SIST EN 61029-2-3:2011

(Main)Safety of transportable motor-operated electric tools - Part 2-3: Particular requirements for planers and thicknessers (IEC 61029-2-3:1993, modified + A1:2001)

Safety of transportable motor-operated electric tools - Part 2-3: Particular requirements for planers and thicknessers (IEC 61029-2-3:1993, modified + A1:2001)

Applies to transportable planers and thicknessers with a maximum planing width of 260 mm.

Sicherheit transportabler motorbetriebener Elektrowerkzeuge - Teil 2-3: Besondere Anforderungen an Abrichthobel und Dickenhobel (IEC 61029-2-3:1993, modifiziert + A1:2001)

Sécurité des machines-outils électriques semi-fixes - Partie 2-3: Règles particulières pour les dégauchisseuses et les raboteuses (CEI 61029-2-3:1993, modifiée + A1:2001)

S'applique aux dégauchisseuses et aux raboteuses semi-fixes présentant une largeur de rabotage maximale de 260 mm.

Varnost premičnih električnih orodij - 2-3. del: Posebne zahteve za skobeljnike in debelinske skobeljne stroje (IEC 61029-2-3:1993, spremenjen + A1:2001)

Ta točka 1. dela se uporablja, razen: Dodatek: Ta evropski standard velja za skobeljnike, debelinske skobeljne stroje in kombinirane skobeljnike ter debelinske skobeljne stroje za rezanje lesa in podobnih materialov z največjo debelino skobljanja 330 mm.

General Information

- Status

- Published

- Publication Date

- 27-Jul-2011

- Technical Committee

- I09 - Imaginarni 09

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 13-Jul-2011

- Due Date

- 17-Sep-2011

- Completion Date

- 28-Jul-2011

- Directive

- 98/37/EC - Machinery

- Mandate

- M/083 - Machinery

Overview

EN 61029-2-3:2011 - published by CENELEC - is the European safety standard for transportable motor‑operated electric tools that perform planing and thicknessing of wood and analogous materials. It is Part 2-3 of the EN 61029 series and is intended to be used together with EN 61029-1:2009 (Part 1: General requirements). The standard defines particular safety requirements, tests and marking/information obligations specific to planers, thicknessers and combined machines.

Key topics and requirements

- Scope & definitions: Specific definitions for planer, thicknesser, combined planer/thicknesser and cutter block; applies to transportable machines for cutting wood (see standard for maximum planing width).

- Marking & user information: Mandatory inscriptions such as no‑load cutter block speed, rotation direction, planing width, and comprehensive instruction handbook content (warnings, guard checks, blade sharpening/assembly, push‑stick use and storage).

- Guards and anti‑kickback: Requirements and design guidance for bridge‑type guards, swivel guards, anti‑kickback devices and feed‑safety features to reduce kick‑back and contact hazards. Annex ZA includes stability tests for bridge guards.

- Electrical safety: Protection against electric shock, insulation and leakage current tests, wiring, components and earthing/provision requirements in line with Part 1.

- Mechanical & endurance tests: Mechanical strength, stability, abnormal operation and endurance testing to confirm safe performance under normal and fault conditions.

- Noise, vibration & dust: Measurement and information requirements for noise and vibration (test conditions specified, e.g., Table Z101). Dust measurement procedures and guidance are provided in Annex ZD; the standard also advises on dust‑collection and PPE.

- Construction & materials: Requirements on cutter block construction, blade fixing, clearances, creepage distances, resistance to heat/fire/tracking and corrosion.

Applications and who uses it

- Manufacturers and designers of portable planers, thicknessers and combined machines - for product design, safety compliance and CE marking.

- Test laboratories and conformity assessors - to perform required mechanical, electrical and noise/dust tests.

- Safety engineers, compliance officers and purchasers - to evaluate machine safety, user instructions and suitability for workshop use.

- Technical writers and trainers - to prepare manuals and operator training that meet marking and information requirements.

Related standards

- EN 61029-1:2009 (Part 1 - General requirements)

- EN ISO 12100 (risk assessment and machine safety principles)

- Directive 2006/42/EC (Machinery Directive) - Annex ZZ maps essential requirements

EN 61029-2-3:2011 is an essential reference for ensuring the safe design, testing and information provision for transportable planers and thicknessers in European markets.

Frequently Asked Questions

SIST EN 61029-2-3:2011 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Safety of transportable motor-operated electric tools - Part 2-3: Particular requirements for planers and thicknessers (IEC 61029-2-3:1993, modified + A1:2001)". This standard covers: Applies to transportable planers and thicknessers with a maximum planing width of 260 mm.

Applies to transportable planers and thicknessers with a maximum planing width of 260 mm.

SIST EN 61029-2-3:2011 is classified under the following ICS (International Classification for Standards) categories: 25.140.20 - Electric tools; 79.120.20 - Woodworking tools. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 61029-2-3:2011 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/083, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 61029-2-3:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sicherheit transportabler motorbetriebener Elektrowerkzeuge - Teil 2-3: Besondere Anforderungen an Abrichthobel und Dickenhobel (IEC 61029-2-3:1993, modifiziert + A1:2001)Sécurité des machines-outils électriques semi-fixes - Partie 2-3: Règles particulières pour les dégauchisseuses et les raboteuses (CEI 61029-2-3:1993, modifiée + A1:2001)Safety of transportable motor-operated electric tools - Part 2-3: Particular requirements for planers and thicknessers (IEC 61029-2-3:1993, modified + A1:2001)79.120.20Lesnoobdelovalno orodjeWoodworking tools25.140.20Electric toolsICS:Ta slovenski standard je istoveten z:EN 61029-2-3:2011SIST EN 61029-2-3:2011en01-september-2011SIST EN 61029-2-3:2011SLOVENSKI

STANDARD

EUROPEAN STANDARD EN 61029-2-3 NORME EUROPÉENNE

EUROPÄISCHE NORM June 2011

CENELEC European Committee for Electrotechnical Standardization Comité Européen de Normalisation Electrotechnique Europäisches Komitee für Elektrotechnische Normung

Management Centre: Avenue Marnix 17, B - 1000 Brussels

© 2011 CENELEC -

All rights of exploitation in any form and by any means reserved worldwide for CENELEC members.

Ref. No. EN 61029-2-3:2011 E

ICS 25.140.20

English version

Safety of transportable motor-operated electric tools -

Part 2-3: Particular requirements for planers and thicknessers (IEC 61029-2-3:1993, modified + A1:2001)

Sécurité des machines-outils électriques semi-fixes -

Partie 2-3: Règles particulières pour les dégauchisseuses et les raboteuses (CEI 61029-2-3:1993, modifiée + A1:2001) Sicherheit transportabler motorbetriebener Elektrowerkzeuge -

Teil 2-3: Besondere Anforderungen an Abrichthobel und Dickenhobel (IEC 61029-2-3:1993, modifiziert + A1:2001)

This European Standard was approved by CENELEC on 2011-02-14. CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the Central Secretariat or to any CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CENELEC member into its own language and notified to the Central Secretariat has the same status as the official versions.

CENELEC members are the national electrotechnical committees of Austria, Belgium, Bulgaria, Croatia, Cyprus, the Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, the Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom.

Normative references . 27Annex ZA (normative)

Stability test for bridge type guards . 28Annex ZD (informative)

Dust measurement . 35Annex ZZ (informative)

Coverage of Essential Requirements of Directive 2006/42/EC . 37 SIST EN 61029-2-3:2011

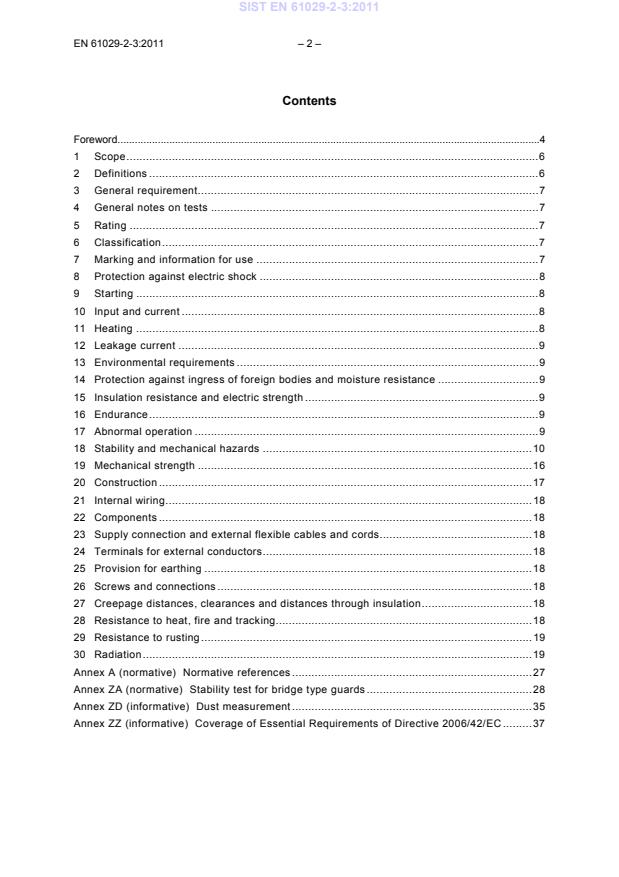

– 3 – EN 61029-2-3:2011 Figures Figure Z101 – Example of a thicknesser . 20Figure Z102 – Example of a combined planer and thicknesser . 21Figure Z103 – Cutter block. 22Figure Z104 – Measurement of the cutter block chip groove . 23Figure Z105 – Details of two alternative bridge type guard leading edge . 23Figure Z106 – Design preventing kick-back . 24Figure Z107 – Examples of anti kick-back devices . 25Figure Z108 – Test probe . 25Figure Z109 – Example of a push-stick . 26Figure Z110 – Example of a swivel-type guard . 26Figure ZA.1 – Bridge-type guard . 31Figure ZA.2 – Bridge deflection . 32Figure ZA.3 – Bridge free play . 32Figure ZA.4 – Bridge strength test . 33Figure ZA.5 – Lateral impact test . 34Figure ZA.6 – Side impact test apparatus . 34Figure ZD.101 – Orientation of tool and operator . 36 Tables Table Z101 – Noise test conditions for planers and thicknessers . 9Table Z102 – Table sizes . 11Table Z103 – Parallel guide sizes . 13Table Z104 – Material specification . 15Table ZD.101 – Conditions for dust measurements on planers . 35Table ZD.102 – Conditions for dust measurements on thicknessers . 35 SIST EN 61029-2-3:2011

(dop)

2012-02-14 – latest date by which the national standards conflicting with the EN have to be withdrawn

(dow)

2014-02-14 This European Standard is divided into two parts: Part 1 General requirements that are common to most transportable electric motor operated tools (for the purpose of this European Standard referred to simply as tools) which could come within the scope of this European Standard; Part 2 Requirements for particular types of tool which either supplement or modify the requirements given in Part 1 to account for the particular hazards and characteristics of these specific tools. This European Standard has been prepared under Mandate M/396 given to CENELEC by the European Commission and the European Free Trade Association and covers essential requirements of EU Directive 2006/42/EC. See Annex ZZ. Compliance with the relevant clauses of Part 1 together with this Part 2-3 provides one means of conforming with the specified essential requirements of the Directives. The requirements defined in EN ISO 12100 are also dealt with in this European Standard. For noise and vibration this European Standard covers the requirements for their measurement, the provision of information arising from these measurements and the provision of information about the personal protective equipment required. Specific requirements for the reduction of the risk arising from noise and vibration through the design of the tool are not given as this reflects the current state of the art.

Warning: Other requirements arising from other European Directives can be applicable to the products falling within the scope of this European Standard. This Part 2-3 is to be used in conjunction with EN 61029-1:2009. This Part 2-3 supplements or modifies the corresponding clauses of EN 61029-1, so as to convert it into the European Standard: “Safety of transportable motor-operated electric tools – Part 2-3: Particular requirements for planers and thicknessers”. Where a particular clause or subclause of Part 1 is not mentioned in this Part 2-3, that clause or subclause applies as far as is reasonable. Where this Part 2-3 states "addition", "modification" or "replacement", the relevant text of Part 1 is to be adapted accordingly. SIST EN 61029-2-3:2011

– 5 – EN 61029-2-3:2011 Clauses, subclauses, notes, tables and figures which are additional to those in Part 1 are numbered starting from 101. Clauses, subclauses, notes, tables and figures which are additional to those in EN 61029-2-3 are prefixed “Z”. NOTEIn this standard the following print types are used:

- requirements proper: in roman type

- test specifications: in italic type;

- explanatory matter: in smaller roman type. SIST EN 61029-2-3:2011

NOTE Z101 EN 859 gives requirements for planers other than transportable. This European Standard does not apply to thicknessers other than transportable.

NOTE Z102 EN 860 gives requirements for thicknessers other than transportable. This European Standard does not apply to planing and thicknessing machines other than transportable. NOTE Z103 EN 861 gives requirements for planing and thicknessing machines other than transportable. 2 Definitions This clause of Part 1 is applicable except as follows: 2.21 Replacement: normal load load to obtain rated input 2.101 planer machine designed to plane the surface of wood by means of a cutter block rotating about a horizontal axis and located between two frames used to position and support the work piece. The lower surface of the work piece is planed 2.102 thicknesser machine designed to plane wood to a set thickness by means of a cutter block rotating about a horizontal axis with mechanical feed, the distance between the knives and the surface of the table supporting the work piece being adjustable. The upper surface of the work piece is planed (see Figure Z101) 2.103 combined planer and thicknesser machine designed to carry out the functions of both a planer and a thicknesser (see Figure Z102) 2.104 cutter block rotating assembly consisting of the drum, the blades, the blade fixing system and the spindle SIST EN 61029-2-3:2011

– 7 – EN 61029-2-3:2011 3 General requirement This clause of Part 1 is applicable. 4 General notes on tests This clause of Part 1 is applicable. 5 Rating This clause of Part 1 is applicable. 6 Classification This clause of Part 1 is applicable. 7 Marking and information for use This clause of Part 1 is applicable except as follows: 7.1 Addition: – no-load speed of the cutter block; – indication of direction of rotation of the cutter block; – planing width. 7.6 Addition: The direction of rotation of the cutter block shall be indicated on the tool by an arrow raised or sunk, or by any other means not less visible and indelible. 7.13 Addition: The instruction handbook shall contain a repeat of the warnings affixed to the tool. The substance of the following instructions shall also be given:

c) Safety precautions – instruction how to check the guard adjusting arrangements and return springs, when fitted, for faultless condition before use; – instruction to use blades which are well sharpened and maintained. If blades are re-sharpenable: information about the limits of re-sharpening; – instruction to use only cutting blades designed for this machine; – instruction how the blades shall be assembled and adjusted, if applicable; – instruction that any portion of the cutter block not being used for planing shall be adjusted to be guarded; – instruction how to inspect the anti-kickback devices and feed speed spindles to ensure safe operation; SIST EN 61029-2-3:2011

– instructions how to adjust the guards and fence in relation to the different work; – information about the effects caused by metal parts penetrated into the work piece and splintery work pieces; – instruction how correctly to use roller tables when cutting long work pieces; – warning not to do the following operations: i) stopped work (i.e. any cut which does not involve the full work piece length); ii) recesses, tenons or moulds; iii) planing of badly bowed wood where there is inadequate contact on the infeed table. NOTE Sketches may be used to illustrate the modes of operation. 8 Protection against electric shock

This clause of Part 1 is applicable. 9 Starting This clause of Part 1 is applicable. 10 Input and current This clause of Part 1 is applicable. 11 Heating This clause of Part 1 is applicable. SIST EN 61029-2-3:2011

– 9 – EN 61029-2-3:2011 12 Leakage current This clause of Part 1 is applicable. 13 Environmental requirements This clause of Part 1 is applicable except as follows: 13.2.1 Addition: The most important sources of noise of planers and thicknessers are: – the cutting blades; – the infeed table. NOTE For general information concerning the reduction of noise see EN ISO 11688-1. 13.2.4 Replacement of paragraphs 1, 2 and 3: Planers and thicknessers are tested under the conditions shown in Table Z101. Table Z101 – Noise test conditions for planers and thicknessers Material Beech – minimum dimensions 20 mm × 50 mm × 400 mm Feed-speed (4 ± 0,5) m/min for planing, maximum feed speed for thicknessing Depth of cut 1 mm

Width of cut-off 50 mm for planing and thicknessing with parallel guide set for maximum width

Tool bit/cutter/ abrasive New blades, as recommended by the manufacturer for solid wood.

Work cycle Five passes, each following the other, to be done on one workpiece

13.3 Modification: This subclause is not applicable. 14 Protection against ingress of foreign bodies and moisture resistance This clause of Part 1 is applicable. 15 Insulation resistance and electric strength This clause of Part 1 is applicable. 16 Endurance This clause of Part 1 is applicable. 17 Abnormal operation This clause of Part 1 is applicable, except as follows: All machines covered by this particular part are considered to be machines in which moving parts are liable to be jammed. SIST EN 61029-2-3:2011

The cutter block shall have a circular shape in any cross section perpendicular to the axis of the cutter block which performs the function of chip thickness limitation. Compliance is checked by inspection. 18.1.101.2

The cutting edge of the blades shall not extend more than 1,1 mm (see dimension a in Figure Z103) past the surface of the cutter block. Compliance is checked by measurement. 18.1.101.3

There shall be no recess in the cutter block except for the cutting blades and their fastening devices (see Figure Z103). The chip groove in front of the blade shall have a maximum depth (d) measured radially to the cutter block in accordance with Figure Z104. Compliance is checked by inspection and measurement. 18.1.101.4

The blades shall be fixed to the cutter block in such a way that friction alone is not relied upon to prevent ejection of the blades. The clamping screws, if any, shall engage for a minimum of six full threads when fitted to a steel cutter block. When the cutter block is made of material other than steel the clamping arrangement shall have the same degree of strength as that provided by the requirement for the clamping screw for steel block. The cutter block shall ensure that blade(s) are clamped over their total length.

Compliance is checked by inspection and by the following test: The blades are fitted to the cutter block in accordance with the manufacturer’s instructions. The projection of the blades is measured and the cutter block is run at maximum speed nmax for 5 min, after this test the projection of the blades is measured again and the displacement shall not exceed 0,15 mm.

The cutter block is then run at the test speed np for 5 min, the projection of the blades is measured and the displacement from the previous shall not exceed 0,15 mm.

where nmax = maximum no-load speed in revolutions per minuteof the cutter block at rated voltage or at the upper limit of the rated voltage range; and np = 1,5 × nmax.

18.1.101.Z1

Handles and levers shall not impede the operator when feeding or loading the work piece. Compliance is checked by inspection. SIST EN 61029-2-3:2011

– 11 – EN 61029-2-3:2011 18.1.102 Planers 18.1.102.1

The dimensions of the tables supporting the work piece shall comply with Table Z102. Table Z102 – Table sizes Working width (W) in millimetres Minimum length of the tables in millimetres measured from the cutter block axis to the end of the table(in-feed and out-feed table) W ≤ 200

1,5 × W W > 200 1,75 × W

The outfeed table surface, if not adjustable, shall be in line with the cutting circle diameter, as illustrated in Figure Z103.

If the outfeed table height is adjustable, it shall not be possible to adjust it more than 1,1 mm below the cutting circle diameter. At any depth of cut, the distance “b” (see Figure Z.103) between the cutting circle and the lips of the tables shall not exceed 5 mm measured radially. 18.1.102.2

Recesses in the lips of the planer tables provided in order to reduce the noise shall not exceed a width of 6,0 mm. Holes to obtain the same effect shall have diameters not exceeding 6,0 mm. 18.1.102.3

The lip of the infeed table shall be strong enough to prevent deformation or damage. Compliance is checked by the following test: Blows are applied on the lip with a spring-operated impact test apparatus (mass of 250 g with an energy of 1,0 J). Three blows are applied to every point of the lip supposed to be weak. After testing, the lip shall remain intact without visible fissure or deformation prejudicial to the correct operating of the machine. 18.1.102.4

Cutting blades for planers designed for rebating shall extend over the edge of the cutter block by not more than 5,0 mm. The thickness of the body of such blades shall be not less than 3,0 mm. For tools designed for rebating the side of the cutting blades shall be guarded when not being used for rebating and the guard shall be lockable in the closed position without the aid of a tool. This guard shall be adjustable or self-closing and shall be not more than 3,0 mm from the cutting blade. The guard shall be designed so it cannot touch the blades. The part of the cutter block not used during the rebating operation shall be completely guarded. Machines not intended for rebating shall be so designed that this operation is not possible. 18.1.102.5

Planers shall have guards covering the cutter block on both sides of the parallel guide. The cover of the cutter block behind the parallel guide shall be fixed to the parallel guide so that the cutter block is automatically protected when moving the parallel guide. SIST EN 61029-2-3:2011

Parts not used during work (behind the parallel guide) Access to blades shall be prevented by a guard, the dimensions of which are such as to cover the cutter block, located behind the guide, whatever the position of the guide, e.g. by extended part of the guide. If the guide is adjustable in position (transverse adjustment or inclination) the guard displacement shall be associated with the guide displacement. 18.1.102.5.2

Parts used during work (in front of the parallel guide) Access to blades usable during work shall be prevented by a device rigidly locked with the frame of the machine, which allows only the used part of the cutter block to be uncovered. This device shall be: – a bridge-type guard or swivel-type guard for planing machines with a planing width not greater than 100 mm; – a bridge-type guard for planing machines with a planing width greater than 100 mm. 18.1.102.5.2.1

Bridge-type guard a) The bridge guard shall be able to lie flat on at least one of the machine tables, when planing is not carried out (rest position). b) The bridge length, intended to prevent access to the blades, shall be at least equal to the working width. c) In the rest position, the bridge shall cover the slot and extend on the tables on both sides, over a distance at least equal to 10 mm from the lips when the slot width, see Figure ZA.1, is maximum. d) When the bridge is set at any height, the front part of the bridge shall cover at least the area in the vertical plane passing through the edge of the infeed table lip, for the maximum slot width. e) At any height, the differences of level between the front part and the rear part of the bridge shall not exceed 5,0 mm. f) During the transverse adjustment, the bridge shall move in a direction parallel with the cutter block axis. g) It shall be possible to lock the horizontal adjustment of the bridge type guard in any position without the aid of a tool and the bridge type guard shall remain in its locked position. h) It shall be adjustable in height from 0 mm to maximum 85 mm above the outfeed table and this adjustment shall be stepless and it shall return automatically to its pre-set position (for example by spring loading) after being pressed down. i) The upper surface of the bridge shall be smooth, rounded and free of projection.

j) Its lower surface shall be so designed that there is no obstruction to the passage of the work piece through the machine. The leading edge of the guard at the infeed side shall be shaped in such a way that one of the requirements of Figure Z105 is met. The guard shall have sufficient stability and shall be in compliance with the tests as described in the Annex ZA. 18.1.102.5.2.2

Swivel-type guard Figure Z110 illustrates an example of swivel-type guard. SIST EN 61029-2-3:2011

– 13 – EN 61029-2-3:2011 a) When planing is not carried out, the guard shall cover the whole cutter block whatever the parallel guide adjustment is. b) Whatever the used working width is, the guard shall cover the part of the cutter block which is not being used and shall open on contact with the work piece. c) It shall remain in contact with the work piece during the whole planing action and there shall be no means to lock it in the open position.

d) It shall return automatically to the closed position with a maximum time of 0,2 s for the maximum working width and the maximum open position.

e) The gap between lower surface of the guard and outfeed table shall be not greater than 4,0 mm. 18.1.102.5.2.3

The bridge or swivel type guard shall be made from a material such that any unintended contact with the rotating cutter block does not cause any of the following: – damage prejudicial to the functioning of the guard such as breaking or partial rupture; – damage to blades; – damage to the guard in case of shock with the work piece. Compliance is checked by applying blows on the guard with a spring-operated impact test apparatus (mass of 250 g with energy of 1,0 J). Three blows are applied to every point of the guard supposed to be weak. After testing, the guard shall remain intact without visible fissure or deformation prejudicial to the correct operating of the machine. 18.1.102.6

Planers shall be provided with a parallel guide. The parallel guide shall comply with the dimensions specified in Table Z103. Table Z103 – Parallel guide sizes Working width (W) in millimetres Minimum length of the guide on both sides of the cutter block in millimetres. The whole length shall not exceed the table length Height of the guide in millimetres

W ≤ 200 2,3 × W 0,4 × W W > 200 2,5 × W 0,5 × W

The guiding surface as well as its upper surface shall have no gaps. If there is no specific compliance statement, compliance with 18.1.102.1 to 18.1.102.6 is checked by measurement and inspection. 18.1.103 Thicknessers 18.1.103.1

Thicknessers shall be designed to prevent kickback by: a) arrangement of the cutter block between barriers on the infeed and outfeed side designed according to Figure Z106; or b) providing anti-kickback devices; or c) other designs. SIST EN 61029-2-3:2011

The test is repeated but with the infeed table set at maximum capacity of thicknessing and a piece of beech wood of the same thickness and 100 mm width. Compliance for other designs is checked as follows: The material as described in Table Z104 is placed on the infeed table with the machine set at operating speed and adjusted to the dimensions of the material and depth of cut as per Table Z104. The material is fed through its full length using a push stick with the operator positioned out of the line of material (in case of kickback). The test shall be conducted in all positions over the cutting width. If the material does not kickback or move backwards more than 50 mm in all sizes and materials the test is fulfilled. SIST EN 61029-2-3:2011

– 15 – EN 61029-2-3:2011 Table Z104 – Material specification

Material Dimensions Depth of cut Hard wood (Mahogany) Maximum capacity × 1 m length × 100 mm width Maximum Hard wood (Mahogany) Minimum capacity × 1 m length × 100 mm width Maximum Soft wood (Pine) Maximum capacity × 1 m length × 100 mm width Maximum Soft wood (Pine) Minimum capacity × 1 m length × 100 mm width Maximum

18.1.103.2

A stop shall be provided to prevent the upward movement of the table to 0,5 mm below the anti-kickback devices, if any.

Compliance is checked by inspection and measurement. 18.1.103.Z1

Thicknessers shall be equipped with an automatic feeding mechanism for the workpiece consisting of infeed and outfeed rollers. Compliance is checked by inspection. 18.1.103.Z2

Thicknessers shall be provided with fixed lateral and top guards which prevent any access to the cutter block.

Compliance is checked by inspection. 18.1.103.Z3

In order to prevent the feeding of oversized work pieces a device located at the infeed side of the machine shall limit the maximum cutting height. Lateral guides shall be provided to restrict the working width to the cutter block width. Compliance is checked by inspection. 18.1.103.Z4

The length of the table shall extend at least from the cutting height limiting device to the centre of the outfeed roller. Compliance is checked by inspection and measurement. 18.1.103.Z5

Chip ejection apertures which are not capable of having powered chip extraction devices fitted to them shall be constructed in such a way that the cutter block is not accessible through them. Compliance is checked by applying the test probe of Figure Z108. 18.1.104 Combined planers and thicknessers 18.1.104.1

For these combined machines the requirements stated for both planers and thicknessers shall be met. SIST EN 61029-2-3:2011

It shall be safe to change between planning and thicknessing mode either by – a design that does not require any alteration of the machine; or – an interlocked removable or adjustable guard. If the planer table can be folded up or removed to realise the different operating modes, it shall be considered as a movable guard. The time for opening the moveable guard shall be longer than the run-down time of the blade. 18.1.104.3

Tables, which can be folded up, shall be automatically secured when in the open position. Compliance with 18.1.104.1 to 18.1.104.3 is checked by inspection and measurement. 18.2 Modification: All machines covered by this European Standard shall be provided with means to fix the machine to a table or a similar support. Compliance is checked by inspection. 18.3 Modification: Machines not fixed to a table shall have a sufficient stability. The tool shall be placed on a horizontal fixed chipboard with smooth surface. When a push force of 100 N is applied to the front edge of the tool in the direction of the work piece feed, the tool shall not move or start to tip. The force in then increased to 300 N or until the tool begins to move horizontally, whichever is achieved first. During this test the tool shall not tip over. 19 Mechanical strength

This clause of Part 1 is applicable except as follows: 19.1 Addition: The guards above and below the table shall be manufactured from: a) steel having the following characteristics: Ultimate tensile strength N/mm² Minimum thickness mm 350

1,50 380

1,25

b) light alloy with the characteristics given below: Ultimate tensile strength N/mm² Minimum thickness mm 160 2,5 200 2,0 SIST EN 61029-2-3:2011

– 17 – EN 61029-2-3:2011 c) polycarbonate with a wall thickness of at least 3 mm or other plastic material having an impact strength equal to or better than a polycarbonate of at least 3 mm thickness. Compliance is checked by examining the relevant drawings, measurement, inspection of the tool and by receipt of confirmation of the ultimate strength by the manufacturer of the material. 20 Construction This clause of Part 1 is applicable except as follows: 20.18 Addition: The actuation of the mains switch or control device shall not be affected by, nor access to the switch or control device be restricted by, adjustment of the table position or by the work piece. Compliance is checked by inspection. The machine shall be designed to avoid inadvertent starting. Compliance is checked by the following test. It shall not be possible to start the machine by applying a sphere with a diameter of (100 ± 1) mm to the switch. 20.19 Addition: After switching off the motor the stopping time of the cutter block shall not exceed 10 s. Compliance is checked by the following test: When selecting the speed, conditions shall be chosen which create the greatest kinetic energy for which the machine is designed. Warm up the cutter block spindle for at least 1 min by running the machine under no-load before beginning the test. The time measuring equipment shall have an accuracy of ± 0,1 s. Unbraked run-down time: Start the motor and run at no-load for 1 min. The unbraked run-down time of the machine is the average of three measurements taken. Braked run-down time: Start the motor and run at no-load for 1 min. The braked run-down time of the machine is the average of ten measurements taken. 20.20 Addition: After voltage recovery following a voltage failure, all machines covered by this European Standard shall not start automatically. Compliance is checked by inspection. SIST EN 61029-2-3:2011

Planers, thicknessers and combined planers and thicknessers shall be provided with effective lifting and transportation positions, which are identified clearly on the machine and in the instructions. 20.Z102

Planers, thicknessers and combined planers and thicknessers shall be provided with a push-stick and a provision to store the push-stick on the machine when not in use. Figure Z109 shows an example of a push stick. Compliance with 20.Z101 to 20.Z102 is checked by inspection. 20.Z103

The machines shall be provided with – tools required for blade change; – a gauge for blade adjustment, if the blades are adjustable in accordance with 7.13 c). Compliance is checked by inspection. 21 Internal wiring This clause of Part 1 is applicable. 22 Components This clause of Part 1 is applicable. 23 Supply connection and external flexible cables and cords This clause of Part 1 is applicable. 24 Terminals for external conductors This clause of Part 1 is applicable. 25 Provision for earthing This clause of Part 1 is applicable. 26 Screws and connections

This clause of Part 1 is applicable. 27 Creepage distances, clearances and distances through insulation

This clause of Part 1 is applicable. 28 Resistance to heat, fire and tracking This clause of Part 1 is applicable. SIST EN 61029-2-3:2011

– 19 – EN 61029-2-3:2011 29 Resistance to rusting

This clause of Part 1 is applicable. 30 Radiation This clause of Part 1 is not applicable. SIST EN 61029-2-3:2011

Figure Z101 – Example of a thicknesser

– 21 – EN 61029-2-3:2011

Key 1 outfeed table 2 guard − bridge type 3 infeed table 4 detachable support 5 parallel guide Figure Z102 – Example of a combined planer and thicknesser

Key 1 outfeed table

2 infeed table 3 table lips 4 cutting circle Figure Z103 – Cutter block SIST EN 61029-2-3:2011

– 23 – EN 61029-2-3:2011

Chip groove dimensions Cutter block diameter (D) in millimetres D ≤ 80 80 < D ≤ 120 d in millimetres 6,00 8,00

Figure Z104 – Measurement of the cutter block chip groove Dimensions in millimetres

Figure Z105 – Details of two alternative bridge type guard leading edge

Key 1 maximum clearance = maximum cutting depth + max. 1 mm 2 maximum clearance ≤ 1 mm 3 direction of workflow 4 infeed rip 5 outfeed rip 6 cutter block 7 motor & enclosure 8 work piece 9 feeding roller 10 direction of rotation Figure Z106 – Design preventing kick-back

– 25 – EN 61029-2-3:2011

Key » feed direction Figure Z107 – Examples of anti kick-back devices

Dimensions in millimetres

Key 1 handle section 2 test section Figure Z108 – Test probe SIST EN 61029-2-3:2011

Figure Z109 – Example of a push-stick

Key 1 parallel guide 2 swivel-type guard Figure Z110 – Example of a swivel-type guard

– 27 – EN 61029-2-3:2011 Annexes The annexes of Part 1 are applicable except as follows:

Annex A (normative)

Normative references Addition: Publication Date Title EN 847-1 + A1 2005 2007 Tools for woodworking – Safety requirements – Part 1: Milling tools,circular saw blades

Informative references Addition: EN 859 + A1 2007 2009 Safety of woodworking machines – Hand fed surface planing machines EN 860 + A1 2007 2009 Safety of woodworking machines – One side thickness planing machines EN 861 + A1 2007 2009 Safety of woodworking machines – Surface planing and thicknessing machines EN ISO 11688-1 2009 Acoustics – Recommended practice for the design of low-noise machinery and equipment –

Part 1: Planning (ISO/TR 11688-1:1995)

(normative)

Stability test for bridge type guards For the following tests, the bridge is set to its low position and to a position where it covers the full width capacity of the machine, unless otherwise specified. ZA.1 Deflection of the bridge support A test force F of 80 N is applied in accordance with Figure ZA.2 to the bridge support, parallel to the cutter block rotational axis. The deflection "a" is measured along the same axis as that of force F. ZA.1.1 Test method Take up any free play in the assembly by applying a force of 20 N to the bridge support in the opposite direction to force F. The position reached will be the origin for measurement. Remove the force. Apply and remove a force of 50 N to the bridge support in the direction of F. Measure the play (deviation from the origin). Apply a test force F = 80 N to the bridge support and measure the deflection "a". ZA.1.2 Test result After the force is released, the guard support should return to the rest position obtained in ZA.1.1, second paragraph. The guard passes the test, if the requirements of the Figure ZA.2 are met. ZA.2 Measuring the free play of the bridge in its support Lock the bridge in position using the device designed for this purpose. Apply to the bridge forces F1 and F2 of 7 N parallel to the tables in a plane perpendicular to the cutter block rotational axis at a point located at 10 mm from the end of the bridge.

The deflection "b" is measured at the application point of force F1 or F2, see Figure ZA.3. ZA.2.1 Test method Apply and remove force F1. The bridge position reached will be the origin for measurements. Apply and remove the force F2. Measure the free play "b" (deviation from the origin). ZA.2.2 Test result The guard passes the test, if the requirements of Figure ZA.3 are met. ZA.3 Bridge blockage Lock the bridge in position using the device designed for this purpose. SIST EN 61029-2-3:2011

– 29 – EN 61029-2-3:2011 A test force F3 of 80 N is applied to the bridge as shown in Figure ZA.2. The direction of F3 is the same as for F (see ZA.1). The bridge shall not slide in its support. ZA.4 Friction test The test only applies, if the guard is equipped with a device that automatically returns the bridge to its preset position. Adjust the guard to be in a position at approximately half the maximum work piece height capacity of the machine. Friction is considered to be correctly adjusted at delivery. ZA.4.1 Test method Note the position of the control lever. Manually push the bridge vertically until it comes into contact with the tables. Release the bridge. Let it return to the position to which it was initially adjusted and monitor the position of the lever after release. Carry out the manoeuvre five times. Check the position of the lever. ZA.4.2 Test result The guard passes the test, if upon release the position of the control lever has not changed. ZA.5 Ergonomic characteristics The force necessary to move the bridge in its support

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...