ISO 11960:2004

(Main)Petroleum and natural gas industries — Steel pipes for use as casing or tubing for wells

Petroleum and natural gas industries — Steel pipes for use as casing or tubing for wells

ISO 11960:2004 specifies the technical delivery conditions for steel pipes (casing, tubing, plain end casing liners and pup joints), coupling stock and accessories and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of ISO 11960:2004. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40 and L-80 9Cr, are contained in Annex H. ISO 11960:2004 is applicable to the following connections in accordance with API Spec 5B: -- short round thread casing (STC); -- long round thread casing (LC); -- buttress thread casing (BC); -- extreme-line casing (XC); -- non-upset tubing (NU); -- external upset tubing (EU); -- integral joint tubing (IJ). For such connections, ISO 11960:2004 specifies the technical delivery conditions for couplings and thread protection. Supplementary requirements that may optionally be agreed for enhanced leak resistance connections are given in Annex A.11 (SR22). ISO 11960:2004 can also be applied to tubulars with connections not covered by ISO/API standards. For pipes covered by ISO 11960:2004, the sizes, masses and wall thicknesses as well as grades and applicable end finishes are given. By agreement between the purchaser and manufacturer, ISO 11960:2004 can also be applied to other plain end pipe sizes and wall thicknesses. The four groups of products to which ISO 11960:2004 is applicable include the following grades of pipe: -- Group 1: All casing and tubing in Grades H, J, K and N; -- Group 2: All casing and tubing in Grades C, L, M and T; -- Group 3: All casing and tubing in Grade P; -- Group 4: All casing in Grade Q. Casing sizes larger than Label 1: 4-1/2 but smaller than Label 1: 10-3/4 may be specified by the purchaser to be used in tubing service. Supplementary requirements that may optionally be agreed between purchaser and manufacturer for non-destructive examination, coupling blanks, upset casing, electric-welded casing, impact testing, seal ring couplings and certificates are given in Annex A. ISO 11960:2004 is not applicable to threading requirements.

Industries du pétrole et du gaz naturel — Tubes d'acier utilisés comme cuvelage ou tubes de production dans les puits

General Information

- Status

- Withdrawn

- Publication Date

- 14-Dec-2004

- Withdrawal Date

- 14-Dec-2004

- Technical Committee

- ISO/TC 67/SC 5 - Casing, tubing and drill pipe

- Drafting Committee

- ISO/TC 67/SC 5/WG 1 - Casing, tubing and drill pipe

- Current Stage

- 9599 - Withdrawal of International Standard

- Start Date

- 16-Jun-2011

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 12-Feb-2026

- Effective Date

- 06-Jun-2022

- Effective Date

- 15-Apr-2008

- Effective Date

- 15-Apr-2008

- Effective Date

- 15-Apr-2008

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

ISO 11960:2004 is a standard published by the International Organization for Standardization (ISO). Its full title is "Petroleum and natural gas industries — Steel pipes for use as casing or tubing for wells". This standard covers: ISO 11960:2004 specifies the technical delivery conditions for steel pipes (casing, tubing, plain end casing liners and pup joints), coupling stock and accessories and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of ISO 11960:2004. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40 and L-80 9Cr, are contained in Annex H. ISO 11960:2004 is applicable to the following connections in accordance with API Spec 5B: -- short round thread casing (STC); -- long round thread casing (LC); -- buttress thread casing (BC); -- extreme-line casing (XC); -- non-upset tubing (NU); -- external upset tubing (EU); -- integral joint tubing (IJ). For such connections, ISO 11960:2004 specifies the technical delivery conditions for couplings and thread protection. Supplementary requirements that may optionally be agreed for enhanced leak resistance connections are given in Annex A.11 (SR22). ISO 11960:2004 can also be applied to tubulars with connections not covered by ISO/API standards. For pipes covered by ISO 11960:2004, the sizes, masses and wall thicknesses as well as grades and applicable end finishes are given. By agreement between the purchaser and manufacturer, ISO 11960:2004 can also be applied to other plain end pipe sizes and wall thicknesses. The four groups of products to which ISO 11960:2004 is applicable include the following grades of pipe: -- Group 1: All casing and tubing in Grades H, J, K and N; -- Group 2: All casing and tubing in Grades C, L, M and T; -- Group 3: All casing and tubing in Grade P; -- Group 4: All casing in Grade Q. Casing sizes larger than Label 1: 4-1/2 but smaller than Label 1: 10-3/4 may be specified by the purchaser to be used in tubing service. Supplementary requirements that may optionally be agreed between purchaser and manufacturer for non-destructive examination, coupling blanks, upset casing, electric-welded casing, impact testing, seal ring couplings and certificates are given in Annex A. ISO 11960:2004 is not applicable to threading requirements.

