ISO 13485:2016

(Main)Medical devices — Quality management systems — Requirements for regulatory purposes

Medical devices — Quality management systems — Requirements for regulatory purposes

ISO 13485:2016 specifies requirements for a quality management system where an organization needs to demonstrate its ability to provide medical devices and related services that consistently meet customer and applicable regulatory requirements. Such organizations can be involved in one or more stages of the life-cycle, including design and development, production, storage and distribution, installation, or servicing of a medical device and design and development or provision of associated activities (e.g. technical support). ISO 13485:2016 can also be used by suppliers or external parties that provide product, including quality management system-related services to such organizations. Requirements of ISO 13485:2016 are applicable to organizations regardless of their size and regardless of their type except where explicitly stated. Wherever requirements are specified as applying to medical devices, the requirements apply equally to associated services as supplied by the organization. The processes required by ISO 13485:2016 that are applicable to the organization, but are not performed by the organization, are the responsibility of the organization and are accounted for in the organization's quality management system by monitoring, maintaining, and controlling the processes. If applicable regulatory requirements permit exclusions of design and development controls, this can be used as a justification for their exclusion from the quality management system. These regulatory requirements can provide alternative approaches that are to be addressed in the quality management system. It is the responsibility of the organization to ensure that claims of conformity to ISO 13485:2016 reflect any exclusion of design and development controls. If any requirement in Clauses 6, 7 or 8 of ISO 13485:2016 is not applicable due to the activities undertaken by the organization or the nature of the medical device for which the quality management system is applied, the organization does not need to include such a requirement in its quality management system. For any clause that is determined to be not applicable, the organization records the justification as described in 4.2.2.

Dispositifs médicaux — Systèmes de management de la qualité — Exigences à des fins réglementaires

L'ISO 13485:2016 énonce les exigences relatives au système de management de la qualité lorsqu'un organisme doit démontrer son aptitude à fournir régulièrement des dispositifs médicaux et des services associés conformes aux exigences des clients et aux exigences réglementaires applicables. Ces organismes peuvent être impliqués dans une ou plusieurs étapes du cycle de vie incluant la conception et le développement, la production, le stockage et la distribution, l'installation ou les prestations associées d'un dispositif médical, ainsi que la conception, le développement ou la prestation d'activités associées (par exemple support technique). L'ISO 13485:2016 peut également être utilisée par les fournisseurs ou les parties externes qui fournissent des produits, notamment des services associés au système de management de la qualité à de tels organismes. Les exigences de L'ISO 13485:2016 s'appliquent aux organismes, indépendamment de leur taille ou de leur nature, à l'exception des cas où cela est clairement indiqué. Lorsque les exigences s'appliquent effectivement aux dispositifs médicaux, elles s'appliquent également aux services associés fournis par l'organisme. Les processus requis par l'ISO 13485:2016, qui sont applicables à l'organisme, mais non mis en ?uvre par celui-ci, relèvent de la responsabilité de ce dernier qui en tient compte dans son système de management de la qualité en surveillant, en tenant à jour et en maîtrisant les processus. Le fait que des exigences réglementaires applicables autorisent l'exclusion des systèmes de contrôle de conception et de développement peut servir à justifier leur exclusion du système de management de la qualité. Ces exigences réglementaires peuvent prévoir d'autres approches qu'il faut appliquer dans le système de management de la qualité. Il incombe à l'organisme de s'assurer que ses demandes de conformité à l'ISO 13485:2016 correspondent à toute exclusion des systèmes de contrôle de conception et de développement. Lorsqu'une exigence définie à l'Article 6, 7 ou 8 de l'ISO 13485:2016 ne peut être appliquée en raison des activités entreprises par l'organisme ou de la nature du dispositif médical auquel s'applique le système de management de la qualité, l'organisme n'est pas tenu d'inclure cette exigence dans son système de management de la qualité. Pour les paragraphes apparaissant comme non applicables, l'organisme enregistre la justification comme cela est décrit en 4.2.2.

General Information

- Status

- Published

- Publication Date

- 24-Feb-2016

- Technical Committee

- ISO/TC 210 - Quality management and corresponding general aspects for medical devices

- Drafting Committee

- ISO/TC 210/WG 1 - Application of quality systems to medical devices

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 31-Oct-2025

- Completion Date

- 12-Feb-2026

Relations

- Effective Date

- 12-Feb-2026

- Consolidated By

ISO 8331:2016 - Rubber and plastics hoses and hose assemblies — Guidelines for selection, storage, use and maintenance - Effective Date

- 06-Jun-2022

- Effective Date

- 13-Feb-2016

- Revises

ISO 13485:2003 - Medical devices — Quality management systems — Requirements for regulatory purposes - Effective Date

- 14-May-2011

Overview

ISO 13485:2016 - Medical devices - Quality management systems - Requirements for regulatory purposes - specifies requirements for a quality management system (QMS) for organizations that design, produce, install, distribute or service medical devices. The standard focuses on demonstrating consistent ability to meet customer and applicable regulatory requirements across the medical device life‑cycle. ISO 13485:2016 is applicable to organizations of any size or type and can also be adopted by suppliers and external parties providing goods or QMS‑related services to the medical device sector.

Key topics and requirements

ISO 13485:2016 structures its QMS requirements around a process approach and includes (but is not limited to) the following technical topics:

- Quality management system and documentation (general QMS requirements, document and record control)

- Management responsibility (leadership, quality policy, management review, customer focus)

- Resource management (human resources, infrastructure, work environment)

- Product realization (planning, customer‑related processes, design and development, purchasing, production and service provision)

- Monitoring, measurement and improvement (control of monitoring/measurement devices, control of nonconforming product, corrective actions, data analysis)

- Regulatory alignment (identifying and incorporating applicable regulatory requirements; justification and recording of any excluded design and development controls per clause 4.2.2)

- Supplier and outsourced process control (organizations are responsible for processes they do not perform and must monitor, maintain and control those processes)

- Risk‑focused elements (process effectiveness, meeting safety/performance regulatory expectations)

(The content mirrors major clauses 4–8 of the standard and emphasizes regulatory‑driven requirements for medical devices.)

Applications - who uses ISO 13485:2016

- Medical device manufacturers (designers, OEMs)

- Contract manufacturers, sterilization and calibration service providers

- Distributors, importers and authorized representatives

- Suppliers contracted for QMS‑related services

- Regulatory affairs teams and conformity assessment/certification bodies

ISO 13485:2016 is widely used to support regulatory submissions, supplier qualification, product launch controls, and to demonstrate conformity for market access.

Benefits / Practical value

- Harmonizes QMS requirements for regulatory compliance across jurisdictions

- Improves product safety, traceability and consistency of device performance

- Facilitates supplier control and outsourced process accountability

- Supports certification and confidence in regulatory audits and market acceptance

Related standards

- ISO 9001 (format and process approach relationship; differences explained in Annex A)

- ISO 9000:2005 (fundamentals and vocabulary)

- Guidance: ISO/TR 14969 (application guidance for ISO 13485)

Keywords: ISO 13485:2016, medical devices, quality management system, regulatory requirements, design and development, supplier control, certification.

