ISO 1101:1983/Ext 1:1983

(Main)Technical drawings - Geometrical tolerancing - Tolerancing of form, orientation, location and run-out - Generalities, definitions, symbols, indications on drawings - Extract 1: Toleranced characteristics and symbols - Examples of indication and interpretation

Technical drawings - Geometrical tolerancing - Tolerancing of form, orientation, location and run-out - Generalities, definitions, symbols, indications on drawings - Extract 1: Toleranced characteristics and symbols - Examples of indication and interpretation

Dessins techniques — Tolérancement géométrique — Tolérancement de forme, orientation, position et battement — Généralités, définitions, symboles, indications sur les dessins — Extrait 1: géométrique — Caractéristiques à tolérancer et symboles — Exemples d'indication et d'interprétation

General Information

Relations

Frequently Asked Questions

ISO 1101:1983/Ext 1:1983 is a standard published by the International Organization for Standardization (ISO). Its full title is "Technical drawings - Geometrical tolerancing - Tolerancing of form, orientation, location and run-out - Generalities, definitions, symbols, indications on drawings - Extract 1: Toleranced characteristics and symbols - Examples of indication and interpretation". This standard covers: Technical drawings - Geometrical tolerancing - Tolerancing of form, orientation, location and run-out - Generalities, definitions, symbols, indications on drawings - Extract 1: Toleranced characteristics and symbols - Examples of indication and interpretation

Technical drawings - Geometrical tolerancing - Tolerancing of form, orientation, location and run-out - Generalities, definitions, symbols, indications on drawings - Extract 1: Toleranced characteristics and symbols - Examples of indication and interpretation

ISO 1101:1983/Ext 1:1983 is classified under the following ICS (International Classification for Standards) categories: 01.100.20 - Mechanical engineering drawings. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 1101:1983/Ext 1:1983 has the following relationships with other standards: It is inter standard links to ISO 1101:1983; is excused to ISO 1101:1983. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 1101:1983/Ext 1:1983 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

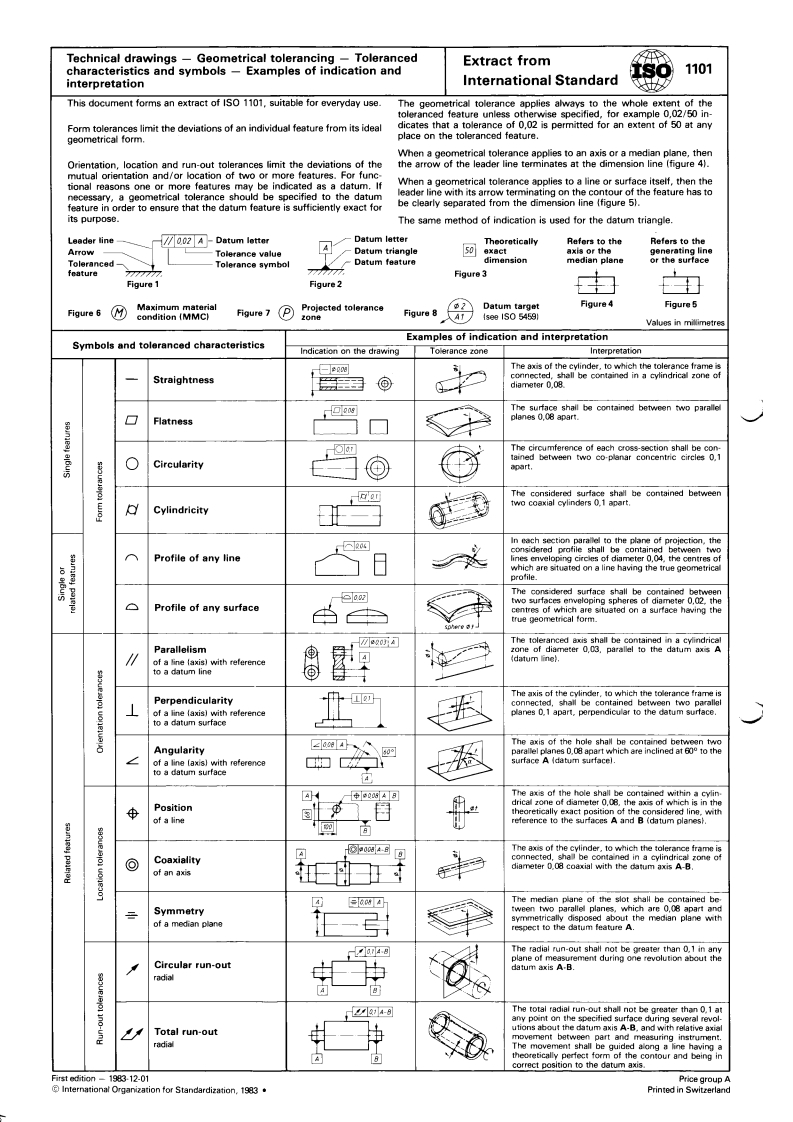

Technical drawings - Geometrical tolerancing - Toleranced

Extract from

characteristics and symbols - Examples of indication and

International Standard

interpretation

This document forms an extract of IS0 1101, suitable for everyday use.