ISO 11960:2004 specifies the technical delivery conditions for steel pipes (casing, tubing, plain end casing liners and pup joints), coupling stock and accessories and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of ISO 11960:2004. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40 and L-80 9Cr, are contained in Annex H. ISO 11960:2004 is applicable to the following connections in accordance with API Spec 5B: -- short round thread casing (STC); -- long round thread casing (LC); -- buttress thread casing (BC); -- extreme-line casing (XC); -- non-upset tubing (NU); -- external upset tubing (EU); -- integral joint tubing (IJ). For such connections, ISO 11960:2004 specifies the technical delivery conditions for couplings and thread protection. Supplementary requirements that may optionally be agreed for enhanced leak resistance connections are given in Annex A.11 (SR22). ISO 11960:2004 can also be applied to tubulars with connections not covered by ISO/API standards. For pipes covered by ISO 11960:2004, the sizes, masses and wall thicknesses as well as grades and applicable end finishes are given. By agreement between the purchaser and manufacturer, ISO 11960:2004 can also be applied to other plain end pipe sizes and wall thicknesses. The four groups of products to which ISO 11960:2004 is applicable include the following grades of pipe: -- Group 1: All casing and tubing in Grades H, J, K and N; -- Group 2: All casing and tubing in Grades C, L, M and T; -- Group 3: All casing and tubing in Grade P; -- Group 4: All casing in Grade Q. Casing sizes larger than Label 1: 4-1/2 but smaller than Label 1: 10-3/4 may be specified by the purchaser to be used in tubing service. Supplementary requirements that may optionally be agreed between purchaser and manufacturer for non-destructive examination, coupling blanks, upset casing, electric-welded casing, impact testing, seal ring couplings and certificates are given in Annex A. ISO 11960:2004 is not applicable to threading requirements.

ISO 11960:2004 is classified under the following ICS (International Classification for Standards) categories: 75.180.10 - Exploratory, drilling and extraction equipment; 77.140.75 - Steel pipes and tubes for specific use. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 11960:2004 has the following relationships with other standards: It is inter standard links to EN ISO 11960:2004, ISO/IEC ISP 12060-4:1995, ISO 11960:2001/Cor 1:2002, ISO 11960:2011, ISO 11960:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 11960:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 11960

