ISO 2321:2017

(Main)Rubber threads — Methods of test

Rubber threads — Methods of test

ISO 2321:2017 specifies methods of test for determining general physical and mechanical properties of rubber threads, as well as specific mechanical properties of such threads in contact with fabrics. Owing to the comparatively small cross-section and the unusual conditions of service of this material, certain special methods have been developed. Some of the tests included in this document are not entirely suitable for threads made from certain synthetic rubbers (e.g. urethane rubber). These tests are intended for natural or synthetic polyisoprene rubbers. Comparisons can only be made on new rubber threads or on those with identical processing histories. In the interpretation of results from threads which have been subjected to spooling, fabrication or any other process, the previous history is important, and what is known of this and of any relaxation treatments used is intended to be reported.

Fils élastiques — Méthodes d'essai

General Information

- Status

- Published

- Publication Date

- 30-Aug-2017

- Technical Committee

- ISO/TC 45/SC 4 - Products (other than hoses)

- Drafting Committee

- ISO/TC 45/SC 4 - Products (other than hoses)

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 29-Jul-2022

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 04-Nov-2015

Overview

ISO 2321:2017 - Rubber threads - Methods of test specifies standardized laboratory methods for determining the physical and mechanical properties of rubber threads (elastic threads). The standard addresses both general properties and specific behaviours of rubber threads in contact with fabrics. It is intended primarily for natural and synthetic polyisoprene rubber threads; some tests are not fully suitable for other elastomers (for example, urethane-based threads). The standard also stresses that comparisons are valid only for new threads or threads with identical processing histories, and that previous processing (spooling, fabrication) and any relaxation treatments must be reported.

Key topics and technical requirements

ISO 2321:2017 organizes test methods and reporting requirements that cover:

- Conditioning of samples and test-piece preparation prior to testing

- Count (sectional and conventional/size number) and metric yield determination

- Density measurement (two alternative methods)

- Tensile strength, modulus and elongation at break, with loop-formation testing procedures

- Schwartz value (SV) determination

- Elongation under a specified load, stress retention, and tension set tests

- Accelerated ageing of relaxed threads and dry-heat resistance testing

- Adhesion/ribbons testing to assess bonding between threads and fabrics

- Resistance to copper staining during laundering, effect of washing, and resistance to atmospheric fume staining

- Detailed apparatus, procedures, expression of results, and test reporting requirements

Applications and practical value

ISO 2321:2017 is used to:

- Establish quality control criteria for elastic threads in manufacturing

- Provide reproducible methods for R&D and material comparison (when processing histories match)

- Define test requirements for product specifications, procurement, and supplier acceptance

- Assess durability and compatibility of rubber threads in textiles, garments, medical elastics, and technical textiles where thread‑fabric interaction is critical

- Evaluate ageing, laundering behaviour, and staining risks in end‑use conditions

Who should use this standard

- Elastic thread and rubber thread manufacturers

- Textile and rubber testing laboratories and quality assurance teams

- Garment and hosiery producers specifying elastics for apparel

- Product developers, material scientists, and procurement specialists seeking consistent test methods

Related guidance

Refer to other ISO and national standards covering rubber and textile testing for complementary test methods and cross-references when building a full testing program. For reliable comparisons, ensure sample histories and conditioning are documented as required by ISO 2321:2017.

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

ISO 2321:2017 is a standard published by the International Organization for Standardization (ISO). Its full title is "Rubber threads — Methods of test". This standard covers: ISO 2321:2017 specifies methods of test for determining general physical and mechanical properties of rubber threads, as well as specific mechanical properties of such threads in contact with fabrics. Owing to the comparatively small cross-section and the unusual conditions of service of this material, certain special methods have been developed. Some of the tests included in this document are not entirely suitable for threads made from certain synthetic rubbers (e.g. urethane rubber). These tests are intended for natural or synthetic polyisoprene rubbers. Comparisons can only be made on new rubber threads or on those with identical processing histories. In the interpretation of results from threads which have been subjected to spooling, fabrication or any other process, the previous history is important, and what is known of this and of any relaxation treatments used is intended to be reported.

