ISO 20419:2018

(Main)Treated wastewater reuse for irrigation - Guidelines for the adaptation of irrigation systems and practices to treated wastewater

Treated wastewater reuse for irrigation - Guidelines for the adaptation of irrigation systems and practices to treated wastewater

This document provides guidelines to planners and practitioners on how to adjust irrigation equipment so as to allow direct utilization of treated wastewater (TWW) for irrigation. It deals with the adjustment of all components of irrigation systems to TWW quality in respect to physical, chemical and biological parameters. This document provides guidelines on how to protect irrigation equipment so as to guarantee water systems functionality at high levels of efficiency. This document includes recommendations for a) pumping stations, b) filtration, c) water network systems, d) irrigation equipment: emitters (drippers, sprinklers, mini sprinklers, micro sprinklers, sprayers and irrigation machine (sprinklers and sprayers), e) physical treatment of irrigation equipment, and f) chemical treatment of irrigation equipment. This document defines TWW parameters at the irrigation system inlet after a wastewater treatment plant, in order to allow optimal and continual functioning of the irrigation systems and to allow uniformity of emitters' discharge.

Réutilisation des eaux usées traitées en irrigation — Lignes directrices pour l’adaptation des systèmes et pratiques d’irrigation aux eaux usées traitées

General Information

- Status

- Published

- Publication Date

- 23-Oct-2018

- Technical Committee

- ISO/TC 282/SC 1 - Treated wastewater reuse for irrigation

- Drafting Committee

- ISO/TC 282/SC 1 - Treated wastewater reuse for irrigation

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 24-May-2024

- Completion Date

- 13-Dec-2025

Overview

ISO 20419:2018 - Treated wastewater reuse for irrigation - provides practical guidelines for adapting irrigation systems and practices to treated wastewater (TWW). It helps planners and practitioners adjust all irrigation components (physical, chemical and biological aspects) so TWW can be used directly while maintaining system functionality, emitter uniformity and high operational efficiency.

Key topics

The standard addresses technical measures across the irrigation chain, including:

- TWW quality at the irrigation inlet - defines parameters to ensure optimal and continual system performance and uniform emitter discharge.

- Monitoring for micro‑irrigation - recommended monitoring devices such as flushing counters for automated filters, pH sensors, clogging‑capacity meters and chlorine‑demand sensors, plus monitoring procedures.

- Reservoirs and storage - design, safety, quality control, stratification prevention and biological processes that affect TWW quality.

- Filtration systems - filter station layout, filtration media, flow/area ratios, filtration grade, and maintenance/cleaning guidance.

- Pumping stations - design features to handle TWW (e.g., floating suction, bottom pumping chambers) and operational considerations to prevent stratification and sediment intake.

- Emitters and irrigation equipment adaptation - guidance for drippers, sprinklers (mini, micro, overhead), sprayers and irrigation machines to resist clogging and maintain longevity.

- Physical and chemical treatment of irrigation equipment - flushing strategies, pipe cleaning, chemical treatments and maintenance to mitigate biofouling, scale and sedimentation.

- Informative annexes - additional material on TWW quality parameters, test methods, pH effect on chlorine, clogging metrics, reservoir maintenance and case experience.

Applications

ISO 20419:2018 is directly applicable to:

- Irrigation system designers and planners adapting systems to reuse treated wastewater.

- Water utilities and wastewater treatment operators managing TWW supply for agriculture or landscaping.

- Agricultural consultants, farmers and irrigation contractors implementing micro‑irrigation (drip and micro‑sprinkler) systems with TWW.

- Equipment manufacturers and suppliers of filters, pumps and emitters who need to specify TWW‑compatible components.

- Regulators and asset managers developing operational guidance, maintenance schedules and procurement specifications.

Practical benefits include reduced downtime, improved emitter uniformity, longer equipment life, and safer, more reliable reuse of TWW for irrigation.

Related standards (if applicable)

While ISO 20419:2018 focuses on adaptation of irrigation systems to TWW, users typically consult complementary standards and guidance on wastewater treatment, water quality testing and irrigation design when implementing reuse projects. Keywords: ISO 20419:2018, treated wastewater reuse, TWW irrigation, filtration, emitters, pumping stations, reservoir design, clogging prevention.