Third edition

2004-12-15

Petroleum and natural gas industries —

Steel pipes for use as casing or tubing

for wells

Industries du pétrole et du gaz naturel — Tubes d'acier utilisés comme

cuvelage ou tubes de production dans les puits

Reference number

©

ISO 2004

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO 2004

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2004 – All rights reserved

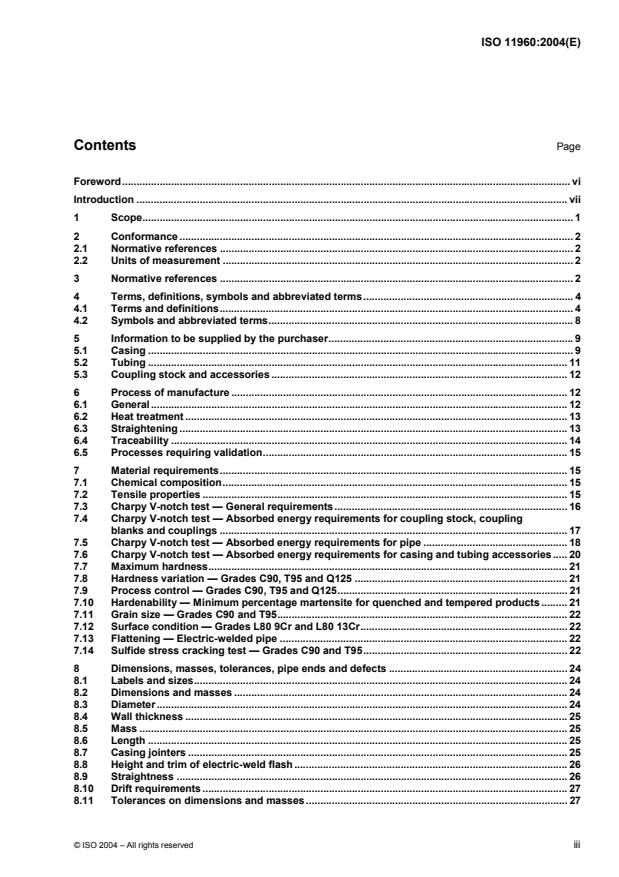

Contents Page

Foreword. vi

Introduction . vii

1 Scope. 1

2 Conformance . 2

2.1 Normative references . 2

2.2 Units of measurement . 2

3 Normative references . 2

4 Terms, definitions, symbols and abbreviated terms. 4

4.1 Terms and definitions. 4

4.2 Symbols and abbreviated terms. 8

5 Information to be supplied by the purchaser.9

5.1 Casing . 9

5.2 Tubing . 11

5.3 Coupling stock and accessories . 12

6 Process of manufacture . 12

6.1 General. 12

6.2 Heat treatment . 13

6.3 Straightening . 13

6.4 Traceability . 14

6.5 Processes requiring validation. 15

7 Material requirements. 15

7.1 Chemical composition. 15

7.2 Tensile properties . 15

7.3 Charpy V-notch test — General requirements. 16

7.4 Charpy V-notch test — Absorbed energy requirements for coupling stock, coupling

blanks and couplings . 17

7.5 Charpy V-notch test — Absorbed energy requirements for pipe . 18

7.6 Charpy V-notch test — Absorbed energy requirements for casing and tubing accessories . 20

7.7 Maximum hardness. 21

7.8 Hardness variation — Grades C90, T95 and Q125 . 21

7.9 Process control — Grades C90, T95 and Q125. 21

7.10 Hardenability — Minimum percentage martensite for quenched and tempered products . 21

7.11 Grain size — Grades C90 and T95. 22

7.12 Surface condition — Grades L80 9Cr and L80 13Cr. 22

7.13 Flattening — Electric-welded pipe . 22

7.14 Sulfide stress cracking test — Grades C90 and T95. 22

8 Dimensions, masses, tolerances, pipe ends and defects . 24

8.1 Labels and sizes. 24

8.2 Dimensions and masses . 24

8.3 Diameter. 24

8.4 Wall thickness . 25

8.5 Mass . 25

8.6 Length . 25

8.7 Casing jointers . 25

8.8 Height and trim of electric-weld flash. 26

8.9 Straightness . 26

8.10 Drift requirements . 27

8.11 Tolerances on dimensions and masses. 27

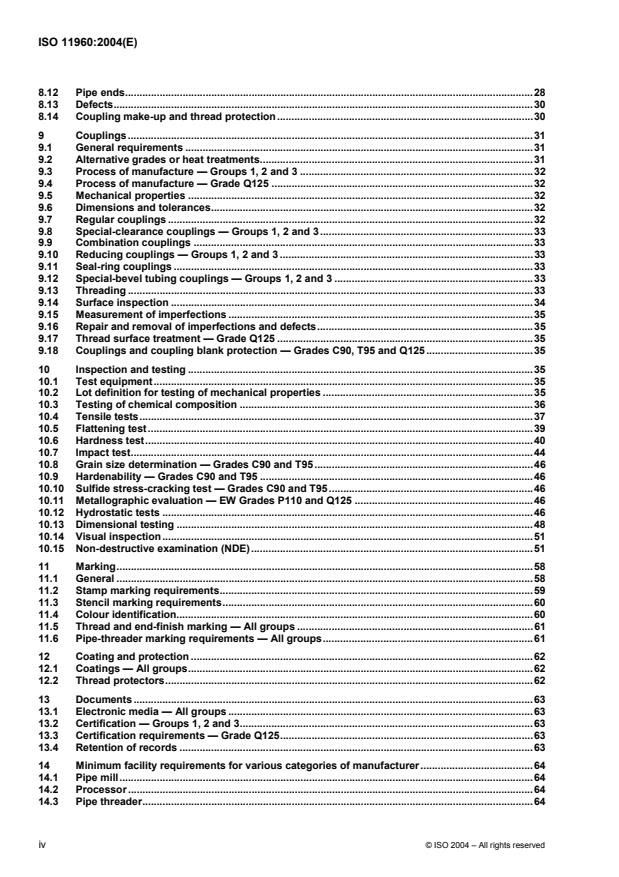

8.12 Pipe ends.28

8.13 Defects.30

8.14 Coupling make-up and thread protection.30

9 Couplings .31

9.1 General requirements .31

9.2 Alternative grades or heat treatments.31

9.3 Process of manufacture — Groups 1, 2 and 3 .32

9.4 Process of manufacture — Grade Q125 .32

9.5 Mechanical properties .32

9.6 Dimensions and tolerances.32

9.7 Regular couplings .32

9.8 Special-clearance couplings — Groups 1, 2 and 3.33

9.9 Combination couplings .33

9.10 Reducing couplings — Groups 1, 2 and 3 .33

9.11 Seal-ring couplings .33

9.12 Special-bevel tubing couplings — Groups 1, 2 and 3 .33

9.13 Threading .33

9.14 Surface inspection .34

9.15 Measurement of imperfections .35

9.16 Repair and removal of imperfections and defects.35

9.17 Thread surface treatment — Grade Q125 .35

9.18 Couplings and coupling blank protection — Grades C90, T95 and Q125.35

10 Inspection and testing .35

10.1 Test equipment.35

10.2 Lot definition for testing of mechanical properties .35

10.3 Testing of chemical composition .36

10.4 Tensile tests.37

10.5 Flattening test.39

10.6 Hardness test.40

10.7 Impact test.44

10.8 Grain size determination — Grades C90 and T95.46

10.9 Hardenability — Grades C90 and T95 .46

10.10 Sulfide stress-cracking test — Grades C90 and T95.46

10.11 Metallographic evaluation — EW Grades P110 and Q125 .46

10.12 Hydrostatic tests .46

10.13 Dimensional testing .48

10.14 Visual inspection.51

10.15 Non-destructive examination (NDE).51

11 Marking.58

11.1 General .58

11.2 Stamp marking requirements.59

11.3 Stencil marking requirements.60

11.4 Colour identification.60

11.5 Thread and end-finish marking — All groups .61

