ISO 20915:2018

(Main)Life cycle inventory calculation methodology for steel products

Life cycle inventory calculation methodology for steel products

This document specifies guidelines and requirements for conducting life cycle inventory (LCI) studies of steel products reflecting steel's capacity for closed-loop recycling, including: a) specification of the functional unit used for LCI calculation of steel products; b) definition of the system boundaries used for LCI calculation of steel products; c) evaluation of scrap in LCI calculation of steel products; d) evaluation of co-products in LCI calculation of steel products; e) reporting of LCI calculation results of steel products. The application of LCI results, including life cycle impact assessment (LCIA), is outside the scope of this document.

Méthodologie de calcul de l’inventaire du cycle de vie des produits en acier

General Information

- Status

- Published

- Publication Date

- 11-Nov-2018

- Technical Committee

- ISO/TC 17 - Steel

- Drafting Committee

- ISO/TC 17 - Steel

- Current Stage

- 9092 - International Standard to be revised

- Start Date

- 27-Jun-2024

- Completion Date

- 12-Feb-2026

Overview

ISO 20915:2018 - Life cycle inventory calculation methodology for steel products - provides a standardized methodology for preparing life cycle inventory (LCI) studies specific to steel. The standard focuses on the factory-gate (cradle-to-gate) stages of steel production and explicitly incorporates steel’s capacity for closed‑loop recycling. ISO 20915:2018 defines how to set the functional unit, determine system boundaries, treat scrap and co‑products, and report LCI results. The standard conforms to ISO 14040 and ISO 14044 principles; application of LCI results to life cycle impact assessment (LCIA) is outside its scope.

Key topics and requirements

- Functional unit and function definition: Guidance on selecting the functional unit appropriate for steel products LCI to ensure comparability and consistency.

- System boundaries: Requirements for defining system boundaries that capture raw material sourcing, production at the steelworks, and scrap recycling processes.

- Scrap evaluation and recycling: Methodology to account for ferrous scrap inputs, scrap treatment, and calculation of burdens and credits associated with recycling to reflect closed‑loop recycling.

- Co‑product handling and allocation: Procedures for allocating inputs and outputs among primary products and co‑products, including system expansion options.

- Data quality and data collection: Criteria for temporal, geographical and technological coverage, data sources, and cut‑off rules.

- Cradle‑to‑gate LCI calculation: Steps for performing LCI calculations with and without allocation for scrap input.

- Reporting and critical review: Prescribed reporting elements and requirements for critical review to ensure transparency and reproducibility.

- Supporting annexes: Informative annexes provide worked examples (LCI calculations, recycling rate calculations, electricity/steam treatments) and comparisons among standards.

Applications and practical value

ISO 20915:2018 is practical for:

- Steel producers preparing consistent LCIs for product lines or EPD inputs.

- LCA practitioners performing product LCA where steel is a major material.

- Sustainability and supply‑chain managers assessing environmental performance and recycling benefits.

- Product designers and OEMs optimizing material choices and design‑for‑recycling strategies.

- Policy makers and certifiers seeking standardized LCI inputs for regulation or procurement.

Use cases include LCI development for Environmental Product Declarations (EPDs), comparative LCA of material options, supplier reporting, and internal sustainability accounting where accurate representation of scrap recycling is essential.

Related standards

- ISO 14040:2006 - Environmental management - Life cycle assessment - Principles and framework

- ISO 14044:2006 - Environmental management - Life cycle assessment - Requirements and guidelines

Keywords: ISO 20915:2018, life cycle inventory, LCI, steel products, closed‑loop recycling, scrap evaluation, functional unit, system boundaries, co‑products, reporting.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

ISO 20915:2018 is a standard published by the International Organization for Standardization (ISO). Its full title is "Life cycle inventory calculation methodology for steel products". This standard covers: This document specifies guidelines and requirements for conducting life cycle inventory (LCI) studies of steel products reflecting steel's capacity for closed-loop recycling, including: a) specification of the functional unit used for LCI calculation of steel products; b) definition of the system boundaries used for LCI calculation of steel products; c) evaluation of scrap in LCI calculation of steel products; d) evaluation of co-products in LCI calculation of steel products; e) reporting of LCI calculation results of steel products. The application of LCI results, including life cycle impact assessment (LCIA), is outside the scope of this document.