ISO 13485:2016 - Medical devices -- Quality management systems -- Requirements for regulatory purposes

REDLINE ISO 13485:2016 - Medical devices -- Quality management systems -- Requirements for regulatory purposes

ISO 13485:2016 - Dispositifs médicaux -- Systèmes de management de la qualité -- Exigences à des fins réglementaires

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

Sponsored listings

Frequently Asked Questions

ISO 13485:2016 is a standard published by the International Organization for Standardization (ISO). Its full title is "Medical devices — Quality management systems — Requirements for regulatory purposes". This standard covers: ISO 13485:2016 specifies requirements for a quality management system where an organization needs to demonstrate its ability to provide medical devices and related services that consistently meet customer and applicable regulatory requirements. Such organizations can be involved in one or more stages of the life-cycle, including design and development, production, storage and distribution, installation, or servicing of a medical device and design and development or provision of associated activities (e.g. technical support). ISO 13485:2016 can also be used by suppliers or external parties that provide product, including quality management system-related services to such organizations. Requirements of ISO 13485:2016 are applicable to organizations regardless of their size and regardless of their type except where explicitly stated. Wherever requirements are specified as applying to medical devices, the requirements apply equally to associated services as supplied by the organization. The processes required by ISO 13485:2016 that are applicable to the organization, but are not performed by the organization, are the responsibility of the organization and are accounted for in the organization's quality management system by monitoring, maintaining, and controlling the processes. If applicable regulatory requirements permit exclusions of design and development controls, this can be used as a justification for their exclusion from the quality management system. These regulatory requirements can provide alternative approaches that are to be addressed in the quality management system. It is the responsibility of the organization to ensure that claims of conformity to ISO 13485:2016 reflect any exclusion of design and development controls. If any requirement in Clauses 6, 7 or 8 of ISO 13485:2016 is not applicable due to the activities undertaken by the organization or the nature of the medical device for which the quality management system is applied, the organization does not need to include such a requirement in its quality management system. For any clause that is determined to be not applicable, the organization records the justification as described in 4.2.2.

ISO 13485:2016 specifies requirements for a quality management system where an organization needs to demonstrate its ability to provide medical devices and related services that consistently meet customer and applicable regulatory requirements. Such organizations can be involved in one or more stages of the life-cycle, including design and development, production, storage and distribution, installation, or servicing of a medical device and design and development or provision of associated activities (e.g. technical support). ISO 13485:2016 can also be used by suppliers or external parties that provide product, including quality management system-related services to such organizations. Requirements of ISO 13485:2016 are applicable to organizations regardless of their size and regardless of their type except where explicitly stated. Wherever requirements are specified as applying to medical devices, the requirements apply equally to associated services as supplied by the organization. The processes required by ISO 13485:2016 that are applicable to the organization, but are not performed by the organization, are the responsibility of the organization and are accounted for in the organization's quality management system by monitoring, maintaining, and controlling the processes. If applicable regulatory requirements permit exclusions of design and development controls, this can be used as a justification for their exclusion from the quality management system. These regulatory requirements can provide alternative approaches that are to be addressed in the quality management system. It is the responsibility of the organization to ensure that claims of conformity to ISO 13485:2016 reflect any exclusion of design and development controls. If any requirement in Clauses 6, 7 or 8 of ISO 13485:2016 is not applicable due to the activities undertaken by the organization or the nature of the medical device for which the quality management system is applied, the organization does not need to include such a requirement in its quality management system. For any clause that is determined to be not applicable, the organization records the justification as described in 4.2.2.

ISO 13485:2016 is classified under the following ICS (International Classification for Standards) categories: 03.100.70 - Management systems; 03.120.10 - Quality management and quality assurance; 11.040.01 - Medical equipment in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 13485:2016 has the following relationships with other standards: It is inter standard links to EN ISO 13485:2016, ISO 8331:2016, ISO/TR 14969:2004, ISO 13485:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ISO 13485:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 13485

Third edition

2016-03-01

Medical devices — Quality

management systems —

Requirements for regulatory purposes

Dispositifs médicaux — Systèmes de management de la qualité —

Exigences à des fins réglementaires

Reference number

©

ISO 2016

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

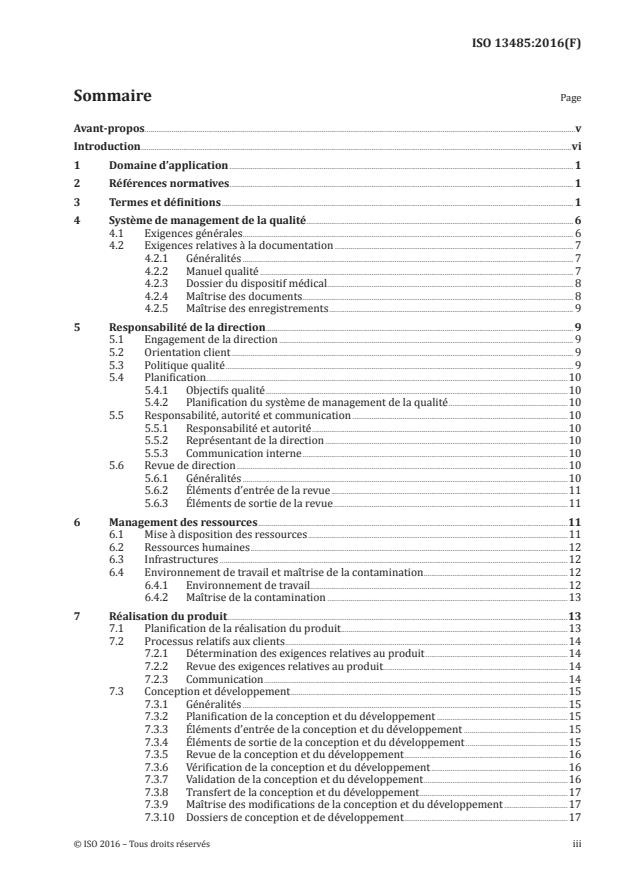

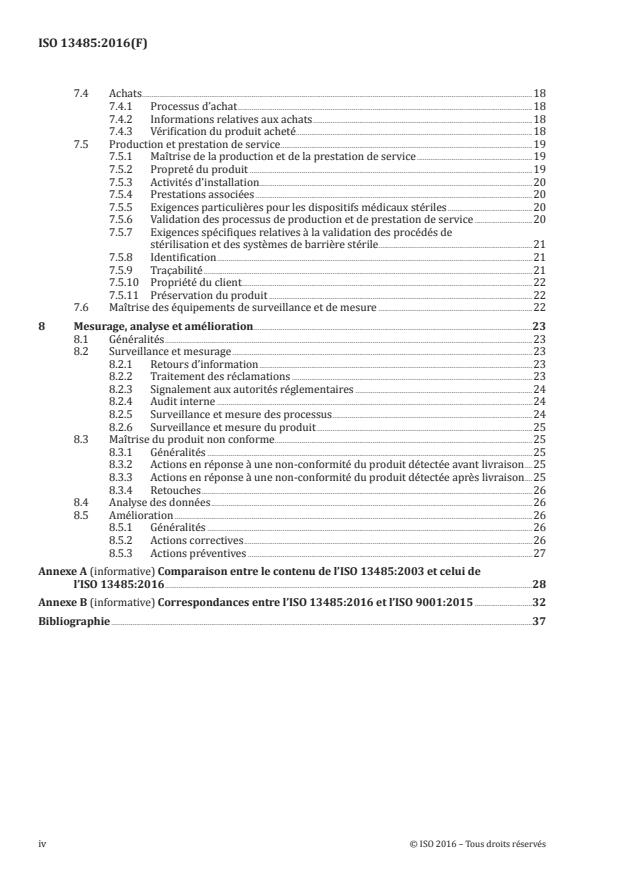

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Quality management system . 6