11.6 Pipe-threader marking requirements — All groups.61

12 Coating and protection .62

12.1 Coatings — All groups.62

12.2 Thread protectors.62

13 Documents .63

13.1 Electronic media — All groups .63

13.2 Certification — Groups 1, 2 and 3.63

13.3 Certification requirements — Grade Q125.63

13.4 Retention of records .63

14 Minimum facility requirements for various categories of manufacturer.64

14.1 Pipe mill.64

14.2 Processor .64

14.3 Pipe threader.64

iv © ISO 2004 – All rights reserved

14.4 Coupling, pup-joint or accessory manufacturer. 64

Annex A (normative) Supplementary requirements . 66

Annex B (normative) Purchaser inspection. 80

Annex C (normative) Tables in SI units. 81

Annex D (normative) Figures in SI (USC) units. 154

Annex E (normative) Tables in USC units. 184

Annex F (informative) Marking instructions for API licensees . 258

Annex G (informative) Procedures used to convert from USC units to SI units. 263

Annex H (normative) Product Specification Levels. 276

Annex I (normative) Requirements for thread protector design validation . 283

Annex J (informative) Summary of Product Specification Level (PSL) requirements . 287

Bibliography . 291

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 11960 was prepared by Technical Committee ISO/TC 67, Materials, equipment and offshore structures

for petroleum, petrochemical and natural gas industries, Subcommittee SC 5, Casing, tubing and drill pipe.

This third edition cancels and replaces the second edition (ISO 11960:2001), which has been technically

revised. It also incorporates the Technical Corrigendum ISO 11960:2001/Cor.1:2002.

It is the intent of TC 67 that the second and third editions of ISO 11960 both be applicable, at the option of the

purchaser (as defined in 4.1.35), for a period of six months from the first day of the calendar quarter

immediately following the date of publication of this third edition, after which period the second edition will no

longer be applicable.

vi © ISO 2004 – All rights reserved

Introduction

This International Standard is based on API 5CT (Specification for Casing and Tubing).

Users of this International Standard should be aware that further or differing requirements may be needed for

individual applications. This International Standard is not intended to inhibit a vendor from offering, or the

purchaser from accepting, alternative equipment or engineering solutions for the individual application. This

may be particularly applicable where there is innovative or developing technology. Where an alternative is

offered, the vendor should identify any variations from this International Standard and provide details.

This International Standard includes requirements of various nature. These are identified by the use of certain

verbal forms:

SHALL is used to indicate that a provision is MANDATORY;

SHOULD is used to indicate that a provision is not mandatory, but RECOMMENDED as good practice;

MAY is used to indicate that a provision is OPTIONAL.

INTERNATIONAL STANDARD ISO 11960:2004(E)

Petroleum and natural gas industries — Steel pipes for use as

casing or tubing for wells

1 Scope

1.1 This International Standard specifies the technical delivery conditions for steel pipes (casing, tubing,

plain-end casing liners and pup joints), coupling stock and accessories and establishes requirements for three

Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this

International Standard. The requirements that define different levels of standard technical requirements for

PSL-2 and PSL-3, for all Grades except H-40 and L-80 9Cr, are contained in Annex H.

For pipes covered by this International Standard, the sizes, masses and wall thicknesses as well as grades

and applicable end-finishes are listed in Tables C.1 to C.3 and Tables E.1 to E.3.

By agreement between the purchaser and manufacturer, this International Standard can also be applied to

other plain-end pipe sizes and wall thicknesses.