This document specifies guidelines and requirements for conducting life cycle inventory (LCI) studies of steel products reflecting steel's capacity for closed-loop recycling, including: a) specification of the functional unit used for LCI calculation of steel products; b) definition of the system boundaries used for LCI calculation of steel products; c) evaluation of scrap in LCI calculation of steel products; d) evaluation of co-products in LCI calculation of steel products; e) reporting of LCI calculation results of steel products. The application of LCI results, including life cycle impact assessment (LCIA), is outside the scope of this document.

ISO 20915:2018 is classified under the following ICS (International Classification for Standards) categories: 77.080.20 - Steels. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 20915:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 20915

First edition

2018-11

Life cycle inventory calculation

methodology for steel products

Méthodologie de calcul de l’inventaire du cycle de vie des produits

en acier

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

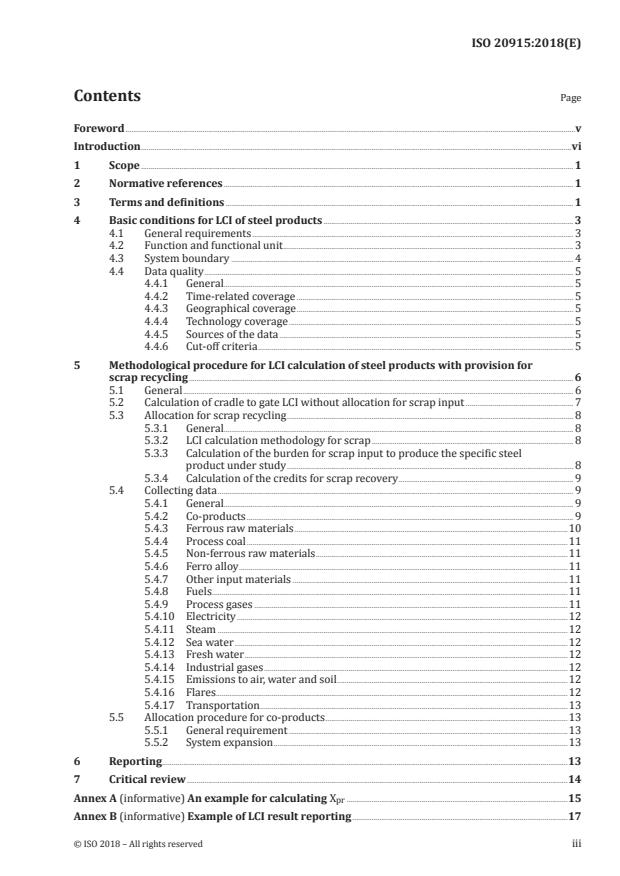

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Basic conditions for LCI of steel products . 3

