SIST EN 14242:2023

(Main)Aluminium and aluminium alloys - Chemical analysis - Inductively coupled plasma optical emission spectrometric analysis

Aluminium and aluminium alloys - Chemical analysis - Inductively coupled plasma optical emission spectrometric analysis

This document specifies an inductively coupled plasma optical emission spectrometric method

(ICP-OES) for the analysis of aluminium and aluminium alloys.

This method is applicable to the determination of silicon, iron, copper, manganese, magnesium, chromium, nickel, zinc, titanium, gallium, vanadium, beryllium, bismuth, calcium, cadmium, cobalt, lithium, sodium, lead, antimony, tin, strontium and zirconium in aluminium and aluminium alloys.

The content of the elements to be determined should be at least 10 times higher than the corresponding detection limits.

Aluminium und Aluminiumlegierungen - Chemische Analyse - Optische Emissionsspektrometrie mit induktiv gekoppeltem Plasma

Dieses Dokument legt ein Verfahren für die optische Emissionsspektrometrie mit induktiv gekoppeltem Plasma (ICP OES, en: inductively coupled plasma optical emission spectrometric method) zur Analyse von Aluminium und Aluminiumlegierungen fest.

Dieses Verfahren ist für die Bestimmung von Silicium, Eisen, Kupfer, Mangan, Magnesium, Chrom, Nickel, Zink, Titan, Gallium, Vanadium, Beryllium, Bismut, Calcium, Cadmium, Cobalt, Lithium, Natrium, Blei, Antimon, Zinn, Strontium und Zirconium in Aluminium und Aluminiumlegierungen anwendbar.

Der Gehalt der zu bestimmenden Elemente sollte mindestens 10 mal höher sein als die entsprechende Nachweisgrenze.

Aluminium et alliages d’aluminium - Analyse chimique - Analyse par spectrométrie d’émission optique avec source à plasma induit par haute fréquence

Le présent document spécifie une méthode par spectrométrie d’émission optique avec source à plasma induit par haute fréquence (SEP) pour l’analyse de l’aluminium et des alliages d’aluminium.

Cette méthode est applicable à la détermination des teneurs en silicium, fer, cuivre, manganèse, magnésium, chrome, nickel, zinc, titane, gallium, vanadium, béryllium, bismuth, calcium, cadmium, cobalt, lithium, sodium, plomb, antimoine, étain, strontium et zirconium dans l’aluminium et les alliages d’aluminium.

Il convient que la teneur des éléments à déterminer soit au moins 10 fois supérieure aux limites de détection correspondantes.

Aluminij in aluminijeve zlitine - Kemična analiza - Analiza s spektrometrijo optične emisije z induktivno sklopljeno plazmo

Ta evropski standard podrobno opisuje korake za raztapljanje in pripravo kalibracijskih raztopin. Prednostno se uporablja za certificiranje in analizo referenc. Vsi instrumenti, vključno s programsko opremo za preskuševalne laboratorije, se razlikujejo in so predmet sprememb. Za to so določena splošna merila za umerjanje in merjenje.

To metodo je treba uporabljati s prednostnimi referenčnimi materiali, katerih snovi ima bistveno manjšo stopnjo negotovosti, kot je potrebna za ponovljivost preskusnega postopka.

General Information

- Status

- Published

- Public Enquiry End Date

- 05-Apr-2022

- Publication Date

- 22-Mar-2023

- Technical Committee

- INEK - Nonferrous metals

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 09-Mar-2023

- Due Date

- 14-May-2023

- Completion Date

- 23-Mar-2023

Relations

- Effective Date

- 19-Jan-2023

Overview

EN 14242:2023 - published by CEN - specifies a validated ICP‑OES (inductively coupled plasma optical emission spectrometric) method for the chemical analysis of aluminium and aluminium alloys. The standard replaces EN 14242:2004 and defines procedures for sample dissolution, calibration, measurement, correction of drift and interferences, and expression of results. It covers a broad set of alloying and trace elements and includes annexes with analytical wavelengths and suggested instrument performance criteria.

Key topics and requirements

- Scope & elements: Applicable to determination of Si, Fe, Cu, Mn, Mg, Cr, Ni, Zn, Ti, Ga, V, Be, Bi, Ca, Cd, Co, Li, Na, Pb, Sb, Sn, Sr and Zr in aluminium and aluminium alloys.

- Detection requirement: Element concentrations should be at least 10× the corresponding detection limits.

- Sample dissolution options: Four validated dissolution routes depending on alloy type and analyte:

- Sodium hydroxide with subsequent acidification (HNO3 + HCl)

- Nitric acid with hydrofluoric acid (HNO3 + HF)

- Mixed acid digestion (HCl + HNO3)

- Hydrochloric acid with hydrogen peroxide (HCl + H2O2)

- Reagents & standards: Use analytical grade reagents and grade 2 water (EN ISO 3696). Standard solutions must be traceable to SI units; stability and suitability requirements are specified.

- Calibration & internal standards: Procedures for calibration solutions, drift correction solutions and optional internal reference elements are described to ensure accurate ICP‑OES quantification.

- Instrument performance & data quality: Annex A lists analytical wavelengths and approximate ranges; Annex B suggests performance checks. Sections cover short‑term fluctuation correction, drift correction, interference investigation, and result expression.

- Sampling & reporting: References EN 14361 for sampling from metal melts; the standard specifies required test report content.

Applications and users

EN 14242:2023 is intended for:

- Analytical laboratories performing routine or accredited chemical analysis of aluminium alloys

- Metallurgical and quality‑control teams in aluminium production and fabrication

- Certification bodies and regulatory laboratories requiring traceable alloy composition data

- R&D teams developing or qualifying new aluminium alloys where multi‑element analysis by ICP‑OES is needed

Use cases include alloy specification verification, process control, failure analysis, and supplier/product certification.

Related standards

- EN 14361 (sampling from metal melts)

- EN 12258‑2 (terms and definitions for aluminium chemical analysis)

- EN ISO 3696 (water for analytical laboratory use)

Keywords: EN 14242:2023, ICP‑OES, aluminium and aluminium alloys, chemical analysis, inductively coupled plasma optical emission spectrometric analysis, CEN.

Frequently Asked Questions

SIST EN 14242:2023 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Aluminium and aluminium alloys - Chemical analysis - Inductively coupled plasma optical emission spectrometric analysis". This standard covers: This document specifies an inductively coupled plasma optical emission spectrometric method (ICP-OES) for the analysis of aluminium and aluminium alloys. This method is applicable to the determination of silicon, iron, copper, manganese, magnesium, chromium, nickel, zinc, titanium, gallium, vanadium, beryllium, bismuth, calcium, cadmium, cobalt, lithium, sodium, lead, antimony, tin, strontium and zirconium in aluminium and aluminium alloys. The content of the elements to be determined should be at least 10 times higher than the corresponding detection limits.

This document specifies an inductively coupled plasma optical emission spectrometric method (ICP-OES) for the analysis of aluminium and aluminium alloys. This method is applicable to the determination of silicon, iron, copper, manganese, magnesium, chromium, nickel, zinc, titanium, gallium, vanadium, beryllium, bismuth, calcium, cadmium, cobalt, lithium, sodium, lead, antimony, tin, strontium and zirconium in aluminium and aluminium alloys. The content of the elements to be determined should be at least 10 times higher than the corresponding detection limits.

SIST EN 14242:2023 is classified under the following ICS (International Classification for Standards) categories: 77.040.30 - Chemical analysis of metals; 77.120.10 - Aluminium and aluminium alloys. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 14242:2023 has the following relationships with other standards: It is inter standard links to SIST EN 14242:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 14242:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2023

Aluminij in aluminijeve zlitine - Kemična analiza - Analiza s spektrometrijo optične

emisije z induktivno sklopljeno plazmo

Aluminium and aluminium alloys - Chemical analysis - Inductively coupled plasma optical

emission spectrometric analysis

Aluminium und Aluminiumlegierungen - Chemische Analyse - Optische

Emissionsspektrometrie mit induktiv gekoppeltem Plasma

Aluminium et alliages d’aluminium - Analyse chimique - Analyse par spectrométrie

d’émission optique avec source à plasma induit par haute fréquence

Ta slovenski standard je istoveten z: EN 14242:2023

ICS:

77.040.30 Kemijska analiza kovin Chemical analysis of metals

77.120.10 Aluminij in aluminijeve zlitine Aluminium and aluminium

alloys

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14242

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2023

EUROPÄISCHE NORM

ICS 77.040.30; 77.120.10 Supersedes EN 14242:2004

English Version

Aluminium and aluminium alloys - Chemical analysis -

Inductively coupled plasma optical emission spectrometric

analysis

Aluminium et alliages d'aluminium - Analyse chimique Aluminium und Aluminiumlegierungen - Chemische

- Analyse par spectrométrie d'émission optique avec Analyse - Optische Emissionsspektrometrie mit

source à plasma induit par haute fréquence induktiv gekoppeltem Plasma

This European Standard was approved by CEN on 23 January 2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14242:2023 E

worldwide for CEN national Members.

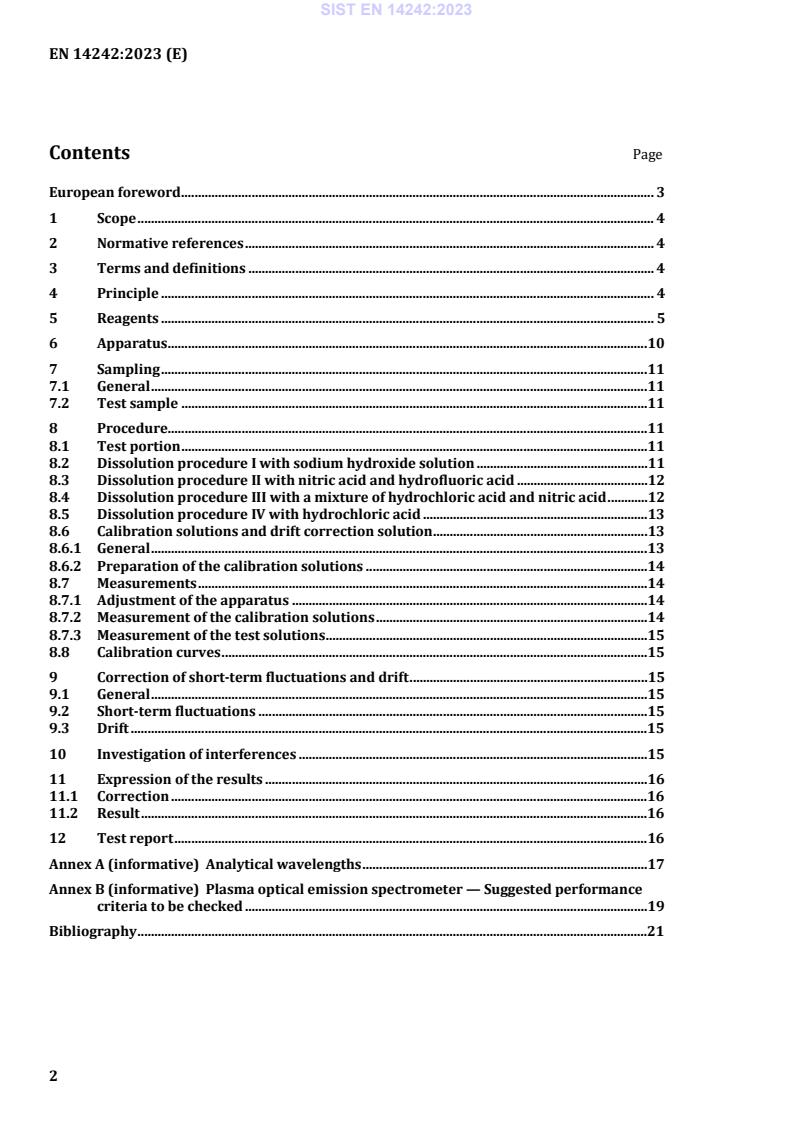

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 4

4 Principle . 4

5 Reagents . 5

6 Apparatus .10

7 Sampling .11

7.1 General .11

7.2 Test sample .11

8 Procedure.11

8.1 Test portion .11

8.2 Dissolution procedure I with sodium hydroxide solution .11

8.3 Dissolution procedure II with nitric acid and hydrofluoric acid .12

8.4 Dissolution procedure III with a mixture of hydrochloric acid and nitric acid .12

8.5 Dissolution procedure IV with hydrochloric acid .13

8.6 Calibration solutions and drift correction solution .13

8.6.1 General .13

8.6.2 Preparation of the calibration solutions .14

8.7 Measurements .14

8.7.1 Adjustment of the apparatus .14

8.7.2 Measurement of the calibration solutions .14

8.7.3 Measurement of the test solutions .15

8.8 Calibration curves .15

9 Correction of short-term fluctuations and drift .15

9.1 General .15

9.2 Short-term fluctuations .15

9.3 Drift .15

10 Investigation of interferences .15

11 Expression of the results .16

11.1 Correction .16

11.2 Result .16

12 Test report .16

Annex A (informative) Analytical wavelengths .17

Annex B (informative) Plasma optical emission spectrometer — Suggested performance

criteria to be checked .19

Bibliography .21

European foreword

This document (EN 14242:2023) has been prepared by Technical Committee CEN/TC 132 “Aluminium

and aluminium alloys”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2023, and conflicting national standards shall

be withdrawn at the latest by September 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14242:2004.

The main changes compared to the previous edition are listed below:

— modification of the title and Scope;

— new subclause 5.15.6;

— several editorial modifications.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document specifies an inductively coupled plasma optical emission spectrometric method

(ICP-OES) for the analysis of aluminium and aluminium alloys.

This method is applicable to the determination of silicon, iron, copper, manganese, magnesium,

chromium, nickel, zinc, titanium, gallium, vanadium, beryllium, bismuth, calcium, cadmium, cobalt,

lithium, sodium, lead, antimony, tin, strontium and zirconium in aluminium and aluminium alloys.

The content of the elements to be determined should be at least 10 times higher than the corresponding

detection limits.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12258-2:2004, Aluminium and aluminium alloys - Terms and definitions - Part 2: Chemical analysis

EN 14361, Aluminium and aluminium alloys - Chemical analysis - Sampling from metal melts

EN ISO 648, Laboratory glassware - Single-volume pipettes (ISO 648)

EN ISO 1042, Laboratory glassware - One-mark volumetric flasks (ISO 1042)

EN ISO 3696, Water for analytical laboratory use - Specification and test methods (ISO 3696)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 12258-2:2004 apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

4 Principle

A test portion is dissolved with:

— a sodium hydroxide solution followed by acidification with a mixture of nitric acid and hydrochloric

acid; or

— nitric acid and hydrofluoric acid; or

— a mixture of hydrochloric acid and nitric acid; or

— hydrochloric acid and hydrogen peroxide

according to the alloy type and the element to be determined.

After suitable dilution and, if necessary, addition of an internal reference element, the solution is

nebulized into an inductively coupled plasma optical emission spectrometer and the intensity of the

emitted light (including, where appropriate, that of the internal reference element) is measured. The

emission signals on the selected analytical lines (see Annex A) are then compared with those of the

calibration solutions.

NOTE 1 The ranges of application and the accuracy of the method or any alternative steps are validated by the

laboratory. Approximate ranges of application are given in Annex A.

NOTE 2 All instrumentation, including software used in the laboratories, are different and subject to change.

Therefore, only general criteria for calibration and measurement are specified.

5 Reagents

During the analysis, unless otherwise specified, use only reagents of recognized analytical grade and only

grade 2 water as specified in EN ISO 3696 or equivalent quality.

The same reagents should be used for preparation of calibration solutions and of sample solutions.

5.1 Aluminium, purity ≥ 99,999 % by mass.

5.2 Sodium carbonate (Na CO )

2 3

5.3 Potassium carbonate (K CO )

2 3

5.4 Sodium nitrite (NaNO )

5.5 Potassium disulphate (K S O )

2 2 7

5.6 Nitric acid, ρ = 1,40 g/ml approximately.

5.7 Nitric acid solution, 1 + 1

Carefully add 500 ml of nitric acid (5.6) to 400 ml water, allow to cool, dilute to 1 l with water and mix.

5.8 Nitric acid solution, 4 mol/l

Carefully add 27,7 ml of nitric acid (5.6) to 50 ml water, allow to cool, dilute to 100 ml with water and

mix.

5.9 Hydrochloric acid, ρ = 1,19 g/ml, approximately

5.10 Hydrochloric acid solution, 1 + 1

Carefully add 500 ml of hydrochloric acid (5.9) to 400 ml water, allow to cool, dilute to 1 l with water and

mix.

5.11 Hydrofluoric acid, ρ = 1,14 g/ml, approximately.

5.12 Sulphuric acid, ρ = 1,84 g/ml approximately.

5.13 Hydrogen peroxide, 30 % (by mass) solution.

5.14 Sodium hydroxide solution, 400 g/l

Transfer 400,0 g of sodium hydroxide (NaOH) into a plastic beaker with a lid and carefully add 500 ml of

water. Transfer the solution into a 1 000 ml volumetric plastic flask.

Dilute to the mark with water and mix.

5.15 Standard solutions

The standard solutions shall be traceable to international units mass or amount of substances i.e.

kilogram or mol. They should be prepared from pure metals or stoichiometric compounds.

Standard solutions containing sulphate ions shall not be used for the determination of elements which

form insoluble compounds with sulphate ions.

Standard solutions and calibration solutions with element concentrations ≤ 50 mg/l can be unstable and

shall be controlled before use.

NOTE 1 Calibration solutions can be prepared directly from standard solutions by weighing (see 8.6).

NOTE 2 For routine analysis, commercial standard solutions with stated traceability can also be used.

In the case of solution prepared before use and stored in appropriate receptacles, their concentration

shall either be controlled before use, or their stability over time be documented.

5.15.1 Antimony standard solution, 200 mg/l

Transfer 0,100 g of antimony (purity ≥ 99,99 % by mass) into a 250 ml beaker with a lid. Add 50 ml of

hydrochloric acid (5.9) and 2 ml of nitric acid (5.6), heat to complete the dissolution. Allow to cool.

Carefully add 50 ml of water and 50 ml of hydrochloric acid (5.9), transfer the solution quantitatively into

a 500 ml one-mark volumetric flask. Dilute to the mark with water and mix.

1 ml of this solution contains 200 µg of antimony.

5.15.2 Beryllium standard solution, 1 g/l

Transfer 1,000 g of beryllium (purity ≥ 99,99 % by mass) into a 400 ml beaker with a lid. Add 20 ml of

hydrochloric acid solution (5.10). Heat gently, if necessary, until the dissolution is complete, allow to cool

and transfer the solution quantitatively into a 1 000 ml one-mark volumetric flask. Dilute to the mark

with water and mix.

1 ml of this solution contains 1 mg of beryllium.

5.15.3 Bismuth standard solution, 1 g/l

Transfer 1,000 g of bismuth (purity ≥ 99,99 % by mass) into a 400 ml beaker with a lid. Add 18 ml of

hydrochloric acid (5.9), 6 ml of nitric acid (5.6) and 10 ml of water. Heat gently, if necessary, until the

dissolution is complete. Add 160 ml of hydrochloric acid solution (5.10), transfer the solution

quantitatively into a 1 000 ml one-mark volumetric flask. Dilute to the mark with water and mix.

1 ml of this solution contains 1 mg of bismuth.

5.15.4 Cadmium standard solution, 1 g/l

Transfer 1,000 g of cadmium (purity ≥ 99,99 % by mass) into a 400 ml beaker with a lid. Add of 10 ml of

water and 30 ml of nitric acid (5.6). Heat gently, if necessary, until the dissolution is complete, allow to

cool and transfer the solution quantitatively into a 1 000 ml one-mark volumetric flask. Dilute to the mark

with water and mix.

1 ml of this solution contains 1 mg of cadmium.

5.15.5 Calcium standard solution, 1 g/l

Transfer 2,497 3 g of calcium carbonate (purity ≥ 99,99 % by mass), previously dried at 200 °C to

constant mass into a 400 ml beaker with a lid. Dissolve in 40 ml of hydrochloric acid solution (5.10),

transfer the solution quantitatively into a 1 000 ml one-mark volumetric flask. Dilute to the mark with

water and mix.

1 ml of this solution contains 1 mg of calcium.

5.15.6 Chromium standard solution, 1 g/l

5.15.6.1 Preparation using chromium metal

Transfer 0,5 g of chromium (purity ≥ 99,99 % by mass) into a 250 ml beaker with a lid. Add 40 ml of water

and 20 ml of hydrochloric acid (5.9). Heat gently, if necessary, until the dissolution is complete, allow to

cool and transfer the solution quantitatively into a 500 ml one-mark volumetric flask. Dilute to the mark

with water and mix.

1 ml of this solution contains 1 mg of chromium.

5.15.6.2 Preparation using potassium dichromate

Transfer 2,828 9 g of potassium dichromate (K Cr O ) previously dried at 130 °C to constant mass, into

2 2 7

a 400 ml beaker with a lid. Add 40 ml of water, 20 ml of hydrochloric acid solution (5.10) and dropwise

20 ml of hydrogen peroxide (5.13). Heat gently, without boiling, to evaporate the excess of hydrogen

peroxide. Allow to cool and transfer the solution quantitatively into a 1 000 ml volumetric flask. Dilute to

the mark with water and mix.

1 ml of this solution contains 1 mg of chromium.

5.15.7 Cobalt standard solution, 1 g/l

Transfer 1,000 g of cobalt (purity ≥ 99,99 % by mass) into a 400 ml beaker with a lid. Add 10 ml of water,

18 ml of hydrochloric acid (5.9) and 6 ml of nitric acid (5.6). Heat gently, if necessary, until the dissolution

is complete, allow to cool and transfer the solution quantitatively into a 1 000 ml one-mark volumetric

flask. Dilute to the mark with water and mix.

1 ml of this solution contains 1 mg of cobalt.

5.15.8 Copper standard solution, 1 g/l

Transfer 1,000 g of copper (purity ≥ 99,99 % by mass) into a 400 ml beaker with a lid. Add 40 ml of

hydrochloric acid solution (5.10) and stepwise 5 ml of hydrogen peroxide (5.13) while stirring. Heat until

the solution boils, allow to cool, transfer the solution quantitatively into a 1 000 ml one-mark volumetric

flask. Dilute to the mark with water and mix.

1 ml of this solution contains 1 mg of copper.

5.15.9 Gallium standard solution, 1 g/l

Transfer 1,000 g of gallium (purity ≥ 99,99 % by mass) into a 400 ml beaker with a lid. Add 10 ml of water

and 30 ml of nitric acid (5.6). Heat gently, if necessary, until the dissolution is complete, allow to cool and

transfer the solution quantitatively into a 1 000 ml one-mark volumetric flask. Dilute to the mark with

water and mix.

1 ml of this solution contains 1 mg of gallium.

5.15.10 Iron standard solution, 1 g/l

Transfer 1,000 g of iron (purity ≥ 99,99 % by mass) into a 400 ml beaker with a lid. Add 40 ml of

hydrochloric acid solution (5.10). Heat gently, if necessary, until the dissolution is complete, allow to cool

and transfer the solution quantitatively into a 1 000 ml one-mark volumetric flask. Dilute to the mark

with water and mix.

1 ml of this solution contains 1 mg of iron.

5.15.11 Lead standard solution, 1 g/l

Transfer 1,000 g of lead (purity ≥ 99,99 % by mass), into a 250 ml beaker with a lid. Add 10 ml of water

and 10 ml of nitric acid solution (5.7). Heat gently, if necessary, until the dissolution is complete, then boil

until nitrous fumes have been expelled. Allow to cool and transfer the solution quantitatively into a

1 000 ml one-mark volumetric flask. Dilute to the mark with water and mix.

1 ml of this solution contains 1 mg of lead.

5.15.12 Lithium standard solution, 1 g/l

Transfer 5,324 0 g of lithium carbonate (purity ≥ 99,99 % by mass), previously dried at 200 °C to constant

mass into a 400 ml beaker with a lid. Dissolve in 40 ml hydrochloric acid solution (5.10), transfer the

solution quantitatively into a 1 000 ml one-mark volumetric flask. Dilute to the mark with water and mix.

1 ml of this solution contains 1 mg of lithium.

5.15.13 Magnesium standard solution, 1 g/l

Transfer 1,000 g of magnesium (purity ≥ 99,99 % by mass) into a 400 ml beaker with a lid. Add, by small

fractions, 40 ml of hydrochloric acid solution (5.10). Heat gently, if necessary, until the dissolution is

complete, allow to cool and transfer the solution quantitatively into a 1 000 ml one-mark volumetric flask.

Dilute to the mark with water and mix.

1 ml of this solution contains 1 mg of magnesium.

5.15.14 Manganese standard solution, 1 g/l

The manganese (purity ≥ 99,99 % by mass) used to prepare the solution is released from superficial oxide

possibly present by introducing a few grams of metal in a 250 ml beaker containing 150 to 160 ml of

water and 15 to 20 ml of sulphuric acid (5.12). Shake and after a few seconds, allow the solution to settle

and add water. Repeat the water cleaning several times. Remove the metallic manganese and rinse with

acetone. Dry the metal in an oven at 100 °C for 2 minutes or with a hair dryer. Cool in a desiccator.

Transfer 1,000 g of manganese, precleaned as described above, into a 400 ml beaker with a lid. Add 40 ml

of hydrochloric acid solution (5.10). Heat gently, if necessary, until the dissolution is complete, allow to

cool, transfer the solution quantitatively into a 1 000 ml one-mark volumetric flask. Dilute to the mark

with water and mix.

1 ml of this solution contains 1 mg of manganese.

5.15.15 Nickel standard solution, 1 g/l

Transfer 1,000 g of nickel (purity ≥ 99,99 % by mass) into a 400 ml beaker with a lid. Add 40 ml of

hydrochloric acid solution (5.10). Heat gently, if necessary, until the dissolution is complete, allow to cool

and transfer the solution quantitatively into a 1 000 ml one-mark volumetric flask. Dilute to the mark

with water and mix.

1 ml of this solution contains 1 mg of nickel.

5.15.16 Sodium standard solution, 1 g/l

Transfer 2,305 1 g of sodium carbonate (purity ≥ 99,99 % by mass), previously dried at 200 °C to

constant mass into a 400 ml beaker with a lid. Dissolve in 40 ml of hydrochloric acid solution (5.10),

transfer the solution into a 1 000 ml volumetric flask. Dilute to the mark with water and mix.

1 ml of this solution contains 1 mg of sodium.

5.15.17 Silicon standard solution, 100 mg/l

In a large platinum crucible with a lid, fuse 0,213 92 g of silica (SiO , purity ≥ 99,999 % by mass),

previously calcined at 1 000 °C to constant mass, with 2 g of a mixture of equal parts of sodium carbonate

(5.2) and potassium carbonate (5.3). Continue the fusion until a clear melt is obtained. Allow to cool,

transfer the melt into a 600 ml PTFE beaker with a lid, dissolve the fused mass with 400 ml of water. Heat

gently until the dissolution is complete. Slowly add 40 ml of nitric acid (5.6), while stirring strongly if

possible by means of a magnetic stirrer. Transfer the solution quantitatively into a 1 000 ml one-mark

volumetric flask, dilute to the mark with water and mix.

1 ml of this solution contains 100 µg of silicon.

NOTE This solution can be used for about 2 weeks.

5.15.18 Strontium standard solution, 1 g/l

Transfer 1,685 0 g of strontium carbonate (purity ≥ 99,99 % by mass), previously dried at 150 °C to

constant mass into a 400 ml beaker with a lid. Dissolve in 40 ml of hydrochloric acid solution (5.10),

transfer the solution quantitatively into a 1 000 ml one-mark volumetric flask. Dilute to the mark with

water and mix.

1 ml of this solution contains 1 mg of strontium.

5.15.19 Tin standard solution, 500 mg/l

Transfer 0,500 g of tin (purity ≥ 99,99 % by mass) into a 400 ml beaker with a lid. Add 100 ml of

hydrochloric acid (5.9). Heat gently until the dissolution is complete, allow to cool and transfer the

solution quantitatively into a 1 000 ml one-mark volumetric flask. Dilute to the mark with water and mix.

1 ml of this solution contains 500 µg of tin.

5.15.20 Titanium standard solution, 1 g/l

Transfer 0,200 g of titanium (purity ≥ 99,99 % by mass) into a 250 ml beaker with a lid. Add 50 ml of

hydrochloric acid solution (5.10) and 5 drops of hydrofluoric acid (5.11). Heat gently, if necessary, until

the dissolution is complete, allow to cool and transfer the solution quantitatively into a 200 ml one-mark

volumetric flask. Dilute to the mark with water and mix.

1 ml of this solution contains 1 mg of titanium.

5.15.21 Vanadium standard solution, 1 g/l

Transfer 0,5 g of vanadium (purity ≥ 99,99 % by mass) into a 250 ml beaker with a lid. Add 30 ml of

hydrochloric acid (5.9) and 10 ml of nitric acid (5.6). Heat gently, if necessary, until the dissolution is

complete, allow to cool an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...