ISO/IEC 28360-1:2021

(Main)Information technology — Determination of chemical emission rates from electronic equipment — Part 1: Using consumables

Information technology — Determination of chemical emission rates from electronic equipment — Part 1: Using consumables

This document (all parts) specifies methods to determine chemical emission rates of analytes from ICT & CE equipment during intended operation in an Emission Test Chamber (ETC). This document (all parts) includes specific methods for equipment using consumables, such as printers, and equipment not using consumables, such as monitors and PC’s. Part 1 specifies the methods to determine the emission rates of VOC and carbonyl compounds, ozone, particulate matter, fine particles (FP) and ultra-fine particles (UFP) from electronic equipment using consumables. The methods comprise preparation, sampling (or monitoring) in a controlled ETC, storage and analysis, calculation and reporting of emission rates. Part 1 has two different methods for the determination of emission rates of VOC and carbonyl compounds. The two methods use two different emission models, the quasi-equilibrium model (QEM) and the constant emission model (CEM) respectively, to determine the emission rates of VOC and carbonyl compounds during the pre-operating phase. The quasi-equilibrium model method has been developed with hard copy devices for office or home use in mind whose energy-saving modes automatically activate during most intervals between operations. The calculation of emission rates during the pre-operating phase is based on the quasi-equilibrium assumption as shown in Annex C. The emission rates determined with this method can be used to compare equipment in the same class since test procedures are specified more narrowly than the other method (CEM). The constant emission model (CEM) has been developed for hard copy devices whose energy-saving modes have such a negligible effect on the determination of emission rates of VOC and carbonyl compounds that the generalised constant emission model shown in Annex D can be used for the determination of their emission rates during the pre-operating phase. This method presents more flexible test procedures than the QEM. Due to such features of this method, it may be used for hard copy devices whose idling mode usually lasts throughout intervals between operations, such as large hard copy devices used professionally. It may also be used for various equipment having different functions and structure for its intended use and the determination of carbonyl compounds requiring longer sampling duration due to a lack of sensitivity. Annex A specifies monochrome and colour print patterns for use in the operating phase of EUT using consumables. The operational readiness of AMS is confirmed according to Annex B. Predictions of “real indoor” concentrations from the determined emission rates are outside the scope of this document.

Technologies de l'information — Détermination des taux d'émission chimique d'un équipement électronique — Partie 1: Utilisation de consommables

General Information

- Status

- Published

- Publication Date

- 27-Oct-2021

- Technical Committee

- ISO/IEC JTC 1 - Information technology

- Drafting Committee

- ISO/IEC JTC 1 - Information technology

- Current Stage

- 6060 - International Standard published

- Start Date

- 28-Oct-2021

- Due Date

- 16-Jun-2022

- Completion Date

- 28-Oct-2021

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 10-Jul-2021

Overview

ISO/IEC 28360-1:2021 specifies standardized laboratory methods for determining chemical emission rates from electronic equipment using consumables (for example, printers and other hard‑copy devices). Tests are performed in an Emission Test Chamber (ETC) to measure analytes released during intended operation. The standard covers preparation, chamber requirements, sampling (or monitoring), sample storage and analysis, calculation of emission rates, and reporting. Measured analytes include volatile organic compounds (VOC), carbonyl compounds, ozone, particulate matter (PM), fine particles (FP) and ultrafine particles (UFP). Note: predicting real indoor concentrations from measured emission rates is outside the scope.

Key Topics and Requirements

- ETC design and operation: construction materials, air tightness, air mixing efficiency and air-exchange settings required to obtain reproducible emissions data.

- Test phases: defined pre‑operating, operating, and post‑operating procedures, including EUT (equipment under test) preparation, loading factor, purging and background concentration determination.

- Analyte‑specific methods:

- VOC and carbonyls: two emission models are provided - the Quasi‑Equilibrium Model (QEM) and the Constant Emission Model (CEM) - to calculate pre‑operating emission rates from chamber concentrations.

- QEM: optimized for small office/home hard‑copy devices with energy‑saving modes that activate between operations.

- CEM: intended for devices with continuous idling (e.g., large professional hard‑copy devices) or where longer sampling is needed.

- Ozone: analyzer and sampling line requirements, continuous monitoring and emission rate calculation.

- Particulate matter, FP and UFP: gravimetric sampling, aerosol measuring systems (AMS) readiness, particle counting and calculation methods.

- VOC and carbonyls: two emission models are provided - the Quasi‑Equilibrium Model (QEM) and the Constant Emission Model (CEM) - to calculate pre‑operating emission rates from chamber concentrations.

- Sampling, storage and analysis: guidance on sorbents, filter conditioning, sample collection, and laboratory analysis.

- Reporting: standardized test report content to ensure comparability.

Practical Applications and Users

ISO/IEC 28360-1:2021 is used by:

- Manufacturers of printers and other consumable‑based electronic equipment for product development and internal emissions verification.

- Independent test laboratories performing compliance and comparative emission testing in ETCs.

- Regulatory bodies and procurement teams requiring objective emission data for environmental and indoor‑air quality assessments.

- R&D and environmental health researchers studying VOC, ozone and particulate emissions from ICT/CE devices.