4.1 General requirements . 3

4.2 Function and functional unit . 3

4.3 System boundary . 4

4.4 Data quality . 5

4.4.1 General. 5

4.4.2 Time-related coverage . 5

4.4.3 Geographical coverage . 5

4.4.4 Technology coverage . 5

4.4.5 Sources of the data . 5

4.4.6 Cut-off criteria . 5

5 Methodological procedure for LCI calculation of steel products with provision for

scrap recycling . 6

5.1 General . 6

5.2 Calculation of cradle to gate LCI without allocation for scrap input . 7

5.3 Allocation for scrap recycling . 8

5.3.1 General. 8

5.3.2 LCI calculation methodology for scrap . 8

5.3.3 Calculation of the burden for scrap input to produce the specific steel

product under study . 8

5.3.4 Calculation of the credits for scrap recovery . 9

5.4 Collecting data . 9

5.4.1 General. 9

5.4.2 Co-products . 9

5.4.3 Ferrous raw materials .10

5.4.4 Process coal .11

5.4.5 Non-ferrous raw materials .11

5.4.6 Ferro alloy .11

5.4.7 Other input materials .11

5.4.8 Fuels .11

5.4.9 Process gases .11

5.4.10 Electricity .12

5.4.11 Steam .12

5.4.12 Sea water .12

5.4.13 Fresh water .12

5.4.14 Industrial gases .12

5.4.15 Emissions to air, water and soil .12

5.4.16 Flares .12

5.4.17 Transportation .13

5.5 Allocation procedure for co-products .13

5.5.1 General requirement .13

5.5.2 System expansion .13

6 Reporting .13

7 Critical review .14

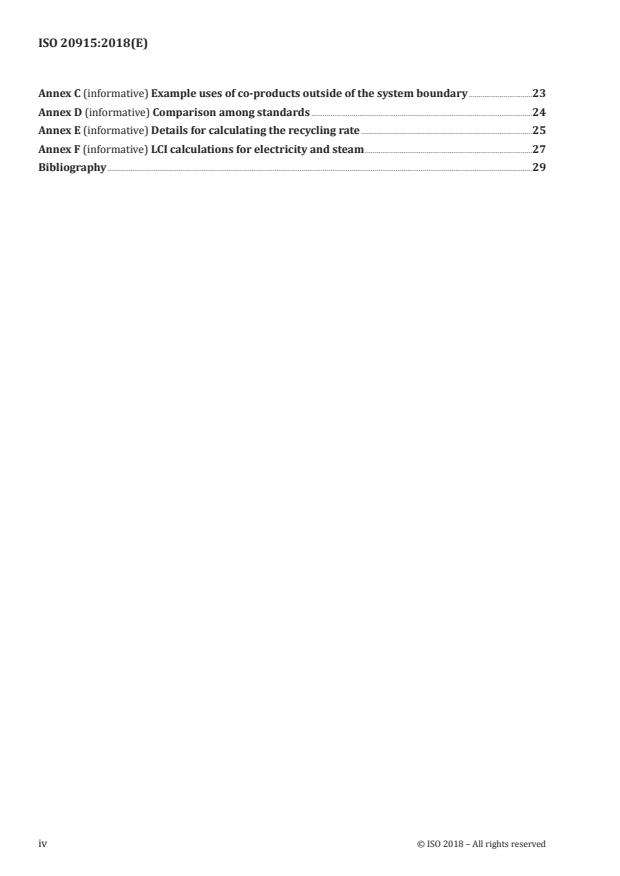

Annex A (informative) An example for calculating X .15

pr

Annex B (informative) Example of LCI result reporting .17

Annex C (informative) Example uses of co-products outside of the system boundary .23

Annex D (informative) Comparison among standards .24

Annex E (informative) Details for calculating the recycling rate .25

Annex F (informative) LCI calculations for electricity and steam .27

Bibliography .29

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso

.org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 17, Steel.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

Introduction

The life cycle inventory (LCI) of steel products is an important component in the support of life cycle

assessments for a wide range of products and applications that contain steel or where steel is used to

support the manufacture, production or delivery of products.

This document describes the methodology for the calculation of the steel life cycle inventories that can

be applied to a wide range of steel products, and represents the main process routes for global steel

production. This includes the extraction of raw materials from the earth through to the production

of steel products at the factory gate, as well as provision for scrap recycling of steel products and

the treatment of steel scrap. The methodology conforms to the principles and framework set out in

ISO 14040:2006 and ISO 14044:2006 and demonstrates how these principles can be applied to steel

product manufacture and steel recycling.

As illustrated in Figure 1, the life cycle of steel products consists of the following stages:

— sourcing of natural resources (which includes mining, transportation and intermediate processing

of raw materials) and ferrous scrap (recovered from both the manufacturing process and the end of

life of final products);

— production of steel products at the steelworks;

— manufacturing of final products by downstream users, for example, by customers of the steel

industry, such as automotive, construction and engineering industries;

— use of final products, where the environmental performance of the final product depends on the

steel products being used; for example, the fuel (or energy) consumption of an automobile depends

partly upon the weight of its steel components;

— recovery of material from the end of life of final products;

— recycling of ferrous scrap from both the manufacturing process and the end of life of final products

to substitute the use of raw materials from the earth.

The schematic diagram of the full life cycle of steel is shown in Figure 1. This document covers life

cycle stages including sourcing of raw materials from the earth and ferrous scrap, production of steel

products at the steelworks, and recycling of ferrous scrap. It does not cover the manufacturing of final

products and the use of final products.

All global steel production is sourced from different ratios of ferrous scrap and primary ores. Therefore,

an understanding of the value of steel recycling becomes a necessary part of the steel product LCI.

It is generally understood that the recycling of materials makes a positive contribution towards

reducing resource consumption and energy requirements, and helps to avoid the potential impacts of

raw materials extraction and processing. However, all recycling routes (including the processing and

transport of recycled materials) carry environmental burdens and these can be quantified as part of a

life cycle assessment.

A critical factor in the understanding of the benefits of materials recycling is the quality of the materials

and products that can be produced from the recycled material. Where the recycled products can be

made to the same inherent properties as those sourced from primary materials, this is described as

closed loop recycling.

With the existing process and scrap quality controls, steel sourced from (scrap based) steel recycling

can be made to the same specification as steels sourced from the (iron ore based) primary routes.