4.1 General requirements . 6

4.2 Documentation requirements. 7

4.2.1 General. 7

4.2.2 Quality manual . 7

4.2.3 Medical device file . 7

4.2.4 Control of documents . 8

4.2.5 Control of records . 8

5 Management responsibility . 9

5.1 Management commitment . 9

5.2 Customer focus . 9

5.3 Quality policy . 9

5.4 Planning . 9

5.4.1 Quality objectives . 9

5.4.2 Quality management system planning . 9

5.5 Responsibility, authority and communication .10

5.5.1 Responsibility and authority .10

5.5.2 Management representative .10

5.5.3 Internal communication .10

5.6 Management review .10

5.6.1 General.10

5.6.2 Review input .10

5.6.3 Review output .11

6 Resource management .11

6.1 Provision of resources .11

6.2 Human resources .11

6.3 Infrastructure .12

6.4 Work environment and contamination control .12

6.4.1 Work environment .12

6.4.2 Contamination control .12

7 Product realization .12

7.1 Planning of product realization .12

7.2 Customer-related processes .13

7.2.1 Determination of requirements related to product .13

7.2.2 Review of requirements related to product .13

7.2.3 Communication .14

7.3 Design and development .14

7.3.1 General.14

7.3.2 Design and development planning .14

7.3.3 Design and development inputs .14

7.3.4 Design and development outputs .15

7.3.5 Design and development review .15

7.3.6 Design and development verification .15

7.3.7 Design and development validation .15

7.3.8 Design and development transfer .16

7.3.9 Control of design and development changes .16

7.3.10 Design and development files .16

7.4 Purchasing .17

7.4.1 Purchasing process .17

7.4.2 Purchasing information .17

7.4.3 Verification of purchased product .17

7.5 Production and service provision .18

7.5.1 Control of production and service provision .18

7.5.2 Cleanliness of product .18

7.5.3 Installation activities .18

7.5.4 Servicing activities .19

7.5.5 Particular requirements for sterile medical devices.19

7.5.6 Validation of processes for production and service provision .19

7.5.7 Particular requirements for validation of processes for sterilization and

sterile barrier systems .19

7.5.8 Identification .20

7.5.9 Traceability .20

7.5.10 Customer property .20

7.5.11 Preservation of product .20

7.6 Control of monitoring and measuring equipment .21

8 Measurement, analysis and improvement .22

8.1 General .22

8.2 Monitoring and measurement .22

8.2.1 Feedback .22

8.2.2 Complaint handling .22

8.2.3 Reporting to regulatory authorities .23

8.2.4 Internal audit .23

8.2.5 Monitoring and measurement of processes .23

8.2.6 Monitoring and measurement of product .23

8.3 Control of nonconforming product .24

8.3.1 General.24

8.3.2 Actions in response to nonconforming product detected before delivery .24

8.3.3 Actions in response to nonconforming product detected after delivery .24

8.3.4 Rework .24

8.4 Analysis of data .24

8.5 Improvement .25

8.5.1 General.25

8.5.2 Corrective action .25

8.5.3 Preventive action .25

Annex A (informative) Comparison of content between ISO 13485:2003 and ISO 13485:2016 .27

Annex B (informative) Correspondence between ISO 13485:2016 and ISO 9001:2015 .30

Bibliography .36

iv © ISO 2016 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www.iso.org/iso/foreword.html.

The committee responsible for this document is Technical Committee ISO/TC 210, Quality management

and corresponding general aspects for medical devices.

This third edition of ISO 13485 cancels and replaces the second edition (ISO 13485:2003) and

ISO/TR 14969:2004, which have been technically revised. It also incorporates the Technical

Corrigendum ISO 13485:2003/Cor.1:2009. A summary of the changes incorporated into this edition

compared with the previous edition is given in Annex A.

Introduction

0.1 General

This International Standard specifies requirements for a quality management system that can be used by

an organization involved in one or more stages of the life-cycle of a medical device, including design and

development, production, storage and distribution, installation, servicing and final decommissioning

and disposal of medical devices, and design and development, or provision of associated activities (e.g.

technical support). The requirements in this International Standard can also be used by suppliers or

other external parties providing product (e.g. raw materials, components, subassemblies, medical

devices, sterilization services, calibration services, distribution services, maintenance services) to such

organizations. The supplier or external party can voluntarily choose to conform to the requirements of

this International Standard or can be required by contract to conform.

Several jurisdictions have regulatory requirements for the application of quality management systems

by organizations with a variety of roles in the supply chain for medical devices. Consequently, this

International Standard expects that the organization:

— identifies its role(s) under applicable regulatory requirements;

— identifies the regulatory requirements that apply to its activities under these roles;

— incorporates these applicable regulatory requirements within its quality management system.

The definitions in applicable regulatory requirements differ from nation to nation and region to region.

The organization needs to understand how the definitions in this International Standard will be

interpreted in light of regulatory definitions in the jurisdictions in which the medical devices are made

available.

This International Standard can also be used by internal and external parties, including certification

bodies, to assess the organization’s ability to meet customer and regulatory requirements applicable

to the quality management system and the organization’s own requirements. It is emphasized that the

quality management system requirements specified in this International Standard are complementary

to the technical requirements for product that are necessary to meet customer and applicable

regulatory requirements for safety and performance.

The adoption of a quality management system is a strategic decision of an organization. The design and

implementation of an organization’s quality management system is influenced by the:

a) organizational environment, changes in that environment, and the influence that the organizational

environment has on the conformity of the medical devices;

b) organization’s varying needs;

c) organization’s particular objectives;

d) product the organization provides;

e) processes the organization employs;

f) organization’s size and organizational structure;

g) regulatory requirements applicable to the organization’s activities.

It is not the intent of this International Standard to imply the need for uniformity in the structure of

different quality management systems, uniformity of documentation or alignment of documentation to

the clause structure of this International Standard.

There is a wide variety of medical devices and some of the particular requirements of this International

Standard only apply to named groups of medical devices. These groups are defined in Clause 3.

vi © ISO 2016 – All rights reserved

0.2 Clarification of concepts

In this International Standard, the following terms or phrases are used in the context described below.

— When a requirement is qualified by the phrase “as appropriate”, it is deemed to be appropriate unless

the organization can justify otherwise. A requirement is considered appropriate if it is necessary for:

— product to meet requirements;

— compliance with applicable regulatory requirements;

— the organization to carry out corrective action;

— the organization to manage risks.

— When the term “risk” is used, the application of the term within the scope of this International

Standard pertains to safety or performance requirements of the medical device or meeting

applicable regulatory requirements.

— When a requirement is required to be “documented”, it is also required to be established,

implemented and maintained.

— When the term “product” is used, it can also mean “service”. Product applies to output that is

intended for, or required by, a customer, or any intended output resulting from a product realization

process.

— When the term “regulatory requirements” is used, it encompasses requirements contained in any

law applicable to the user of this International Standard (e.g. statutes, regulations, ordinances or

directives). The application of the term “regulatory requirements” is limited to requirements for the

quality management system and the safety or performance of the medical device.

In this International Standard, the following verbal forms are used:

— “shall” indicates a requirement;

— “should” indicates a recommendation;

— “may” indicates a permission;

— “can” indicates a possibility or a capability.

Information marked as “NOTE” is for guidance in understanding or clarifying the associated

requirement.

0.3 Process approach

This International Standard is based on a process approach to quality management. Any activity that

receives input and converts it to output can be considered as a process. Often the output from one

process directly forms the input to the next process.

For an organization to function effectively, it needs to identify and manage numerous linked processes.

The application of a system of processes within an organization, together with the identification and

interactions of these processes, and their management to produce the desired outcome, can be referred

to as the “process approach.”

When used within a quality management system, such an approach emphasizes the importance of:

a) understanding and meeting requirements;

b) considering processes in terms of added value;

c) obtaining results of process performance and effectiveness;

d) improving processes based on objective measurement.

0.4 Relationship with ISO 9001

While this is a stand-alone standard, it is based on ISO 9001:2008, which has been superseded by

ISO 9001:2015. For the convenience of users, Annex B shows the correspondence between this

International Standard and ISO 9001:2015.