Practical benefits include comparable, reproducible emission rates across device classes, support for product improvement (material selection, ventilation design) and consistent test reporting.

Related Standards

- ISO/IEC 28360 series (Part 2 covers equipment not using consumables)

- ECMA‑328 (committee origin and harmonization reference)

- RAL test methods referenced in the standard (e.g., RAL‑UZ options)

Frequently Asked Questions

ISO/IEC 28360-1:2021 is a standard published by the International Organization for Standardization (ISO). Its full title is "Information technology — Determination of chemical emission rates from electronic equipment — Part 1: Using consumables". This standard covers: This document (all parts) specifies methods to determine chemical emission rates of analytes from ICT & CE equipment during intended operation in an Emission Test Chamber (ETC). This document (all parts) includes specific methods for equipment using consumables, such as printers, and equipment not using consumables, such as monitors and PC’s. Part 1 specifies the methods to determine the emission rates of VOC and carbonyl compounds, ozone, particulate matter, fine particles (FP) and ultra-fine particles (UFP) from electronic equipment using consumables. The methods comprise preparation, sampling (or monitoring) in a controlled ETC, storage and analysis, calculation and reporting of emission rates. Part 1 has two different methods for the determination of emission rates of VOC and carbonyl compounds. The two methods use two different emission models, the quasi-equilibrium model (QEM) and the constant emission model (CEM) respectively, to determine the emission rates of VOC and carbonyl compounds during the pre-operating phase. The quasi-equilibrium model method has been developed with hard copy devices for office or home use in mind whose energy-saving modes automatically activate during most intervals between operations. The calculation of emission rates during the pre-operating phase is based on the quasi-equilibrium assumption as shown in Annex C. The emission rates determined with this method can be used to compare equipment in the same class since test procedures are specified more narrowly than the other method (CEM). The constant emission model (CEM) has been developed for hard copy devices whose energy-saving modes have such a negligible effect on the determination of emission rates of VOC and carbonyl compounds that the generalised constant emission model shown in Annex D can be used for the determination of their emission rates during the pre-operating phase. This method presents more flexible test procedures than the QEM. Due to such features of this method, it may be used for hard copy devices whose idling mode usually lasts throughout intervals between operations, such as large hard copy devices used professionally. It may also be used for various equipment having different functions and structure for its intended use and the determination of carbonyl compounds requiring longer sampling duration due to a lack of sensitivity. Annex A specifies monochrome and colour print patterns for use in the operating phase of EUT using consumables. The operational readiness of AMS is confirmed according to Annex B. Predictions of “real indoor” concentrations from the determined emission rates are outside the scope of this document.

This document (all parts) specifies methods to determine chemical emission rates of analytes from ICT & CE equipment during intended operation in an Emission Test Chamber (ETC). This document (all parts) includes specific methods for equipment using consumables, such as printers, and equipment not using consumables, such as monitors and PC’s. Part 1 specifies the methods to determine the emission rates of VOC and carbonyl compounds, ozone, particulate matter, fine particles (FP) and ultra-fine particles (UFP) from electronic equipment using consumables. The methods comprise preparation, sampling (or monitoring) in a controlled ETC, storage and analysis, calculation and reporting of emission rates. Part 1 has two different methods for the determination of emission rates of VOC and carbonyl compounds. The two methods use two different emission models, the quasi-equilibrium model (QEM) and the constant emission model (CEM) respectively, to determine the emission rates of VOC and carbonyl compounds during the pre-operating phase. The quasi-equilibrium model method has been developed with hard copy devices for office or home use in mind whose energy-saving modes automatically activate during most intervals between operations. The calculation of emission rates during the pre-operating phase is based on the quasi-equilibrium assumption as shown in Annex C. The emission rates determined with this method can be used to compare equipment in the same class since test procedures are specified more narrowly than the other method (CEM). The constant emission model (CEM) has been developed for hard copy devices whose energy-saving modes have such a negligible effect on the determination of emission rates of VOC and carbonyl compounds that the generalised constant emission model shown in Annex D can be used for the determination of their emission rates during the pre-operating phase. This method presents more flexible test procedures than the QEM. Due to such features of this method, it may be used for hard copy devices whose idling mode usually lasts throughout intervals between operations, such as large hard copy devices used professionally. It may also be used for various equipment having different functions and structure for its intended use and the determination of carbonyl compounds requiring longer sampling duration due to a lack of sensitivity. Annex A specifies monochrome and colour print patterns for use in the operating phase of EUT using consumables. The operational readiness of AMS is confirmed according to Annex B. Predictions of “real indoor” concentrations from the determined emission rates are outside the scope of this document.

