ISO 20816-1:2016

(Main)Mechanical vibration — Measurement and evaluation of machine vibration — Part 1: General guidelines

Mechanical vibration — Measurement and evaluation of machine vibration — Part 1: General guidelines

ISO 20816-1:2016 establishes general conditions and procedures for the measurement and evaluation of vibration using measurements made on rotating, non-rotating and non-reciprocating parts of complete machines. It is applicable to measurements of both absolute and relative radial shaft vibration with regard to the monitoring of radial clearances, but excludes axial shaft vibration. The general evaluation criteria, which are presented in terms of both vibration magnitude and change of vibration, relate to both operational monitoring and acceptance testing. They have been provided primarily with regard to securing reliable, safe, long-term operation of the machine while minimizing adverse effects on associated equipment. Guidelines are also presented for setting operational limits. NOTE 1 The evaluation criteria for different classes of machinery will be included in other parts of ISO 20816 when they become available. In the meantime, guidelines are given in Clause 6. NOTE 2 The term "shaft vibration" is used throughout ISO 20816 because, in most cases, measurements are made on machine shafts. However, the ISO 20816 series is also applicable to measurements made on other rotating elements if such elements are found to be more suitable, provided that the guidelines are respected. For the purposes of ISO 20816, operational monitoring is considered to be those vibration measurements made during the normal operation of a machine. The ISO 20816 series permits the use of different measurement quantities and methods, provided that they are well-defined and their limitations are set out, so that the interpretation of the measurements is well-understood. The evaluation criteria relate only to the vibration produced by the machine itself and not the vibration transmitted to it from outside. ISO 20816-1:2016 does not include consideration of torsional vibration. NOTE 3 For torsional vibration, see, for example, ISO 3046‑5, ISO 22266‑1 or VDI 2039.

Vibrations mécaniques — Mesurage et évaluation des vibrations de machines — Partie 1: Lignes directrices générales

General Information

- Status

- Published

- Publication Date

- 08-Nov-2016

- Technical Committee

- ISO/TC 108/SC 2 - Measurement and evaluation of mechanical vibration and shock as applied to machines, vehicles and structures

- Drafting Committee

- ISO/TC 108/SC 2/WG 1 - Rotordynamics and vibration of machines

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 24-Jun-2024

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 28-Dec-2013

- Effective Date

- 28-Dec-2013

- Effective Date

- 28-Dec-2013

Overview - What ISO 20816-1:2016 covers

ISO 20816-1:2016 - titled Mechanical vibration - Measurement and evaluation of machine vibration - Part 1: General guidelines - establishes general conditions, procedures and evaluation principles for measuring and assessing mechanical vibration of complete machines. It applies to measurements made on rotating and non-rotating (non-reciprocating) parts, and covers both absolute and relative radial shaft vibration (including monitoring of radial clearances). The standard excludes axial shaft vibration and does not address torsional vibration. Its guidance is targeted primarily at operational monitoring and acceptance testing, with recommendations for setting operational limits, alarm and trip levels, and interpreting changes in vibration over time.

Key technical topics and requirements

- Measurement scope: Broad-band vibration measurement on shafts, bearing housings and other suitable rotating elements; emphasis on well-defined measurement quantities and methods.

- Measurement quantities: Recognizes the three primary vibration quantities - displacement, velocity and acceleration - and explains their appropriate use and limitations.

- Types of measurements: Guidance on measurements taken on non-rotating parts, relative shaft vibration, and absolute shaft vibration (radial).

- Measuring positions and frequency range: Recommended positions on shafts and housings, and requirements for capturing the machine’s frequency spectrum.

- Instrumentation and mounting: References instrument requirements and accelerometer mounting best practices (see normative references).

- Evaluation criteria: General criteria presented in terms of vibration magnitude and change in vibration (Criterion I and II), for both steady operation and acceptance testing. Includes advice on setting operational limits, alarms and trips.

- Diagnostics: Informative annexes on bearing-problem detection techniques and vector analysis of vibration change help in root-cause analysis.

Practical applications and target users

ISO 20816-1 is essential for:

- Condition monitoring engineers and vibration analysts establishing routine monitoring programs.

- Maintenance and reliability teams setting alarm/trip thresholds and acceptance criteria for new or repaired machinery.

- OEMs and test laboratories conducting in-situ or test-facility vibration acceptance tests.

- Consultants performing diagnostic assessments of rotating machinery (pumps, turbines, compressors, electric machines).

Use cases include commissioning and acceptance testing, baseline vibration surveys, setting limit levels for online protection systems, and guiding diagnostic investigations into bearing or rotor issues.