This International Standard is intended to facilitate global alignment of appropriate regulatory

requirements for quality management systems applicable to organizations involved in one or more

stages of the life-cycle of a medical device. This International Standard includes some particular

requirements for organizations involved in the life-cycle of medical devices and excludes some

of the requirements of ISO 9001 that are not appropriate as regulatory requirements. Because of

these exclusions, organizations whose quality management systems conform to this International

Standard cannot claim conformity to ISO 9001 unless their quality management system meets all the

requirements of ISO 9001.

0.5 Compatibility with other management systems

This International Standard does not include requirements specific to other management systems,

such as those particular to environmental management, occupational health and safety management,

or financial management. However, this International Standard enables an organization to align or

integrate its own quality management system with related management system requirements. It is

possible for an organization to adapt its existing management system(s) in order to establish a quality

management system that complies with the requirements of this International Standard.

viii © ISO 2016 – All rights reserved

INTERNATIONAL STANDARD ISO 13485:2016(E)

Medical devices — Quality management systems —

Requirements for regulatory purposes

1 Scope

This International Standard specifies requirements for a quality management system where an

organization needs to demonstrate its ability to provide medical devices and related services that

consistently meet customer and applicable regulatory requirements. Such organizations can be involved

in one or more stages of the life-cycle, including design and development, production, storage and

distribution, installation, or servicing of a medical device and design and development or provision of

associated activities (e.g. technical support). This International Standard can also be used by suppliers

or external parties that provide product, including quality management system-related services to such

organizations.

Requirements of this International Standard are applicable to organizations regardless of their size

and regardless of their type except where explicitly stated. Wherever requirements are specified as

applying to medical devices, the requirements apply equally to associated services as supplied by the

organization.

The processes required by this International Standard that are applicable to the organization, but

are not performed by the organization, are the responsibility of the organization and are accounted

for in the organization’s quality management system by monitoring, maintaining, and controlling the

processes.

If applicable regulatory requirements permit exclusions of design and development controls, this can

be used as a justification for their exclusion from the quality management system. These regulatory

requirements can provide alternative approaches that are to be addressed in the quality management

system. It is the responsibility of the organization to ensure that claims of conformity to this

International Standard reflect any exclusion of design and development controls.

If any requirement in Clauses 6, 7 or 8 of this International Standard is not applicable due to the

activities undertaken by the organization or the nature of the medical device for which the quality

management system is applied, the organization does not need to include such a requirement in its

quality management system. For any clause that is determined to be not applicable, the organization

records the justification as described in 4.2.2.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

1)

ISO 9000:2015 , Quality management systems — Fundamentals and vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 9000:2015 and the

following apply.

1) Supersedes ISO 9000:2005.

3.1

advisory notice

notice issued by the organization, subsequent to delivery of the medical device, to provide supplementary

information or to advise on action to be taken in the:

— use of a medical device,

— modification of a medical device,

— return of the medical device to the organization that supplied it, or

— destruction of a medical device

Note 1 to entry: Issuance of an advisory notice can be required to comply with applicable regulatory requirements.

3.2

authorized representative

natural or legal person established within a country or jurisdiction who has received a written mandate

from the manufacturer to act on his behalf for specified tasks with regard to the latter’s obligations

under that country or jurisdiction’s legislation

[SOURCE: GHTF/SG1/N055:2009, 5.2]

3.3

clinical evaluation

assessment and analysis of clinical data pertaining to a medical device to verify the clinical safety and

performance of the device when used as intended by the manufacturer

[SOURCE: GHTF/SG5/N4:2010, Clause 4]

3.4

complaint

written, electronic or oral communication that alleges deficiencies related to the identity, quality,

durability, reliability, usability, safety or performance of a medical device that has been released from

the organization’s control or related to a service that affects the performance of such medical devices

Note 1 to entry: This definition of “complaint” differs from the definition given in ISO 9000:2015.

3.5

distributor

natural or legal person in the supply chain who, on his own behalf, furthers the availability of a medical

device to the end user

Note 1 to entry: More than one distributor may be involved in the supply chain.

Note 2 to entry: Persons in the supply chain involved in activities such as storage and transport on behalf of the

manufacturer, importer or distributor, are not distributors under this definition.

[SOURCE: GHTF/SG1/N055:2009, 5.3]

3.6

implantable medical device

medical device which can only be removed by medical or surgical intervention and which is intended to:

— be totally or partially introduced into the human body or a natural orifice, or

— replace an epithelial surface or the surface of the eye, and

— remain after the procedure for at least 30 days

Note 1 to entry: This definition of implantable medical device includes active implantable medical device

2 © ISO 2016 – All rights reserved

3.7

importer

natural or legal person in the supply chain who is the first in a supply chain to make a medical device,

manufactured in another country or jurisdiction, available in the country or jurisdiction where it is to

be marketed

[SOURCE: GHTF/SG1/N055:2009, 5.4]

3.8

labelling

label, instructions for use, and any other information that is related to identification, technical

description, intended purpose and proper use of the medical device, but excluding shipping documents

[SOURCE: GHTF/SG1/N70:2011, Clause 4]

3.9

life-cycle

all phases in the life of a medical device, from the initial conception to final decommissioning and

disposal

[SOURCE: ISO 14971:2007, 2.7]

3.10

manufacturer

natural or legal person with responsibility for design and/or manufacture of a medical device with the

intention of making the medical device available for use, under his name; whether or not such a medical

device is designed and/or manufactured by that person himself or on his behalf by another person(s)

Note 1 to entry: This “natural or legal person” has ultimate legal responsibility for ensuring compliance with

all applicable regulatory requirements for the medical devices in the countries or jurisdictions where it is

intended to be made available or sold, unless this responsibility is specifically imposed on another person by the

Regulatory Authority (RA) within that jurisdiction.

Note 2 to entry: The manufacturer’s responsibilities are described in other GHTF guidance documents. These

responsibilities include meeting both pre-market requirements and post-market requirements, such as adverse

event reporting and notification of corrective actions.

Note 3 to entry: “Design and/or manufacture”, as referred to in the above definition, may include specification

development, production, fabrication, assembly, processing, packaging, repackaging, labelling, relabelling,

sterilization, installation, or remanufacturing of a medical device; or putting a collection of devices, and possibly

other products, together for a medical purpose.

Note 4 to entry: Any person who assembles or adapts a medical device that has already been supplied by another

person for an individual patient, in accordance with the instructions for use, is not the manufacturer, provided

the assembly or adaptation does not change the intended use of the medical device.

Note 5 to entry: Any person who changes the intended use of, or modifies, a medical device without acting on

behalf of the original manufacturer and who makes it available for use under his own name, should be considered

the manufacturer of the modified medical device.

Note 6 to entry: An authorized representative, distributor or importer who only adds its own address and

contact details to the medical device or the packaging, without covering or changing the existing labelling, is not

considered a manufacturer.

Note 7 to entry: To the extent that an accessory is subject to the regulatory requirements of a medical device, the

person responsible for the design and/or manufacture of that accessory is considered to be a manufacturer.

[SOURCE: GHTF/SG1/N055:2009, 5.1]

3.11

medical device

instrument, apparatus, implement, machine, appliance, implant, reagent for in vitro use, software,

material or other similar or related article, intended by the manufacturer to be used, alone or in

combination, for human beings, for one or more of the specific medical purpose(s) of:

— diagnosis, prevention, monitoring, treatment or alleviation of disease;

— diagnosis, monitoring, treatment, alleviation of or compensation for an injury;

— investigation, replacement, modification, or support of the anatomy or of a physiological process;

— supporting or sustaining life;

— control of conception;

— disinfection of medical devices;

— providing information by means of in vitro examination of specimens derived from the human body;

and does not achieve its primary intended action by pharmacological, immunological or metabolic

means, in or on the human body, but which may be assisted in its intended function by such means

Note 1 to entry: Products which may be considered to be medical devices in some jurisdictions but not in others

include:

— disinfection substances;

— aids for persons with disabilities;

— devices incorporating animal and/or human tissues;

— devices for in vitro fertilization or assisted reproduction technologies.