This International Standard is applicable to the following connections in accordance with API Spec 5B:

short round thread casing (STC);

long round thread casing (LC);

buttress thread casing (BC);

extreme-line casing (XC);

non-upset tubing (NU);

external upset tubing (EU);

integral joint tubing (IJ).

For such connections, this International Standard specifies the technical delivery conditions for couplings and

thread protection. Supplementary requirements that may optionally be agreed for enhanced leak resistance

connections are given in Annex A.11 (SR22).

This International Standard can also be applied to tubulars with connections not covered by ISO/API

standards.

1.2 The four groups of products to which this International Standard is applicable include the following

grades of pipe:

Group 1: All casing and tubing in Grades H, J, K and N;

Group 2: All casing and tubing in Grades C, L, M and T;

Group 3: All casing and tubing in Grade P;

Group 4: All casing in Grade Q.

1.3 Casing sizes larger than Label 1: 4-1/2 but smaller than Label 1: 10-3/4 may be specified by the

purchaser to be used in tubing service, see Tables C.1, C.24, C.30 and C.31 or Tables E.1, E.24, E.30 and

E.31.

1.4 Supplementary requirements that may optionally be agreed between purchaser and manufacturer for

non-destructive examination, coupling blanks, upset casing, electric-welded casing, impact testing, seal ring

couplings and certificates are given in Annex A.

1.5 This International Standard is not applicable to threading requirements.

NOTE Dimensional requirements on threads and thread gauges, stipulations on gauging practice, gauge

specifications, as well as instruments and methods for inspection of threads are given in API Spec 5B.

2 Conformance

2.1 Normative references

In the interests of world-wide application of this International Standard, ISO/TC 67 has decided, after detailed

technical analysis, that certain of the normative documents listed in Clause 3 and prepared by ISO/TC 67 or

other ISO Technical Committee are interchangeable in the context of the relevant requirement with the

relevant document prepared by the American Petroleum Institute (API), the American Society for Testing and

Materials (ASTM) or the American National Standards Institute (ANSI). These latter documents are cited in

the running text following the ISO reference and preceded by “or”, for example “ISO XXXX or API YYYY”.

Application of an alternative normative document cited in this manner will lead to technical results different

from the use of the preceding ISO reference. However, both results are acceptable and these documents are

thus considered interchangeable in practice.

2.2 Units of measurement

In this International Standard, data are expressed in both the International System (SI) of units and the United

States Customary (USC) system of units. For a specific order item, it is intended that only one system of units

be used, without combining data expressed in the other system.

Products manufactured to specifications expressed in either of these unit systems shall be considered

equivalent and totally interchangeable. Consequently, compliance with the requirements of this International

Standard as expressed in one system provides compliance with requirements expressed in the other system.

For data expressed in the SI, a comma is used as the decimal separator and a space as the thousands

separator. For data expressed in the USC system, a dot (on the line) is used as the decimal separator and a

space as the thousands separator.

In the text, data in SI units are followed by data in USC units in parentheses.

Separate tables for data expressed in SI units and USC units are given in Annex C and Annex E respectively.

Figures are contained in Annex D and express data in both SI and USC units.

3 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 31-0, Quantities and units — Part 0: General principles

ISO 643, Steels — Micrographic determination of the apparent grain size

2 © ISO 2004 – All rights reserved

ISO 6506-1, Metallic materials — Brinell hardness test — Part 1:Test method

ISO 6508-1, Metallic materials — Rockwell hardness test — Part 1:Test method (Scales A, B, C, D, E, F, G, H,

K, N, T)

ISO 6892, Metallic materials — Tensile testing at ambient temperature

ISO 7500-1, Metallic materials — Verification of static uniaxial testing machines — Part 1:

Tension/compression testing machines — Verification and calibration of the force-measuring system

ISO 8501-1, Preparation of steel substrates before application of paints and related products — Visual

assessment of surface cleanliness — Part 1: Rust grades and preparation grades of uncoated steel

substrates and of steel substrates after overall removal of previous coatings

ISO 9303, Seamless and welded (except submerged arc-welded) steel tubes for pressure purposes — Full

peripheral ultrasonic testing for the detection of longitudinal imperfections

ISO 9304, Seamless and welded (except submerged arc-welded) steel tubes for pressure purposes — Eddy

current testing for the detection of imperfections

ISO 9305, Seamless steel tubes for pressure purposes — Full peripheral ultrasonic testing for the detection of

transverse imperfections

ISO 9402, Seamless and welded (except submerged arc-welded) steel tubes for pressure purposes — Full

peripheral magnetic transducer/flux leakage testing of ferromagnetic steel tubes for the detection of

longitudinal imperfections

ISO 9598, Seamless steel tubes for pressure purposes — Full peripheral magnetic transducer/flux leakage

testing of ferromagnetic steel tubes for the detection of transverse imperfections