The properties of the different steel grades are achieved through different alloying concepts as well

as process steps, such as heat treatment. Steel metallurgy allows the control of alloying and tramp

elements to achieve closed loop recycling.

Life cycle assessment can be used to quantify the potential benefits of recycling to conform to the

guidance set out in ISO 14040:2006 and ISO 14044:2006.

vi © ISO 2018 – All rights reserved

Figure 1 — Schematic diagram of the life cycle of steel

INTERNATIONAL STANDARD ISO 20915:2018(E)

Life cycle inventory calculation methodology for steel

products

1 Scope

This document specifies guidelines and requirements for conducting life cycle inventory (LCI) studies

of steel products reflecting steel’s capacity for closed-loop recycling, including:

a) specification of the functional unit used for LCI calculation of steel products;

b) definition of the system boundaries used for LCI calculation of steel products;

c) evaluation of scrap in LCI calculation of steel products;

d) evaluation of co-products in LCI calculation of steel products;

e) reporting of LCI calculation results of steel products.

The application of LCI results, including life cycle impact assessment (LCIA), is outside the scope of this

document.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 14040:2006, Environmental management — Life cycle assessment — Principles and framework

ISO 14044:2006, Environmental management — Life cycle assessment — Requirements and guidelines

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1

steel product

product produced from steel and shipped out from steelworks

EXAMPLE Hot rolled steel, pickled hot rolled steel, cold rolled steel, finished cold rolled steel,

electrogalvanized steel, hot-dip galvanized steel, tin-free steel, tinplated steel, organic coated steel, section,

plate, rebar, engineering steel, wire rod, seamless pipe, UO pipe, welded pipe.

3.2

final product

product that requires no additional transformation prior to its use

EXAMPLE Automobiles, building structures, building envelopes, packaging.

[SOURCE: ISO/TS 18110:2015, 2.2, modified — The example has been added.]

3.3

scrap

iron and steel material in metallic form that is recovered in multiple life cycle stages, including steel

production processes, the manufacturing processes of final products (3.2) and the end of life of final

products, and is recycled as a raw material for steel production

3.4

internal scrap

scrap (3.3) from a crude steel making unit process that is then recycled within the same unit process

[e.g. basic oxygen furnace (BOF) or electric arc furnace (EAF)]

3.5

home scrap

scrap (3.3) from a downstream steel production process within the steelworks (e.g. rolling, coating)

that is returned to steel making processes (e.g. BOF or EAF)

3.6

manufacturing scrap

scrap (3.3) from the manufacturing processes of final products (3.2), such as automobiles and buildings

3.7

end of life scrap

scrap (3.3) from after the end of life of final products (3.2)

3.8

external scrap

scrap (3.3) provided from outside of the steelworks, including manufacturing scrap (3.6) and end of life

scrap (3.7)

3.9

recycling rate

ratio of the mass of external scrap (3.8) recycled to the mass of steel products to be shipped out from

the steelworks gate

3.10

end of life recycling rate

ratio of the mass of end of life scrap (3.7) recycled to the mass of steel in final products (3.2)

3.11

manufacturing yield

ratio of the mass of steel contained in final products (3.2) to the total mass of steel products (3.1) used

for manufacturing the final product

3.12

ferrous raw material

raw material from the earth that becomes one of the main constituents of steel products (3.1), and which

may have undergone intermediate processing to prepare it for ironmaking

EXAMPLE Lump ore, iron ore fine, sinter, pellet, hot briquetted iron (HBI), direct reduced iron (DRI).

3.13

process coal

coal used in iron and steel making processes

EXAMPLE Coking coal, injection coal, sintering coal, BOF coal, EAF coal, DRI coal.

3.14

non-ferrous raw material

non-ferrous ingredient material for steel products (3.1) other than ferrous raw material (3.12) or process

coal (3.13)

EXAMPLE Zinc, tin. aluminium.

2 © ISO 2018 – All rights reserved

3.15

ferro alloy

alloy of iron with non-iron alloy metals, such as manganese, silicon or chromium used in the

steelmaking process

3.16

other input material

material input and consumables for steel production other than ferrous raw material (3.12), process coal

(3.13), non-ferrous raw material (3.14), ferro alloy (3.15) and scrap (3.3), which does not ultimately form

part of the steel product (3.1)

EXAMPLE Refractory, electrode, chemical materials, limestone, dolomite.