[SOURCE: GHTF/SG1/N071:2012, 5.1]

3.12

medical device family

group of medical devices manufactured by or for the same organization and having the same basic

design and performance characteristics related to safety, intended use and function

3.13

performance evaluation

assessment and analysis of data to establish or verify the ability of an in vitro diagnostic medical device

to achieve its intended use

3.14

post-market surveillance

systematic process to collect and analyse experience gained from medical devices that have been placed

on the market

3.15

product

result of a process

Note 1 to entry: There are four generic product categories, as follows:

— services (e.g. transport);

— software (e.g. computer program, dictionary);

— hardware (e.g. engine mechanical part);

— processed materials (e.g. lubricant).

4 © ISO 2016 – All rights reserved

Many products comprise elements belonging to different generic product categories. Whether the product is

then called service, software, hardware or processed material depends on the dominant element. For example,

the offered product “automobile” consists of hardware (e.g. tyres), processed materials (e.g. fuel, cooling liquid),

software (e.g. engine control software, driver’s manual), and service (e.g. operating explanations given by the

salesman).

Note 2 to entry: Service is the result of at least one activity necessarily performed at the interface between the

supplier and customer and is generally intangible. Provision of a service can involve, for example, the following:

— an activity performed on a customer-supplied tangible product (e.g. automobile to be repaired);

— an activity performed on a customer-supplied intangible product (e.g. the income statement needed to

prepare a tax return);

— the delivery of an intangible product (e.g. the delivery of information in the context of knowledge

transmission);

— the creation of ambience for the customer (e.g. in hotels and restaurants).

Software consists of information and is generally intangible and can be in the form of approaches, transactions

or procedures.

Hardware is generally tangible and its amount is a countable characteristic. Processed materials are generally

tangible and their amount is a continuous characteristic. Hardware and processed materials often are referred

to as goods.

Note 3 to entry: This definition of “product” differs from the definition given in ISO 9000:2015.

2)

[SOURCE: ISO 9000:2005 , 3.4.2, modified]

3.16

purchased product

product provided by a party outside the organization’s quality management system

Note 1 to entry: The provision of product does not necessarily infer a commercial or financial arrangement.

3.17

risk

combination of the probability of occurrence of harm and the severity of that harm

Note 1 to entry: This definition of “risk” differs from the definition given in ISO 9000:2015.

[SOURCE: ISO 14971:2007, 2.16]

3.18

risk management

systematic application of management policies, procedures and practices to the tasks of analysing,

evaluating, controlling and monitoring risk

[SOURCE: ISO 14971:2007, 2.22]

3.19

sterile barrier system

minimum package that prevents ingress of microorganisms and allows aseptic presentation of the

product at the point of use

[SOURCE: ISO 11607-1:2006, 3.22]

2) Superseded by ISO 9000:2015.

3.20

sterile medical device

medical device intended to meet the requirements for sterility

Note 1 to entry: The requirements for sterility of a medical device can be subject to applicable regulatory

requirements or standards.

4 Quality management system

4.1 General requirements

4.1.1 The organization shall document a quality management system and maintain its effectiveness in

accordance with the requirements of this International Standard and applicable regulatory requirements.

The organization shall establish, implement and maintain any requirement, procedure, activity or

arrangement required to be documented by this International Standard or applicable regulatory

requirements.

The organization shall document the role(s) undertaken by the organization under the applicable

regulatory requirements.

NOTE Roles undertaken by the organization can include manufacturer, authorized representative, importer

or distributor.

4.1.2 The organization shall:

a) determine the processes needed for the quality management system and the application of

these processes throughout the organization taking into account the roles undertaken by the

organization;

b) apply a risk based approach to the control of the appropriate processes needed for the quality

management system;

c) determine the sequence and interaction of these processes.

4.1.3 For each quality management system process, the organization shall:

a) determine criteria and methods needed to ensure that both the operation and control of these

processes are effective;

b) ensure the availability of resources and information necessary to support the operation and

monitoring of these processes;

c) implement actions necessary to achieve planned results and maintain the effectiveness of these

processes;

d) monitor, measure as appropriate, and analyse these processes;

e) establish and maintain records needed to demonstrate conformance to this International Standard

and compliance with applicable regulatory requirements (see 4.2.5).

4.1.4 The organization shall manage these quality management system processes in accordance with

the requirements of this International Standard and applicable regulatory requirements. Changes to be

made to these processes shall be:

a) evaluated for their impact on the quality management system;

b) evaluated for their impact on the medical devices produced under this quality management system;

6 © ISO 2016 – All rights reserved

c) controlled in accordance with the requirements of this International Standard and applicable

regulatory requirements.

4.1.5 When the organization chooses to outsource any process that affects product conformity to

requirements, it shall monitor and ensure control over such processes. The organization shall retain

responsibility of conformity to this International Standard and to customer and applicable regulatory

requirements for outsourced processes. The controls shall be proportionate to the risk involved and the

ability of the external party to meet the requirements in accordance with 7.4. The controls shall include

written quality agreements.

4.1.6 The organization shall document procedures for the validation of the application of computer

software used in the quality management system. Such software applications shall be validated prior to

initial use and,

...

INTERNATIONAL ISO

STANDARD 13485

Redline version

compares Third edition to

Second edition

Medical devices — Quality

management systems —

Requirements for regulatory purposes

Dispositifs médicaux — Systèmes de management de la qualité —

Exigences à des fins réglementaires

Reference number

ISO 13485:redline:2016(E)

©

ISO 2016

ISO 13485:redline:2016(E)

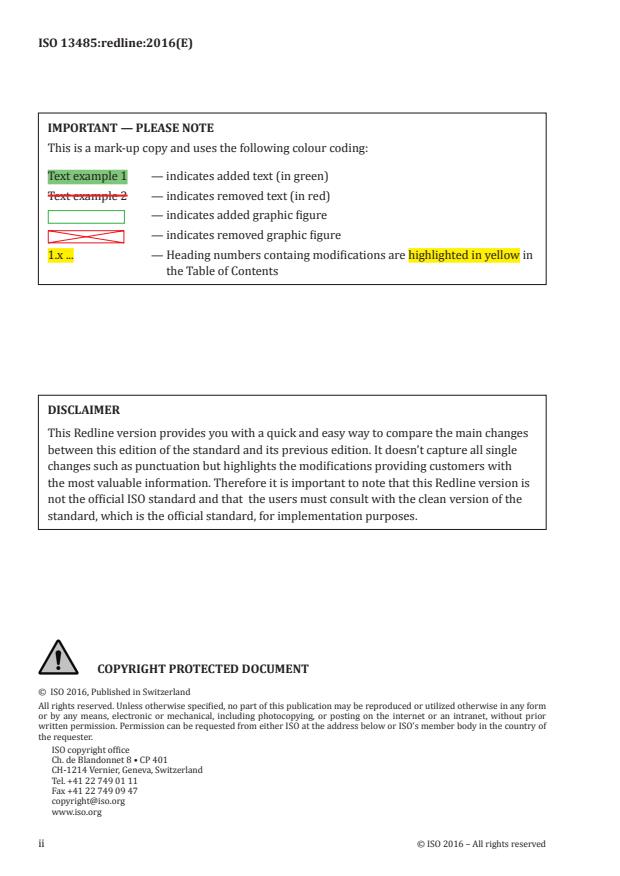

IMPORTANT — PLEASE NOTE

This is a mark-up copy and uses the following colour coding:

Text example 1 — indicates added text (in green)

Text example 2 — indicates removed text (in red)

— indicates added graphic figure

— indicates removed graphic figure

1.x . — Heading numbers containg modifications are highlighted in yellow in

the Table of Contents

DISCLAIMER

This Redline version provides you with a quick and easy way to compare the main changes

between this edition of the standard and its previous edition. It doesn’t capture all single

changes such as punctuation but highlights the modifications providing customers with

the most valuable information. Therefore it is important to note that this Redline version is

not the official ISO standard and that the users must consult with the clean version of the

standard, which is the official standard, for implementation purposes.