ISO 9764, Electric resistance and induction welded steel tubes for pressure purposes — Ultrasonic testing of

the weld seam for the detection of longitudinal imperfections

ISO/TR 9769, Steel and iron — Review of available methods of analysis

ISO 10400, Petroleum and natural gas industries — Formulae and calculation for casing, tubing, drill pipe and

line pipe properties

ISO 11484, Steel tubes for pressure purposes — Qualification and certification of non-destructive testing

(NDT) personnel

ISO 13665, Seamless and welded steel tubes for pressure purposes — Magnetic particle inspection of the

tube body for the detection of surface imperfections

ISO 13678, Petroleum and natural gas industries — Evaluation and testing of thread compounds for use with

casing, tubing and line pipe

ANSI-NACE TM0177:1996, Laboratory testing of metals for resistance to sulfide stress cracking at ambient

temperature in H S environment

API Bull 5C2, Bulletin on performance properties of casing, tubing and drill pipe

API Bull 5C3, Bulletin on formulas and calculations for casing, tubing, drill pipe and line pipe properties (plus

Supplement 1)

API Spec 5B, Specification for threading, gauging and thread inspection of casing, tubing and line pipe

threads

API Std 5T1, Imperfection terminology

ASNT SNT-TC-1A:1984, Recommended practice, personnel qualification and certification in non destructive

testing

ASTM A370, Standard test methods and definitions for mechanical testing of steel products

ASTM A751, Standard test methods, practices and terminology for chemical analysis of steel products

ASTM A941, Terminology relating to steel, stainless steel, related alloys and ferroalloys

ASTM B117, Standard practice for operating salt spray (fog) apparatus

ASTM E4, Standard practices for force verification of testing machines

ASTM E10, Standard test method for Brinell hardness of metallic materials

ASTM E18, Standard test methods for Rockwell hardness and Rockwell superficial hardness of metallic

materials

ASTM E23, Standard test methods for notched bar impact testing of metallic materials

ASTM E29, Standard practice for using significant digits in test data to determine conformance with

specifications

ASTM E83, Standard practice for verification and classification of extensometer system

ASTM E112, Standard test methods for determining average grain size

ASTM E213, Standard practice for ultrasonic examination of metal pipe and tubing

ASTM E273, Standard practice for ultrasonic examination of the weld zone of welded pipe and tubing

ASTM E309, Standard practice for eddy-current examination of steel tubular products using magnetic saturation

ASTM E570, Standard practice for flux leakage examination of ferromagnetic steel tubular products

ASTM E709, Standard guide for magnetic particle examination

IADC/SPE 11396, B.A. Dale, M.C. Moyer, T.W. Sampson, A Test Program for the Evaluation of Oilfield

Thread Protectors, IADC/SPE Drilling Conference, New Orleans, LA, 20-23 February 1983

MIL-STD-810c, Military Environmental Test Methods, March 10, 1975

4 Terms, definitions, symbols and abbreviated terms

4.1 Terms and definitions

For the purposes of this document, the terms and definitions in ASTM A941 for heat treatment operations and

the following apply.

4.1.1

accessory material

seamless standard casing or tubing, or seamless thick-wall tubes or mechanical tubes, or bar stock or hot

forgings used for the manufacture of accessories

4.1.2

API threads

threads as specified in API Spec 5B

4 © ISO 2004 – All rights reserved

4.1.3

carload

quantity of pipe loaded on a railway car for shipment from the pipe-making facilities

4.1.4

casing

pipe run from the surface and intended to line the walls of a drilled well

4.1.5

casing and tubing accessory

one-piece tubular section used in a pipe string to provide mechanical and pressure integrity within the pipe

string and facilitate the performance of some other function required of that pipe string

EXAMPLES Crossover connectors, swages, nipples, flow couplings, blast joints, etc.

NOTE Accessories exclude the other tubular products specifically defined in this International Standard or products

included in other ISO (API) specifications.

4.1.6

connection

threaded assembly of tubular components

4.1.7

controlled cooling

cooling from an elevated temperature in a pre-determined manner to avoid hardening, cracking or internal

damage, or to produce a desired microstructure or mechanical properties

4.1.8

coupling

internally threaded cylinder for joining two lengths of threaded pipe

4.1.9

coupling blank

unthreaded material used to produce an individual coupling

4.1.10

coupling stock

seamless thick-wall tube or mechanical tube used for the manufacture of coupling blanks

4.1.11

defect

imperfection of sufficient magnitude to warrant rejection of the product based on criteria defined in this

International Standard

4.1.12

electric-welded pipe

pipe having one longitudinal seam formed by electric-resistance or electric-induction welding, without the

addition of filler metal, wherein the edges to be welded are mechanically pressed together and the heat for

welding is generated by the resistance to flow of electric current

4.1.13

handling tight

sufficiently tight that the coupling cannot be removed except by the use of a wrench

4.1.14

heat

metal produced by a single cycle of a batch melting process

4.1.15

heat analysis

chemical analysis representative of a heat as reported by the metal producer

4.1.16

imperfection

discontinuity in the product wall or on the product surface that can be detected by a NDE method included in

Table C.62 or Table E.62 of this International Standard

4.1.17

inspection

process of measuring, examining, testing, gauging or otherwise comparing a unit of product with the

applicable requirements

4.1.18

inspection lot

definite quantity of product manufactured under conditions that are considered uniform for the attribute to be

inspected

4.1.19

inspection lot sample

one or more units of product selected from an inspection lot to represent that inspection lot

4.1.20

inspection lot size

number of units of product in an inspection lot

4.1.21

interrupted quenching

quenching in which the pipe being quenched is removed from the quenching medium while the pipe is at a

temperature substantially higher than that of the quenching medium

4.1.22

label 1

dimensionless designation for the size or specified outside diameter that may be used when ordering pipe

4.1.23

label 2

dimensionless designation for the mass per unit length that may be used when ordering pipe

4.1.24

length

piece of pipe that may be plain-end, threaded, or threaded and coupled, that is in accordance with the range

requirements in Table C.30 or Table E.30 of this International Standard

4.1.25

linear imperfection

imperfection which includes, but is not limited to, seams, laps, cracks, plug scores, cuts and gouges

NOTE See API Std 5T1.

4.1.26

manufacturer

one or more of the following, depending on the context: pipe mill; processor; threader; coupling manufacturer,

pup-joint manufacturer; accessory manufacturer

NOTE See Clause 14.

6 © ISO 2004 – All rights reserved

4.1.27

non-linear imperfection

imperfection which includes, but is not limited to, pits and round-bottom die stamping

NOTE See API Std 5T1.

4.1.28

pipe

casing, tubing, plain-end casing liners and pup joints as a group

4.1.29

pipe mill

firm, company or corporation that operates pipe-making facilities

4.1.30

plain-end casing liner

casing provided unthreaded and with a wall thickness often greater than that specified for J55

4.1.31

processor

firm, company or corporation that operates facilities capable of heat-treating pipe made by a pipe mill

4.1.32

product

pipe, coupling, accessory, coupling stock or coupling blank, either individually or collectively as applicable

4.1.33

pup joint

casing, tubing or plain-end casing liner of length shorter than Range 1

4.1.34

pup-joint material

standard casing or tubing, or thick-wall tubes or mechanical tubes, or bar stock used for the manufacture of

pup joints

4.1.35

purchaser

party responsible for both the definition of requirements for a product order and for payment for that order

4.1.36

quench crack

crack in steel resulting from stresses produced during the transformation from austenite to martensite

NOTE This transformation is accompanied by an increase in volume.

4.1.37

seamless pipe

wrought steel tubular product made without a weld seam

NOTE It is manufactured by hot-working steel, and if necessary, by subsequently cold-working or heat-treating, or a

combination of these operations, to produce the desired shape, dimensions and properties.

4.1.38

skelp

hot-rolled steel strip used for manufacturing EW pipe

4.1.39

special end-finish

threads with thread form and features, manufacturing specifications, dimensions, connection make-up and

performance properties which are beyond the scope of this International Standard

4.1.40

thread protector

cap or insert used to protect threads and seals during handling, transportation and storage

4.1.41

tubing

pipe placed within a well and serving to produce well fluids or to inject fluids

4.1.42

upper critical temperature

Ar

temperature at which austenite begins to transform to ferrite during cooling

4.2 Symbols and abbreviated terms

BC buttress thread casing connection

C Charpy V-notch impact test minimum absorbed energy

V

CVN Charpy V-notch

D specified outside diameter for pipe

d calculated inside diameter

EMI electromagnetic inspection

EU external upset tubing connection

EW electric-welded process

FBH flat-bottomed hole

HBW Brinell hardness, when testing with a tungsten carbide ball

HRC Rockwell hardness C-scale

ID inside diameter

IJ integral joint tubing connection

k a constant used in the calculation of elongation

LC long round thread casing connection

N ·heat-treat processÒ full-length normalized

N&T normalized and tempered

NDE non-destructive examination

NU non-upset tubing connection

OD outside diameter

PSL product specification level

Q quenched and tempered

S seamless process (when not referencing the chemical element sulfur)