3.17

fuel

energy source for generating heat, steam and power other than process gas (3.20)

EXAMPLE Boiler coal, fuel oils, natural gas, LPG.

3.18

industrial gas

gas for steel production other than fuels (3.17) or reducing agent

EXAMPLE Oxygen, nitrogen, argon, hydrogen, carbon dioxide, compressed air.

Note 1 to entry: Hydrogen can be used as a fuel, or is included here as an industrial gas when used as an

uncombusted industrial gas, e.g. for the provision of reducing atmospheres in production processes.

3.19

co-product

any of two or more products coming from the same unit process or product system

[SOURCE: ISO 14044:2006, 3.10]

3.20

process gas

gas that is produced as part of the processes on the steel production site

EXAMPLE Coke oven gas, blast furnace gas, BOF gas.

3.21

waste

materials disposed of in landfills, both internal and external to steel works, or incinerated

4 Basic conditions for LCI of steel products

4.1 General requirements

The requirements and guidelines set in this document shall be followed in addition to those set by

ISO 14040:2006 and ISO 14044:2006.

4.2 Function and functional unit

The function of steel products is to form a part of final products, such as automobiles, cans and bridges.

For a LCI of steel products, the functional unit should be set as a mass-based unit of steel products to

be shipped out from the steelworks gate. Where applications are based on other functional capacities,

suitable explanation and conversion guidance shall be provided.

4.3 System boundary

As shown in Figure 2, the system boundary used for the LCI study of steel products shall include all of

the production steps from input materials (raw materials in the earth, scrap, etc.) to finished products

ready to be shipped from the steelworks, including the recycling of steel products (i.e. cradle to gate).

This includes production processes at the steelworks and all the upstream processes, including energy

conversion, raw material mining, material preparation and transportation of materials to the steelworks

site. The effect of scrap recycling, or the burdens of using scrap and the credits for the recovery of steel

products, should be considered according to the procedure described in 5.3. The calculation of steel

product LCIs should include allocation on scrap to reflect the nature of closed loop recycling. Cradle to

gate LCIs without scrap allocation may be reported when this is aligned to the goals and scope of the

study. Additionally, care should be taken that if no burdens are assigned to scrap inputs, then no credits

should be applied to steel recycling. Also, the recovery and use of steel industry co-products outside of

the steelworks shall be taken into account according to the allocation procedure described in 5.5. The

system boundary does not include the manufacturing of final products using steel products or their use

in the society.

Figure 2 — System boundary

The following items should be excluded from the system boundary. If any of them are included in the

system boundary, this shall be clearly stated and explained.

— Transportation of steel products beyond the gate.

— Transportation of co-products beyond the gate.

— Manufacturing of final products.

— Use of final products.

— Research and development.

— Business travel of employees.

4 © ISO 2018 – All rights reserved

— Production, decommissioning, repair and maintenance of capital goods.

— Cleaning and legal services.

— Marketing.

— Operation of administration offices.

4.4 Data quality

4.4.1 General

The data quality requirements set out in of ISO 14044:2006, 4.2.3.6, should be followed, including time-

related coverage (4.4.2), geographical coverage (4.4.3) and technology coverage (4.4.4).

4.4.2 Time-related coverage

The timeframe of data collection should be one full representative year to adjust for seasonal variations.

If the data set is not possible for a full year, this shall be explained and justified. Moreover, since the LCI

results are prone to change over time for reasons, such as changes in operational rate due to economic

conditions and technological improvements, the time period in which the data are collected shall

be stated clearly. Primary data sets used in LCI studies should not be more than five years old. Any

secondary data used should be less than 10 years old, unless its ongoing validity is justified. When

using data outside of the reference year, the choice shall be explained and justified.

4.4.3 Geographical coverage

An LCI study of steel products may be reported with various geographical representations, for example,

one steelworks, one steel company, national, regional or global coverage. When the study covers

multiple steelworks (or companies, regions, etc.), the geographical coverage and representation should

be clearly stated. The LCI should be presented as a weighted average by the production quantity of the

covered scope, not a simple arithmetic average. For example, Product A produced by sites 1, 2 and 3

with mass M1, M2 and M3 would be averaged as: (LCI1 × M1 + LCI2 × M2 + LCI3 × M3)/(M1 + M2 + M3).

Manufacturers contributing to the LCI shall be documented, and use of the data set shall be noted as

applicable within the bounds of the contributing manufacturers.

4.4.4 Technology coverage

This document covers production technologies of unalloyed steels and alloy steels, as defined in

ISO 4948-1:1982. This document does not cover the production of stainless steel.

