ISO 26262-2:2018

(Main)Road vehicles — Functional safety — Part 2: Management of functional safety

Road vehicles — Functional safety — Part 2: Management of functional safety

This document is intended to be applied to safety-related systems that include one or more electrical and/or electronic (E/E) systems and that are installed in series production road vehicles, excluding mopeds. This document does not address unique E/E systems in special vehicles such as E/E systems designed for drivers with disabilities. NOTE Other dedicated application-specific safety standards exist and can complement the ISO 26262 series of standards or vice versa. Systems and their components released for production, or systems and their components already under development prior to the publication date of this document, are exempted from the scope of this edition. This document addresses alterations to existing systems and their components released for production prior to the publication of this document by tailoring the safety lifecycle depending on the alteration. This document addresses integration of existing systems not developed according to this document and systems developed according to this document by tailoring the safety lifecycle. This document addresses possible hazards caused by malfunctioning behaviour of safety-related E/E systems, including interaction of these systems. It does not address hazards related to electric shock, fire, smoke, heat, radiation, toxicity, flammability, reactivity, corrosion, release of energy and similar hazards, unless directly caused by malfunctioning behaviour of safety-related E/E systems. This document describes a framework for functional safety to assist the development of safety-related E/E systems. This framework is intended to be used to integrate functional safety activities into a company-specific development framework. Some requirements have a clear technical focus to implement functional safety into a product; others address the development process and can therefore be seen as process requirements in order to demonstrate the capability of an organization with respect to functional safety. This document does not address the nominal performance of E/E systems. This document specifies the requirements for functional safety management for automotive applications, including the following: — project-independent requirements with regard to the organizations involved (overall safety management), and — project-specific requirements with regard to the management activities in the safety lifecycle, i.e. management during the concept phase and the product development phases (at the system, hardware and software level), and regarding production, operation, service and decommissioning. Annex A provides an overview on objectives, prerequisites and work products of this document.

Véhicules routiers — Sécurité fonctionnelle — Partie 2: Gestion de la sécurité fonctionnelle

General Information

- Status

- Published

- Publication Date

- 16-Dec-2018

- Technical Committee

- ISO/TC 22/SC 32 - Electrical and electronic components and general system aspects

- Drafting Committee

- ISO/TC 22/SC 32/WG 8 - Functional safety

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 08-Jul-2024

- Completion Date

- 14-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Revises

ISO 26262-2:2011 - Road vehicles — Functional safety — Part 2: Management of functional safety - Effective Date

- 05-Nov-2015

Overview

ISO 26262-2:2018 - Management of functional safety is Part 2 of the ISO 26262 series for automotive functional safety. It defines the management framework and process requirements to integrate functional safety activities across the safety lifecycle for safety‑related electrical/electronic (E/E) systems in series‑production road vehicles (excluding mopeds and certain special‑purpose vehicles). The edition updates the original 2011 series and provides guidance on tailoring, integration, and organization‑level responsibilities for functional safety.

Key topics and technical requirements

ISO 26262-2 focuses on management activities rather than specific technical implementations. Major areas include:

- Overall safety management: company‑level safety policy, safety culture, quality management and handling of safety anomalies.

- Project‑dependent safety management: planning and coordination of safety activities during concept and product development (system, hardware, software), including tailoring and reuse of existing elements.

- Safety lifecycle planning: integration of functional safety activities into a company’s development framework and tailoring for modifications or integrations of legacy systems.

- Confirmation measures and independence: requirements for verification reviews, confirmation reviews, and independent assessment authority.

- Safety case and release for production: documentation and evidence required to justify that safety goals are met prior to production release.

- Production, operation, service and decommissioning: post‑release safety management, responsibilities and required processes.

- Competence and role definitions: competence management, defined roles and responsibilities for safety activities.

- ASIL‑dependent requirements and adaptations: requirements that vary by Automotive Safety Integrity Level (ASIL) and adaptations for vehicle classes (e.g., motorcycles, trucks/buses).

- Interface topics: interaction with cybersecurity and other safety‑relevant domains (informative guidance in annexes).

Practical applications and users

Who uses ISO 26262-2:

- Automotive OEMs and Tier‑1/Tier‑2 suppliers for establishing compliant safety management systems.

- Functional safety engineers, project managers and system architects responsible for safety lifecycle planning.

- Quality assurance, process auditors, and certification bodies assessing organizational capability for functional safety.

- Teams integrating legacy E/E systems or altering production systems that require tailoring of the safety lifecycle.

Practical uses include creating safety management plans, defining safety roles, preparing safety cases for production release, conducting functional safety audits and assessments, and aligning company processes with ASIL‑based requirements.

Related standards

ISO 26262-2 is part of the ISO 26262 series (Parts 1–10) - the automotive adaptation of IEC 61508. Relevant adjacent parts include:

- Part 1: Vocabulary

- Part 3: Concept phase

- Part 4/5/6: Product development at system, hardware, software levels

- Part 7: Production and operation

- Part 9/10: Analysis and guidelines (and semiconductor guidance)

Keywords: ISO 26262-2:2018, functional safety management, automotive functional safety, safety lifecycle, ASIL, E/E systems, safety case, functional safety audit.

Buy Documents

ISO 26262-2:2018 - Road vehicles — Functional safety — Part 2: Management of functional safety Released:12/17/2018

REDLINE ISO 26262-2:2018 - Road vehicles — Functional safety — Part 2: Management of functional safety Released:12/17/2018

Get Certified

Connect with accredited certification bodies for this standard

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

AIAG (Automotive Industry Action Group)

American automotive industry standards and training.

Sponsored listings

Frequently Asked Questions

ISO 26262-2:2018 is a standard published by the International Organization for Standardization (ISO). Its full title is "Road vehicles — Functional safety — Part 2: Management of functional safety". This standard covers: This document is intended to be applied to safety-related systems that include one or more electrical and/or electronic (E/E) systems and that are installed in series production road vehicles, excluding mopeds. This document does not address unique E/E systems in special vehicles such as E/E systems designed for drivers with disabilities. NOTE Other dedicated application-specific safety standards exist and can complement the ISO 26262 series of standards or vice versa. Systems and their components released for production, or systems and their components already under development prior to the publication date of this document, are exempted from the scope of this edition. This document addresses alterations to existing systems and their components released for production prior to the publication of this document by tailoring the safety lifecycle depending on the alteration. This document addresses integration of existing systems not developed according to this document and systems developed according to this document by tailoring the safety lifecycle. This document addresses possible hazards caused by malfunctioning behaviour of safety-related E/E systems, including interaction of these systems. It does not address hazards related to electric shock, fire, smoke, heat, radiation, toxicity, flammability, reactivity, corrosion, release of energy and similar hazards, unless directly caused by malfunctioning behaviour of safety-related E/E systems. This document describes a framework for functional safety to assist the development of safety-related E/E systems. This framework is intended to be used to integrate functional safety activities into a company-specific development framework. Some requirements have a clear technical focus to implement functional safety into a product; others address the development process and can therefore be seen as process requirements in order to demonstrate the capability of an organization with respect to functional safety. This document does not address the nominal performance of E/E systems. This document specifies the requirements for functional safety management for automotive applications, including the following: — project-independent requirements with regard to the organizations involved (overall safety management), and — project-specific requirements with regard to the management activities in the safety lifecycle, i.e. management during the concept phase and the product development phases (at the system, hardware and software level), and regarding production, operation, service and decommissioning. Annex A provides an overview on objectives, prerequisites and work products of this document.