© ISO 2016, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2016 – All rights reserved

ISO 13485:redline:2016(E)

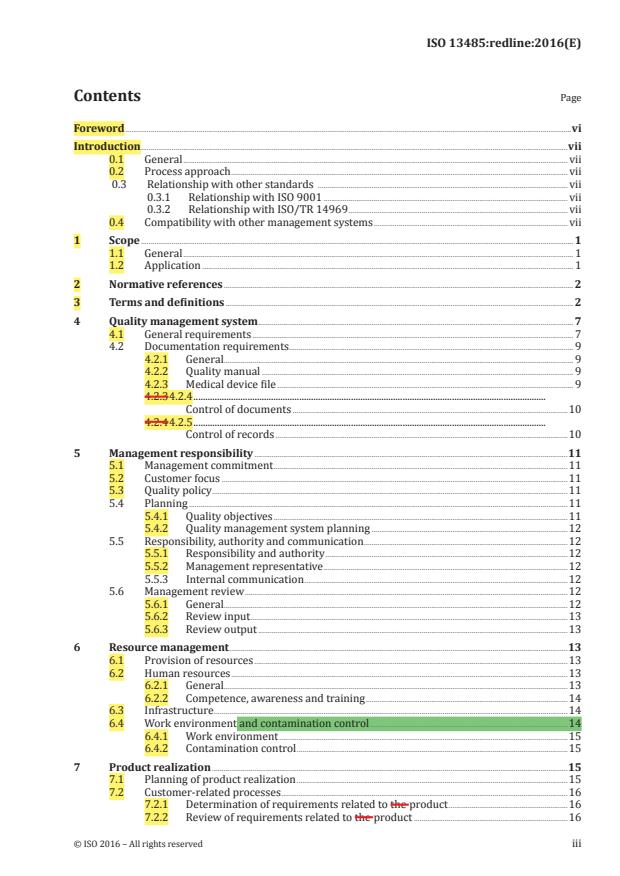

Contents Page

Foreword .vi

Introduction .vii

0.1 General . vii

0.2 Process approach . vii

0.3 Relationship with other standards . vii

0.3.1 Relationship with ISO 9001 . vii

0.3.2 Relationship with ISO/TR 14969 . vii

0.4 Compatibility with other management systems . vii

1 Scope . 1

1.1 General . 1

1.2 Application . 1

2 Normative references . 2

3 Terms and definitions . 2

4 Quality management system . 7

4.1 General requirements . 7

4.2 Documentation requirements. 9

4.2.1 General. 9

4.2.2 Quality manual . 9

4.2.3 Medical device file . 9

4.2.3 4.2.4 .

Control of documents .10

4.2.4 4.2.5 .

Control of records .10

5 Management responsibility .11

5.1 Management commitment .11

5.2 Customer focus .11

5.3 Quality policy .11

5.4 Planning .11

5.4.1 Quality objectives .11

5.4.2 Quality management system planning .12

5.5 Responsibility, authority and communication .12

5.5.1 Responsibility and authority .12

5.5.2 Management representative .12

5.5.3 Internal communication .12

5.6 Management review .12

5.6.1 General.12

5.6.2 Review input .13

5.6.3 Review output .13

6 Resource management .13

6.1 Provision of resources .13

6.2 Human resources .13

6.2.1 General.13

6.2.2 Competence, awareness and training .14

6.3 Infrastructure .14

6.4 Work environment and contamination control .14

6.4.1 Work environment .15

6.4.2 Contamination control .15

7 Product realization .15

7.1 Planning of product realization .15

7.2 Customer-related processes .16

7.2.1 Determination of requirements related to the product .16

7.2.2 Review of requirements related to the product .16

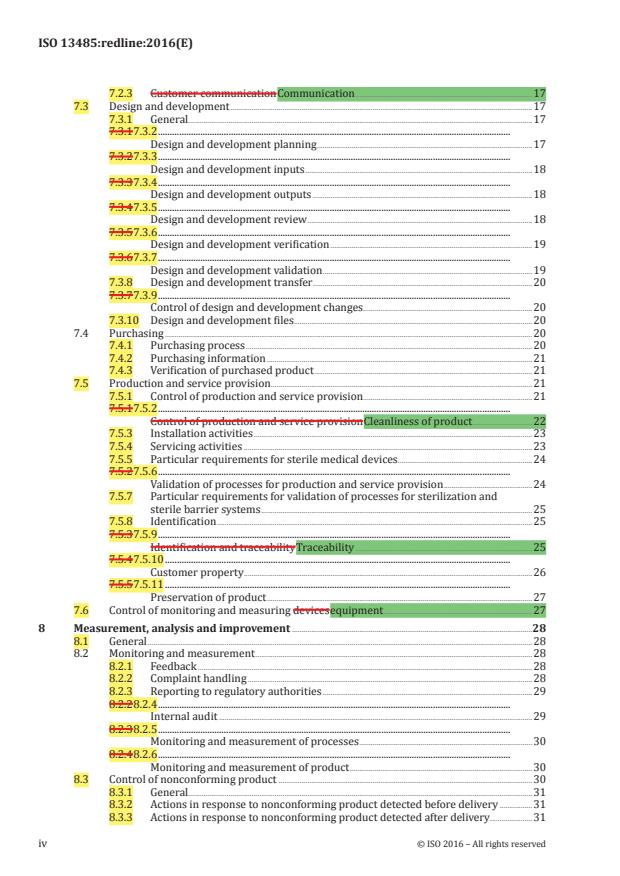

ISO 13485:redline:2016(E)

7.2.3 Customer communication Communication .17

7.3 Design and development .17

7.3.1 General.17

7.3.1 7.3.2 .

Design and development planning .17

7.3.2 7.3.3 .

Design and development inputs .18

7.3.3 7.3.4 .

Design and development outputs .18

7.3.4 7.3.5 .

Design and development review .18

7.3.5 7.3.6 .

Design and development verification .19

7.3.6 7.3.7 .

Design and development validation .19

7.3.8 Design and development transfer .20

7.3.7 7.3.9 .

Control of design and development changes .20

7.3.10 Design and development files .20

7.4 Purchasing .20

7.4.1 Purchasing process .20

7.4.2 Purchasing information .21

7.4.3 Verification of purchased product .21

7.5 Production and service provision .21

7.5.1 Control of production and service provision .21

7.5.1 7.5.2 .

Control of production and service provision Cleanliness of product .22

7.5.3 Installation activities .23

7.5.4 Servicing activities .23

7.5.5 Particular requirements for sterile medical devices.24

7.5.2 7.5.6 .

Validation of processes for production and service provision .24

7.5.7 Particular requirements for validation of processes for sterilization and

sterile barrier systems .25

7.5.8 Identification .25

7.5.3 7.5.9 .

Identification and traceability Traceability .25

7.5.4 7.5.10 .

Customer property .26

7.5.5 7.5.11 .

Preservation of product .27

7.6 Control of monitoring and measuring devices equipment .27

8 Measurement, analysis and improvement .28

8.1 General .28

8.2 Monitoring and measurement .28

8.2.1 Feedback .28

8.2.2 Complaint handling .28

8.2.3 Reporting to regulatory authorities .29

8.2.2 8.2.4 .

