available, industry codes of practice. The designer may assume that the clearances specified in relation to the material handling equipment intended for use with its operational specification, are such that accidental collision forces may be neglected in the structural design. 4.3 Storage equipment dimensioning For adjustable pallet racking, EN 15620 shall be used in the design and layout to provide guidance on the relevant tolerances, deformations and clearances. 4.4 Storage equipment installation If it is specified that the installation work is not to be undertaken by the supplier, then the supplier shall provide written assembly and installation instructions to their customers on the basis that the installers are experienced and competent for the work involved. NOTE The correct assembly and installation of the storage equipment is of equal importance to the provision of a safe structural design. The persons carrying out the assembly and installation should be trained and experienced in the work to be done and should be properly supervised and controlled to ensure that the health and safety of all persons is safeguarded. The quality and accuracy of the installation work can have a significant effect on the performance and structural integrity of the storage equipment. The supplier’s workforce should be trained to carry out this work efficiently and have the experience to do so safely. SIST EN 15629:2009

NOTE 2 The deformations of the floor, occurring as a consequence of the imposed loads, will cause the racking to be out of plumb. If the racking is no longer vertical, the gravity loads exerted by the contents of the racking will generate a horizontal sway load component, (see Figures 1 and 2). For a large unanticipated floor deformation, this horizontal component of load can be greater than the safe value considered in the design of the storage equipment.

CCCTφ∆ Key C compression T tension ∆ floor deflection - floor slope under the rack frame Figure 2 — Additional horizontal and vertical forces on the storage equipment components such as portal ties, frame bracing, uprights and floor fixings due to suspended floor deformation 6.2.1.3 Floor deformations The properties of the foundation base, including floor deformation over time, shall be defined by the specifier.

NOTE 1 Elastic floor deformation effects, such as those shown in Figures 1 and 2, can increase with time due to the creep of structural materials such as concrete, timber or unstable floor materials such as bitumen. Settlement of the subsoil under a concrete ground bearing floor slab or foundation base can also cause these effects.

NOTE 2 The storage equipment designer may consider the floor as quasi rigid (see EN 15620) unless otherwise specified. NOTE 3 When VNA lift trucks are used, there is a relationship between the flatness, levelness, and deformation of the floor and safety and efficiency in use. For a given unevenness of the floor, the truck, which may elevate loads while travelling, will sway sideways in the aisle so as to risk colliding with the equipment or loads already placed. SIST EN 15629:2009

Figure 3 — Over-rack mezzanine floor

1 Guidance on shelving design is available in FEM 10.2.06. SIST EN 15629:2009

Figure 4 — Over-rack mezzanine floor supporting shelving

Figure 5 — Multi-tier shelf racking

Figure 6 — Walkways suspended between the upright frames SIST EN 15629:2009

NOTE 1 Areas where goods are raised or lowered by means of a lift truck are high risk areas. One method of edge guarding an opening at the edge of a floor can be to provide a special type of fence or barrier, which the worker can raise without having to approach the edge. NOTE 2 Examples of edge guarding are handrails, knee rails, pallet gates, mesh screens and kickboards. 6.5 Details of goods to be stored 6.5.1 Non-palletized goods Data to be provided in the specification shall include: a) length, width, height and shape per item; b) tolerances of unit load dimensions; c) weight per item; d) manner of handling. 6.5.2 Palletized goods Data to be provided in the specification shall include: a) maximum weight of goods on one pallet; b) type and quality of pallet, pallet tolerances (actual minimum pallet dimensions) and pallet entry directions; SIST EN 15629:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...