ISO/IEC 28360-1:2021 is classified under the following ICS (International Classification for Standards) categories: 37.100.10 - Reproduction equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO/IEC 28360-1:2021 has the following relationships with other standards: It is inter standard links to EN ISO 27548:2024, ISO/IEC 28360-1:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO/IEC 28360-1:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 28360-1

Second edition

2021-10

Information technology —

Determination of chemical emission

rates from electronic equipment —

Part 1:

Using consumables

Technologies de l'information — Détermination des taux d'émission

chimique d'un équipement électronique —

Partie 1: Utilisation de consommables

Reference number

© ISO/IEC 2021

© ISO/IEC 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

© ISO/IEC 2021 – All rights reserved

Contents Page

Foreword . v

Introduction . vi

1 Scope . 1

2 Conformance . 2

3 Normative references . 2

4 Terms and definitions . 2

5 Symbols and Abbreviated terms . 6

5.1 Abbreviated terms . 6

5.2 Symbols . 7

6 Method overview . 8

7 ETC requirements . 9

7.1 Construction materials . 9

7.2 Air tightness . 9

7.3 Air mixing efficiency . 10

8 Determination method . 10

8.1 Test conditions . 10

8.1.1 General . 10

8.1.2 Operating temperature and relative humidity (RH) . 10

8.1.3 Air exchange rate (n) . 10

8.1.4 Air velocity . 10

8.1.5 Sampled air flow . 10

8.2 Handling of EUT and ETC . 10

8.2.1 Selection and storage of EUT . 10

8.2.2 Loading Factor . 11

8.2.3 ETC purging . 11

8.2.4 Background concentrations (Cbg and Cpbg) . 11

8.2.5 EUT unpacking . 12

8.2.6 Preparation of the EUT before testing . 12

8.2.7 EUT installation . 12

8.3 EUT Operation during Test . 13

8.3.1 General . 13

8.3.2 Pre-operating phase . 13

8.3.3 Operating phase . 13

8.3.4 Post-operating phase . 14

8.3.5 Recording of EUT operation . 14

8.4 VOC and carbonyl compounds . 14

8.4.1 Sorbents . 14

8.4.2 Sample collection . 14

8.4.3 Emission rate calculation . 15

8.4.4 Total VOC emission rate . 17

8.5 Ozone . 17

8.5.1 Analyser and sampling line requirements . 18

8.5.2 Monitoring . 18

8.5.3 Emission rate calculation . 18

8.6 Particulate matter . 19

8.6.1 Weighing and Filter conditioning . 20

8.6.2 Sampling . 20

8.6.3 Emission rate calculation . 20

8.7 Fine and Ultrafine Particles (FP and UFP) . 21

8.7.1 General Requirements for Aerosol Measuring Systems (AMS) . 22

8.7.2 Measurement . 24

8.7.3 Calculation . 24

© ISO/IEC 2021 – All rights reserved iii

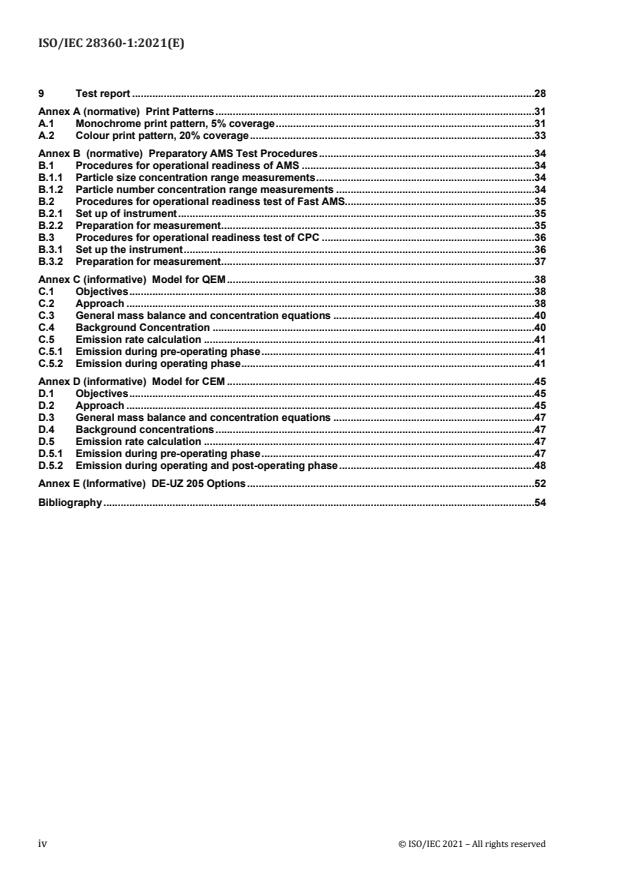

9 Test report .28

Annex A (normative) Print Patterns .31

A.1 Monochrome print pattern, 5% coverage .31

A.2 Colour print pattern, 20% coverage .33

Annex B (normative) Preparatory AMS Test Procedures .34

B.1 Procedures for operational readiness of AMS .34

B.1.1 Particle size concentration range measurements .34

B.1.2 Particle number concentration range measurements .34

B.2 Procedures for operational readiness test of Fast AMS.35

B.2.1 Set up of instrument .35

B.2.2 Preparation for measurement .35

B.3 Procedures for operational readiness test of CPC .36

B.3.1 Set up the instrument .36

B.3.2 Preparation for measurement .37

Annex C (informative) Model for QEM .38

C.1 Objectives .38

C.2 Approach .38

C.3 General mass balance and concentration equations .40

C.4 Background Concentration .40

C.5 Emission rate calculation .41

C.5.1 Emission during pre-operating phase .41

C.5.2 Emission during operating phase .41

Annex D (informative) Model for CEM .45

D.1 Objectives .45

D.2 Approach .45

D.3 General mass balance and concentration equations .47

D.4 Background concentrations .47

D.5 Emission rate calculation .47

D.5.1 Emission during pre-operating phase .47

D.5.2 Emission during operating and post-operating phase .48

Annex E (Informative) DE-UZ 205 Options .52

Bibliography .54

iv © ISO/IEC 2021 – All rights reserved

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical

Commission) form the specialized system for worldwide standardization. National bodies that are members of

ISO or IEC participate in the development of International Standards through technical committees

established by the respective organization to deal with particular fields of technical activity. ISO and IEC

technical committees collaborate in fields of mutual interest. Other international organizations, governmental

and non-governmental, in liaison with ISO and IEC, also take part in the work.