4.4.5 Sources of the data

Steel production data shall be directly sourced from steel producers based on primary data, such as

measurement, engineering calculations and purchasing records.

Upstream data produced by suppliers should be used. If the information is not available, secondary

data produced by LCA-related organizations, academic institutions, public institutions, such as regional

and national governments, and steel-related organizations may be used. All secondary data should be

checked for geographical relevance to the LCI.

4.4.6 Cut-off criteria

As stated in ISO 14044:2006, 4.2.3.3.3, the cut-off criteria for initial inclusion of inputs and outputs and

the assumptions on which the cut-off criteria are established shall be clearly described. In particular,

for LCI of steel products, cut-off criteria may be established for all energetic inputs and outputs to the

process stages, including fuels, electricity, steam and other converted energy as well as for all inputs

and outputs to the process stages of ferrous raw materials, process coal and non-ferrous raw materials.

To avoid the need to pursue trivial input and outputs to the system, cut-off criteria should be applied as

follows:

— all energetic inputs to the process stages should be reported including fuels, electricity, steam and

compressed air;

— each excluded material flow should not exceed 1 % of mass, energy or environmental relevance for

each unit process;

— the sum of the excluded material flows in the system should not exceed 5 % of mass, energy or

environmental relevance.

5 Methodological procedure for LCI calculation of steel products with provision

for scrap recycling

5.1 General

The calculation of steel product LCIs should include allocation on scrap to reflect the nature of closed

loop recycling. Cradle to gate LCIs without scrap allocation may be reported when this is aligned to the

goals and scope of the study.

To evaluate the benefits of steel recycling it will be necessary to allocate a LCI value to scrap and to

apply this value to both the inputs (burdens) and outputs (credits) of the system. The reporting of

this will depend upon the goals of the study, but if no burdens are assigned to scrap inputs, then no

credits shall be applied to the external scrap (i.e. end of life and manufacturing scrap). It is important

to be consistent with the allocation of credits and burdens throughout the scope of the life cycle study.

Note also that the value assigned to scrap reflects the initial investment of the primary production of

steel, which if recycled, will be carried forward for future generations. The resulting formulae show

that the LCI burdens of steel in an application are reduced by higher end of life recycling rates (R) and

by improving the yield of the recycling process (y). This indicates that the sustainability of product

designs involving steel products should make provision for high values of R and y.

The LCI for steel products which takes account of scrap recycling is calculated in three stages (see

Figure 3), as follows.

— A: In a first step, the LCI of the steel product to the factory gate is calculated without allocation for

scrap. At this stage, scrap will appear as a mass input but will not be allocated with an LCI (inventory

flows to/from earth related to scrap).

— B: Secondly, an LCI value for scrap (as described in 5.3) is calculated. It is then applied in the

substages B1 and B2 as described below. Both of these steps have to be conducted.

— B1: The LCI value is applied as a burden for the mass of scrap consumed in the process.

— B2: The same LCI value for scrap is credited for the mass of scrap that is going to be recovered.

— Thirdly, by aggregating the three components (A + B1 + B2) the LCI value for the steel product with

consideration for scrap recycling can be determined.

6 © ISO 2018 – All rights reserved

Figure 3 — Illustration of LCI of steel products

5.2 Calculation of cradle to gate LCI without allocation for scrap input

The cradle to gate LCI without a burden for scrap input is calculated process by process by aggregating

the upstream LCI of each input (other than scrap) as well as what happens on-site. An example of

calculation flow is depicted in Figure 4.

Figure 4 — Schematic example of calculation procedure for cradle to gate LCI without allocation

for scrap input

5.3 Allocation for scrap recycling

5.3.1 General

Steel can be recycled into new steel products without loss of inherent properties. Because of this nature,

a closed-loop allocation procedure for the recycling of steel is described in this document; this follows

ISO 14044:2006, 4.3.4.3, which describes the allocation procedures for closed loop material recycling.

Allocation methods shall be clearly documented along with justification.

Detailed guidance for calculation is provided in 5.3.2, 5.3.3 and 5.3.4.

Scrap inputs shall only carry a burden providing that scrap allocations have been applied to system

inputs (burdens) and system outputs (credits) equivalently. This will ensure consistency with

ISO 14044:2006.