Internal audit .29

8.2.3 8.2.5 .

Monitoring and measurement of processes .30

8.2.4 8.2.6 .

Monitoring and measurement of product .30

8.3 Control of nonconforming product .30

8.3.1 General.31

8.3.2 Actions in response to nonconforming product detected before delivery .31

8.3.3 Actions in response to nonconforming product detected after delivery .31

iv © ISO 2016 – All rights reserved

ISO 13485:redline:2016(E)

8.3.4 Rework .31

8.4 Analysis of data .32

8.5 Improvement .32

8.5.1 General.32

8.5.2 Corrective action .32

8.5.3 Preventive action .33

Bibliography .34

ISO 13485:redline:2016(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

International Standards areThe procedures used to develop this document and those intended for its

further maintenance are described in the ISO/IEC Directives, Part 1. In particular the different approval

criteria needed for the different types of ISO documents should be noted. This document was drafted

in accordance with the rules given ineditorial rules of the ISO/IEC Directives, Part 2 (see www.iso.

org/directives).

The main task of technical committees is to prepare International Standards. Draft International

Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies

casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity assessment,

as well as information about ISO’s adherence to the World Trade Organization (WTO) principles in the

Technical Barriers to Trade (TBT) see the following URL: www.iso.org/iso/foreword.html.

ISO 13485 was prepared byThe committee responsible for this document is Technical Committee

ISO/TC 210, Quality management and corresponding general aspects for medical devices.

This secondthird edition of ISO 13485 cancels and replaces the firstsecond edition

(ISO 13485:19962003) and ISO/TR 14969:2004, which hashave been technically revised. It also cancels

and replacesincorporates the Technical Corrigendum ISO 13488:199613485:2003/Cor.1:2009. Those

organizations which have used ISO 13488 in the past may use this International Standard by excluding

certain requirements in accordance withA summary of the changes incorporated into this 1.2edition

compared with the previous edition is given in Annex A.

This edition of ISO 13485 has a revised title and addresses quality assurance of product, customer

requirements, and other elements of quality system management.

vi © ISO 2016 – All rights reserved

ISO 13485:redline:2016(E)

Introduction

0.1 General

This International Standard specifies requirements for a quality management system that can be used

by an organization for the design and development, production, installation and servicing of medical

devices, and the design, development, and provision of related services.

It can also be used by internal and external parties, including certification bodies, to assess the

organization’s ability to meet customer and regulatory requirements.

Information marked “NOTE” is for guidance in understanding or clarifying the associated requirement.

It is emphasized that the quality management system requirements specified in this International

Standard are complementary to technical requirements for products.

The adoption of a quality management system should be a strategic decision of an organization. The

design and implementation of an organization’s quality management system is influenced by varying

needs, particular objectives, the products provided, the processes employed and the size and structure

of the organization. It is not the intent of this International Standard to imply uniformity in the structure

of quality management systems or uniformity of documentation.

There is a wide variety of medical devices and some of the particular requirements of this International

Standard only apply to named groups of medical devices. These groups are defined in Clause 3.

0.2 Process approach

This International Standard is based on a process approach to quality management.

Any activity that receives inputs and converts them to outputs can be considered as a process.

For an organization to function effectively, it has to identify and manage numerous linked processes.

Often the output from one process directly forms the input to the next.

The application of a system of processes within an organization, together with the identification and

interactions of these processes, and their management, can be referred to as the “process approach”.

0.3 Relationship with other standards

0.3.1 Relationship with ISO 9001

While this is a stand-alone standard, it is based on ISO 9001.

Those clauses or subclauses that are quoted directly and unchanged from ISO 9001 are in normal font.

The fact that these subclauses are presented unchanged is noted in Annex B.

Where the text of this International Standard is not identical to the text of ISO 9001, the sentence or

indent containing that text as a whole is shown in italics (in blue italics for electronic versions). The

nature and reasons for the text changes are noted in Annex B.

0.3.2 Relationship with ISO/TR 14969

ISO/TR 14969 is a Technical Report intended to provide guidance for the application of ISO 13485.

0.4 Compatibility with other management systems

This International Standard follows the format of ISO 9001 for the convenience of users in the medical

device community.

ISO 13485:redline:2016(E)

This International Standard does not include requirements specific to other management systems,

such as those particular to environmental management, occupational health and safety management,

or financial management.

However, this International Standard enables an organization to align or integrate its own quality

management system with related management system requirements. It is possible for an organization

to adapt its existing management system(s) in order to establish a quality management system that

complies with the requirements of this International Standard.

0.1 General

This International Standard specifies requirements for a quality management system that can be used by

an organization involved in one or more stages of the life-cycle of a medical device, including design and

development, production, storage and distribution, installation, servicing and final decommissioning

and disposal of medical devices, and design and development, or provision of associated activities (e.g.

technical support). The requirements in this International Standard can also be used by suppliers or

other external parties providing product (e.g. raw materials, components, subassemblies, medical

devices, sterilization services, calibration services, distribution services, maintenance services) to such

organizations. The supplier or external party can voluntarily choose to conform to the requirements of

this International Standard or can be required by contract to conform.

Several jurisdictions have regulatory requirements for the application of quality management systems

by organizations with a variety of roles in the supply chain for medical devices. Consequently, this

International Standard expects that the organization:

— identifies its role(s) under applicable regulatory requirements;

— identifies the regulatory requirements that apply to its activities under these roles;

— incorporates these applicable regulatory requirements within its quality management system.

The definitions in applicable regulatory requirements differ from nation to nation and region to region.

The organization needs to understand how the definitions in this International Standard will be

interpreted in light of regulatory definitions in the jurisdictions in which the medical devices are made

available.

This International Standard can also be used by internal and external parties, including certification

bodies, to assess the organization’s ability to meet customer and regulatory requirements applicable

to the quality management system and the organization’s own requirements. It is emphasized that the

quality management system requirements specified in this International Standard are complementary

to the technical requirements for product that are necessary to meet customer and applicable

regulatory requirements for safety and performance.

The adoption of a quality management system is a strategic decision of an organization. The design and

implementation of an organization’s quality management system is influenced by the:

a) organizational environment, changes in that environment, and the influence that the organizational

environment has on the conformity of the medical devices;

b) organization’s varying needs;

c) organization’s particular objectives;

d) product the organization provides;

e) processes the organization employs;

f) organization’s size and organizational structure;

g) regulatory requirements applicable to the organization’s activities.

viii © ISO 2016 – All rights reserved

ISO 13485:redline:2016(E)

It is not the intent of this International Standard to imply the need for uniformity in the structure of

different quality management systems, uniformity of documentation or alignment of documentation to

the clause structure of this International Standard.

There is a wide variety of medical devices and some of the particular requirements of this International

Standard only apply to named groups of medical devices. These groups are defined in Clause 3.

ISO 13485:redline:2016(E)

0.2 Clarification of concepts

In this International Standard, the following terms or phrases are used in the context described below.

— When a requirement is qualified by the phrase “as appropriate”, it is deemed to be appropriate unless

the organization can justify otherwise. A requirement is considered appropriate if it is necessary for:

— product to meet requirements;

— compliance with applicable regulatory requirements;

— the organization to carry out corrective action;

— the organization to manage risks.

— When the term “risk” is used, the application of the term within the scope of this International

Standard pertains to safety or performance requirements of the medical device or meeting

applicable regulatory requirements.

— When a requirement is required to be “documented”, it is also required to be established,

implemented and maintained.

— When the term “product” is used, it can also mean “service”. Product applies to output that is

intended for, or required by, a customer, or any intended output resulting from a product realization

process.