Related standards

- ISO 2954 (instruments for measuring vibration severity)

- ISO 5348 (accelerometer mounting)

- ISO 10817-1 (relative/absolute sensing of radial vibration)

- For torsional vibration (not covered): ISO 3046-5, ISO 22266-1, VDI 2039

Keywords: ISO 20816-1, mechanical vibration, shaft vibration measurement, vibration evaluation, vibration monitoring, acceptance testing, rotating machinery.

Get Certified

Connect with accredited certification bodies for this standard

BSMI (Bureau of Standards, Metrology and Inspection)

Taiwan's standards and inspection authority.

Sponsored listings

Frequently Asked Questions

ISO 20816-1:2016 is a standard published by the International Organization for Standardization (ISO). Its full title is "Mechanical vibration — Measurement and evaluation of machine vibration — Part 1: General guidelines". This standard covers: ISO 20816-1:2016 establishes general conditions and procedures for the measurement and evaluation of vibration using measurements made on rotating, non-rotating and non-reciprocating parts of complete machines. It is applicable to measurements of both absolute and relative radial shaft vibration with regard to the monitoring of radial clearances, but excludes axial shaft vibration. The general evaluation criteria, which are presented in terms of both vibration magnitude and change of vibration, relate to both operational monitoring and acceptance testing. They have been provided primarily with regard to securing reliable, safe, long-term operation of the machine while minimizing adverse effects on associated equipment. Guidelines are also presented for setting operational limits. NOTE 1 The evaluation criteria for different classes of machinery will be included in other parts of ISO 20816 when they become available. In the meantime, guidelines are given in Clause 6. NOTE 2 The term "shaft vibration" is used throughout ISO 20816 because, in most cases, measurements are made on machine shafts. However, the ISO 20816 series is also applicable to measurements made on other rotating elements if such elements are found to be more suitable, provided that the guidelines are respected. For the purposes of ISO 20816, operational monitoring is considered to be those vibration measurements made during the normal operation of a machine. The ISO 20816 series permits the use of different measurement quantities and methods, provided that they are well-defined and their limitations are set out, so that the interpretation of the measurements is well-understood. The evaluation criteria relate only to the vibration produced by the machine itself and not the vibration transmitted to it from outside. ISO 20816-1:2016 does not include consideration of torsional vibration. NOTE 3 For torsional vibration, see, for example, ISO 3046‑5, ISO 22266‑1 or VDI 2039.

ISO 20816-1:2016 establishes general conditions and procedures for the measurement and evaluation of vibration using measurements made on rotating, non-rotating and non-reciprocating parts of complete machines. It is applicable to measurements of both absolute and relative radial shaft vibration with regard to the monitoring of radial clearances, but excludes axial shaft vibration. The general evaluation criteria, which are presented in terms of both vibration magnitude and change of vibration, relate to both operational monitoring and acceptance testing. They have been provided primarily with regard to securing reliable, safe, long-term operation of the machine while minimizing adverse effects on associated equipment. Guidelines are also presented for setting operational limits. NOTE 1 The evaluation criteria for different classes of machinery will be included in other parts of ISO 20816 when they become available. In the meantime, guidelines are given in Clause 6. NOTE 2 The term "shaft vibration" is used throughout ISO 20816 because, in most cases, measurements are made on machine shafts. However, the ISO 20816 series is also applicable to measurements made on other rotating elements if such elements are found to be more suitable, provided that the guidelines are respected. For the purposes of ISO 20816, operational monitoring is considered to be those vibration measurements made during the normal operation of a machine. The ISO 20816 series permits the use of different measurement quantities and methods, provided that they are well-defined and their limitations are set out, so that the interpretation of the measurements is well-understood. The evaluation criteria relate only to the vibration produced by the machine itself and not the vibration transmitted to it from outside. ISO 20816-1:2016 does not include consideration of torsional vibration. NOTE 3 For torsional vibration, see, for example, ISO 3046‑5, ISO 22266‑1 or VDI 2039.

ISO 20816-1:2016 is classified under the following ICS (International Classification for Standards) categories: 17.160 - Vibrations, shock and vibration measurements. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 20816-1:2016 has the following relationships with other standards: It is inter standard links to ISO 10816-1:1995/Amd 1:2009, ISO 10816-1:1995, ISO 7919-1:1996. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 20816-1:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 20816-1

First edition

2016-11-15

Mechanical vibration — Measurement

and evaluation of machine

vibration —

Part 1:

General guidelines

Vibrations mécaniques — Mesurage et évaluation des vibrations de

machines —

Partie 1: Lignes directrices générales

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

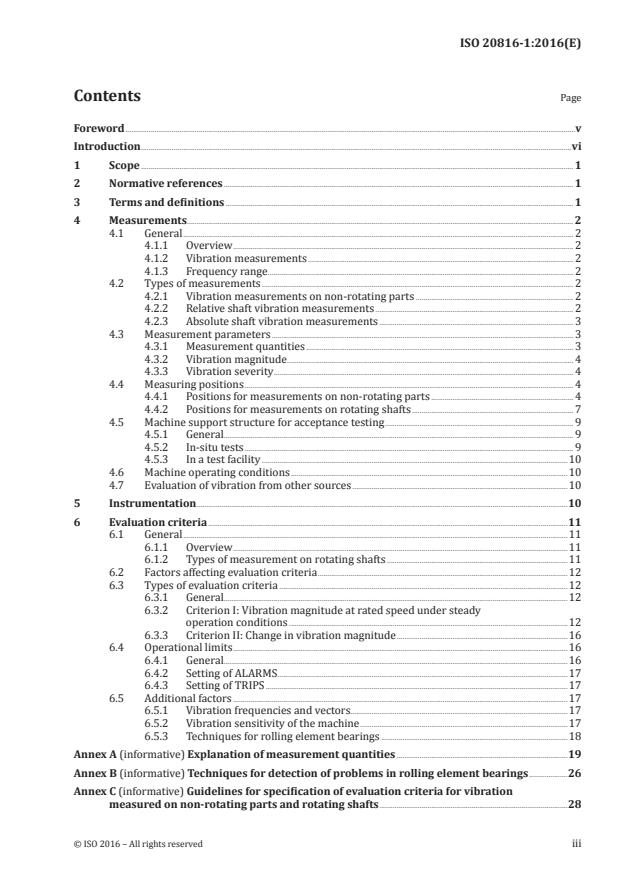

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Measurements . 2

4.1 General . 2

4.1.1 Overview . 2

4.1.2 Vibration measurements . 2

4.1.3 Frequency range . 2

4.2 Types of measurements . 2

4.2.1 Vibration measurements on non-rotating parts . 2

4.2.2 Relative shaft vibration measurements . 2

4.2.3 Absolute shaft vibration measurements . 3

4.3 Measurement parameters . 3

4.3.1 Measurement quantities . 3

4.3.2 Vibration magnitude . . 4

4.3.3 Vibration severity . . 4

4.4 Measuring positions . 4

4.4.1 Positions for measurements on non-rotating parts . 4

4.4.2 Positions for measurements on rotating shafts . 7

4.5 Machine support structure for acceptance testing . 9

4.5.1 General. 9

4.5.2 In-situ tests . 9

4.5.3 In a test facility .10

4.6 Machine operating conditions .10

4.7 Evaluation of vibration from other sources .10

5 Instrumentation .10

6 Evaluation criteria .11

6.1 General .11

6.1.1 Overview .11

6.1.2 Types of measurement on rotating shafts .11

6.2 Factors affecting evaluation criteria .12

6.3 Types of evaluation criteria .12

6.3.1 General.12

6.3.2 Criterion I: Vibration magnitude at rated speed under steady

operation conditions .12

6.3.3 Criterion II: Change in vibration magnitude .16

6.4 Operational limits .16

6.4.1 General.16

6.4.2 Setting of ALARMS .17

6.4.3 Setting of TRIPS .17

6.5 Additional factors .17

6.5.1 Vibration frequencies and vectors . .17

6.5.2 Vibration sensitivity of the machine .17

6.5.3 Techniques for rolling element bearings .18

Annex A (informative) Explanation of measurement quantities .19

Annex B (informative) Techniques for detection of problems in rolling element bearings .26

Annex C (informative) Guidelines for specification of evaluation criteria for vibration

measured on non-rotating parts and rotating shafts .28

Annex D (informative) Vector analysis of change in vibration .31

Bibliography .33

iv © ISO 2016 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www.iso.org/iso/foreword.html.

The committee responsible for this document is ISO/TC 108, Mechanical vibration, shock and condition

monitoring, Subcommittee SC 2, Measurement and evaluation of mechanical vibration and shock as applied

to machines, vehicles and structures.

This first edition of ISO 20816-1 cancels and replaces ISO 7919-1:1996, ISO 10816-1:1995 and

ISO 10816-1:1995/Amd 1:2009 which have been merged and editorially revised.

A list of all parts in the ISO 20816 series can be found on the ISO website.

Introduction

Machines are now being operated at increasingly high rotational speeds and loads, as well as more

flexible operation at part and full load, and under increasingly severe operating conditions. This has

become possible, to a large extent, by the more efficient use of materials, although this has sometimes

resulted in there being less margin for design and application errors.

At present, it is not uncommon for continuous operation to be expected and required for 2 years or

3 years between maintenance operations. Consequently, more restrictive requirements are being

specified for operating vibration values of rotating machinery, in order to ensure continued safe and

reliable operation.

This document is a basic document which establishes general guidelines for the measurement and

evaluation of mechanical vibration of machinery, as measured on rotating and on non-rotating (and,

where applicable, non-reciprocating) parts of complete machines, such as shafts or bearing housings.

Recommendations for measurements and evaluation criteria pertaining to specific machine types are

provided in additional parts of ISO 20816 as they become available as a replacement of the relevant

parts of ISO 7919 and ISO 10816. ISO/TR 19201 gives an overview over these and further machinery

vibration standards.

For some machines, measurements made on non-rotating parts are sufficient to characterize adequately

their running conditions with respect to trouble-free operation. There are also types of machine, such as

steam turbines, gas turbines and turbo compressors, all of which can have several modes of vibration in

the service speed range, for which measurements on structural members, such as the bearing housings,

might not adequately characterize the running condition of the machine, although such measurements

are useful. Such machines generally contain flexible rotor shaft systems, and changes in the vibration

condition can be detected more decisively and more sensitively by measurements on the rotating

elements. Machines having relatively stiff and/or heavy casings in comparison to rotor mass are typical

of those classes of machines for which shaft vibration measurements are frequently preferred.

Vibration measurements are used for a number of purposes, ranging from routine operational

monitoring and acceptance tests to advanced experimental testing, as well as diagnostic and analytical

investigations. These various measurement objectives lead to many differences in methods of

interpretation and evaluation. To limit the number of these differences, this document is designed to

provide guidelines primarily for operational monitoring and acceptance tests.

Three primary vibration quantities (displacement, velocity and acceleration) are defined and their

limitations given. Adherence to the guidelines presented should, in most cases, ensure satisfactory

service performance.

vi © ISO 2016 – All rights reserved

INTERNATIONAL STANDARD ISO 20816-1:2016(E)

Mechanical vibration — Measurement and evaluation of

machine vibration —

Part 1:

General guidelines

1 Scope

This document establishes general conditions and procedures for the measurement and evaluation of

vibration using measurements made on rotating, non-rotating and non-reciprocating parts of complete

machines. It is applicable to measurements of both absolute and relative radial shaft vibration with

regard to the monitoring of radial clearances, but excludes axial shaft vibration. The general evaluation

criteria, which are presented in terms of both vibration magnitude and change of vibration, relate to

both operational monitoring and acceptance testing. They have been provided primarily with regard

to securing reliable, safe, long-term operation of the machine while minimizing adverse effects on

associated equipment. Guidelines are also presented for setting operational limits.

NOTE 1 The evaluation criteria for different classes of machinery will be included in other parts of ISO 20816

when they become available. In the meantime, guidelines are given in Clause 6.

NOTE 2 The term “shaft vibration” is used throughout ISO 20816 because, in most cases, measurements

are made on machine shafts. However, the ISO 20816 series is also applicable to measurements made on other

rotating elements if such elements are found to be more suitable, provided that the guidelines are respected.

For the purposes of ISO 20816, operational monitoring is considered to be those vibration measurements

made during the normal operation of a machine. The ISO 20816 series permits the use of different

measurement quantities and methods, provided that they are well-defined and their limitations are set

out, so that the interpretation of the measurements is well-understood.

The evaluation criteria relate only to the vibration produced by the machine itself and not the vibration

transmitted to it from outside.

This document does not include consideration of torsional vibration.

NOTE 3 For torsional vibration, see, for example, ISO 3046-5, ISO 22266-1 or VDI 2039.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 2954, Mechanical vibration of rotating and reciprocating machinery — Requirements for instruments

for measuring vibration severity

ISO 5348, Mechanical vibration and shock — Mechanical mounting of accelerometers

ISO 10817-1, Rotating shaft vibration measuring systems — Part 1: Relative and absolute sensing of radial

vibration

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

4 Measurements

4.1 General

4.1.1 Overview

This clause describes the measurements, procedures and operating conditions recommended for

assessing machine vibration. The guidelines given permit the evaluation of vibration in accordance

with the general criteria and principles given in Clause 6.

4.1.2 Vibration measurements

It is common practice to measure vibration on non-rotating parts or to measure relative shaft vibration,

or both. The measurement type for the protection system is normally based on the experience from the

machine manufacturer.

4.1.3 Frequency range

The measurement of vibration shall be broad band, so that the frequency spectrum of the machine is

adequately covered.

The frequency range depends on the type of machine being considered (e.g. the frequency range

necessary to assess the integrity of rolling element bearings should include frequencies higher than

those on machines with fluid-film bearings only).

Guidelines for instrumentation frequency ranges for specific machine classes are given in the

appropriate parts of ISO 20816.

NOTE 1 In the past, broad-band measurements in the range 10 Hz to 1 000 Hz were the intended metric for

full-load acceptance testing. This might not meet the requirements of a condition monitoring scheme and might

need to be modified for the purposes of vibration monitoring and diagnostics.

NOTE 2 Vibration condition monitoring and diagnostics of machines are described in ISO 13373.

On certain equipment, e.g. gearboxes and rolling element bearings, it can be appropriate to use a

different frequency range for acceptance purposes.

4.2 Types of measurements

4.2.1 Vibration measurements on non-rotating parts

Vibration measurements on non-rotating parts are generally carried out with a seismic transducer

which senses the absolute velocity or acceleration of structure parts on which it is mounted (e.g. the

bearing housing).

4.2.2 Relative shaft vibration measurements

Relative shaft vibration measurements are generally carried out with a non-contacting transducer

which senses the vibratory displacement between the shaft and a structural member on which it is

mounted (e.g. the bearing housing).

2 © ISO 2016 – All rights reserved

4.2.3 Absolute shaft vibration measurements

Absolute shaft vibration measurements are carried out by one of the following methods:

a) by a shaft-riding probe on which a seismic transducer (velocity type or accelerometer) is mounted

so that it measures absolute shaft vibration directly;

b) by a non-contacting transducer which measures relative shaft vibration in combination with a

seismic transducer (velocity type or accelerometer) which measures the support vibration. Both

transducers shall be mounted close together so that they undergo the same absolute motion in the

direction of measurement. Their conditioned outputs are summed to provide a measurement of the

absolute shaft motion.

NOTE In order to avoid incorrect results, it is important to ensure that the same datum time reference be

used for the outputs from both the seismic and non-contacting transducers.

4.3 Measurement parameters

4.3.1 Measurement quantities

For the purposes of this document, the following measurement quantities can be used:

a) vibration displacement, measured in micrometres;

b) vibration velocity, measured in millimetres per second;

c) vibration acceleration, measured in metres per square second.

The use, application and limitations of these quantities are discussed in Clause 6.

Generally, there is no simple relationship between broad-band acceleration, velocity and displacement;

nor is there between peak (0–p), peak-to-peak (p–p), root-mean-square (r.m.s.) and average values of

vibration. The reasons for this are briefly discussed in A.1, which also defines some precise relationships

between the above quantities when the harmonic content of the vibration waveform is known.

In order to avoid confusion and to ensure correct interpretation, it is important at all times to identify

–6

clearly the measurement quantity and its unit, e.g. peak-to-peak displacement in µm (1 µm = 10 m),

r.m.s. velocity in mm/s.

NOTE Vibration is a vector quantity and therefore, when comparing two different values, it can be necessary

to consider the phase angle between them (see Annex D).

Generally, it can be stated that the preferred measurement quantity for the measurement of vibration

of non-rotating parts is r.m.s. velocity while the preferred measurement quantity for the measurement

of shaft vibration is peak-to-peak displacement.

Since this document applies to both relative and absolute shaft vibration measurements, displacement

is further defined as follows:

— relative displacement which is the vibratory displacement of the shaft with reference to support

structure, such as a bearing housing or machine casing;

— absolute displacement which is the vibratory displacement of the shaft with reference to an inertial

reference system.

It should be clearly indicated whether displacement values are relative or absolute.

Relative and absolute displacements are further defined by several different displacement quantities,

each of which is now in widespread use. These include the following:

maximum vibratory displacement in the plane of measurement, measured from time-

S

max

integrated mean position, see Formula (A.10);

peak-to-peak vibratory displacement in the direction of measurement defined as

S

(p–p)

S = max [S , S ];

(p–p) A(p–p) B(p–p)

S maximum peak-to-peak vibratory displacement in the plane of measurement.

(p–p)max

Any of these displacement quantities may be used for the measurement of shaft vibration. However,

the quantities shall be clearly identified so as to ensure correct interpretation of the measurements in

terms of the criteria of Clause 6. The relationships between these quantities are shown in Figure A.3.

4.3.2 Vibration magnitude

The result of measurements made with an instrument which complies with the requirements of

Clause 5 is called the vibration magnitude at a specific measuring position and direction.

It is common practice, based on experience, when evaluating broad-band vibration of rotating

machinery to consider the r.m.s. value of vibration velocity, since this can be related to the vibration

energy. However, other quantities such as displacement or acceleration and peak values instead of r.m.s.

values may be preferred. In this case, alternative criteria, which are not necessarily simply related to

criteria based on r.m.s. values, are required.

For shaft vibration measurement, it is common practice to consider peak-to-peak values.

4.3.3 Vibration severity

Normally, measurements are made at various measuring positions and in one, two or three measuring

directions, leading to a set of different vibration magnitude values. The maximum broad-band

magnitude value measured under agreed machine support and operating conditions is defined as the

vibration severity.

For most machine types, one value of vibration severity characterizes the vibratory state of that

machine. However, for some machines, this approach can be inadequate and the vibration severity

should then be assessed independently for measurement positions at a number of locations.

4.4 Measuring positions

4.4.1 Positions for measurements on non-rotating parts

Measurements on non-rotating parts should be taken on the bearings, bearing support housing or

other structural parts which significantly respond to the dynamic forces transmitted from the rotating

elements at the bearing locations and characterize the overall vibration of the machine. Typical

measurement locations are shown in Figure 1 to Figure 5.

To determine the vibrational behaviour at each measuring position, it is necessary to take measurements

in three mutually perpendicular directions. The full complement of measurements represented in

Figure 1 to Figure 5 is generally only required for acceptance testing.

The requirement for operational monitoring is usually met by performing one or both measurements in

the radial direction (i.e. normally in the horizontal transverse and/or vertical directions). These can be

supplemented by a measurement of the vibration in the axial direction, but are to be evaluated only on

thrust bearings. The latter can be of significance at thrust bearing locations where direct axial dynamic

forces are transmitted.

Detailed recommendations for specific machine types are provided in the additional parts of ISO 20816.

4 © ISO 2016 – All rights reserved

Figure 1 — Measuring points for pedestal bearings

Figure 2 — Measuring points for housing-type bearings

Figure 3 — Measuring points for small electrical machines

Figure 4 — Measuring points for reciprocating engines close to the bearing locations

Figure 5 — Measuring points for vertical machine sets

6 © ISO 2016 – All rights reserved

4.4.2 Positions for measurements on rotating shafts

4.4.2.1 General

For the measurements on rotating shafts, it is desirable to locate transducers at positions such that

the lateral movement of the shaft at points of importance can be assessed. It is recommended that, for

both relative and absolute measurements, two transducers be located at, or adjacent to, each machine

bearing, see Figure 6. They should be radially mounted in the same transverse plane perpendicular

to the shaft axis or as close as practicable, with their axes within ±5° of a radial line. It is preferable to

mount both transducers 90° ± 5° apart on the same bearing half and the positions chosen should be the

same at each bearing. See Figure 7.

A single transducer may be used at each measurement plane in place of the more typical pair of

orthogonal transducers if it is known to provide adequate information about the shaft vibration.

It is recommended that special measurements be made in order to determine the total non-vibration

runout, which is caused by shaft surface metallurgical non-homogeneities, local residual magnetism

and shaft mechanical runout. It should be noted that, for anisotropic rotors such as, for example, two-

pole generators, the effect of gravity can cause a false runout signal.

Key

1 to signal processing

2 signal conditioning units

3 non-contacting transducers

4 shaft

5 bearing housings

6 bearings

Figure 6 — Measuring points for measurements on rotating shafts

Key

1 to signal processing

2 signal conditioning units

3 shaft

4 non-contacting transducers

Figure 7 — Mounting of non-contacting probes for the measurement of shaft relative vibration

4.4.2.2 Positions for relative shaft vibration measurements

Relative vibration transducers of the non-contacting type are normally mounted in tapped holes

in the bearing housing or by rigid brackets adjacent to the bearing housing or bearing shell. Where

the transducers are mounted in the bearing, they should be located so as not to interfere with the

lubrication pressure wedge. However, special arrangements for mounting transducers in other axial

locations may be made, but different vibration criteria for assessment will then have to be used. For

bracket-mounted transducers, the bracket shall be free from natural frequencies which adversely affect

the capability of the transducer to measure the relative shaft vibration.

The surface of the shaft at the location of the transducer, taking into account the total axial float of the

shaft under all thermal conditions, shall be smooth and free from any geometric discontinuities (such

as keyways, lubrication passages and threads), metallurgical non-homogeneities and local residual

magnetism which can cause false signals. In some circumstances, an electroplated or metallized shaft

surface may be acceptable, but it should be noted that the calibration can be different. It is recommended

that the total combined electrical and mechanical runout, as measured by the transducer, does not

exceed 25 % of the allowable vibration displacement, specified in accordance with 6.3.2.2, or 6 μm,

whichever is greater. For measurements made on machines already in service, where provision was not

originally made for shaft vibration measurements, it can be necessary to use other runout criteria.

4.4.2.3 Positions for absolute shaft vibration measurements using combined seismic and

non-contacting relative vibration transducers

If a combination of seismic and non-contacting relative vibration transducers is used, the absolute shaft

vibration is obtained by

a) integrating the signal from the seismic transducer to convert the acceleration or velocity output to

displacement, and

b) summing the displacement outputs from both transducers.

NOTE 1 In order to avoid incorrect results, it is important to ensure that the same datum time reference is

used for the outputs from both the seismic and non-contacting transducers.

8 © ISO 2016 – All rights reserved

The mounting and other requirements for the non-contacting transducer are as specified in 4.4.2.2.

In addition, the seismic transducer shall be rigidly mounted to the machine structure (e.g. the bearing

housing) close to the non-contacting transducer so that both transducers undergo the same absolute

vibration of the support structure in the direction of measurement. The sensitive axes of the non-

contacting and seismic transducers shall be parallel, so that their summed, conditioned signals result in

an accurate measure of the absolute shaft vibration. See Figure 8.

NOTE 2 Information on mounting accelerometers for seismic measurements is given in ISO 5348.

NOTE 3 In the past, absolute shaft vibration measurements have also been performed using a shaft-riding

mechanism with a seismic transducer.

Key

1 to signal processing

2 signal conditioning units

3 shaft

4 non-contacting transducers

5 seismic transducers

Figure 8 — Mounting of non-contacting and seismic probes for the measurement of shaft

absolute vibration

4.5 Machine support structure for acceptance testing

4.5.1 General

The acceptance criteria should be agreed between the customer and manufacturer.

4.5.2 In-situ tests

When acceptance is carried out in situ, the support structure shall be that supplied for the machine.

In this case, it is important to ensure that all the major components of the machine and structure are

installed when the test is carried out.

Valid comparisons of vibration for machines of the same type but on different foundations or sub-

foundations can only be made if the foundations concerned have similar dynamic characteristics.

4.5.3 In a test facility

There are many classes of machines for which, because of economic or other reasons, acceptance is

carried out on a test bed which can have different support structure characteristics from those at the

site. The support structure can significantly affect the measured vibration and every attempt should be

made to ensure that the natural frequencies of the complete test arrangement do not coincide with the

rotational frequencies of the machine or with any of its significant harmonics.

The test arrangement normally meets these requirements if the vibration magnitude measured in the

horizontal and vertical directions at the machine feet, or at the base frame near the bearing support or

stator feet, does not exceed 50 % of the vibration magnitude measured in the same measuring direction

at that bearing. Additionally, the test arrangement shall not cause a substantial change in any of the

major resonance frequencies.

If a significant support resonance is present during acceptance test and it cannot be eliminated, the

vibration acceptance may have to be carried out on the fully installed machine in situ.

For some classes of machines (e.g. small electrical machinery), acceptance tests can be carried out

when machines are supported by a resilient system (see, for example, IEC 60034-14). In this case, all

the rigid-body mode frequencies of the machine on its support system shall be less than one-half of the

lowest significant excitation frequency of the machine. Appropriate support conditions can be achieved

by mounting the machine on a resilient support baseplate or by free suspension on a soft spring.

4.6 Machine operating conditions

Shaft vibration measurements shall be made after achieving contractually agreed normal operating

conditions (speed, load, temperature, pressure, etc.). Additional vibration measurements that may be

taken under other conditions are not applicable for evaluation in accordance with Clause 6.

4.7 Evaluation of vibration from other sources

If the measured vibration magnitude exceeds the recommended limit, it can then be necessary to take

measurements of environmental vibration with the machine shut down to ensure that this is not making

a significant contribution to the observed vibration. Where possible, steps should be taken to reduce the

magnitude of environmental vibration if it is greater than one-third of the recommended limits.

5 Instrumentation

The instrumentation used shall be designed to operate satisfactorily in the environment for which it

is to be used, for example, with respect to temperature and humidity. Specification for instruments for

measuring vibration severity is given in ISO 2954 and instruments for measuring shaft vibration are

specified in ISO 10817-1.

Particular attention shall be given to ensure that the vibration transducer is correctly mounted and

that its presence does not affect the vibration response characteristics of the machine. Specifications

for mounting accelerometers are given in ISO 5348, which, in principle, are applicable also to velocity

transducers.

Modern instrumentation can provide multiple methods to deliver a measurement value. The acceptance

criteria here are based on r.m.s. velocity in mm/s for measurements on non-rotating parts and peak-

to-peak displacement in micrometres for measurements on rotating parts. The acceptance criteria

may be scaled suitably to match the units in common use at the site, using the same assumptions as

programmed into the distributed control systems.

It is desirable that the measurement system has provision for on-line calibration of the readout

instrumentation and, in addition, has suitable isolated outputs to permit further analysis as required.

10 © ISO 2016 – All rights reserved

6 Evaluation criteria

6.1 General

6.1.1 Overview

This clause specifies general criteria and principles for the evaluation of machine vibration. The

evaluation criteria relate to both operational monitoring and acceptance testing, and they apply only to

the vibration produced by the machine itself and not the vibration transmitted from outside.

The specification of evaluation criteria for machine vibration is dependent upon a wide range of

factors and the criteria adopted vary significantly for different types of machine and, in some cases,

for different rotors in the same coupled line. It is important, therefore, to ensure that valid criteria are

adopted for a particular machine and that the criteria which relate to a certain type of machine are not

erroneously applied to other types.

EXAMPLE Evaluation criteria for a high-speed compressor operating in a petrochemical plant are likely to

be different from those for large turbo-generators.

This clause establishes a basis for specifying evaluation criteria for measurements on non-rotating

parts, as well as on rotating shafts. No attempt has been made to specify vibration values. If the

procedures of both kinds of measurements are applicable, the one which is more restrictive shall

generally apply. Specific criteria for different classes and types of machinery are given in the relevant

parts of ISO 20816.

The criteria presented in this clause are applicable only to the vibration due to excitation from the

rotating elements. The criteria are not applicable to the evaluation of the electromagnetic vibration

excited at twice the line frequency (i.e. twice the electrical system frequency) and transmitted from the

generator stator core to the bearings.

6.1.2 Types of measurement on rotating shafts

6.1.2.1 There are two principal factors by which shaft vibration is judged:

a) absolute vibration of the shaft;

b) vibration of the shaft relative to the structural elements.

6.1.2.2 If the evaluation criterion is the change in shaft vibration, then

a) when the vibration of the structure, on which the shaft-relative transducer is mounted, is small (i.e.

less than 20 % of the relative shaft vibration), either the relative shaft vibration or absolute shaft

vibration may be used as a measure of shaft vibration, and

b) when the vibration of the structure, on which the shaft-relative transducer is mounted, is 20 % or

more of the relative shaft vibration, the absolute shaft vibration shall be measured and, if found to

be larger than the relative shaft vibration, it shall be used as the measure of shaft vibration.

6.1.2.3 If the evaluation criterion is the dynamic load on the bearing, the relative shaft vibration shall

be used as the measure of shaft vibration.

6.1.2.4 If the evaluation criterion is stator/rotor clearance, then

a) when the vibration of the structure, on which the shaft-relative transducer is mounted, is small

(i.e. less than 20 % of the relative shaft vibration), the relative shaft vibration shall be used as a

measure of clearance absorption, and

b) when the vibration of the structure, on which the shaft-relative transducer is mounted, is 20 % or

more of the relative shaft vibration, the relative shaft vibration measurement may still be used as a

measure of clearance absorption unless the vibration of the structure, on which the shaft-relative

transducer is mounted, is not representative of the total stator vibration. In this latter case, special

measurements are required.

6.1.2.5 The shaft vibration associated with a particular evaluation range depends on the size and mass

of the vibrating body, the characteristics of the mounting system and the output and use of the machine.

It is therefore necessary to take into account the various purposes and circumstances concerned when

specifying different ranges of shaft vibration for a specific class of machinery. Where appropriate,

reference should be made to the product specification.

6.2 Factors affecting evaluation criteria

There are a wide range of different factors which need to be taken into account when specifying

evaluation criteria for vibration measurements. Amongst these are the following:

a) the purpose for which the measurement is made (e.g. the requirement for ensuring that running

clearances are maintained is, in general, different from that if the avoidance of excessive dynamic

load on the bearing is the main concern);

b) the type of measurement made (vibration of non-rotating parts, relative or absolute shaft vibration);

c) the quantities measured (see Annex A);

d) the positions where the measurements are made;

e) the rotational speed of the shaft;

f) the bearing type, clearance and diameter;

g) the function, output and size of the machine;

h) the stiffness of the bearings, pedestals and foundations;

i) the rotor mass and stiffness.

Clearly, this wide range of factors makes it impossible to define unique evaluation criteria which can be

applied to all machines. Different criteria, which have been derived from operational experience, are

necessary for different machines, but at best, they can only be regarded as guidelines and there will be

occasions where machines will operate safely and satisfactorily outside any general recommendations

or are unable to operate despite vibration values are well within guideline values.

6.3 Types of evaluation criteria

6.3.1 General

Two evaluation criteria are used to assess vibration severity on various classes of machines. One

criterion considers the magnitude of observed broad-band vibration; the second considers changes in

magnitude, irrespective of whether they are increases or decreases.

6.3.2 Criterion I: Vibration magnitude at rated speed under steady operation conditions

6.3.2.1 Non-rotating parts

For non-rotating parts, this criterion is concerned with defining limits for absolute vibration magnitude

consistent with acceptable dynamic loads on the bearings and acceptable vibration transmission into

the support structure and foundation. The maximum vibration magnitude observed at each bearing

or pedestal is assessed against four evaluation zones established from international experience. This

maximum magnitude of vibration measured is defined as the vibration severity (see 4.3.3).

12 © ISO 2016 – All rights reserved

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...