5.3.2 LCI calculation methodology for scrap

The LCI of scrap is determined by considering the benefits of producing new steel from scrap compared

with producing the same steel from purely iron ore based process route. Providing that the LCI

associated with the process of recycling scrap (X ) is less than the LCI of producing steel from iron ores

re

(X ), then this will be beneficial to society. In the evaluation of X and X , scrap is assumed to be free

pr re pr

of burdens. The resulting value of the LCI of scrap can then be input into the product LCI study, where

the scrap inputs, scrap outputs, recycling rates and recycling yields are known. This LCI of 1 kg of scrap,

X , can be calculated from Formula (1):

sc

XX=−Xy× (1)

()

sc pr re

where

X is the LCI of producing 1 kg of crude steel without steel scrap;

pr

X is the LCI of producing 1 kg of crude steel only from steel scrap;

re

y is the yield of crude steel in the X route (the mass of crude steel per 1 kg of scrap input).

re

The values for X and y may be obtained as primary data or as secondary data from reliable sources.

re

In practice, it is rare for steel to be produced without scrap inputs. Therefore, X is a theoretical value

pr

based upon calculations derived from real data sets. The approach to these calculations is given in

Annex A. One of the methods is an extrapolation of LCI data values for sets of data from iron ore based

process routes with varying degrees of scrap inputs (typically from 3 % up to 20 %), which can then be

extrapolated to estimate zero scrap (0 %) input value for the iron ore based process route (X ). This

pr

method can be useful when analysing specific LCI values but becomes less practical to apply across all

LCI values. The alternative is described in Annex A.

5.3.3 Calculation of the burden for scrap input to produce the specific steel product under study

The burden for scrap input to produce one functional unit of a specific steel product under study, B1,

can be calculated shown by Formula (2):

BX1=×M (2)

sc sc

8 © ISO 2018 – All rights reserved

where

X is the LCI of scrap [see Formula (1)];

sc

M is the mass of scrap used for producing one functional unit (e.g. 1 kg) of steel products.

sc

5.3.4 Calculation of the credits for scrap recovery

The credit for scrap recovery, B2, is calculated as shown by Formula (3):

BX2=×R (3)

sc

where

X is the LCI of scrap [see Formula (1)];

sc

R is the recycling rate.

The recycling rate, R, is calculated as shown by Formula (4):

Ra=+bP/ (4)

()

where

a is the mass of manufacturing scrap recycled;

b is the mass of end of life scrap recycled;

P is the mass of steel products shipped out of the gate.

Moreover, the end of life recycling rate, β, is calculated as shown by Formula (5):

β =bF/ (5)

where

b is the mass of end of life scrap recycled;

F is the mass of steel products contained in the final product.

Depending on the goals and scope of the study, either of these recycling rates may be used.

Details for calculating the recycling rate are given in Annex E.

5.4 Collecting data

5.4.1 General

In the system boundary described in 4.3, all inputs and outputs of materials, energy and co-products

across each unit process shall be captured.

5.4.2 Co-products

Among the outputs listed in Table 1, those which are used beneficially are co-products of steel

production. Co-products other than main products (coke, hot metal, slab, bloom, billet, steel products)

shall be allocated in accordance with 5.5. If there are co-products other than those listed in Table 1,

they can also be allocated.

Table 1 — Examples of main outputs from iron and steel making processes

Processes Main outputs/co-products

Coke making Coke

Light oil

Benzene

Tar

Toluene

Xylene

Sulfur

Ammonia

Coke oven gas

Recovered steam

Iron making Hot metal

Blast furnace gas

Slag

Dust

Recovered electricity

Steel making (basic oxygen Steel (slab, bloom, billet)

furnace, BOF) + casting

BOF gas

Slag

Dust

Recovered steam

Scrap (internal scrap)

Steel making (electric arc Steel (slab, bloom, billet)

furnace, EAF) + casting

Slag

Dust

Electrode

Scrap (internal scrap)

Other processes Steel products

Iron powder

Zinc oxide

Dross

Sludge

Dust

Recovered steam

Recovered electricity

Scrap (home scrap)

Scale

5.4.3 Ferrous raw materials

Many of these iron resources are processed before used in steel production. Cradle to gate LCIs

associated with processing of raw materials, such as direct reduced iron (DRI) making, pelletizing, hot

briquetted iron (HBI) making and sintering, shall be included, both for the cases where the processing

is done in-house and external to the steelworks.

If no primary data or upstream data are available, the LCI may be based on secondary and literature data.