The procedures used to develop this document and those intended for its further maintenance are described

in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the different types of

document should be noted (see www.iso.org/directives or www.iec.ch/members_experts/refdocs).

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO and IEC shall not be held responsible for identifying any or all such patent rights. Details of any

patent rights identified during the development of the document will be in the Introduction and/or on the ISO

list of patent declarations received (see www.iso.org/patents) or the IEC list of patent declarations received

(see patents.iec.ch).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and expressions

related to conformity assessment, as well as information about ISO's adherence to the World Trade

Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www.iso.org/iso/foreword.html.

In the IEC, see www.iec.ch/understanding-standards.

This document was prepared by ECMA International (as ECMA-328-1) and was adopted, under a special

“fast-track procedure”, by Joint Technical Committee ISO/IEC JTC 1, Information technology, in parallel with

its approval by national bodies of ISO and IEC.

This second edition cancels and replaces the first edition (ISO/IEC 28360-1:2018), which has been technically

revised.

The main change compared to the previous edition is as follows:

— reorganization to incorporate RAL-UZ Options into the main text as one of the two methods for

determining emission rates of VOC and carbonyl compounds.

A list of all parts in the ISO/IEC 28360 series can be found on the ISO and IEC websites.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html and www.iec.ch/national-

committees.

© ISO/IEC 2021 – All rights reserved v

Introduction

Globally, governmental agencies, academic institutions, environmental organizations and manufacturers have

started to develop methods to determine chemical emissions from electronic equipment. These attempts

however, initially resulted in a range of tests from which the results were not necessarily comparable, either

qualitatively or quantitatively.

Following the publications of the 1st edition of ECMA-328 in 2001 and the “Test method for the determination

of emissions from Hard Copy Devices” (RAL-UZ 122), experts from BAM and Ecma have collaborated to

harmonise methods to determine the chemical emission rates from ICT & CE equipment in the 2nd edition.

In addition to stricter test procedures, the 2nd edition used generalised emission formulae, and their

derivations developed in Annex C, to calculate emission rates from concentrations of analytes that are

measured in Emission Test Chambers.

The 3rd edition was fully aligned with the 1st edition of ISO/IEC 28360:2007 adopted under ISO/IEC JTC 1

fast track procedure and published in September 2007.

In addition, the 4th edition fixed a number of errata on ISO/IEC 28360:2007 that JTC 1/SC 28 identified.

Following the publications of the 4th edition of ECMA-328 and the “Test method for the determination of

emissions from Hard Copy Devices” (RAL-UZ 122), experts from BAM, WKI, JBMIA and Ecma have

collaborated to harmonise methods to determine the Fine Particle (FP) and Ultrafine Particle (UFP) emissions

from hard copy devices in the 5th edition.

The 6th edition was aligned with the 2nd edition of ISO/IEC 28360:2012, and it added a new ozone calculation

method. “Test method for the determination of emission from Hard Copy Devices” (RAL-UZ 122) has been

replaced by “Test method for the determination of emission from Hard Copy Devices” (RAL-UZ 171) published

in January 2013. Therefore, “RAL-UZ 122 option” is replaced with “RAL-UZ 171 option” in the 6th edition.

The 7th edition of ECMA-328 is fully aligned with ISO/IEC 28360:2015.

The 8th edition was divided into two parts, a part for electronic equipment using consumables and a part for

electronic equipment not using consumables:

• Determination of Chemical Emission Rates from Electronic Equipment – Part 1 (using consumables)

• Determination of Chemical Emission Rates from Electronic Equipment – Part 2 (not using consumables)

The purpose of the split was to make the description of test procedures simpler (they included considerable

differences between the two equipment categories) and to facilitate users’ understanding.

This 8th edition is fully aligned with “Test method for the determination of emission from Hard Copy Devices”

(RAL-UZ 205).

The 9th edition is fully aligned with the third edition of ISO/IEC 28360:2018.

The 10th edition has been re-organised to incorporate RAL-UZ Options into the main text as one of the two

methods for determining emission rates of VOC and carbonyl compounds.

One method (QEM), which is in harmony with DE-UZ 205 , Test Method for the Determination of Emissions

from Hardcopy Devices (Appendix S-M), originates from the former RAL-UZ 205 Options. The other method

(CEM) employs the generalised constant emission model in the former editions. The two methods may yield

slightly different emission rates, so the user is encouraged to select the one that satisfies their technical

application.

vi © ISO/IEC 2021 – All rights reserved

Different elements of the two methods are described alongside each other in the main text. The models used

to calculate emission rates in each method are explained in the informative Annexes C and D. Some

requirements in the former RAL-UZ Options which appear too detailed and stringent as an international

standard are now listed in the informative Annex E so that users can fully meet the requirements of DE-

UZ 205 (Appendix S-M).