The geometrical tolerance applies always to the whole extent of the

I toleranced feature unless otherwise SDecified. for examde 0.02/50 in-

dicates that a tolerance of 0.02 is permitted for an extent of 50 at any

Form tolerances limit the deviations of an individual feature from its ideal

place on the toleranced feature.

geometrical form.

When a geometrical tolerance applies to an axis or a median plane, then

I Orientation. location and run-out tolerances limit the deviations of the the arrow of the leader line terminates at the dimension line (figure 4).

mutual orientation and/or location of two or more features. For func-

When a geometrical tolerance applies to a line or surface itself, then the

tional reasons one or features may be indicated as a If

leader line with its arrow terminating on the contour of the feature has to

neceçsary, a geometrical tolerance should be specified to the datum

line (figure 5).

be clearly separated from the

feature in order to ensure that the datum feature is sufficiently exact for

its purpose.

The same method of indication is used for the datum triangle.

Lz Datum letter Theoretically Refers to the Refers to the

Tolerance value Datum triangle exact axis or the generating line

Datum feature dimension median plane or the surface

Tolerance symbol

Figure 3

Figure 1 Figure 2

Projected tolerance Figure ,@ Datum target Figure 4 Figure 5

Maximum material

Figure 6 Figure 7

8 condition (MMC) @ zone (see IS0 54591

Values . .~ in millimetres . .

Examoies of indication and interoretation

Symbols and toleranced characteristics

Indication on the drawing Tolerance zone Interpretation

-

The axis of the cylinder, to which the tolerance frame is

connected, shall be contained in a cylindrical zone of

7 Straightness

diameter 0.08.

The surface shall be contained between two parallel

planes 0.08 apart.

0 Flatness

The circumference of each cross-section shall be con-

tained between two co-planar concentric circles 0.1

Circularity

apart.

0 c

O1

m

-

The considered surface shall be contained between

e

a ,

two coaxial cylinders 0.1 apart.

E

Cylindricity

- -

LL

In each section parallel to the plane of projection, the

c

...