ISO 2321:2017 specifies methods of test for determining general physical and mechanical properties of rubber threads, as well as specific mechanical properties of such threads in contact with fabrics. Owing to the comparatively small cross-section and the unusual conditions of service of this material, certain special methods have been developed. Some of the tests included in this document are not entirely suitable for threads made from certain synthetic rubbers (e.g. urethane rubber). These tests are intended for natural or synthetic polyisoprene rubbers. Comparisons can only be made on new rubber threads or on those with identical processing histories. In the interpretation of results from threads which have been subjected to spooling, fabrication or any other process, the previous history is important, and what is known of this and of any relaxation treatments used is intended to be reported.

ISO 2321:2017 is classified under the following ICS (International Classification for Standards) categories: 83.140.99 - Other rubber and plastics products. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 2321:2017 has the following relationships with other standards: It is inter standard links to ISO 2321:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 2321:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 2321

Fourth edition

2017-08

Rubber threads — Methods of test

Fils élastiques — Méthodes d'essai

Reference number

©

ISO 2017

© ISO 2017, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2017 – All rights reserved

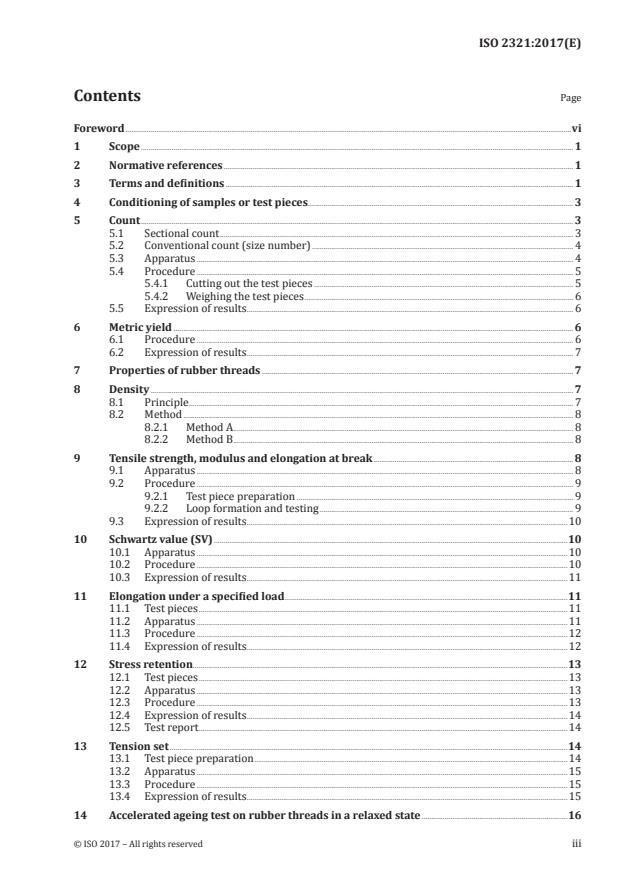

Contents Page

Foreword .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Conditioning of samples or test pieces . 3

5 Count . 3

5.1 Sectional count . 3

5.2 Conventional count (size number) . 4

5.3 Apparatus . 4

5.4 Procedure . 5

5.4.1 Cutting out the test pieces . 5

5.4.2 Weighing the test pieces . 6

5.5 Expression of results . 6

6 Metric yield . 6

6.1 Procedure . 6

6.2 Expression of results . 7

7 Properties of rubber threads . 7

8 Density . 7

8.1 Principle . 7

8.2 Method . 8

8.2.1 Method A . 8

8.2.2 Method B . 8

9 Tensile strength, modulus and elongation at break . 8

9.1 Apparatus . 8

9.2 Procedure . 9

9.2.1 Test piece preparation . 9

9.2.2 Loop formation and testing . 9

9.3 Expression of results .10

10 Schwartz value (SV) .10

10.1 Apparatus .10

10.2 Procedure .10

10.3 Expression of results .11

11 Elongation under a specified load .11

11.1 Test pieces .11

11.2 Apparatus .11

11.3 Procedure .12

11.4 Expression of results .12

12 Stress retention .13

12.1 Test pieces .13

12.2 Apparatus .13

12.3 Procedure .13

12.4 Expression of results .14

12.5 Test report .14

13 Tension set .14

13.1 Test piece preparation .14

13.2 Apparatus .15

13.3 Procedure .15

13.4 Expression of results .15

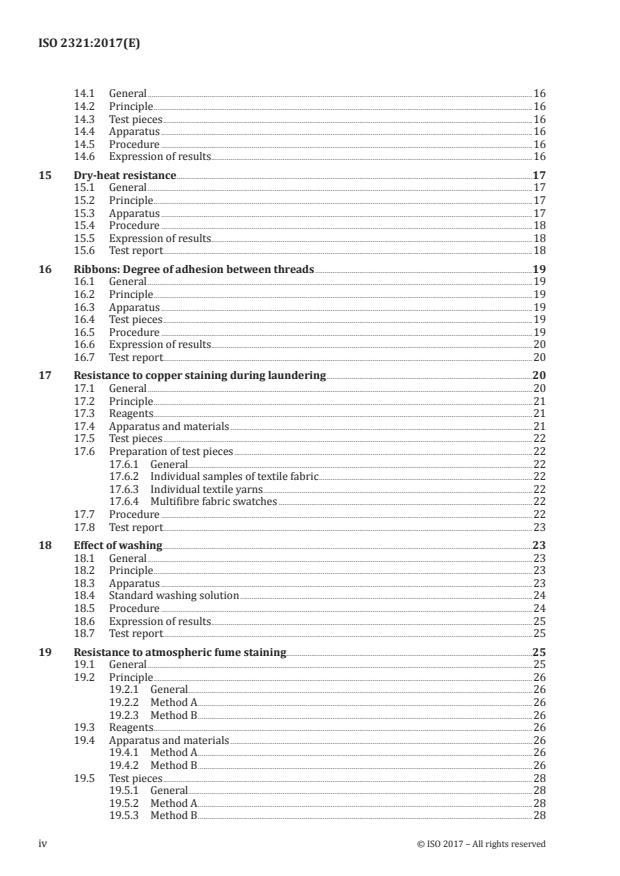

14 Accelerated ageing test on rubber threads in a relaxed state .16

14.1 General .16

14.2 Principle .16

14.3 Test pieces .16

14.4 Apparatus .16

14.5 Procedure .16

14.6 Expression of results .16

15 Dry-heat resistance .17

15.1 General .17

15.2 Principle .17

15.3 Apparatus .17

15.4 Procedure .18

15.5 Expression of results .18

15.6 Test report .18

16 Ribbons: Degree of adhesion between threads .19

16.1 General .19

16.2 Principle .19

16.3 Apparatus .19

16.4 Test pieces .19

16.5 Procedure .19

16.6 Expression of results .20

16.7 Test report .20

17 Resistance to copper staining during laundering .20

17.1 General .20

17.2 Principle .21

17.3 Reagents.21

17.4 Apparatus and materials .21

17.5 Test pieces .22

17.6 Preparation of test pieces .22

17.6.1 General.22

17.6.2 Individual samples of textile fabric .22

17.6.3 Individual textile yarns .22

17.6.4 Multifibre fabric swatches .22

17.7 Procedure .22

17.8 Test report .23

18 Effect of washing .23

18.1 General .23

18.2 Principle .23

18.3 Apparatus .23

18.4 Standard washing solution .24

18.5 Procedure .24

18.6 Expression of results .25

18.7 Test report .25

19 Resistance to atmospheric fume staining.25

19.1 General .25

19.2 Principle .26

19.2.1 General.26

19.2.2 Method A .26

19.2.3 Method B .26

19.3 Reagents.26

19.4 Apparatus and materials .26

19.4.1 Method A .26

19.4.2 Method B .26

19.5 Test pieces .28

19.5.1 General.28

19.5.2 Method A .28

19.5.3 Method B .28

iv © ISO 2017 – All rights reserved

19.6 Procedure .28

19.6.1 Method A .28

19.6.2 Method B .28

19.7 Test report .29

Bibliography .30

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 45, Rubber and rubber products,

Subcommittee SC 4, Products (other than hoses).

This fourth edition cancels and replaces the third edition (ISO 2321:2006), which has been technically

revised.

The main changes compared to the previous edition are as follows:

— Clause 3 has been added to list all the terms and definitions;

— the distance between cutting blades in Figure 1 has been added;

— the tensile testing of type A rings in Figure 2 has been added and all the figure numbers have been

updated;

— a new test, namely tension set, has been added in Clause 13;

— the clause numbers in Table 1 and Table 2 have been updated;

— the unit of density has been changed from megagram per cubic metre (Mg/m ) to gram per cubic

centimetre (g/cm ).

vi © ISO 2017 – All rights reserved

INTERNATIONAL STANDARD ISO 2321:2017(E)

Rubber threads — Methods of test

1 Scope

This document specifies methods of test for determining general physical and mechanical properties of

rubber threads, as well as specific mechanical properties of such threads in contact with fabrics. Owing

to the comparatively small cross-section and the unusual conditions of service of this material, certain

special methods have been developed.

Some of the tests included in this document are not entirely suitable for threads made from certain

synthetic rubbers (e.g. urethane rubber). These tests are intended for natural or synthetic polyisoprene

rubbers.

Comparisons can only be made on new rubber threads or on those with identical processing histories.

In the interpretation of results from threads which have been subjected to spooling, fabrication or

any other process, the previous history is important, and what is known of this and of any relaxation

treatments used is intended to be reported.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 37, Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

ISO 105-A02, Textiles — Tests for colour fastness — Part A02: Grey scale for assessing change in colour

ISO 105-A03, Textiles — Tests for colour fastness — Part A03: Grey scale for assessing staining

ISO 188, Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests

ISO 648, Laboratory glassware — Single-volume pipettes

ISO 1042, Laboratory glassware — One-mark volumetric flasks

ISO 1183-2, Plastics — Methods for determining the density of non-cellular plastics — Part 2: Density

gradient column method

ISO 23529, Rubber — General procedures for preparing and conditioning test pieces for physical test methods

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

metric yield

unstretched length, in metres, of 1 000 g of the thread

3.2

density

mass per unit volume of a test piece of thread measured at a standard laboratory

temperature

Note 1 to entry: It is expressed in grams per cubic centimetre.

Note 2 to entry: The standard laboratory temperatures are given in ISO 23529.

3.3

tensile strength

stress at which the thread breaks when it is stretched under specified conditions, based on the initial

cross-sectional area

Note 1 to entry: The value is expressed in megapascals (1MPa = 1N/mm ).

3.4

modulus at 300 % and 500 %

stress calculated with respect to the original cross-sectional area, at 300 % and 500 % elongation

Note 1 to entry: It is measured in megapascals (1MPa = 1N/mm ).

3.5

elongation at break

increase in length of the thread at break when it is stretched under the specified conditions, expressed

as the percentage increase of the original length

EXAMPLE A test piece, 30 mm in length which increases in length to 210 mm at break, is said to give an

elongation of 600 % at break.

3.6

Schwartz value

average of the stresses calculated with respect to the original cross-sectional area at a specified elongation

measured on extension and retraction of a previously massaged (mechanically conditioned) thread

Note 1 to entry: It is expressed in megapascals (1MPa = 1N/mm ).

c

Note 2 to entry: It is denoted by the abbreviated term, SV , where c is the massaging elongation (the elongation

n

to which the test piece is stretched during mechanical conditioning) and n the elongation at which the readings

are taken. Both c and n are expressed as percentages of the initial length as multiples of 100 and, unless otherwise

specified, are chosen so that c = n + 100.

Note 3 to entry: The preferred values of n are 300 % and 500 %, depending on the type of thread under test.

3.7

Schwartz hysteresis ratio

ratio of the loads at a specified elongation measured on extension and retraction, after massaging

(mechanical conditioning)

c

Note 1 to entry: It is denoted by the abbreviated term, SHR , where c is the massaging elongation (the elongation

n

to which the test piece is stretched during mechanical conditioning) and n the elongation at which readings are

taken. Both c and n are expressed as percentages of the initial length as multiples of 100 and, unless otherwise

specified, are chosen so that c = n + 100.

Note 2 to entry: The preferred values of n are 300 % and 500 %, depending on the type of thread under test.

2 © ISO 2017 – All rights reserved

3.8

elongation under specified load

percentage elongation of a rubber thread when stressed by the application of a specified load per unit area

Note 1 to entry: It is determined by applying a load to an unmassaged thread (i.e. a thread which has not been

mechanically conditioned) and so is liable to be affected by the age and previous history (including storage

history and any conditioning) of the thread.

Note 2 to entry: It is normally determined at two levels of applied force: 15,5 kPa (= 15,5 mN/mm ) and 27,4 kPa

(= 27,4 mN/mm ).

3.9

stress retention

residual load, expressed as a percentage of the original load on the thread, after the test piece has been

maintained at a constant elongation (usually 100 %) for a specified time

3.10

tension set

elongation remaining in a test piece in the relaxed condition after it has been subjected to a constant

elongation at a specified time, expressed as a percentage of the elongation

3.11

discoloration

change in the original shade of a product, resulting from outside influences

3.12

colour staining

undesired pick-up of colour by a fabric

a) when immersed in water, dry-cleaning solvent or a similar liquid medium, which contains dyestuffs

or colouring material not intended for colouring the fabric;

b) by direct contact with other dyed material from which colour is transferred by bleeding or

sublimation

4 Conditioning of samples or test pieces

The samples or test pieces shall be kept in a relaxed state in one of the standard atmospheres described

in ISO 23529, for not less than 16 h before testing. The tests shall be carried out under similar

atmospheric conditions. The test piece selected shall be clean, dry and free from any visual defects.

Samples or test pieces shall not be allowed to come into contact with copper or manganese of their

compounds during conditioning or testing.

5 Count

5.1 Sectional count

The sectional count of a rubber thread is given by the value of its cross-sectional area, expressed in

square millimetres.

The sectional count corresponds to the tex count for a nominal density of 1 g/cm . The use of the

sectional count is recommended.

5.2 Conventional count (size number)

5.2.1 The conventional count of a rubber thread is the number of threads which, when placed side by

side, measure 25,4 mm.

The conventional count of a round thread is calculated by dividing 25,4 by the diameter, in millimetres,

of the thread.

The conventional count of a square thread is calculated by dividing 25,4 by the length, in millimetres, of

one of the sides of the thread.

The conventional count of a rectangular thread is generally quoted as the count of a square thread of

equivalent cross-sectional area.

Thus, in the case of a round thread, the number, 100, is the conventional count of a thread, whose

diameter is equal to 0,254 mm: In the case of a square thread, the number 40 is the conventional count

of a thread whose sides are equal to 0,635 mm.

5.2.2 It is customary to quote the conventional count of a round thread, followed by the whole even

number which is nearest to the actual conventional count of the square thread of equivalent cross-

sectional area (count of round thread × 1,13 = actual count of square thread).

EXAMPLE A round thread of count 50 is indicated by 50/56.

5.2.3 The conventional count of a multi-filament round thread is expressed by stating successively the

number of components, the count of the single round thread which would have the same total cross-

sectional area as the component threads, and the count of the corresponding square thread.

EXAMPLE The conventional count of a multi-filament round thread, made up of three components equal in

total cross-sectional area to a round thread of count 32, is indicated by 3/32/36.

5.3 Apparatus

See Figure 1.

The apparatus for cutting the test pieces consists of a rectangular vertical frame at the upper and lower

ends of which are mounted two metallic plates whose inside edges are parallel and sharp. Two cutting

devices (the fixed blade of which consists of the inside edge of the metal plate) and two external clamps

are provided. The clamps shall be of a spring-loaded type and the distance between the internal edges

of the metal plates shall be 100 mm ± 1 mm.

4 © ISO 2017 – All rights reserved

Dimension in millimetres

Key

1 metal plate

2 clamp

3 cutting device

Figure 1 — Apparatus for cutting test pieces

5.4 Procedure

5.4.1 Cutting out the test pieces

Take five strips of thread samples and cut them to a length of approximately 110 mm.

Tear off threads equally from both edges of each strip until there are only 10 threads in each one. If

these strips are taken from bobbins or from any other type of presentation in which the strip is

under tension, heat-treat them for 30 min in a thermostatically controlled oven at a temperature of

70 °C ± 2 °C. After this heat treatment, condition the strip as specified in Clause 4. For strips taken from

other forms of presentation where no tension is applied to the strip, condition as specified in Clause 4.

Suspend each conditioned strip from the upper clamp. When it has settled in the vertical position

without stretch, fix it by means of the lower clamp. Cut the strip to the required length with the two

cutting devices, using the lower one first.

5.4.2 Weighing the test pieces

Free the cut strips from any loose dusting powder by shaking or brushing them gently, and weigh to an

accuracy of ±1 %.

5.5 Expression of results

5.5.1 The sectional count, S, is given by Formula (1):

m 1

S = × (1)

ρ 1000

where

ρ is the density, expressed in grams per cubic centimetre, of the thread, determined as specified

in Clause 8;

m is the mass, in miligrams, of the strip.

5.5.2 The conventional count, C, is given by Formulae (2) and (3):

For round thread

ρ

C=22,51 (2)

m

For square thread

ρ

C=25,40 (3)

m

where

ρ is the density, expressed in grams per cubic centimetre, of the thread, determined as specified

in Clause 8;

m is the mass, in milligrams, of the strip.

5.5.3 Express the count of the thread as the median of the values for the five test pieces, as indicated in

Clause 5. The maximum and minimum values obtained shall also be stated.

6 Metric yield

6.1 Procedure

Determine the mass of each of five test pieces as specified in 5.4.2.

6 © ISO 2017 – All rights reserved

6.2 Expression of results

6.2.1 The metric yield of rubber thread, expressed in metres per kilogram, is given by Formula (4):

(4)

m

where m is the mass, in grams, of 1 000 mm of thread.

6.2.2 Express the metric yield of the thread as the median of the values for the five test pieces.

7 Properties of rubber threads

Properties of rubber threads are made up of two kinds: general physical and mechanical properties,

and specific mechanical properties of the threads in contact with fabrics. They shall be determined by

the test methods specified in Table 1 and Table 2, respectively.

Table 1 — General properties of rubber threads

Physical and mechanical properties Clause No.

Density 8

Tensile strength, modulus, elongation at break 9

Schwartz value (SV) 10

Elongation under a specified load 11

Stress retention 12

Tension set 13

Accelerated-ageing test on rubber threads in a relaxed state 14

Dry-heat resistance test 15

Table 2 — Specific properties of rubber threads

Mechanical properties in contact with fabrics Clause No.

Ribbons: Degree of adhesion between threads 16

Resistance to copper staining during laundering 17

Effect of washing 18

Resistance to atmospheric fume staining 19

8 Density

8.1 Principle

Test pieces are placed in a suitable mixture of liquids, the density of which is adjusted until the test

pieces neither float nor sink; this density is determined.

8.2 Method

8.2.1 Method A

8.2.1.1 Most of the rubber threads on the market have a density in the range of 0,90 g/cm to

1,11 g/cm . It is necessary, therefore, to have a series of liquids having densities within this range.

3 3

Mixtures of ethanol (0,79 g/cm ) and ethylene glycol (1,11 g/m ) are suitable.

For threads of greater density, a suitable inorganic salt solution can be used. A solution of sodium

chloride is suitable.

8.2.1.2 Before the mixtures are used, it shall be ensured that they are homogeneous and free from

air bubbles. They shall be kept in closed containers so as to avoid evaporation. They shall be used at a

temperature of 20 °C ± 2 °C.

8.2.1.3 Apparatus

8.2.1.3.1 Glass cylinder, with a capacity of about 1 000 cm .

8.2.1.3.2 Hydrometer or hydrostatic balance or other apparatus allowing measurement of the

density of liquids to an accuracy of at least 0,005 g/cm .

8.2.1.4 Procedure

8.2.1.4.1 Take four test pieces, approximately 10 mm long, from the sample. Dip each test piece

in ethanol and then rub between the fingers to remove dusting powder and any air bubbles from the

surface.

8.2.1.4.2 Take a suitable liquid mixture (see 8.2.1.1) and thoroughly homogenize it, taking care not to

introduce any air bubbles. Place one of the test pieces in the liquid. Adjust the density of the liquid by the

addition of the appropriate component, mixing thoroughly after each addition. Continue this adjustment

until the test piece neither sinks nor floats.

8.2.1.4.3 Test the other three test pieces in the mixture; at least two of these three test pieces shall

reach equilibrium within a period of 3 min to 10 min.

8.2.1.4.4 Determine the density of the liquid mixture to the nearest 0,005 g/cm .

8.2.2 Method B

Determine the density of the test pieces in accordance with ISO 1183-2.

9 Tensile strength, modulus and elongation at break

9.1 Apparatus

9.1.1 Loop-forming machine

9.1.2 Tensile-testing machine, as described in ISO 37, with modified O-ring grips based on the

standard pulleys for type A rings (see Figure 2).

For example, B can be 24 mm to be used conveniently.

8 © ISO 2017 – All rights reserved

Key

1 freely rotating pulley ⌀d 25 ± 0,05 mm

2 freely rotating pulley ⌀d 25 ± 0,05 mm

3 direction of extension L (circumference of sample − circumference of roller)/2

Figure 2 — Pulley arrangement for tensile testing of type A rings

9.2 Procedure

9.2.1 Test piece preparation

The thread test piece is allowed to relax at room temperature for 60 min to ensure that all stresses in

the thread have been released. It is then weighed and the average diameter of the thread calculated.

Using a loop-forming machine, the rubber thread is made into a loop and the ends tied securely. The

diameter of the loop is dependent on the distance between the two cylinders of the tensile-testing

machine (see 9.2.2). Usually, these are set at 100 mm apart. The total number of loops for each sample

is dependent on the count of the thread and the load capacity of the tensile tester. The more loops there

are, the greater the total cross-sectional area, and hence the greater the force that will be needed to

stretch the test piece to breaking point.

9.2.2 Loop formation and testing

The test piece is looped over the two cylinders of the tensile tester. The loop diameter shall be such that

it fits exactly over the two cylinders without stretching.

The tensile tester is then run to stretch the test piece to breaking point. The machine is set to read

the modulus at 300 % and 500 %, and the tensile strength and the elongation at break. Depending on

the complexity of the machine, the cross-sectional area of the loop is usually entered into the machine,

and the modulus and tensile strength are then automatically calculated and printed out on a printer or

displayed on a computer screen. The elongation at break, calculated as the percentage stretch relative to

the original length (100 mm), is automatically displayed by the tensile tester on completion of the test.

Test five test pieces.

9.3 Expression of results

Results are calculated as follows:

Modulus at 300 % (in mN/mm ) = F /A (5)

Modulus at 500 % (in mN/mm ) = F /A (6)

Tensile strength (in mN/mm ) = F /A (7)

B

LL−

Bo

Elongation at break (in %) = ×100 (8)

L

o

where

F is the force, in millinewtons, necessary to stretch the test piece to 300 %;

F is the force, in millinewtons, necessary to stretch the test piece to 500 %;

F is the force, in millinewtons, necessary to stretch the test piece to the break point;

B

A is the total cross-sectional area, in square millimetres, of the test piece;

L is the length at break of the test piece;

B

L is the original length of the test piece.

o

Express the tensile strength, modulus and elongation at break of the thread as the median of the values

for the five test pieces. The maximum and minimum values shall also be quoted. In addition, the test

report shall indicate the type of apparat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...