In this edition, it is deduced in the CEM that emission rates of VOC and carbonyl compounds during the

operating phase (SER ) originate from the pre-operating phase (SER ) and printing (SER ) operations as

ope pre prp

well as in the QEM and the former RAL-UZ Options.

This part of the Standard is Part 1.

This Ecma Standard was developed by Technical Committee 38 and was adopted by the General

Assembly of December 2020.

The German Blue Angel Environmental Label changed the naming convention of its award criteria from

RAL-UZ 205 to DE-UZ 205 in 2019.

© ISO/IEC 2021 – All rights reserved vii

INTERNATIONAL STANDARD ISO/IEC 28360-1:2021(E)

Information technology — Determination of chemical

emission rates from electronic equipment —

Part 1:

Using consumables

1 Scope

This Standard (all parts) specifies methods to determine chemical emission rates of analytes from ICT & CE

equipment during intended operation in an Emission Test Chamber (ETC).

This Standard (all parts) includes specific methods for equipment using consumables, such as printers, and

equipment not using consumables, such as monitors and PC’s.

Part 1 specifies the methods to determine the emission rates of VOC and carbonyl compounds, ozone,

particulate matter, fine particles (FP) and ultra-fine particles (UFP) from electronic equipment using

consumables.

The methods comprise preparation, sampling (or monitoring) in a controlled ETC, storage and analysis,

calculation and reporting of emission rates.

Part 1 has two different methods for the determination of emission rates of VOC and carbonyl compounds.

The two methods use two different emission models, the quasi-equilibrium model (QEM) and the constant

emission model (CEM) respectively, to determine the emission rates of VOC and carbonyl compounds during

the pre-operating phase.

The quasi-equilibrium model method has been developed with hard copy devices for office or home use in

mind whose energy-saving modes automatically activate during most intervals between operations. The

calculation of emission rates during the pre-operating phase is based on the quasi-equilibrium assumption as

shown in Annex C.

The emission rates determined with this method can be used to compare equipment in the same class since

test procedures are specified more narrowly than the other method (CEM).

The constant emission model (CEM) has been developed for hard copy devices whose energy-saving modes

have such a negligible effect on the determination of emission rates of VOC and carbonyl compounds that the

generalised constant emission model shown in Annex D can be used for the determination of their emission

rates during the pre-operating phase. This method presents more flexible test procedures than the QEM. Due

to such features of this method, it may be used for hard copy devices whose idling mode usually lasts

throughout intervals between operations, such as large hard copy devices used professionally. It may also be

used for various equipment having different functions and structure for its intended use and the determination

of carbonyl compounds requiring longer sampling duration due to a lack of sensitivity.

Annex A specifies monochrome and colour print patterns for use in the operating phase of EUT using

consumables.

The operational readiness of AMS is confirmed according to Annex B.

Predictions of “real indoor” concentrations from the determined emission rates are outside the scope of this

document.

© ISO/IEC 2021 – All rights reserved 1

2 Conformance

Determinations of emission rates and total number of emitted particles conform to this Standard (Part 1) when:

1. Executed using a Quality Assurance Project Plan, Quality Assurance and Quality Control as specified in

ISO 16000-9;

2. Tested in a controlled ETC as specified in Clause 7;

3. Sampled/monitored and calculated as specified in Clause 8 and Annex B;

4. Reported as specified in Clause 9.

3 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 554:1976, Standard atmospheres for conditioning and/or testing – Specifications

ISO 16000-3:2011, Indoor air – Part 3: Determination of formaldehyde and other carbonyl compounds –

Active sampling method

ISO 16000-6:2011, Indoor air – Part 6: Determination of volatile organic compounds in indoor and chamber air

by active sampling on TENAX TA sorbent, thermal desorption and gas chromatography using MS/FID

ISO 16000-9:2006, Indoor air – Part 9: Determination of the emission of volatile organic compounds from

building products and furnishing – Emission test chamber method

ISO 16017-1:2000, Indoor ambient and workplace air - Sampling and analysis of volatile organic compounds

by sorbent tube / thermal desorption / capillary gas chromatography – Part 1: Pumped sampling

rd

CIE 15:2004, Commission Internationale de l’Eclairage – Colorimetry, 3 edition

4 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

4.1

averaged concentration time series

simple moving average of total particle number concentration (Cp) over 31 ± 3 seconds

4.2

averaged ozone concentration time series

simple moving average of ozone concentration (Co ) over 80 ± 5 seconds

4.3

aerosol

suspension of solid particles and/or liquid droplets in a gas

4.4

aerosol measuring system

AMS

device category for measuring the total particle number concentration of an aerosol within a size range at a

certain frequency

2 © ISO 2021 – All rights reserved

NOTE CPC (4.8) and fast AMS (4.14) belong to AMS.