— When the term “regulatory requirements” is used, it encompasses requirements contained in any

law applicable to the user of this International Standard (e.g. statutes, regulations, ordinances or

directives). The application of the term “regulatory requirements” is limited to requirements for the

quality management system and the safety or performance of the medical device.

In this International Standard, the following verbal forms are used:

— “shall” indicates a requirement;

— “should” indicates a recommendation;

— “may” indicates a permission;

— “can” indicates a possibility or a capability.

Information marked as “NOTE” is for guidance in understanding or clarifying the associated

requirement.

0.3 Process approach

This International Standard is based on a process approach to quality management. Any activity that

receives input and converts it to output can be considered as a process. Often the output from one

process directly forms the input to the next process.

For an organization to function effectively, it needs to identify and manage numerous linked processes.

The application of a system of processes within an organization, together with the identification and

interactions of these processes, and their management to produce the desired outcome, can be referred

to as the “process approach.”

When used within a quality management system, such an approach emphasizes the importance of:

a) understanding and meeting requirements;

b) considering processes in terms of added value;

c) obtaining results of process performance and effectiveness;

d) improving processes based on objective measurement.

x © ISO 2016 – All rights reserved

ISO 13485:redline:2016(E)

0.4 Relationship with ISO 9001

While this is a stand-alone standard, it is based on ISO 9001:2008, which has been superseded by

ISO 9001:2015. For the convenience of users, Annex B shows the correspondence between this

International Standard and ISO 9001:2015.

This International Standard is intended to facilitate global alignment of appropriate regulatory

requirements for quality management systems applicable to organizations involved in one or more

stages of the life-cycle of a medical device. This International Standard includes some particular

requirements for organizations involved in the life-cycle of medical devices and excludes some

of the requirements of ISO 9001 that are not appropriate as regulatory requirements. Because of

these exclusions, organizations whose quality management systems conform to this International

Standard cannot claim conformity to ISO 9001 unless their quality management system meets all the

requirements of ISO 9001.

0.5 Compatibility with other management systems

This International Standard does not include requirements specific to other management systems,

such as those particular to environmental management, occupational health and safety management,

or financial management. However, this International Standard enables an organization to align or

integrate its own quality management system with related management system requirements. It is

possible for an organization to adapt its existing management system(s) in order to establish a quality

management system that complies with the requirements of this International Standard.

INTERNATIONAL STANDARD ISO 13485:redline:2016(E)

Medical devices — Quality management systems —

Requirements for regulatory purposes

1 Scope

1.1 General

This International Standard specifies requirements for a quality management system where an

organization needs to demonstrate its ability to provide medical devices and related services that

consistently meet customer requirements and regulatory requirements applicable to medical devices

and related services.

The primary objective of this International Standard is to facilitate harmonized medical device

regulatory requirements for quality management systems. As a result, it includes some particular

requirements for medical devices and excludes some of the requirements of ISO 9001 that are not

appropriate as regulatory requirements. Because of these exclusions, organizations whose quality

management systems conform to this International Standard cannot claim conformity to ISO 9001

unless their quality management systems conform to all the requirements of ISO 9001 (see Annex B).

1.2 Application

All requirements of this International Standard are specific to organizations providing medical devices,

regardless of the type or size of the organization.

If regulatory requirements permit exclusions of design and development controls (see 7.3), this can be

used as a justification for their exclusion from the quality management system. These regulations can

provide alternative arrangements that are to be addressed in the quality management system. It is the

responsibility of the organization to ensure that claims of conformity with this International Standard

reflect exclusion of design and development controls [see 4.2.2 a) and 7.3].

If any requirement(s) in Clause 7 of this International Standard is(are) not applicable due to the nature

of the medical device(s) for which the quality management system is applied, the organization does not

need to include such a requirement(s) in its quality management system [see 4.2.2 a)].

The processes required by this International Standard, which are applicable to the medical device(s),

but which are not performed by the organization, are the responsibility of the organization and are

accounted for in the organization’s quality management system [see 4.1 a)].

In this International Standard the terms “if appropriate” and “where appropriate” are used several

times. When a requirement is qualified by either of these phrases, it is deemed to be “appropriate” unless

the organization can document a justification otherwise. A requirement is considered “appropriate” if it

is necessary in order for

— the product to meet specified requirements, and/or

— the organization to carry out corrective action.

This International Standard specifies requirements for a quality management system where an

organization needs to demonstrate its ability to provide medical devices and related services that

consistently meet customer and applicable regulatory requirements. Such organizations can be involved

in one or more stages of the life-cycle, including design and development, production, storage and

distribution, installation, or servicing of a medical device and design and development or provision of

associated activities (e.g. technical support). This International Standard can also be used by suppliers

or external parties that provide product, including quality management system-related services to such

organizations.

ISO 13485:redline:2016(E)

Requirements of this International Standard are applicable to organizations regardless of their size

and regardless of their type except where explicitly stated. Wherever requirements are specified as

applying to medical devices, the requirements apply equally to associated services as supplied by the

organization.

The processes required by this International Standard that are applicable to the organization, but

are not performed by the organization, are the responsibility of the organization and are accounted

for in the organization’s quality management system by monitoring, maintaining, and controlling the

processes.

If applicable regulatory requirements permit exclusions of design and development controls, this can

be used as a justification for their exclusion from the quality management system. These regulatory

requirements can provide alternative approaches that are to be addressed in the quality management

system. It is the responsibility of the organization to ensure that claims of conformity to this

International Standard reflect any exclusion of design and development controls.

If any requirement in Clauses 6, 7 or 8 of this International Standard is not applicable due to the

activities undertaken by the organization or the nature of the medical device for which the quality

management system is applied, the organization does not need to include such a requirement in its

quality management system. For any clause that is determined to be not applicable, the organization

records the justification as described in 4.2.2.

2 Normative references

The following referenced documentsdocuments, in whole or in part, are normatively referenced in

this document and are indispensable for the application of this documentits application. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

1)

ISO 9000:2000 2015 , Quality management systems — Fundamentals and vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 9000:2015 apply, together

with the following. and the following apply.

The following terms, used in this edition of ISO 13485 to describe the supply chain, have been changed

to reflect the vocabulary currently used:

supplier -------------> organization ----------> customer

The term “organization” replaces the term “supplier” used in ISO 13485:1996 , and refers to the

unit to which this International Standard applies. Also, the term “supplier” now replaces the term

“subcontractor”.

Throughout the text of this International Standard, wherever the term “product” occurs, it can also

mean “service”.

Wherever requirements are specified as applying to “medical devices”, the requirements apply equally

to related services as supplied by the organization.

The following definitions should be regarded as generic, as definitions provided in national regulations

can differ slightly and take precedence.

1) Supersedes ISO 9000:2005.

2 © ISO 2016 – All rights reserved

ISO 13485:redline:2016(E)

3.1

active implantable medical device

active medical device which is intended to be totally or partially introduced, surgically or medically,

into the human body or by medical intervention into a natural orifice, and which is intended to remain

after the procedure

3.2

active medical device

medical device relying for its functioning on a source of electrical energy or any source of power other

than that directly generated by the human body or gravity

3.3 3.1

advisory notice

notice issued by the organization

...

NORME ISO

INTERNATIONALE 13485

Troisième édition

2016-03-01

Dispositifs médicaux — Systèmes

de management de la qualité —

Exigences à des fins réglementaires

Medical devices — Quality management systems — Requirements for

regulatory purposes

Numéro de référence

©

ISO 2016

DOCUMENT PROTÉGÉ PAR COPYRIGHT

© ISO 2016, Publié en Suisse

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni utilisée

sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie, l’affichage sur

l’internet ou sur un Intranet, sans autorisation écrite préalable. Les demandes d’autorisation peuvent être adressées à l’ISO à

l’adresse ci-après ou au comité membre de l’ISO dans le pays du demandeur.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland