kSIST FprEN 16477-2:2016

(Main)Glass in building - Painted glass for internal use - Part 2: Evaluation of conformity/Product standard

Glass in building - Painted glass for internal use - Part 2: Evaluation of conformity/Product standard

This European Standard covers the evaluation of conformity and the factory production control of painted glass for internal use in buildings.

Note For glass products with electrical wiring or connections for, e.g. alarm or heating purposes, other directives, e.g. Low Voltage Directive, may apply.

Glas im Bauwesen - Farbiges Glas für den Innenbereich - Teil 2: Konformitätsbewertung/Produktnorm

Diese Europäische Norm behandelt die Konformitätsbewertung und die werkseigene Produktionskontrolle von farbigem Flachglas für den Innenbereich von Gebäuden.

Anmerkung Für Glaserzeugnisse mit elektrischer/-n Verkabelung oder Anschlüssen, z. B. für Alarm- oder Heizungsanlagen, können andere Richtlinien, z. B. die Niederspannungsrichtlinie, gelten.

Verre dans la construction - Verre peint pour usage interieur - Partie 2 : Evaluation de la conformité/Norme de produit

La présente Norme européenne spécifie l’évaluation de la conformité et le contrôle de la production en usine du verre laqué destiné à un usage à l’intérieur des bâtiments.

NOTE Pour les produits verriers équipés d’un câblage ou de branchements électriques, par exemple pour les alarmes ou le chauffage, d’autres directives, notamment la Directive Basse tension, peuvent s’appliquer.

Steklo v gradbeništvu - Poslikano steklo za interno uporabo - 2. del: Vrednotenje skladnosti/Standard za proizvod TC: Steklo v gradbeništvu - Barvano/Pobarvano steklo...

General Information

- Status

- Not Published

- Public Enquiry End Date

- 08-Sep-2016

- Technical Committee

- STV - Steklo, svetloba in razsvetljava v gradbeništvu

- Current Stage

- 5520 - Unique Acceptance Procedure (UAP) (Adopted Project)

- Start Date

- 20-Jun-2016

- Due Date

- 07-Nov-2016

- Completion Date

- 25-Oct-2016

Overview

kSIST FprEN 16477-2:2016 is a European Standard developed by CEN that focuses on painted glass intended for internal use in building applications. This part 2 of the standard specifically addresses the evaluation of conformity and factory production control (FPC) requirements for painted glass products. The document supports manufacturers in ensuring that their painted glass complies with essential performance characteristics for safe, consistent, and quality use inside buildings.

This standard complements EN 16477-1, which defines terminology, requirements, and test methods related to painted glass. Together, these standards provide a comprehensive framework for product assessment and quality assurance in the glass manufacturing industry-particularly for interior architectural applications.

Key Topics

Scope and Application: Covers conformity assessment and FPC for painted glass used internally within buildings, excluding products with electrical components, which may require compliance with other directives like the Low Voltage Directive.

Product Description: Manufacturers are responsible for maintaining a detailed product description describing raw materials, glass substrates, layers of paint, and process parameters ensuring reproducibility and conformity.

Important Characteristics:

- Glass substrate properties including density, hardness (Knoop hardness), Young’s modulus, Poisson’s ratio, bending strength, thermal resistance, specific heat capacity, coefficient of linear expansion, thermal conductivity, and refractive index.

- Determination of these characteristics must consider both harmonized European specifications and equivalency demonstrations for non-standard glass components.

Assessment and Verification of Constancy of Performance (AVCP):

- Type testing to verify performance characteristics.

- Factory production control measures, including ongoing inspection and testing.

- Initial and continuous factory audits to ensure compliance and consistent quality production.

- Procedures to manage production changes or modifications impacting product conformity.

Marking and Labelling: Provides guidelines for appropriate product marking ensuring traceability and compliance with regulatory requirements.

Additional Provisions: Annexes detail factory production control requirements, testing plans, voluntary third-party involvement, and alignment with EU Regulation 305/2011.

Applications

Architectural Interiors: Painted glass products conforming to kSIST FprEN 16477-2:2016 are widely used for decorative walls, partitions, and internal glazing applications where aesthetics and performance are critical.

Building Safety: Ensuring conformity enhances fire safety, mechanical stability, and resistance to thermal stresses in environments such as offices, commercial buildings, and residential interiors.

Quality Management: The standard offers manufacturers a robust framework for internal production quality assurance and external certification, facilitating trade and compliance within the European construction market.

Product Innovation: Manufacturers can rely on this standard when introducing new painted glass products or modifying existing product lines while maintaining regulatory compliance.

Related Standards

- EN 16477-1: Provides definitions, requirements, and test methods for painted glass used internally.

- EN 356: Security glazing - resistance against manual attack.

- EN 410: Determination of luminous and solar characteristics of glazing.

- EN 673: Determination of thermal transmittance (U value).

- EN 12600: Pendulum impact test and classification for flat glass.

- EN 13501 Series: Fire classification of construction products and building elements.

- EN 15998: Fire resistance testing methodology for glass.

- prEN 16612: Load resistance determination of glass panes.

These related standards collectively support comprehensive evaluation criteria for painted glass and other glazing products in construction, enhancing safety, performance, and reliability.

Keywords: painted glass standard, internal use glass, conformity evaluation, factory production control, kSIST FprEN 16477-2:2016, glass in building, glass performance characteristics, painted glass compliance, European glass standards, construction glazing quality.

Frequently Asked Questions

kSIST FprEN 16477-2:2016 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Glass in building - Painted glass for internal use - Part 2: Evaluation of conformity/Product standard". This standard covers: This European Standard covers the evaluation of conformity and the factory production control of painted glass for internal use in buildings. Note For glass products with electrical wiring or connections for, e.g. alarm or heating purposes, other directives, e.g. Low Voltage Directive, may apply.

This European Standard covers the evaluation of conformity and the factory production control of painted glass for internal use in buildings. Note For glass products with electrical wiring or connections for, e.g. alarm or heating purposes, other directives, e.g. Low Voltage Directive, may apply.

kSIST FprEN 16477-2:2016 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building. The ICS classification helps identify the subject area and facilitates finding related standards.

kSIST FprEN 16477-2:2016 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 88/609/EEC; Standardization Mandates: M/135, M/135_AM1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

kSIST FprEN 16477-2:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Steklo v gradbeništvu - Poslikano steklo za interno uporabo - 2. del: Vrednotenje skladnosti/Standard za proizvodGlas im Bauwesen - Teil 2: Konformitätsbewertung/ProduktnormVerre dans la construction - Verre peint pour usage interieur - Partie 2 : Evaluation de la conformité/Norme de produitGlass in building - Painted glass for internal use - Part 2: Evaluation of conformity/Product standard81.040.20Steklo v gradbeništvuGlass in buildingICS:Ta slovenski standard je istoveten z:FprEN 16477-2kSIST FprEN 16477-2:2016en,fr,de01-september-2016kSIST FprEN 16477-2:2016SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

FINAL DRAFT

June

t r s x ICS

z sä r v rä t r English Version

Glass in building æ Painted glass for internal use æ Part

tã Verre dans la construction æ Verre peint pour usage interieur æ Partie

t ã Evaluation de la

Glas im Bauwesen æ Teil

tã This draft European Standard is submitted to CEN members for unique acceptance procedureä It has been drawn up by the

If this draft becomes a European Standardá CEN members are bounwhich stipulate the conditions for giving this European Standard the status of a national standard without any alterationä

This draft European Standard was established by CEN in three ofer language made by translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

Recipients of this draft are invited to submitá with their commentsá notification of any relevant patent rights of which they are aware and to provide supporting documentationä

Warning ã This document is not a European Standardä It is distributed for review and commentsä It is subject to change without notice and shall not be referred to as a European Standardä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä FprEN

s x v y yæ tã t r s x EkSIST FprEN 16477-2:2016

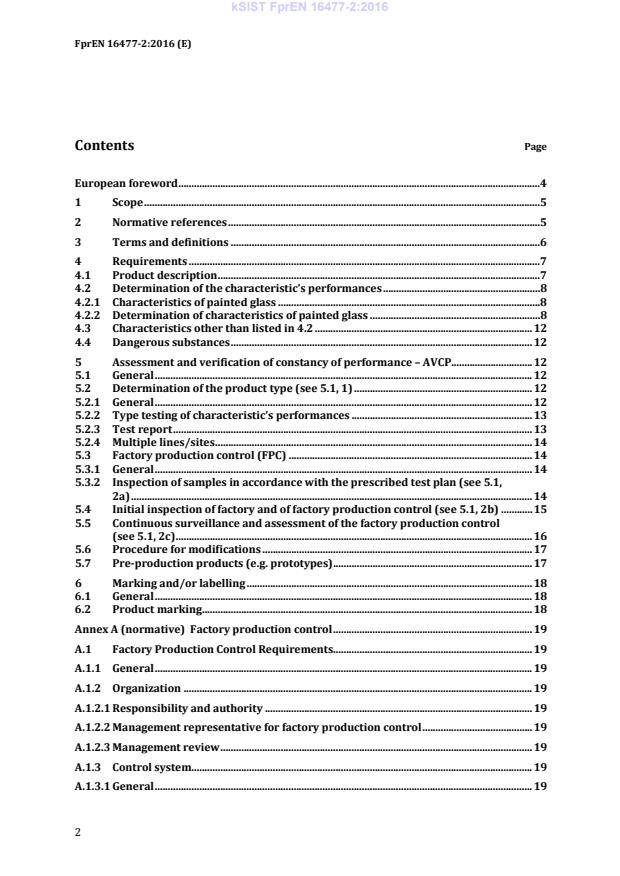

Factory production control . 19 A.1 Factory Production Control Requirements. 19 A.1.1 General . 19 A.1.2 Organization . 19 A.1.2.1 Responsibility and authority . 19 A.1.2.2 Management representative for factory production control . 19 A.1.2.3 Management review . 19 A.1.3 Control system. 19 A.1.3.1 General . 19 kSIST FprEN 16477-2:2016

Tests for factory production control . 24 Annex C (informative)

Provisions for voluntary involvement of third party(ies) . 25 C.1 General . 25 C.2 Voluntary tasks for third parties . 25 C.3 Marking and labelling . 25 Annex ZA (informative) Relationship of this European Standard with Regulation (EU) No.305/2011 . 26 ZA.1 Scope and relevant characteristics . 26 ZA.2 System of Assessment and Verification of Constancy of Performance (AVCP) . 27 ZA.3 Assignment of AVCP tasks . 27 Bibliography . 30

kg/m3 Hardness (Knoop hardness in accordance with ISO 9385) HK0,1/20 Dimensionless Young's modulus E GPa Poisson's ratio

Dimensionless Characteristic bending strength ƒg, k MPa Resistance against sudden temperature changes and temperature differentials

K Specific heat capacity c J/(kg.K) Coefficient of linear expansion l K «1 Thermal conductivity

W/(m.K) Mean refractive index to visible radiation n Dimensionless 4.2.1.2 Glass panes used as components for the production of laminated and laminated safety glass The glass substrate listed in FprEN 16477-1:2016, Clause 4 may be used for the production of painted glass. 4.2.2 Determination of characteristics of painted glass 4.2.2.1 General If the painted glass manufacturer wishes to claim that any performance characteristic is independent of the production equipment used then the factory production control system shall be in accordance with this standard including his specific process control conditions. kSIST FprEN 16477-2:2016

Also the durability of glass products depends on: — building and construction movements due to various actions; — building and construction vibrations due to various actions; — deflection and racking of the glass support due to various actions; — glass support design (e.g. drainage of infiltrated water in the rebate, prevention of direct contact between glass support members and glass); — accuracy of glass support and glass support member dimensions; — quality of the assembling of glass support members up to a glass support; — quality of installation of the glass support into or onto the buildings or constructions; — glass support expansion due to adsorbed moisture from the air or other sources; — the quality of installation of the glass product into or onto its support. kSIST FprEN 16477-2:2016

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...