4.5

air exchange rate

n

3 3

ratio (n) of the volume of clean air brought into the ETC per hour [m /h] to the unloaded ETC volume [m ]

4.6

air velocity

air speed [m/s] measured in the unloaded ETC

4.7

analyte

volatile organic compounds (VOC), carbonyl compounds, ozone, particulate matter, fine particles (FP) and

ultrafine particles (UFP)

4.8

condensation particle counter

CPC

instrument that measures the particle number concentration of an aerosol

NOTE For the purpose of this standard a CPC is used as a standalone instrument which measures the total particle

number concentration within a device dependent size range.

4.9

constant emission model method

CEM

method to determine emission rates of VOC and carbonyl compounds using the constant emission model,

assuming that an emission rate is constant throughout the pre-operating phase

NOTE This method can apply to the pre-operating phase which consists of the warming-up and following idling and

energy saving modes as far as constant emission during that phase can be assumed.

4.10

consumables

toner, ink, paper and ribbon

4.11

emission test chamber

ETC

enclosure with controlled operational parameters for testing analyte mass emitted from EUT

4.12

energy saving mode

mode in a lower power state than that of the idling mode which hard copy devices enter after a period of

inactivity

4.13

equipment under test

EUT

electronic equipment from which chemical emission rates are determined

4.14

fast AMS

instrument with rapid time resolution and particle size classification

4.15

fine particles

FP

particles with particle size / diameter range between 0.1 μm and 2.5 μm

© ISO/IEC 2021 – All rights reserved 3

4.16

hard copy devices

class of EUT using Consumables that includes printers, (photo)copiers and Multi-Functional Devices (MFD)

4.17

idling mode

mode where hard copy devices are kept ready to perform its intended functions lasting from the end of

warming-up mode or its operation to the start of an energy saving mode

4.18

loading factor

ratio of the EUT volume to the volume of the unloaded ETC

4.19

operating phase

phase in which the EUT is performing its intended functions

4.20

particle

solid or liquid matter with defined physical boundaries suspended in a gas

4.21

particle emission rate

PER

averaged time dependent particle emission rate between the points in time of the start (tstart) and end (tstop) of

particle emission

4.22

time dependent particle emission rate

PER(t)

time dependent emission rate of particles in a specified particle size range after the start of the operating

phase

4.23

particle loss coefficient

β

coefficient describes the loss of particles in a specified particle size range in an ETC

4.24

particle size / particle diameter

measurement category to describe the physical dimension of a particle

NOTE The term particle size is often used as a synonym for particle diameter. The particle diameter is used to assign

a particle to a particle size class (e.g. UFP).

4.25

particulate matter

PM

quantity of particles measured by gravimetric methods

4.26

pre-operating phase

phase between the points in time at which the EUT is powered-on and the signal to start the operating phase

is sent to the EUT

NOTE The pre-operating phase can include warming-up and energy saving modes.

4.27

post-operating phase

phase following the operating phase

4 © ISO 2021 – All rights reserved

NOTE The post-operating phase can include energy saving modes.

4.28

quasi-equilibrium model method

QEM

method to determine emission rates of VOC and carbonyl compounds using the quasi-equilibrium model

characterized by the assumption that the concentration of an analyte in the ETC reaches a quasi-equilibrium

much earlier than expected in theory due to the activation of energy saving modes

4.29

specific emission rate

SER

mass, in micrograms, of a specific analyte emitted per hour

4.30

stabilizing period

ts

Suspension time between the pre-operating and operating phases, which starts when the air exchange rate is

changed and ends when the operating-phase begins if the air exchange rates during the pre-operating and

operating phases differ

NOTE A certain length of suspension time may exist for preparation for sampling, conditioning of humidity in the ETC,

stabilization of the air exchange rate and the concentrations of VOC and carbonyl compounds before the start of the

operating phase.

4.31

standard particle emission rate

PER

calculated number of particles emitted during a 10-minute operating phase in a specified particle size range

4.32

total number of emitted particles

TP

calculated total number of particles in a specified particle size range between the points in time of the start

(t ) and end (t ) of particle emission

start stop

4.33

total particle number concentration

Cp

particle number concentration in a specified particle size range

4.34

total usage time before testing

TUT

ratio between the total number of prints carried out by the EUT and the printing speed of the EUT

NOTE Total usage time is equal to or shorter than 120 minutes to be tested as newly manufactured EUT.

4.35

total volatile organic compounds

TVOC

the sum of the concentrations of identified VOC and the concentrations of the converted areas of unidentified

peaks using the toluene response factor

NOTE This definition of “total volatile organic compounds” differs from the definition in ISO 16000-6:2011.

4.36

ultrafine particles

UFP

particles with particle diameter less or equal to 0.1 µm

© ISO/IEC 2021 – All rights reserved 5

4.37

volatile organic compounds

VOC

compounds that elute between n-hexane and n-hexadecane (including these compounds) on a nonpolar GC-

column

5 Symbols and Abbreviated terms

5.1 Abbreviated terms

AMS Aerosol Measuring System

CEM Constant Emission Model Method

CPC Condensation Particle Counter

DNPH 2,4-Dinitrophenylhydrazine

ETC Emission Test Chamber

EUT Equipment Under Test

FID Flame Ionisation Detector

FP Fine Particles

GC/MS Gas Chromatography/Mass Spectrometry

MFD Multi Functional Device

PER Averaged Particle Emission Rate

PER(t) Time-dependent Particle Emission Rate

PER Standard Particle Emission Rate

PTFE Polytetrafluoroethene (Polytetrafluoroethylene)