10 © ISO 2018 – All rights reserved

5.4.4 Process coal

For the iron and steel making processes, different kinds of coals are used (coking coal, injection coal,

sintering coal, DRI coal, BOF coal, EAF coal and other coals for iron and steel making processes) and

appropriate LCIs shall be collected separately for those types of coal. For each of these types, an average

value (e.g. national or regional, whichever is deemed to be most appropriate) shall be used to reflect the

wide variety of their characteristics.

The LCI for coal shall consider the whole supply chain from coal mining to coal processing as well as the

transport to the coal terminal of the source country. All relevant process steps and technologies shall

be covered; the data shall be representative of deep coal mining and open cast mining. The LCI may be

based on secondary and literature data as applicable for the coal used.

Regarding methane emissions, the net value shall be provided (occurring mine methane emissions

minus the use of captured mine methane).

As for process coal, all the upstream LCI of process coal shall be considered.

5.4.5 Non-ferrous raw materials

As for non-ferrous raw materials, all the upstream LCI of non-ferrous raw materials shall be considered.

5.4.6 Ferro alloy

As for ferro alloys, the upstream LCI of all ferro alloys shall be considered.

5.4.7 Other input materials

As for other input materials, all the upstream LCI of these materials shall be considered. Minor material

inputs may be omitted in accordance with the cut-off criteria as defined by the person who is conducting

the LCI calculation.

5.4.8 Fuels

Upstream LCI of fuel production should cover mining, processing and transportation.

5.4.9 Process gases

Process gases are produced from blast furnaces, coke ovens and BOF. Process gases can be used as

energy sources within and outside steelworks. Therefore, data on the amount produced and used

should be collected.

Process gases are used as energy sources for steel production processes within the steelworks and

partially as energy sources for electricity generation facilities on or off the steelworks. For this reason,

the generation of process gases shall be equal to the sum of the use of process gases on-site and the

amount exported and flared.

Process gas can be either used to produce thermal energy or electricity. Surplus gas that is not used

on-site but that is exported beyond the system boundaries is also used to replace thermal energy or is

supplied to local power stations to generate electricity.

Generally, the alternative fuel to process gases would be coal, fuel oil or natural gas for the production

of thermal energy.

In case of electricity the national/regional grid should be used as replaced energy. The replaced fuel or

electricity is determined by the site as part of the data collection process and the national grid mix for

the country of location.

When process gases are partially exported outside the steelworks or boundary of the steel product

LCI, the choice of equivalent fuel should be justified and reported. For example, where process gases

are exported outside of the steelworks to an electricity generation facility nearby, the credit should be

equivalent to the fuels that are avoided in the electricity generation of the local electricity grid (system

expansion).

5.4.10 Electricity

Electricity may be supplied from the grid or generated on-site. Data should be collected for each source

used (see Annex F).

5.4.11 Steam

Steam may be supplied from outside of the steelworks or generated on-site. Data should be collected for

each source used (see Annex F).

5.4.12 Sea water

Data on sea water used for once-through cooling of condensers, heat exchangers, furnaces, etc. shall be

collected.

Data on electricity consumption associated with intake and drainage of sea water shall be collected.

Emission of chemical agents associated with sea water shall be collected.

All other uses of sea water shall be collected.

5.4.13 Fresh water

Fresh water is supplied as circulating cooling water and as a source of process water, such as de-ionized

water. The amount of water shall be collected.

Data on electricity consumption and chemical inputs associated with intake and drainage facilities, de-

ionizer, water treatment facility and fresh water circulating facility shall be collected.

Data on emissions to water associated with drainage shall be collected.

5.4.14 Industrial gases

When industrial gases are supplied from outside of the steelworks, the upstream LCI of production and

transportation of those gases shall be collected.

When industrial gases are produced on-site, inventories are calculated from consumed utilities, such as

electricity and materials.

5.4.15 Emissions to air, water and soil

A list of all emissions to air, water and soil to be included in the study shall be defined and collected for

each process stage. Emissions, such as CO , that cannot be measured directly should be calculated from

available information, such as energy consumption and/or appropriate emission factors.

5.4.16 Flares

Data on flares of blast furnace gas, coke oven gas and BOF gas should be measured and all known

emissions included.

When the quantity of flares cannot be measured directly, the amount of flared gas may be calculated

either as the difference between the generation and the use of process gas, or as the difference between

the balance of carbon content of hot metal, input carbon used as heat source and carbon content of

recovered BOF gases. The emissions associated with flaring shall also be included.

12 © ISO 2018 – All rights reserved

---------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...