This document is intended to be applied to safety-related systems that include one or more electrical and/or electronic (E/E) systems and that are installed in series production road vehicles, excluding mopeds. This document does not address unique E/E systems in special vehicles such as E/E systems designed for drivers with disabilities. NOTE Other dedicated application-specific safety standards exist and can complement the ISO 26262 series of standards or vice versa. Systems and their components released for production, or systems and their components already under development prior to the publication date of this document, are exempted from the scope of this edition. This document addresses alterations to existing systems and their components released for production prior to the publication of this document by tailoring the safety lifecycle depending on the alteration. This document addresses integration of existing systems not developed according to this document and systems developed according to this document by tailoring the safety lifecycle. This document addresses possible hazards caused by malfunctioning behaviour of safety-related E/E systems, including interaction of these systems. It does not address hazards related to electric shock, fire, smoke, heat, radiation, toxicity, flammability, reactivity, corrosion, release of energy and similar hazards, unless directly caused by malfunctioning behaviour of safety-related E/E systems. This document describes a framework for functional safety to assist the development of safety-related E/E systems. This framework is intended to be used to integrate functional safety activities into a company-specific development framework. Some requirements have a clear technical focus to implement functional safety into a product; others address the development process and can therefore be seen as process requirements in order to demonstrate the capability of an organization with respect to functional safety. This document does not address the nominal performance of E/E systems. This document specifies the requirements for functional safety management for automotive applications, including the following: — project-independent requirements with regard to the organizations involved (overall safety management), and — project-specific requirements with regard to the management activities in the safety lifecycle, i.e. management during the concept phase and the product development phases (at the system, hardware and software level), and regarding production, operation, service and decommissioning. Annex A provides an overview on objectives, prerequisites and work products of this document.

ISO 26262-2:2018 is classified under the following ICS (International Classification for Standards) categories: 43.040.10 - Electrical and electronic equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 26262-2:2018 has the following relationships with other standards: It is inter standard links to EN 17106-1:2021, EN ISO 17409:2020, CEN/CLC/TR 17602-80-01:2021, ISO 26262-2:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 26262-2:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 26262-2

Second edition

2018-12

Road vehicles — Functional safety —

Part 2:

Management of functional safety

Véhicules routiers — Sécurité fonctionnelle —

Partie 2: Gestion de la sécurité fonctionnelle

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

Contents Page

Foreword .v

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Requirements for compliance . 2

4.1 Purpose . 2

4.2 General requirements . 2

4.3 Interpretations of tables . 3

4.4 ASIL-dependent requirements and recommendations . 3

4.5 Adaptation for motorcycles . 3

4.6 Adaptation for trucks, buses, trailers and semi-trailers. 3

5 Overall safety management. 4

5.1 Objectives. 4

5.2 General . 4

5.2.1 Overview of the safety lifecycle . 4

5.2.2 Explanatory remarks on the safety lifecycle . 5

5.3 Inputs to this clause . 9

5.3.1 Prerequisites . 9

5.3.2 Further supporting information . 9

5.4 Requirements and recommendations . 9

5.4.1 General. 9

5.4.2 Safety culture . 9

5.4.3 Management of safety anomalies regarding functional safety .10

5.4.4 Competence management .11

5.4.5 Quality management system .11

5.4.6 Project-independent tailoring of the safety lifecycle .12

5.5 Work products .12

6 Project dependent safety management .12

6.1 Objectives.12

6.2 General .13

6.3 Inputs to this clause .14

6.3.1 Prerequisites .14

6.3.2 Further supporting information .14

6.4 Requirements and recommendations .14

6.4.1 General.14

6.4.2 Roles and responsibilities in safety management .14

6.4.3 Impact analysis at the item level .15

6.4.4 Reuse of an existing element .16

6.4.5 Tailoring of the safety activities .16

6.4.6 Planning and coordination of the safety activities .17

6.4.7 Progression of the safety lifecycle .19

6.4.8 Safety case .20

6.4.9 Confirmation measures .20

6.4.10 Confirmation reviews .23

6.4.11 Functional safety audit .24

6.4.12 Functional safety assessment .25

6.4.13 Release for production . . .27

6.5 Work products .28

7 Safety management regarding production, operation, service and decommissioning .28

7.1 Objective .28

7.2 General .28

7.3 Inputs to this clause .28

7.3.1 Prerequisites .28

7.3.2 Further supporting information .28

7.4 Requirements and recommendations .28

7.4.1 General.28

7.4.2 Responsibilities, planning and required processes .29

7.5 Work products .29

Annex A (informative) Overview of and workflow of functional safety management .30

Annex B (informative) Safety culture .33

Annex C (informative) Guidance for the confirmation measures .35

Annex D (informative) Example of a functional safety assessment agenda (for items that

have an ASIL D safety goal) .40

Annex E (informative) Guidance on potential interaction of functional safety with cybersecurity 43

Bibliography .45

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 22, Road vehicles, Subcommittee, SC 32,

Electrical and electronic components and general system aspects.

This edition of ISO 26262 series of standards cancels and replaces the edition ISO 26262:2011 series of

standards, which has been technically revised and includes the following main changes:

— requirements for trucks, buses, trailers and semi-trailers;

— extension of the vocabulary;

— more detailed objectives;

— objective oriented confirmation measures;

— management of safety anomalies;

— references to cyber-security;

— updated target values for hardware architecture metrics;

— guidance on model based development and software safety analysis;

— evaluation of hardware elements;

— additional guidance on dependent failure analysis;

— guidance on fault tolerance, safety related special characteristics and software tools;

— guidance for semiconductors;

— requirements for motorcycles; and

— general restructuring of all parts for improved clarity.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

A list of all parts in the ISO 26262 series can be found on the ISO website.

vi © ISO 2018 – All rights reserved

Introduction

The ISO 26262 series of standards is the adaptation of IEC 61508 series of standards to address the

sector specific needs of electrical and/or electronic (E/E) systems within road vehicles.

This adaptation applies to all activities during the safety lifecycle of safety-related systems comprised

of electrical, electronic and software components.

Safety is one of the key issues in the development of road vehicles. Development and integration of

automotive functionalities strengthen the need for functional safety and the need to provide evidence

that functional safety objectives are satisfied.

With the trend of increasing technological complexity, software content and mechatronic

implementation, there are increasing risks from systematic failures and random hardware failures,

these being considered within the scope of functional safety. ISO 26262 series of standards includes

guidance to mitigate these risks by providing appropriate requirements and processes.

To achieve functional safety, the ISO 26262 series of standards:

a) provides a reference for the automotive safety lifecycle and supports the tailoring of the activities

to be performed during the lifecycle phases, i.e., development, production, operation, service and

decommissioning;

b) provides an automotive-specific risk-based approach to determine integrity levels [Automotive

Safety Integrity Levels (ASILs)];

c) uses ASILs to specify which of the requirements of ISO 26262 are applicable to avoid unreasonable

residual risk;

d) provides requirements for functional safety management, design, implementation, verification,

validation and confirmation measures; and

e) provides requirements for relations between customers and suppliers.