PVC Polyvinylchloride

QEM Quasi-equilibrium Model Method

RH Relative Humidity

SER Unit Specific Emission Rate

TUT Total Usage Time Before Testing

TVOC Total Volatile Organic Compounds

UFP Ultrafine Particles

VOC Volatile Organic Compounds

6 © ISO 2021 – All rights reserved

5.2 Symbols

-3

α Factor in the exponential particle decay function [cm ]

-1

β Particle loss coefficient [h ]

-3

Cbg Background mass concentration [µg m ]

-3

C Maximum mass concentration in the operating phase [µg m ]

max

Cope Average mass concentration during sampling in the operating and post-operating phase

-3

[µg m ]

Co3 Ozone concentration [mg/m3]

-

C Total particle number concentration [cm ³]

p

-

Cpbg Background particle number concentration [cm ³]

-3

C Average mass concentration during sampling in the pre-operating phase [µg m ]

pre

-3

Cs Average mass concentration [µg m ]

-3

C Initial mass concentration [µg m ]

d Equivalent Particle Diameter [nm]

m Sample filter mass [µg] after sampling

after

mbefore Sample filter mass [µg] before sampling

m Sampled mass for chamber background [µg]

bg

mope Sampled mass [µg] during operating and optionally post-operating phase

m Sampled mass [µg] during pre-operating phase

pre

mpm Mass of particulate matter [µg] deposited on the filter

m Reference filter mass [µg] after sampling

ref-after

mref-before Reference filter mass [µg] before sampling

m Sampled mass [µg]

s

-1

n Air exchange rate during operating and post-operating phase [h ]

n Air exchange rate during pre-operating phase

pre

p Atmospheric pressure [Pa]

R Gas constant [PaK-1], (for ozone: 339.8 [PaK-1])

-1

SERbg Background SER [µg h ]

-1

SER SER for ozone [µg min ]

O3

-1

SERope SER during operating phase [µg h ]

© ISO/IEC 2021 – All rights reserved 7

-1

SER SER for particulate matter [µg h ]

pm

-1

SERpre SER during pre-operating phase [µg h ]

SER SER stemming from printing during the operating phase excluding emission at the rate of

prp

-1

SERpre which is lasting from the pre-operating phase [µg h ]

SER = SER - SER

prp ope pre

T Ambient temperature [K]

t Sampling time during operating and optionally post-operating phase [h]

G

TP Total Number of Emitted Particles

t Operating phase duration [h]

ope

tpre Pre-operating phase duration [h]

t Stabilizing period duration [h]

s

tstart Point in time marking the start of particle emission

t Point in time marking the end of particle emission

stop

Δt Time-resolution of the UFP measurement [s]

V ETC volume [m ]

Vbg Sampled air volume [m ] for determination of Cbg

V Sampled air volume [m ] in pre-operating phase

pre

Vope Sampled air volume [m ] in operating and optionally post-operating phase

V Sampled air volume [m ]

s

6 Method overview

The flowchart in Figure 1 illustrates the method; clause numbers are indicated in brackets.

8 © ISO 2021 – All rights reserved

Figure 1 — Determination method overview

7 ETC requirements

7.1 Construction materials

ETC construction materials shall comply with ISO 16000-9.

7.2 Air tightness

The ETC air tightness shall be as specified in ISO 16000-9.

© ISO/IEC 2021 – All rights reserved 9

7.3 Air mixing efficiency

The air mixing efficiency in the ETC shall be as specified in ISO 16000-9.

8 Determination method

8.1 Test conditions

8.1.1 General

To meet the operational requirements specified herein, ETC parameters such as temperature, relative

humidity and supply airflow shall be controlled and measured at regular intervals and recorded in accordance

with ISO 16000-9 and shall be reported as specified in Clause 9.

8.1.2 Operating temperature and relative humidity (RH)

Tests shall be executed at (23 ± 2) °C and (50 ± 5) %RH according to ISO 554. For EUT used in alternative

climatic conditions, higher operating temperature and humidity conditions may be used as specified in

ISO 554.

NOTE To avoid condensation due to vaporisation of water from paper during the operating phase, incoming air with

RH of at most 10% may be inserted in the ETC before the operating phase. In addition, the air exchange rate (n) may

have to be increased to avoid such condensation. Increase of humidity during the operating phase also depends on the

ETC volume. Condensation of water vapour (i.e. RH > 85%) on the ETC walls invalidates the test.

8.1.3 Air exchange rate (n)

For unloaded ETCs with a volume larger than 5 m , “n” shall be in the range from between 1,0 to 2,0. For

unloaded ETC’s with a volume of 5 m or smaller, “n” shall be in the range from between 1,0 to 5,0.

8.1.4 Air velocity

The air velocity in the unloaded ETC should be in the range from 0,1 to 0,3 m/s.

8.1.5 Sampled air flow

The sum of sampled airflow shall be less than 80% of the inlet airflow into the ETC.

8.2 Handling of EUT and ETC

8.2.1 Selection and storage of EUT

EUT shall be selected from normal manufactured batches or shall be a prototype that is representative for

EUT from such batches. EUT shall be stored before the test in a room where EUT is not likely to be

contaminated.

The amount of VOC emitted from electronic equipment generally changes with usage. Newly manufactured

equipment usually emits the highest amount of VOC in its life. EUT belongs to the following two categories in

this standard.

Newly manufactured EUT: The EUT of which the TUT is equal to or shorter than 120 minutes.

Used EUT: The EUT of which he TUT is longer than 120 minutes. TUT shall be reported in the test report, if

known, otherwise “not known” shall be reported.

10 © ISO 2021 – All rights reserved

8.2.2 Loading Factor

To ensure detection of a minimum emission within a practicable time, the ETC with capabilities as specified in

7 shall be selected such that the loading factor is in the range of 1:4 to 1:400. For the ETC where the loading

factor is in the range of 1:100 to 1:400, the air volume flow of the ETC shall be ≤ 5 m³/h.

8.2.3 ETC purging

The selected ETC shall be unloaded and its interior walls shall be cleaned as described in ISO 16000-9.

The ozone half-life, the period of time for the ozone concentration (C) to drop from C to C/2, shall be greater

than 10 minutes, when n = 1.

To determine the ozone half-life, the ETC should be deactivated by exposure to an ozone concentration of

3 3

0,2 mg/m to 0,4 mg/m for at least ten minutes or until a stable concentration is reached.

Thereafter, the ETC shall be purged with 4 ETC volumes of clean air.

8.2.4 Background concentrations (Cbg and Cpbg)

Following purging, the background concentrations of analytes in the unloaded ETC shall be determined and

recorded. The background concentration values at n = 1, shall be below the limits shown in Table 1.

NOTE Cbg of VOC and carbonyl compounds may stem from the ETC itself, supplied air to the ETC and sorbents

used for sampling.

For ETC materials, with SER = SER , the background concentration has reached an equilibrium after

bg

purging:

For supplied air, the background concentration is influenced by supplied air quality and the

performance of filters for the analyte

For sorbents, the background concentration is influenced by blank values of the sorbents and sampling

duration.

The background concentration should be determined in conditions with equivalent air exchange rate,

sampling duration and sampling date to the following tests so that influences of the sources above can

be minimized.

The sampling date, sampling duration and air exchange rate for the ETC shall be recorded with the

background concentration.

The C values at n = 1, shall be below the limits shown in Table 1.

bg

© ISO/IEC 2021 – All rights reserved 11

Table 1 — Background concentrations

Item Limit

VOC and carbonyl compounds 2 [µg/m ] for any analysed substance

TVOC 20 [µg/m ]

Ozone 4 [µg/m ]

PM 10 [µg/m ]

-

FP and UFP C = 2000 [cm ³]

pbg

8.2.5 EUT unpacking

Emissions from packaging may influence measurements considerably, because packaging itself may emit

VOCs that are not representative for EUTs in typical use. Therefore, the EUT to be tested shall be removed

from the shipping containers and all protective shipping packaging such as spacers, film wrapping and any

other shipping/packaging elements before preparation (as specified in 8.2.6).

NOTE After unpacking, installation (step 8.2.7) may precede the preparation step (8.2.6).

8.2.6 Preparation of the EUT before testing

Printing the patterns as specified in A.1 and A.2 are appropriate for the following preparatory operation below.

The maximum duration of the operating phase shall be determined.

One or two 10-minute operating cycles should be performed for the purpose of EUT function testing and

measurement of print speed. The TUT of the EUT shall not exceed 120 minutes when the EUT is tested as

the newly manufactured EUT.

The one or two 10-minute operating cycles shall be performed at least one day before the UFP test to avoid

influence on emissions due to unstable UFP emission which may occur in operation after long-term disuse of

the EUT.

Treatment conditions shall be recorded in the test report.

8.2.7 EUT installation

Before installation, the EUT shall have sufficient consumables to complete the operations. In case of paper

2 2

consumables, 60 g/m to 80 g/m A4 paper with normal water content (preferably from 3,8% to 5,6%) to avoid

water condensation shall be used.

To avoid contamination, the powered-off EUT shall be installed in the middle of the ETC as fast as possible

and all operators shall leave the ETC immediately thereafter.

The EUT shall remain powered-off until the emission tests require the EUT to be powered-on as specified in

8.3.1.

For the determination of FP and UFP specified in 8.7 the EUT shall be installed on the day before the

emission test.

The ETC shall remain closed until all sampling and/or monitoring is completed.

The installation date and time shall be recorded.

Emission testing, as specified in 8.3, shall not begin within at least 3 air exchanges following installation.

12 © ISO 2021 – All rights reserved

8.3 EUT Operation during Test

8.3.1 General

EUT operation during test consists of the pre-operating phase, operating phase and post-operating phase.

QEM and CEM have slightly different operation as shown in the clauses for each phase.

Emission rates of VOC and carbonyl compounds as specified in 8.4, ozone as specified in 8.5, particulate

matter as specified in 8.6 and FP and UFP as specified in 8.7 shall be determined while the EUT is being

controlled from outside the ETC.

NOTE Users can determine emission rates of VOC and carbonyl compounds according to QEM or CEM at their

discretion after comparing their individual purposes of the test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...