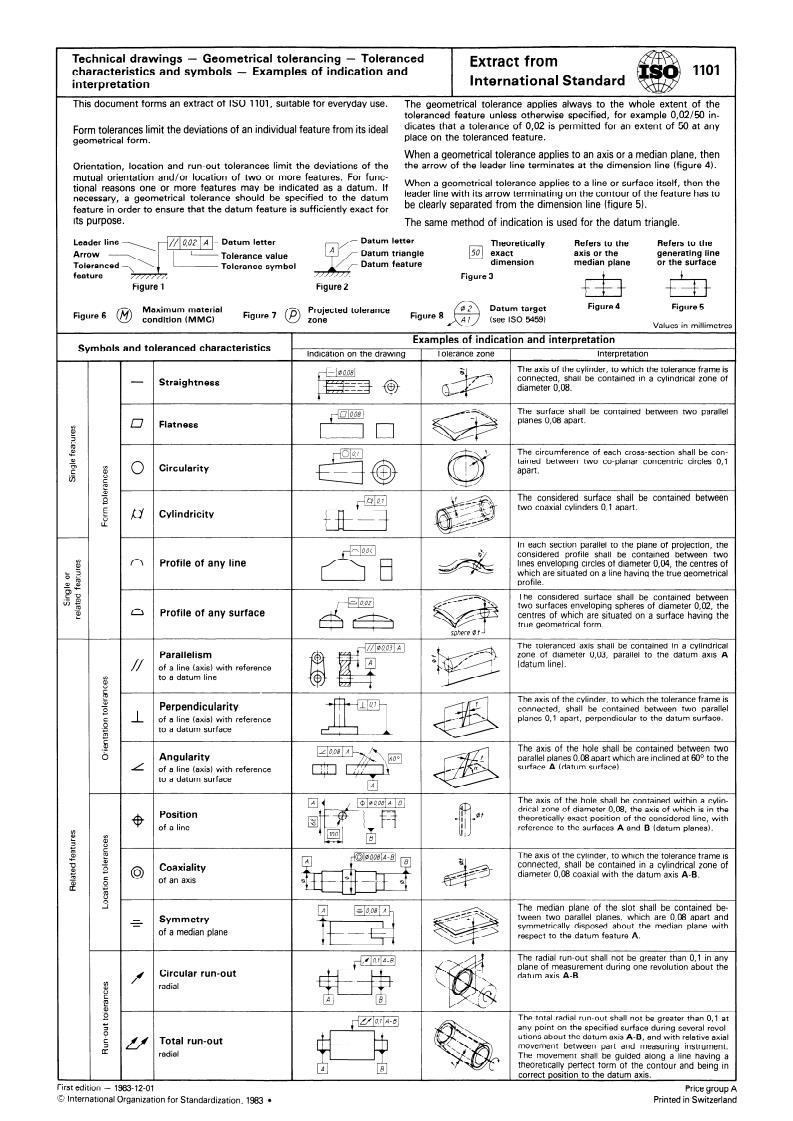

This document forms an extract of ISO 1101, suitable for everyday use.

The geometrical tolerante applies always to the whole extent of the

toleranced feature unless otherwise specified, for example 0,02/50 in-

dicates that a tolerante of 0,02 is permitted for an extent of 50 at any

Form tolerantes limit the deviations of an individual feature from its ideal

place on the toleranced feature.

geometrical form.

When a geometrical tolerante applies to an axis or a median plane, then

the arrow of the leader line terminates at the dimension line (figure 4).

Orientation, location and run-out tolerantes limit the deviations of the

mutual orientation and/or location of two or more features. For func-

When a geometrical tolerante applies to a line or surface itself, then the

tional reasons one or more features may be indicated as a datum. If

leader line with its arrow terminating on the contour of the feature has to

necessary, a geometrical tolerante should be specified to the datum

be clearly separated from the dimension line (figure 5).

feature in Order to ensure that the datum feature is sufficiently exact for

its purpose.

The same method of indication is used for the datum triangle.

Datum letter

Refers to the Refers to the

generating line

axis or the

median plane or the surface

Figure 3

Figure 4

Figure 5

Maximum material

condition (M MC)

Values in millimetres

Examples of indication and interpretation

Symbols and toleranced characteristics

Indication on the drawing Tolerante zone Interpretation

The axis of the cylinder, to which the tolerante frame is

connected shall be contained in a cylindrical zone of

- Straightness

fs* @ & diameter 0108.

The surface shall be contained between two parallel

planes 0,08 apart.

fl Flatness

z

Cl

The circumference of each Cross-section shall be con-

tained between two co-planar concentric circles 0,l

two coaxial cylinders 0,l apart.

Profile of any line

Profile of any surface

centres of which are situated on a surface having the

true geometrical form.

The toleranced axis shall be contained in a cylindrical

zone of diameter 0,03, parallel to the datum axis A

of a line (axis) with reference

Perpendicularity

of a line (axis) with reference

to a datum surface

The axis of the hole shall be contained between two

parallel planes 0,08 apart which are inclined at 60° to the

surface A (datum surface).

The axis of the cylinder, to which the tolerante frame is

connected, shall be contained in a cylindrical zone of

diameter 0,08 coaxial with the datum axis A-B.

of the slot shall be contained be-

planes, which are 0,08 apart and

sed about the median plane with

Circular run-out

un-out shall not be greater than 0,l at

specified surface during several revol-

datum axis A-B, and with relative axial

een part and measuring instrument.

along a line having a

ontour and being in

First edition -

...