The ISO 26262 series of standards is concerned with functional safety of E/E systems that is achieved

through safety measures including safety mechanisms. It also provides a framework within which

safety-related systems based on other technologies (e.g. mechanical, hydraulic and pneumatic) can be

considered.

The achievement of functional safety is influenced by the development process (including such

activities as requirements specification, design, implementation, integration, verification, validation

and configuration), the production and service processes and the management processes.

Safety is intertwined with common function-oriented and quality-oriented activities and work

products. The ISO 26262 series of standards addresses the safety-related aspects of these activities and

work products.

Figure 1 shows the overall structure of the ISO 26262 series of standards. The ISO 26262 series of

standards is based upon a V-model as a reference process model for the different phases of product

development. Within the figure:

— the shaded “V”s represent the interconnection among ISO 26262-3, ISO 26262-4, ISO 26262-5,

ISO 26262-6 and ISO 26262-7;

— for motorcycles:

— ISO 26262-12:2018, Clause 8 supports ISO 26262-3;

— ISO 26262-12:2018, Clauses 9 and 10 support ISO 26262-4;

— the specific clauses are indicated in the following manner: “m-n”, where “m” represents the number

of the particular part and “n” indicates the number of the clause within that part.

EXAMPLE “2-6” represents ISO 26262-2:2018, Clause 6.

Figure 1 — Overview of the ISO 26262 series of standards

viii © ISO 2018 – All rights reserved

INTERNATIONAL STANDARD ISO 26262-2:2018(E)

Road vehicles — Functional safety —

Part 2:

Management of functional safety

1 Scope

This document is intended to be applied to safety-related systems that include one or more electrical

and/or electronic (E/E) systems and that are installed in series production road vehicles, excluding

mopeds. This document does not address unique E/E systems in special vehicles such as E/E systems

designed for drivers with disabilities.

NOTE Other dedicated application-specific safety standards exist and can complement the ISO 26262 series

of standards or vice versa.

Systems and their components released for production, or systems and their components already under

development prior to the publication date of this document, are exempted from the scope of this edition.

This document addresses alterations to existing systems and their components released for production

prior to the publication of this document by tailoring the safety lifecycle depending on the alteration.

This document addresses integration of existing systems not developed according to this document and

systems developed according to this document by tailoring the safety lifecycle.

This document addresses possible hazards caused by malfunctioning behaviour of safety-related E/E

systems, including interaction of these systems. It does not address hazards related to electric shock,

fire, smoke, heat, radiation, toxicity, flammability, reactivity, corrosion, release of energy and similar

hazards, unless directly caused by malfunctioning behaviour of safety-related E/E systems.

This document describes a framework for functional safety to assist the development of safety-

related E/E systems. This framework is intended to be used to integrate functional safety activities

into a company-specific development framework. Some requirements have a clear technical focus to

implement functional safety into a product; others address the development process and can therefore

be seen as process requirements in order to demonstrate the capability of an organization with respect

to functional safety.

This document does not address the nominal performance of E/E systems.

This document specifies the requirements for functional safety management for automotive

applications, including the following:

— project-independent requirements with regard to the organizations involved (overall safety

management), and

— project-specific requirements with regard to the management activities in the safety lifecycle,

i.e. management during the concept phase and the product development phases (at the system,

hardware and software level), and regarding production, operation, service and decommissioning.

Annex A provides an overview on objectives, prerequisites and work products of this document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 26262-1, Road vehicles — Functional safety — Part 1: Vocabulary

ISO 26262-3:2018, Road vehicles — Functional safety — Part 3: Concept phase

ISO 26262-4:2018, Road vehicles — Functional safety — Part 4: Product development at the system level

ISO 26262-5:2018, Road vehicles — Functional safety — Part 5: Product development at the hardware level

ISO 26262-6:2018, Road vehicles — Functional safety — Part 6: Product development at the software level

ISO 26262-7:2018, Road vehicles — Functional safety — Part 7: Production, operation, service and

decommissioning

ISO 26262-8:2018, Road vehicles — Functional safety — Part 8: Supporting processes

ISO 26262-9:2018, Road vehicles — Functional safety — Part 9: Automotive Safety Integrity Level (ASIL)-

oriented and safety-oriented analyses

3 Terms and definitions

For the purposes of this document, the terms, definitions and abbreviated terms given in

ISO 26262-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http: //www .electropedia .org/

— ISO Online browsing platform: available at https: //www .iso .org/obp

4 Requirements for compliance

4.1 Purpose

This clause describes how:

a) to achieve compliance with the ISO 26262 series of standards;

b) to interpret the tables used in the ISO 26262 series of standards; and

c) to interpret the applicability of each clause, depending on the relevant ASIL(s).

4.2 General requirements

When claiming compliance with the ISO 26262 series of standards, each requirement shall be met,

unless one of the following applies:

a) tailoring of the safety activities in accordance with this document has been performed that shows

that the requirement does not apply; or

b) a rationale is available that the non-compliance is acceptable and the rationale has been evaluated

in accordance with this document.

Informative content, including notes and examples, is only for guidance in understanding, or for

clarification of the associated requirement, and shall not be interpreted as a requirement itself or as

complete or exhaustive.

The results of safety activities are given as work products. “Prerequisites” are information which shall

be available as work products of a previous phase. Given that certain requirements of a clause are

ASIL-dependent or may be tailored, certain work products may not be needed as prerequisites.

“Further supporting information” is information that can be considered, but which in some cases is not

required by the ISO 26262 series of standards as a work product of a previous phase and which may be

2 © ISO 2018 – All rights reserved

made available by external sources that are different from the persons or organizations responsible for

the functional safety activities.

4.3 Interpretations of tables

Tables are normative or informative depending on their context. The different methods listed in a table

contribute to the level of confidence in achieving compliance with the corresponding requirement. Each

method in a table is either:

a) a consecutive entry (marked by a sequence number in the leftmost column, e.g. 1, 2, 3), or

b) an alternative entry (marked by a number followed by a letter in the leftmost column, e.g. 2a, 2b, 2c).

For consecutive entries, all listed highly recommended and recommended methods in accordance with

the ASIL apply. It is allowed to substitute a highly recommended or recommended method by others

not listed in the table, in this case, a rationale shall be given describing why these comply with the

corresponding requirement. If a rationale can be given to comply with the corresponding requirement

without choosing all entries, a further rationale for omitted methods is not necessary.

For alternative entries, an appropriate combination of methods shall be applied in accordance with the

ASIL indicated, independent of whether they are listed in the table or not. If methods are listed with

different degrees of recommendation for an ASIL, the methods with the higher recommendation should

be preferred. A rationale shall be given that the selected combination of methods or even a selected

single method complies with the corresponding requirement.

NOTE A rationale based on the methods listed in the table is sufficient. However, this does not imply a bias

for or against methods not listed in the table.

For each method, the degree of recommendation to use the corresponding method depends on the ASIL

and is categorized as follows:

— “++” indicates that the method is highly recommended for the identified ASIL;

— “+” indicates that the method is recommended for the identified ASIL; and

— “o” indicates that the method has no recommendation for or against its usage for the identified ASIL.

4.4 ASIL-dependent requirements and recommendations

The requirements or recommendations of each sub-clause shall be met for ASIL A, B, C and D, if not

stated otherwise. These requirements and recommendations refer to the ASIL of the safety goal.