8 © ISO 2004 – All rights reserved

Sc minimum acceptable result of the ANSI-NACE TM0177:1996 Method B test

SCC special clearance coupling

SSC sulfide stress cracking

STC short round thread casing connection

t specified wall thickness

T&C threaded and coupled

USC United States customary (units)

UT ultrasonic testing

W specified outside diameter for couplings with API threads other than special clearance couplings

W specified outside diameter of special clearance couplings with API threads

c

XC extreme line casing connection

YS specified maximum yield strength

max

YS specified minimum yield strength

min

5 Information to be supplied by the purchaser

5.1 Casing

5.1.1 When enquiring or placing orders for pipe to be manufactured in accordance with this International

Standard, the purchaser shall specify the following:

Requirement Reference

Standard ISO 11960 or API 5CT

Quantity

Type of pipe or couplings

Casing:

Threaded or plain-end 8.12

Type of connection: round (short or long), buttress, 8.12, Table C.1 or Table E.1

extreme-line threads, or other connection

With or without couplings 8.12

Special clearance couplings 9.8, Tables C.1, C.36 or Tables E.1,

E.36

Liners: 8.12.1, Table C.2 or Table E.2

Label 1 or specified outside diameter Tables C.1, C.2 or Tables E.1, E.2

Label 2 or specified mass or wall thickness Tables C.1, C.2 or Tables E.1, E.2

Grade and type where applicable Tables C.1, C.2, C.5 or Tables E.1,

E.2, E.5

Range length 8.6, Table C.30 or Table E.30

Seamless or electric-welded 6.1, Table C.4 or Table E.4

Critical thickness for special end-finish couplings, stock or blanks 7.6.6

Critical thickness for special end-finish accessories 7.6.6

Wall thickness verification of special end-finish accessories 10.13.4

Delivery date and shipping instructions

Inspection by purchaser Annex B

5.1.2 The purchaser shall also state on the purchase agreement the requirements, where applicable,

concerning the following stipulations, which are at the purchaser’s option:

Requirement Reference

Heat treatment 6.2

Lower alternative impact test temperature 7.3.7

Casing jointers 8.7

Alternative drifting requirements 8.10

Casing with couplings detached 8.14

Coupling make-up (other than power-tight) 8.14

Coupling blanks 9.2, A.4 (SR9)

Seal ring couplings 9.11, A.8 (SR13)

Heat and supplementary analyses 10.3

Additional markings 11

Pipe coatings 12.1

Material certification 13.2, A.9 (SR15)

PSL 2 or 3 Annex H

5.1.3 The following may be agreed between purchaser and manufacturer:

Requirement Reference

Cold rotary straightening - Grade Q125 6.3.5

Statistical impact testing 7.3.8, A.7 (SR12)

Impact of Group 1 non-heat-treated pipe 7.5.1, A.10 (SR16)

Sulfide stress cracking test - Grades C90 and T95 7.14

Length of accessories 8.6

Thread and storage compound 8.14

Waiving NDE of Group 1 couplings in Grades H40, J55 and K55 9.14.3

Coupling thread plating - Grade Q125 only 9.17

Additional hardness testing - Grades M65 and L80 10.6.2

Additional hardness testing - Grades C90 and T95 10.6.2

Reduced section tensile specimens – Grade Q125 10.4.6

Hydrostatic pressure test for handling-tight make-up, accessories and 10.12.2

Group 4 pup-joints

Alternative hydrostatic test pressures 10.12.3

Plain-end Grade Q125 casing hydrostatic testing 10.12.2

Non-destructive examination 10.15, A.2 (SR1), A.3 (SR2),

A.5 (SR10) and A.6 (SR11)

Marking requirements 11.1

Thread protectors 12.2

Coupling blanks – Grade Q125 only A.4 (SR9)

Upset casing – Grade Q125 only A.5 (SR10)

Electric-weld casing – Grades P110 and Q125 A.6 (SR11)

Alternative F factor in SR 12 – Grade Q125 A.7 (SR12.2)

Special end-finish for casing, couplings, pup joints or accessories 8.12.8, 9.13.2

Quality assurance requirements

Special size and wall thickness 8.2

Enhanced leak resistance LTC connections A.11 (SR22)

10 © ISO 2004 – All rights reserved

5.2 Tubing

5.2.1 When enquiring or placing orders for pipe to be manufactured in accordance with this International

Standard, the purchaser shall specify the following:

Requirement Reference

Standard ISO 11960 or API 5CT

Quantity

Type of pipe or couplings

Tubing:

Non-upset, external-upset or integral joint Table C.3 or Table E.3

Threaded, plain-end, or other connection

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...