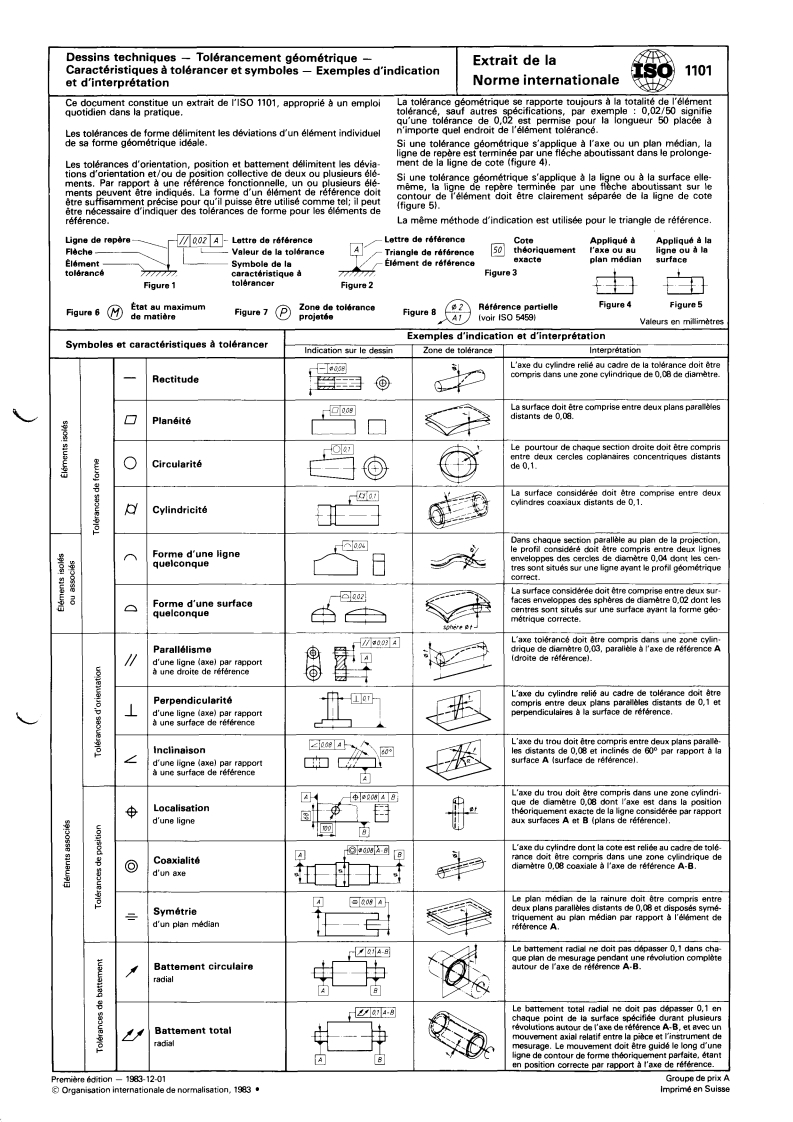

La tolérance géométrique se.rapporte toujours à la totalité de l'élément

Ce document constitue un extrait de 1'1S0 1101, approprié 3 un emploi

tolérancé, sauf autres spécifications, par exemple : 0,02/50 signifie

quotidien dans la pratique.

qu'une tolérance de 0.02 est permise pour la longueur 50 placée à

quel endroit de I'é1ément tolérancé.

Les tolérances de forme délimitent les déviations d'un élément individuel

de sa forme géométrique idéale.

Si une tolérance géométrique s'applique à l'axe ou un plan médian, la

ligne de repère est terminée par une fléche aboutissant dans le prolonge-

ment de la ligne de cote (figure 4).

Les tolérances d'orientation. oosition et battement délimitent les dévia-

~ .~-. ., r.~ ~ ~~~~ ~ ~~ ~ ~~ ~~ .-

tions d'orientation et/ou de position collective de deux ou plusieurs 618-

Si une tolérance géométrique s'applique à la li ne ou a la surface elle-

mentS. Par rapport à une fonctionnelle, un ou plusieurs

même, la ligne de repère terminée par une fiche aboutissant sur ie

ments euvent être indiqués, La forme dru,, élément de doit

contour de l'élément doit être clairement séparée de la ligne de cote

être su,$isamment orecise au,iI Duisse être utilisé tel; II Deut f&.-." CI

'''y"'r

être nécessaire d'indiquer des tolérances de forme pour les éléments de

référence. La même méthode d'indication est utilisée pour le triangle de référence

Ligne de repère

Lettre de référence Cote Appliqué à Appliqué à la

Flèche Triangle de @ théoriquement t'axe ou au ligne ou à ia

exacte plan médian surface

Symbole de la Élément de référence

caractéristique à Figure 3

Figure 1 tolérancer Figure 2

Référence partielle Figure 4 Figure 5

État au maximum

Figure 8 de matière Figure 7 @ ~~~~~

Figure ôB (voir IS0 5459)

Valeurs en millimètre:

Exemples d'indication et d'interprétation

Symboles et caractéristiques A tolérancer

Indication sur le dessin Zone de tolérance Interprétation

L'axe du cylindre relié au cadre de la tolérance doit être

compris dans une zone cylindrique de 0.08 de diamètre.

-

Rectitude

La surface doit être comprise entre deux plans parallèles

distants de 0.08.

0 Pianéité

Le pourtour de chaque section droite doit être compris

mtre deux cercles coplanaires concentriques distants

de0.1.

0 Circularité

La surface considérée doit être comprise entre deux

cylindres coaxiaux distants de O, 1.

Dans chaque section parallèle au plan de la projection,

le profil considéré doit ê

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...