If ASIL decomposition has been performed at an earlier stage of development, in accordance with

ISO 26262-9:2018, Clause 5, the ASIL resulting from the decomposition shall be met.

If an ASIL is given in parentheses in the ISO 26262 series of standards, the corresponding sub-clause

shall be considered as a recommendation rather than a requirement for this ASIL. This has no link with

the parenthesis notation related to ASIL decomposition.

4.5 Adaptation for motorcycles

For items or elements of motorcycles for which requirements of ISO 26262-12 are applicable,

the requirements of ISO 26262-12 supersede the corresponding requirements in this document.

Requirements of this document that are superseded by ISO 26262-12 are defined in Part 12.

4.6 Adaptation for trucks, buses, trailers and semi-trailers

Content that is intended to be unique for trucks, buses, trailers and semi-trailers (T&B) is indicated

as such.

5 Overall safety management

5.1 Objectives

The intent of this clause is to ensure the organizations involved in the execution of the safety lifecycle,

i.e. those that are responsible for the safety lifecycle or are performing safety activities in the safety

lifecycle, achieve the following objectives:

a) to institute and maintain a safety culture that supports and encourages the effective achievement

of functional safety and promotes effective communication with other disciplines related to

functional safety;

b) to institute and maintain adequate organization-specific rules and processes for functional safety;

c) to institute and maintain processes to ensure an adequate resolution of identified safety anomalies;

d) to institute and maintain a competence management system to ensure that the competence of the

involved persons is commensurate with their responsibilities; and

e) to institute and maintain a quality management system to support functional safety.

This clause serves as a prerequisite to the activities in the ISO 26262 safety lifecycle.

5.2 General

5.2.1 Overview of the safety lifecycle

The ISO 26262 reference safety lifecycle encompasses the principal safety activities during the

concept phase, product development, production, operation, service and decommissioning. Planning,

coordinating and monitoring the progress of the safety activities, as well as the responsibility to

ensure that the confirmation measures are performed, are key management tasks and are performed

throughout the lifecycle. The safety lifecycle may be tailored (see Clause 6).

NOTE 1 The safety activities during the concept phase, the product development, production, operation,

service and decommissioning are described in detail in ISO 26262-3, ISO 26262-4, ISO 26262-5, ISO 26262-6 and

ISO 26262-7.

NOTE 2 Table A.1 provides an overview of the objectives, prerequisites and work products of the management

of functional safety.

Figure 2 illustrates the management activities in relation to the safety lifecycle.

4 © ISO 2018 – All rights reserved

NOTE 3 Within the figure, the specific clauses of each part of ISO 26262 are indicated in the following

manner: “m-n”, where “m” represents the number of the part and “n” indicates the number of the clause, e.g. “3-6”

represents ISO 26262-3:2018, Clause 6.

1)

NOTE 4 Sub-phases of the product development at the system level are shown in ISO 26262-4:2018, Figure 2.

2)

NOTE 5 Sub-phases of the product development at the hardware level are shown in ISO 26262-5:2018,

Figure 2.

3)

NOTE 6 Sub-phases of the product development at the software level are shown in ISO 26262-6:2018, Figure 2.

Figure 2 — Management activities in relation to the safety lifecycle

5.2.2 Explanatory remarks on the safety lifecycle

5.2.2.1 General

The ISO 26262 series of standards specifies requirements with regard to specific phases and sub-

phases of the safety lifecycle, but also includes requirements that apply to several, or all, phases of the

safety lifecycle, such as the requirements for the management of functional safety.

The key safety management tasks are to plan, coordinate and track the activities related to functional

safety. These management tasks apply to all phases of the safety lifecycle. The requirements for the

management of functional safety are given in this part, which distinguishes:

— overall safety management (see Clause 5);

— project dependent safety management, regarding the concept phase and the product development

phases at the system, hardware and software level (see Clause 6); and

— safety management regarding production, operation, service and decommissioning (see Clause 7).

The planning of the safety activities regarding development is initiated at the concept phase and is

refined as necessary through the product development phases (system, hardware and software) until

the decision to release the item, or element, for production. The planning of the activities regarding

production, operation, service, and decommissioning is initiated during the product development at the

system level.

Sub-clause 5.2.2.2 explains the definitions of different phases and sub-phases of the safety lifecycle.

Other key concepts to take into consideration during the safety lifecycle are explained in sub-clause

5.2.2.3.

5.2.2.2 Phases and sub-phases of the safety lifecycle

a) item definition (a sub-phase of the concept phase):

The initiating task of the safety lifecycle is to develop a description of the item with regard to its

functionality, interfaces, environmental conditions, legal requirements, known hazards, etc. The

boundary of the item and its interfaces, as well as assumptions concerning other items, elements,

or external measures are determined (see ISO 26262-3:2018, Clause 5).

b) hazard analysis and risk assessment (a sub-phase of the concept phase):

The hazard analysis and risk assessment is performed as given in ISO 26262-3:2018, Clause 6. First,

the hazard analysis and risk assessment estimates the probability of exposure, the controllability

and the severity of the hazardous events with regard to the item. Together, these parameters

determine the ASILs of the hazardous events. Subsequently, the hazard analysis and risk

assessment determines the safety goals for the item, with the safety goals being the top level safety

requirements for the item. The ASILs determined for the hazardous events are assigned to the

corresponding safety goals. The assumptions regarding human behaviour, including controllability

and human response, in the hazard analysis and risk assessment, the functional safety concept and

the technical safety concept, as well as the technical assumptions relevant for the ASIL classification

are validated (see ISO 26262-3:2018, Clause 6, ISO 26262-3:2018, Clause 7 and ISO 26262-4:2018,

Clause 8).

During the subsequent phases and sub-phases, detailed safety requirements are derived from the

safety goals. A safety requirement inherits the ASIL of the corresponding safety goal, or receives the

ASIL after decomposition in the case requirements decomposition with respect to ASIL tailoring

has been applied (see ISO 26262-9:2018, Clause 5).

c) functional safety concept (a sub-phase of the concept phase):

Based on the safety goals, a functional safety concept (see ISO 26262-3:2018, Clause 7) is developed

considering the preliminary architectural assumptions. The functional safety concept is developed

by deriving functional safety requirements from the safety goals and by allocating these functional

safety requirements to the elements of the item. The functional safety concept may also include

other technologies or rely on external measures (see ISO 26262-3:2018, Clause 7). In those cases,

the corresponding assumptions or expected behaviours are validated (see ISO 26262-4:2018,

Clause 8). The implementation of other technologies is outside the scope of the ISO 26262 series

of standards and the implementation of the external measures is outside the scope of the item

development.

d) product development at the system level

After the functional safety concept is specified, the item is developed at the system level, as given

in ISO 26262-4. The system development process is based on the concept of a V-model with the

specification of the technical safety requirements, the system architecture, the system design and

6 © ISO 2018 – All rights reserved

implementation on the left side and the integration, verification and the safety validation on the

right side.

The hardware-software interface is specified in this phase. The interfaces between hardware and

software are updated during the hardware and software development.

ISO 26262-4:2018, Figure 2 provides an overview of the sub-phases of the system development.

The system development incorporates safety validation tasks for activities occurring within other

safety lifecycle phases, including:

— the technical assumptions relevant for the ASIL classification;

— the validation of the assumptions concerning human behaviour, including controllability and

human response;

— the validation of the aspects of the functional safety concept that are implemented by other

technologies; and

— the validation of the assumptions concerning the effectiveness and the performance of external

measures.

e) product development at the hardware level

Based on the system design specification, the hardware is developed (see ISO 26262-5). The

hardware development process is based on the concept of a V-model with the specification of the

hardware requirements and the hardware design and implementation on the left side and the

hardware integration and verification on the right side.

ISO 26262-5:2018, Figure 2 provides an overview of the sub-phases of the hardware development.

f) product development at the software level

Based on the system design specification, the software is developed (see ISO 26262-6). The

software development process is based on the concept of a V-model with the specification of the

software requirements and the software architectural design and implementation on the left side,

and the software integration and the verification on the right side.

ISO 26262-6:2018, Figure 2 provides an overview of the sub-phases of the software development.

g) production, operation, service and decommissioning

The planning of this phase (see ISO 26262-7:2018, Clause 5), and the specification of the associated

requirements, starts during the product development at the system level (see ISO 26262-4) and

takes place in parallel with the system, hardware and software development. Such planning can be

enabled by exchanging information or requirements e.g. safety-related special characteristics or

requirements that improve the ability to produce the product.

This phase addresses the processes, means and instructions to ensure functional safety regarding

production, operation, service and decommissioning of the item or element. The safety-related

special characteristics and the development and management of instructions for the production,

operation, service (maintenance and repair) and decommissioning of the item or element (see

ISO 26262-7:2018, Clauses 6 and 7) are considered.

5.2.2.3 Other key concepts

a) Confirmation measures

The confirmation measures (see Clause 6) are performed to judge the functional safety achieved by

the item, or the contribution to the achievement of functional safety e.g. concerning the development of

elements.

b) Controllability

In the hazard analysis and risk assessment (see ISO 26262-3:2018, Clause 6), credit can be taken for

the ability of the driver, or the other persons at risk (e.g. pedestrians, cyclists, passengers, drivers of

other vehicles) to avoid the specified harm, possibly supported by external measures. The assumptions

regarding the controllability in the hazard analysis and risk assessment and the functional and technical

safety concept are validated (see ISO 26262-3:2018, Clauses 6 and 7 and ISO 26262-4:2018, Clause 8).

NOTE The exposure and the severity depend on the scenario. The eventual controllability through human

intervention is influenced by the design of the item and is therefore evaluated during the safety validation (see

ISO 26262-4:2018, Clause 8).

c) External measures

The external measures refer to the measures outside the boundary of the item (see ISO 26262-3:2018,

Clause 5) that reduce or mitigate the potential hazards resulting from malfunctioning behaviour of the

item. External measures can include additional in-vehicle devices such as dynamic stability controllers

or run-flat tyres, but also devices external to the vehicle, such as crash barriers or tunnel fire-fighting

systems.

The assumptions regarding the external measures in the item definition, the hazard analysis and

risk assessment and the functional and technical safety concept are validated (see ISO 26262-4:2018,

Clause 8).

External measures can be considered in the hazard analysis and risk assessment (see ISO 26262-3:2018,

Clause 6). However, if credit is taken from an external measure in the hazard analysis and risk

assessment e.g. to reduce the ASIL of a safety goal, that external measure cannot be considered again as

a risk reduction in the functional safety concept.

An external measure can be outside the scope of the ISO 26262 series of standards (e.g. if the external

measure is realized by another technology or is implemented external to the vehicle), or in the scope

of the ISO 26262 series of standards (e.g. if the external measure is realized by an E/E system distinct

from the item).

d) Impact analysis at the item level

An impact analysis (see 6.4.3) is performed at the item level to determine whether the item is a new

development, a modification of an existing item, or an existing item with a modified environment. If

there are one or more modifications, the implications of the modifications on functional safety are

analysed.

e) Impact analysis at the element level

An impact analysis is performed at the element level when an existing element is reused (see 6.4.4), so

as to evaluate whether the reused element is able to comply with the safety requirements allocated to

that element, considering the operational context in which the element is reused.

f) Other technologies

Other technologies (e.g. mechanical and hydraulic technologies) are those different from electrical

and electronic technologies. These can be considered in the specification and allocation of safety

requirements (see ISO 26262-3:2018, Clause 7 and ISO 26262-4), or as an external measure. In other

words, an element realized by another technology may be implemented within the item, or may be

specified as an external measure.

g) Release for production

8 © ISO 2018 – All rights reserved

The release for production (see 6.4.13) formalizes the decision to release the item, or element, for

production, considering the results of the safety lifecycle, including the results of the applicable

confirmation measures.

5.3 Inputs to this clause

5.3.1 Prerequisites

None.

5.3.2 Further supporting information

The following information can be considered:

— existing evidence of compliance with standards that support quality management.

EXAMPLE 1 IATF 16949 in conjunction with ISO 9001 regarding quality management across phases of the

safety lifecycle.

EXAMPLE 2 ISO/IEC 33000 series of standards, Capability Maturity Model Integration (“CMMI®”), or

1)

Automotive SPICE® series of standards regarding product development.

5.4 Requirements and recommendations

5.4.1 General

Sub-clauses 5.4.2 to 5.4.6 apply to the organizations involved in the execution of the safety lifecycle.

5.4.2 Safety culture

5.4.2.1 The organization shall create, foster, and sustain a safety culture that supports and encourages

the effective achievement of functional safety.

NOTE Annex B provides more details of what can constitute a safety cul

...

INTERNATIONAL ISO

STANDARD 26262-2

Redline version

compares Second edition to

First edition

Road vehicles — Functional safety —

Part 2:

Management of functional safety

Véhicules routiers — Sécurité fonctionnelle —

Partie 2: Gestion de la sécurité fonctionnelle

Reference number

ISO 26262-2:redline:2018(E)

©

ISO 2018

ISO 26262-2:redline:2018(E)

IMPORTANT

This marked-up version uses the following colour-coding in the marked-up text:

Text example 1 — Text has been added (in green)

— Text has been deleted (in red)

Text example 2

— Graphic figure has been added

— Graphic figure has been deleted

1.x . — If there are changes in a clause/subclause, the corresponding clause/

subclause number is highlighted in yellow in the Table of contents

DISCLAIMER

This marked-up version highlights the main changes in this edition of the document

compared with the previous edition. It does not focus on details (e.g. changes in

punctuation).

This marked-up version does not constitute the official ISO document and is not intended to

be used for implementation purposes.

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

ISO 26262-2:redline:2018(E)

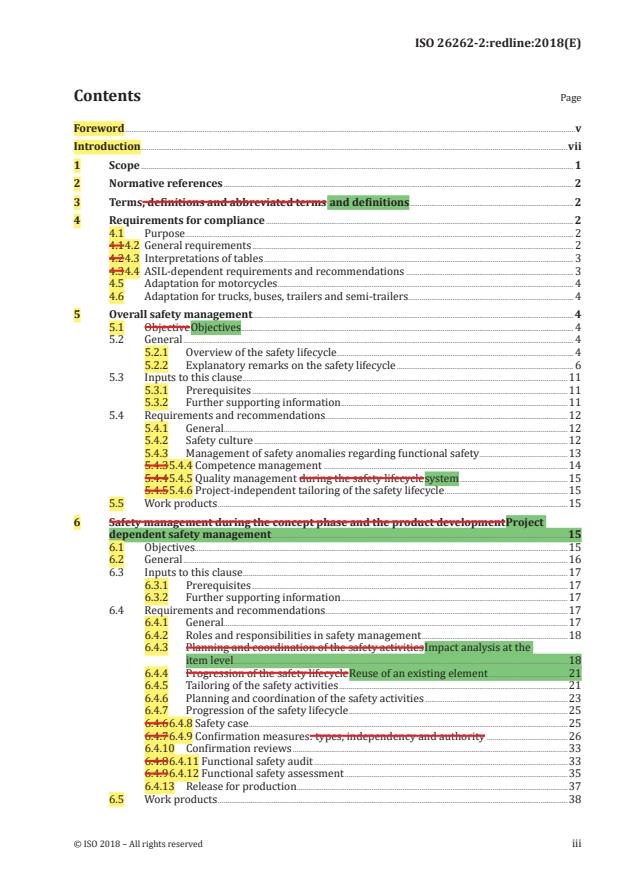

Contents Page

Foreword .v

Introduction .vii

1 Scope . 1

2 Normative references . 2

3 Terms, definitions and abbreviated terms and definitions . 2

4 Requirements for compliance . 2

4.1 Purpose . 2

4.1 4.2 General requirements . 2

4.2 4.3 Interpretations of tables .3

4.3 4.4 ASIL-dependent requirements and recommendations .3

4.5 Adaptation for motorcycles . 4

4.6 Adaptation for trucks, buses, trailers and semi-trailers. 4

5 Overall safety management. 4

5.1 Objective Objectives . . 4

5.2 General . 4

5.2.1 Overview of the safety lifecycle . 4

5.2.2 Explanatory remarks on the safety lifecycle . 6

5.3 Inputs to this clause .11

5.3.1 Prerequisites .11

5.3.2 Further supporting information .11

5.4 Requirements and recommendations .12

5.4.1 General.12

5.4.2 Safety culture .12

5.4.3 Management of safety anomalies regarding functional safety .13

5.4.3 5.4.4 Competence management .14

5.4.4 5.4.5 Quality management during the safety lifecycle system .15

5.4.5 5.4.6 Project-independent tailoring of the safety lifecycle .15

5.5 Work products .15

6 Safety management during the concept phase and the product development Project

dependent safety management .15

6.1 Objectives.15

6.2 General .16

6.3 Inputs to this clause .17

6.3.1 Prerequisites .17

6.3.2 Further supporting information .17

6.4 Requirements and recommendations .17

6.4.1 General.17

6.4.2 Roles and responsibilities in safety management .18

6.4.3 Planning and coordination of the safety activities Impact analysis at the

item level.18

6.4.4 Progression of the safety lifecycle Reuse of an existing element .21

6.4.5 Tailoring of the safety activities .21

6.4.6 Planning and coordination of the safety activities .23

6.4.7 Progression of the safety lifecycle .25

6.4.6 6.4.8 Safety case.25

6.4.7 6.4.9 Confirmation measures: types, independency and authority .26

6.4.10 Confirmation reviews .33

6.4.8 6.4.11 Functional safety audit .33

6.4.9 6.4.12 Functional safety assessment .35

6.4.13 Release for production . . .37

6.5 Work products .38

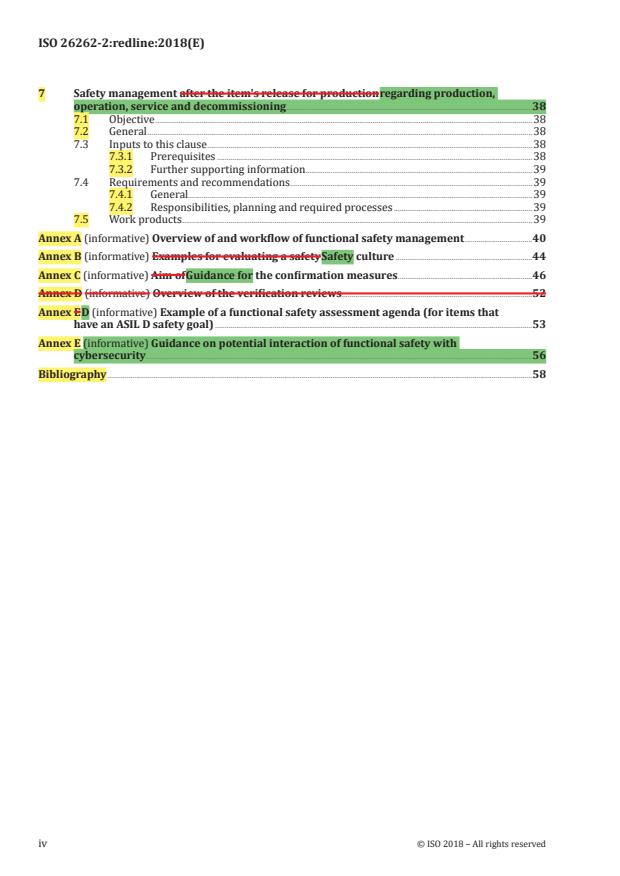

ISO 26262-2:redline:2018(E)

7 Safety management after the item's release for production regarding production,

operation, service and decommissioning .38

7.1 Objective .38

7.2 General .38

7.3 Inputs to this clause .38

7.3.1 Prerequisites .38

7.3.2 Further supporting information .39

7.4 Requirements and recommendations .39

7.4.1 General.39

7.4.2 Responsibilities, planning and required processes .39

7.5 Work products .39

Annex A (informative) Overview of and workflow of functional safety management .40

Annex B (informative) Examples for evaluating a safety Safety culture .44

Annex C (informative) Aim of Guidance for the confirmation measures .46

Annex D (informative) Overview of the verification reviews .52

Annex E D (informative) Example of a functional safety assessment agenda (for items that

have an ASIL D safety goal) .53

Annex E (informative) Guidance on potential interaction of functional safety with

cybersecurity . .56

Bibliography .58

iv © ISO 2018 – All rights reserved

ISO 26262-2:redline:2018(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

International Standards areThe procedures used to develop this document and those intended for

its further maintenance are described in the ISO/IEC Directives, Part 1. In particular, the different

approval criteria needed for the different types of ISO documents should be noted. This document was

drafted in accordance with the rules given ineditorial rules of the ISO/IEC Directives, Part 2 (see www

.iso .org/directives).

The main task of technical committees is to prepare International Standards. Draft International

Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies

casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html.

ISO 26262-2This document was prepared by Technical Committee ISO/TC 22, Road vehicles,

Subcommittee, SC 332, Electrical and electronic equipmentcomponents and general system aspects.

ISO 26262 consists of the following parts, under the general titleThis edition of ISO 26262 series of

standards cancels and replaces the edition ISO 26262:2011 series of standards, which has been

technically revised and includes the Road vehicles — Functional safetyfollowing main changes:

— Part 1: Vocabularyrequirements for trucks, buses, trailers and semi-trailers;

— Part 2: Management of functional safetyextension of the vocabulary;

— Part 3: Concept phasemore detailed objectives;

— Part 4: Product development at the system levelobjective oriented confirmation measures;

— Part 5: Product development at the hardware levelmanagement of safety anomalies;

— references to cybersecurity;

— updated target values for hardware architecture metrics;

— Part 6: Product development at the software levelguidance on model based development and software

safety analysis;

— Part 7: Production and operationevaluation of hardware elements;

— Part 8: Supporting processesadditional guidance on dependent failure analysis;

ISO 26262-2:redline:2018(E)

— Part 9: Automotive Safety Integrity Level (ASIL)-oriented and safety-oriented analysesguidance on

fault tolerance, safety related special characteristics and software tools;

— Part 10: Guideline on ISO 26262guidance for semiconductors;

— requirements for motorcycles; and

— general restructuring of all parts for improved clarity.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

A list of all parts in the ISO 26262 series can be found on the ISO website.

vi © ISO 2018 – All rights reserved

ISO 26262-2:redline:2018(E)

Introduction

The ISO 26262 series of standards is the adaptation of IEC 61508 series to comply with needs specific

to the application sectorof standards to address the sector specific needs of electrical and/or electronic

(E/E) systems within road vehicles.

This adaptation applies to all activities during the safety lifecycle of safety-related systems comprised

of electrical, electronic and software components.

Safety is one of the key issues of future automobile development. New functionalities not only in areas

such as driver assistance, propulsion, in vehicle dynamics control and active and passive safety systems

increasingly touch the domain of system safety engineeringin the development of road vehicles.

Development and integration of theseautomotive functionalities will strengthen the need for safe

system development processesfunctional safety and the need to provide evidence that all reasonable

systemfunctional safety objectives are satisfied.

With the trend of increasing technological complexity, software content and mechatronic

implementation, there are increasing risks from systematic failures and random hardware failures,

these being considered within the scope of functional safety. ISO 26262 series of standards includes

guidance to avoidmitigate these risks by providing appropriate requirements and processes.

System safety is achieved through a number of safety measures, which are implemented in a variety

of technologies (e.g. mechanical, hydraulic, pneumatic, electrical, electronic, programmable electronic)

and applied at the various levels of the development process. Although ISO 26262 is concerned with

functional safety of E/E systems, it provides a framework within which safety-related systems based

on other technologies can be considered.To achieve functional safety, ISO 26262the ISO 26262 series of

standards:

a) provides ana reference for the automotive safety lifecycle (management,and supports the tailoring

of the activities to be performed during the lifecycle phases, i.e., development, production,

operation, service, decommissioning) and supports tailoring the necessary activities during these

lifecycle phases and decommissioning;

b) provides an automotive-specific risk-based approach to determine integrity levels [Automotive

Safety Integrity Levels (ASILASILs)];

c) uses ASILs to specify applicablewhich of the requirements of ISO 26262 so asare applicable to avoid

unreasonable residual risk;

d) provides requirements for validation and confirmation measures to ensure a sufficient and

acceptable level of safety being achieved;functional safety management, design, implementation,

verification, validation and confirmation measures; and

e) provides requirements for relations withbetween customers and suppliers.

The ISO 26262 series of standards is concerned with functional safety of E/E systems that is achieved

through safety measures including safety mechanisms. It also provides a framework within which

safety-related systems based on other technologies (e.g. mechanical, hydraulic and pneumatic) can be

considered.

FunctionalThe achievement of functional safety is influenced by the development process (including

such activities as requirements specification, design, implementation, integration, verification,

validation and configuration), the production and service processes and by the management processes.

Safety issues areis intertwined with common function-oriented and quality-oriented development

activities and work products. The ISO 26262 series of standards addresses the safety-related aspects of

developmentthese activities and work products.

ISO 26262-2:redline:2018(E)

Figure 1 shows the overall structure of this editionthe ISO 26262 series of ISO 26262standards. The ISO

26262 series of standards is based upon a V-model as a reference process model for the different phases

of product development. Within the figure:

— the shaded “V”s represent the interconnection betweenamong ISO 26262-3, ISO 26262-4,

ISO 26262-5, ISO 26262-6 and ISO 26262-7;

— for motorcycles:

— ISO 26262-12:2018, Clause 8 supports ISO 26262-3;

— ISO 26262-12:2018, Clauses 9 and 10 support ISO 26262-4;

— the specific clauses are indicated in the following manner: “m-n”, where “m” represents the number

of the particular part and “n” indicates the number of the clause within that part.

EXAMPLE “2-6” represents Clause 6 of ISO 26262-2ISO 26262-2:2018, Clause 6.

viii © ISO 2018 – All rights reserved

ISO 26262-2:redline:2018(E)

Figure 1 — Overview of ISO 26262the ISO 26262 series of standards

INTERNATIONAL STANDARD ISO 26262-2:redline:2018(E)

Road vehicles — Functional safety —

Part 2:

Management of functional safety

1 Scope

ISO 26262This document is intended to be applied to safety-related systems that include one or more

electrical and/or electronic (E/E) systems and that are installed in series production passenger cars

with a maximum gross vehicle mass up to 3 500 kgroad vehicles, excluding mopeds. ISO 26262This

document does not address unique E/E systems in special purpose vehicles such as vehiclesE/E systems

designed for drivers with disabilities.

NOTE Other dedicated application-specific safety standards exist and can complement the ISO 26262 series

of standards or vice versa.

Systems and their components released for production, or systems and their components already under

development prior to the publication date of ISO 26262this document, are exempted from the scope.

For further development or alterations based on of this edition. This document addresses alterations

to existing systems and their components released for production prior to the publication of ISO 26262,

only the modifications will be developed in accordance withthis document by tailoring the safety

lifecycle depending on the alteration. This document addresses integration of existing systems not

developed ISO 26262according to this document and systems developed according to this document by

tailoring the safety lifecycle.

ISO 26262This document addresses possible hazards caused by malfunctioning behaviour of E/E

safety-related E/E systems, including interaction of these systems. It does not address hazards related

to electric shock, fire, smoke, heat, radiation, toxicity, flammability, reactivity, corrosion, release of

energy and similar hazards, unless directly caused by malfunctioning behaviour of E/E safety-related

E/E systems.

This document describes a framework for functional safety to assist the development of safety-

related E/E systems. This framework is intended to be used to integrate functional safety activities

into a company-specific development framework. Some requirements have a clear technical focus to

implement functional safety into a product; others address the development process and can therefore

be seen as process requirements in order to demonstrate the capability of an organization with respect

to functional safety.

ISO 26262This document does not address the nominal performance of E/E systems., even if dedicated

functional performance standards exist for these systems (e.g. active and passive safety systems, brake

systems, Adaptive Cruise Control).

This part of ISO 26262document specifies the requirements for functional safety management for

automotive applications, including the following:

— project-independent requirements with regard to the organizations involved (overall safety

management), and

— project-specific requirements with regard to the management activities in the safety lifecycle (,

i.e. management during the concept phase and the product development, and after the release

for production) phases (at the system, hardware and software level), and regarding production,

operation, service and decommissioning.

Annex A provides an overview on objectives, prerequisites and work products of this document.

ISO 26262-2:redline:2018(E)

2 Normative references

The following referenced documents are indispensable for the application ofreferred to in the text

in such a way that some or all of their content constitutes requirements of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 26262-1:2011 , Road vehicles — Functional safety — Part 1: Vocabulary

ISO 26262-3:2011 2018, Road vehicles — Functional safety — Part 3: Concept phase

ISO 26262-4:2011 2018, Road vehicles — Functional safety — Part 4: Product development at the system level

ISO 26262-5:2011 2018, Road vehicles — Functional safety — Part 5: Product development at the

hardware level

ISO 26262-6:2011 2018, Road vehicles — Functional safety — Part 6: Product development at the

software level

ISO 26262-7:2011 2018, Road vehicles — Functional safety — Part 7: Production and operation Productiond,

operation, service and decommissioning

ISO 26262-8:2011 2018, Road vehicles — Functional safety — Part 8: Supporting processes

ISO 26262-9:2011 2018, Road vehicles — Functional safety — Part 9: Automotive Safety Integrity Level

(ASIL)-oriented and safety-oriented analyses

3 Terms, definitions and abbreviated terms and definitions

For the purposes of this document, the terms, definitions and abbreviated terms given in

ISO 26262-1:2011 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http: //www .electropedia .org/

— ISO Online browsing platform: available at https: //www .iso .org/obp

4 Requirements for compliance

4.1 Purpose

This clause describes how:

a) to achieve compliance with the ISO 26262 series of standards;

b) to interpret the tables used in the ISO 26262 series of standards; and

c) to interpret the applicability of each clause, depending on the relevant ASIL(s).

4.1 4.2 General requirements

When claiming compliance with the ISO 26262 series of standards, each requirement shall be complied

withmet, unless one of the following applies:

a) tailoring of the safety activities in accordance with this part of ISO 26262document has been

planned andperformed that shows that the requirement does not apply,; or

b) a rationale is available that the non-compliance is acceptable and the rationale has been

assessedevaluated in accordance with this part of ISO 26262document.

2 © ISO 2018 – All rights reserved

ISO 26262-2:redline:2018(E)

Information marked as a “NOTE” or “EXAMPLE”Informative content, including notes and examples, is

only for guidance in understanding, or for clarification of the associated requirement, and shall not be

interpreted as a requirement itself or as complete or exhaustive.

The results of safety activities are given as work products. “Prerequisites” are information which shall

be available as work products of a previous phase. Given that certain requirements of a clause are

ASIL-dependent or may be tailored, certain work products may not be needed as prerequisites.

“Further supporting information” is information that can be considered, but which in some cases is not

required by the ISO 26262 series of standards as a work product of a previous phase and which may be

made available by external sources that are different from the persons or organizations responsible for

the functional safety activities.

4.2 4.3 Interpretations of tables

Tables are normative or informative depending on their context. The different methods listed in a table

contribute to the level of confidence in achieving compliance with the corresponding requirement. Each

method in a table is either:

a) a consecutive entry (marked by a sequence number in the leftmost column, e.g. 1, 2, 3), or

b) an alternative entry (marked by a number followed by a letter in the leftmost column, e.g. 2a, 2b, 2c).

For consecutive entries, all methods shall be applied as recommendedlisted highly recommended and

recommended methods in accordance with the ASIL. If methods other than those listed are to be applied

apply. It is allowed to substitute a highly recommended or recommended method by others not listed

in the table, in this case, a rationale shall be given that these fulfildescribing why these comply with the

corresponding requirement. If a rationale can be given to comply with the corresponding requirement

without choosing all entries, a further rationale for omitted methods is not necessary.

For alternative entries, an appropriate combination of methods shall be applied in accordance with the

ASIL indicated, independent of whether they are listed in the table or not. If methods are listed with

different degrees of recommendation for an ASIL, the methods with the higher recommendation should

be preferred. A rationale shall be given that the selected combination of methods or even a selected

single method complies with the corresponding requirement.

NOTE A rationale based on the methods listed in the table is sufficient. However, this does not imply a bias

for or against methods not listed in the table.

For each method, the degree of recommendation to use the corresponding method depends on the ASIL

and is categorized as follows:

— “++” indicates that the method is highly recommended for the identified ASIL;

— “+” indicates that the method is recommended for the identified ASIL; and

— “o” indicates that the method has no recommendation for or against its usage for the identified ASIL.

4.3 4.4 ASIL-dependent requirements and recommendations

The requirements or recommendations of each subclausesub-clause shall be complied withmet for ASIL

A, B, C and D, if not stated otherwise. These requirements and recommendations refer to the ASIL of the

safety goal. If ASIL decomposition has been performed at an earlier stage of development, in accordance

with ISO 26262-9:20112018, Clause 5, the ASIL resulting from the decomposition shall be complied

with.met.

If an ASIL is given in parentheses in the ISO 26262 series of standards, the corresponding subclausesub-

clause shall be considered as a recommendation rather than a requirement for this ASIL. This has no

link with the parenthesis notation related to ASIL decomposition.

ISO 26262-2:redline:2018(E)

4.5 Adaptation for motorcycles

For items or elements of motorcycles for which requirements of ISO 26262-12 are applicable,

the requirements of ISO 26262-12 supersede the corresponding requirements in this document.

Requirements of this document that are superseded by ISO 26262-12 are defined in Part 12.

4.6 Adaptation for trucks, buses, trailers and semi-trailers

Content that is intended to be unique for trucks, buses, trailers and semi-trailers (T&B) is indicated

as such.

5 Overall safety management

5.1 Objective Objectives

The objectiveintent of this clause is to define the requirements for the organizationsensure the

organizations involved in the execution of the safety lifecycle, i.e. those that are responsible for the

safety lifecycle, or that perform or are performing safety activities in the safety lifecycle., achieve the

following objectives:

a) to institute and maintain a safety culture that supports and encourages the effective achievement

of functional safety and promotes effective communication with other disciplines related to

functional safety;

b) to institute and maintain adequate organization-specific rules and processes for functional safety;

c) to institute and maintain processes to ensure an adequate resolution of identified safety anomalies;

d) to institute and maintain a competence management system to ensure that the competence of the

involved persons is commensurate with their responsibilities; and

e) to institute and maintain a quality management system to support functional safety.

This clause serves as a prerequisite to the activities in the ISO 26262 safety lifecycle.

5.2 General

5.2.1 Overview of the safety lifecycle

The ISO 26262 reference safety lifecycle (see Figure 2) encompasses the principal safety activities

during the concept phase, product development, production, operation, service and decommissioning.

Planning, coordinating and documenting the safety activities of all phases of the safety lifecycle

aremonitoring the progress of the safety activities, as well as the responsibility to ensure that the

confirmation measures are performed, are key management tasks. and are performed throughout the

lifecycle. The safety lifecycle may be tailored (see Clause 6).

Figure 2 represents the reference safety lifecycle model. Tailoring of the safety lifecycle, including

iterations of subphases, is allowed.

NOTE 1 The safety activities during the concept phase and, the product development, and after the release

for productionproduction, operation, service and decommissioning are described in detail in ISO 26262-3

(concept phase), ISO 26262-4 (product development at the system level), ISO 26262-5 (product development at

the hardware level), ISO 26262-6 (product development at the software level) and ISO 26262-7 (production and

operation).

NOTE 2 Table A.1 provides an overview of the objectives, prerequisites and work products of the particular

phases of the management of functional safety.

Figure 2 illustrates the management activities in relation to the safety lifecycle.

4 © ISO 2018 – All rights reserved

ISO 26262-2:redline:2018(E)

NOTE 3 Within the figure, the specific clauses of each part of ISO 26262 are indicated in the following

manner: “m-n”, where “m” represents the number of the part and “n” indicates the number of the clause, e.g. “3-6”