Frequently Asked Questions

ISO 20419:2018 is a standard published by the International Organization for Standardization (ISO). Its full title is "Treated wastewater reuse for irrigation - Guidelines for the adaptation of irrigation systems and practices to treated wastewater". This standard covers: This document provides guidelines to planners and practitioners on how to adjust irrigation equipment so as to allow direct utilization of treated wastewater (TWW) for irrigation. It deals with the adjustment of all components of irrigation systems to TWW quality in respect to physical, chemical and biological parameters. This document provides guidelines on how to protect irrigation equipment so as to guarantee water systems functionality at high levels of efficiency. This document includes recommendations for a) pumping stations, b) filtration, c) water network systems, d) irrigation equipment: emitters (drippers, sprinklers, mini sprinklers, micro sprinklers, sprayers and irrigation machine (sprinklers and sprayers), e) physical treatment of irrigation equipment, and f) chemical treatment of irrigation equipment. This document defines TWW parameters at the irrigation system inlet after a wastewater treatment plant, in order to allow optimal and continual functioning of the irrigation systems and to allow uniformity of emitters' discharge.

This document provides guidelines to planners and practitioners on how to adjust irrigation equipment so as to allow direct utilization of treated wastewater (TWW) for irrigation. It deals with the adjustment of all components of irrigation systems to TWW quality in respect to physical, chemical and biological parameters. This document provides guidelines on how to protect irrigation equipment so as to guarantee water systems functionality at high levels of efficiency. This document includes recommendations for a) pumping stations, b) filtration, c) water network systems, d) irrigation equipment: emitters (drippers, sprinklers, mini sprinklers, micro sprinklers, sprayers and irrigation machine (sprinklers and sprayers), e) physical treatment of irrigation equipment, and f) chemical treatment of irrigation equipment. This document defines TWW parameters at the irrigation system inlet after a wastewater treatment plant, in order to allow optimal and continual functioning of the irrigation systems and to allow uniformity of emitters' discharge.

ISO 20419:2018 is classified under the following ICS (International Classification for Standards) categories: 13.060.30 - Sewage water; 65.060.35 - Irrigation and drainage equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 20419:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 20419

First edition

2018-10

Treated wastewater reuse for

irrigation — Guidelines for the

adaptation of irrigation systems and

practices to treated wastewater

Réutilisation des eaux usées traitées en irrigation — Lignes

directrices pour l’adaptation des systèmes et pratiques d’irrigation

aux eaux usées traitées

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

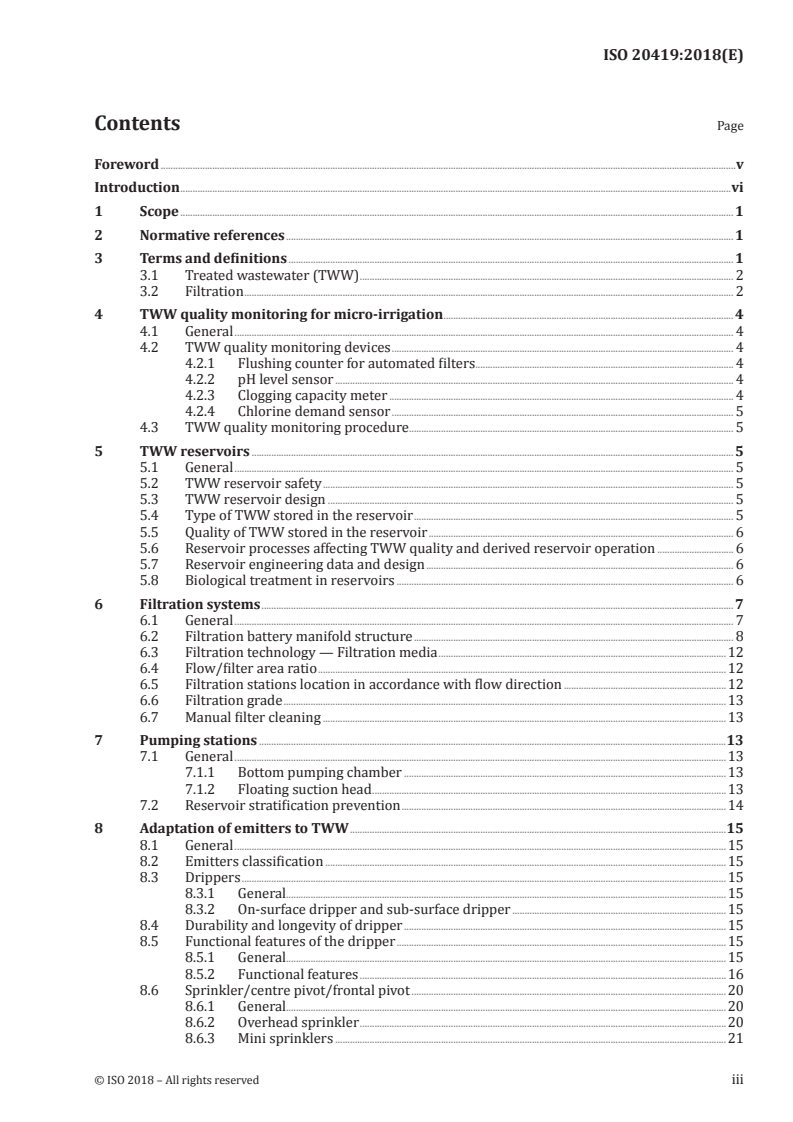

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

3.1 Treated wastewater (TWW) . 2

3.2 Filtration . 2

4 TWW quality monitoring for micro-irrigation . 4

4.1 General . 4

4.2 TWW quality monitoring devices . 4

4.2.1 Flushing counter for automated filters . 4

4.2.2 pH level sensor . 4

4.2.3 Clogging capacity meter . 4

4.2.4 Chlorine demand sensor . 5

4.3 TWW quality monitoring procedure . 5

5 TWW reservoirs . 5

5.1 General . 5

5.2 TWW reservoir safety . 5

5.3 TWW reservoir design . 5

5.4 Type of TWW stored in the reservoir . 5

5.5 Quality of TWW stored in the reservoir . 6

5.6 Reservoir processes affecting TWW quality and derived reservoir operation . 6

5.7 Reservoir engineering data and design . 6

5.8 Biological treatment in reservoirs . 6

6 Filtration systems . 7

6.1 General . 7

6.2 Filtration battery manifold structure . 8

6.3 Filtration technology — Filtration media .12

6.4 Flow/filter area ratio .12

6.5 Filtration stations location in accordance with flow direction .12

6.6 Filtration grade .13

6.7 Manual filter cleaning .13

7 Pumping stations .13

7.1 General .13

7.1.1 Bottom pumping chamber .13

7.1.2 Floating suction head .13

7.2 Reservoir stratification prevention .14

8 Adaptation of emitters to TWW .15

8.1 General .15

8.2 Emitters classification .15

8.3 Drippers .15

8.3.1 General.15

8.3.2 On-surface dripper and sub-surface dripper .15

8.4 Durability and longevity of dripper .15

8.5 Functional features of the dripper .15

8.5.1 General.15

8.5.2 Functional features .16

8.6 Sprinkler/centre pivot/frontal pivot .20

8.6.1 General.20

8.6.2 Overhead sprinkler .20

8.6.3 Mini sprinklers .21

8.6.4 Micro sprinklers and sprayers .21

8.6.5 Center pivot sprinklers/sprayers .22

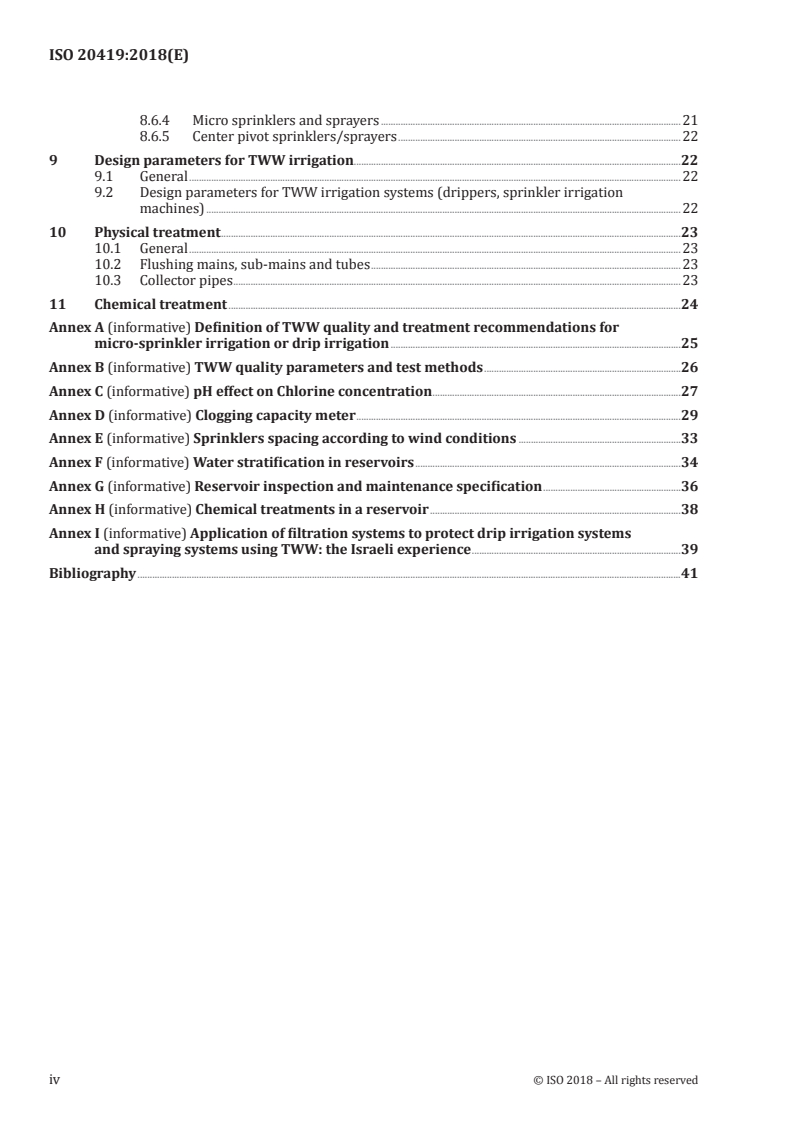

9 Design parameters for TWW irrigation.22

9.1 General .22

9.2 Design parameters for TWW irrigation systems (drippers, sprinkler irrigation

machines) .22

10 Physical treatment .23

10.1 General .23

10.2 Flushing mains, sub-mains and tubes .23

10.3 Collector pipes .23

11 Chemical treatment .24

Annex A (informative) Definition of TWW quality and treatment recommendations for

micro-sprinkler irrigation or drip irrigation .25

Annex B (informative) TWW quality parameters and test methods .26

Annex C (informative) pH effect on Chlorine concentration .27

Annex D (informative) Clogging capacity meter .29

Annex E (informative) Sprinklers spacing according to wind conditions .33

Annex F (informative) Water stratification in reservoirs .34

Annex G (informative) Reservoir inspection and maintenance specification .36

Annex H (informative) Chemical treatments in a reservoir .38

Annex I (informative) Application of filtration systems to protect drip irrigation systems

and spraying systems using TWW: the Israeli experience .39

Bibliography .41

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see www .iso

.org/iso/foreword .html.

This document was prepared by Technical Committee ISO/TC 282, Water reuse, Subcommittee SC 1,

Treated wastewater reuse for irrigation.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/members .html.

Introduction

Irrigation is gaining importance all over the world, and the lack of water available from surface or

groundwater is driving the introduction of treated wastewater for this purpose. Accordingly, some

adaptation is needed to the equipment included in the irrigation system to ensure its proper functioning.

The composition of treated wastewater (TWW) is different from that of freshwater. TWW contains

more nutritional elements and microbial populations. It is also characterized by a higher salt

concentration, anions and cations with a high precipitation potential of sediments of low solubility

salts. These characteristics can severely disrupt the operation of the TWW irrigation systems, which

can result in poor performance of the system, and potentially harmful to the environment.

Changes in water quality of reservoirs or secondary water resources can affect the water systems'

efficiency, as all parts of the irrigation system, such as filters, pipes and emitters, can be adversely

affected by low quality water.

The transport efficiency of irrigation equipment is dependent on the quality of the treated wastewater

used, due to several factors such as:

— formation of biofilm on interior pipe walls,

— scale precipitation, organic material and fertilizers, and

— excess build-up of sediment.

Irrigation systems clogging types can be classified into three categories:

— organic and inorganic particles (minerals) sedimentation,

— chemical precipitation of low solubility salts, and

— biofouling -attachment/detachment of microorganism colonies on the irrigation system interior

surface, which results in biofilm development.

This document provides guidelines on how to use TWW in or with irrigation systems and to protect

them from clogging.

vi © ISO 2018 – All rights reserved

INTERNATIONAL STANDARD ISO 20419:2018(E)

Treated wastewater reuse for irrigation — Guidelines

for the adaptation of irrigation systems and practices to

treated wastewater

1 Scope

This document provides guidelines to planners and practitioners on how to adjust irrigation equipment

so as to allow direct utilization of treated wastewater (TWW) for irrigation. It deals with the adjustment

of all components of irrigation systems to TWW quality in respect to physical, chemical and biological

parameters.

This document provides guidelines on how to protect irrigation equipment so as to guarantee water

systems functionality at high levels of efficiency.

This document includes recommendations for

a) pumping stations,

b) filtration,

c) water network systems,

d) irrigation equipment: emitters (drippers, sprinklers, mini sprinklers, micro sprinklers, sprayers

and irrigation machine (sprinklers and sprayers),

e) physical treatment of irrigation equipment, and

f) chemical treatment of irrigation equipment.

This document defines TWW parameters at the irrigation system inlet after a wastewater treatment

plant, in order to allow optimal and continual functioning of the irrigation systems and to allow

uniformity of emitters' discharge.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https: //www .iso .org/obp

— IEC Electropedia: available at http: //www .electropedia .org/

3.1 Treated wastewater (TWW)

3.1.1

wastewater

water arising from any combination of domestic, industrial or commercial activities, which can include

surface runoff and any accidental sewer inflow/infiltration water and which can include collected

storm water, discharged to the environment or sewer

[SOURCE: ISO 20670:2018, 3.80]

3.1.2

treated wastewater

TWW

wastewater that has gone through physical, chemical and/or biological processes to remove

contaminants

3.1.3

clogging capacity meter

device used for measuring the time to reach a specified pressure loss across a standard filter screen, at

a constant flow rate

[SOURCE: ISO 18471:2015,3.2]

3.1.4

biofilm

attached/detached microorganism colonies on the irrigation systems' interior surface, which results in

organic matter development

3.1.5

self-cleaning strainer

filter located in the reservoir that protects the pumping chamber from clogging and has continuous

flushing capability

3.1.6

bottom pumping chamber

subsystem that pumps water from the bottom of a water source such as a reservoir or pond, which

includes pumping equipment, motors, piping, valves and liquid level controls

3.1.7

floating suction head

unit pumping TWW from the upper level of the reservoir whose pumping point level can be adjusted

according to the quality of TWW

3.2 Filtration

3.2.1

filtration

physical process that separates solid particles from water, by passing the water through a physical

porous barrier to trap and separate suspended solids from the water

Note 1 to entry: Examples of barrier include media bed, surface or depth filter, screen, disc or membrane.

[SOURCE: ISO 20670:2018, 3.27, modified — Note 1 to entry, the word “disc” has been added.]

3.2.2

nominal flow rate of filtration

flow rate through a filter for proper filtration, as declared by manufacturer

[SOURCE: ISO 9912–1:2004, 2.37]

2 © ISO 2018 – All rights reserved

3.2.3

check filter

filter located before the irrigation emitters (drip, sprayers and micro sprinklers)

3.2.4

flushing differential pressure

differential pressure between two points, one upstream and one downstream of the filter media, which

initiates the flushing cycle

3.2.5

emitter

dripper

device fitted to an irrigation lateral and intended to discharge water in the form of drops or

recommended continuous flow at flow rates not exceeding 24 l/h except during flushing

Note 1 to entry: Other emitters flow at flow rates between 24 l/h and 60 l/h.

[SOURCE: ISO 16075–1:2015, 3.4.3]

3.2.6

on-line emitter

emitter intended for installation in the wall of an irrigation lateral, either directly or indirectly by

means such as tubing

[SOURCE: ISO 16075–1:2015, 3.4.12]

3.2.7

in-line emitter

emitter intended for installation between two lengths of pipe in an irrigation lateral

[SOURCE: ISO 9261:2004, 3.2]

3.2.8

unregulated dripper

non-pressure compensating emitter/emitting pipe

Note 1 to entry: An unregulated dripper's flow rate varies with inlet water pressure.

[SOURCE: ISO 9261:2004, 3.10]

3.2.9

regulated dripper

pressure compensating emitter/emitting pipe

Note 1 to entry: A regulated dripper maintains a relatively constant flow rate at varying water pressures.

[SOURCE: ISO 9261:2004, 3.8]

3.2.10

sprinkler

water distribution device of a variety of sizes and types, for example, impact sprinkler, fixed nozzle,

sprayer, irrigation gun

[SOURCE: ISO 16075-1:2015, 3.4.24]

3.2.11

rotating sprinkler

device which by its rotating motion around its vertical axis distributes water over a circular area or

part of a circular area

[SOURCE: ISO 15886-1:2012, 2.38]

3.2.12

irrigation sprayer

device which discharges water in the form of fine jets or in a fan shape without rotation movements of

its parts

[SOURCE: ISO 16075-1:2015, 3.4.7]

3.2.13

center pivot

automated irrigation machine consisting of a number of self-propelled towers supporting a pipeline

rotating around a pivot point and through which water supplied at the pivot point flows radially

outward for distribution by sprayers or sprinklers located along the pipeline

[SOURCE: ISO 16075-1:2015, 3.4.2]

4 TWW quality monitoring for micro-irrigation

4.1 General

4.1.1 Micro-irrigation equipment should be adapted to the quality of the given water.

4.1.2 Water quality parameters should fulfill the recommended values shown in Table A.1 and

Table B.1.

4.1.3 Since TWW quality changes from season to season, from month to month, from week to week,

from day to day or even during the course of one day, TWW users should closely monitor the TWW

quality in the system at key points, to be able to respond to quality changes, which can otherwise quickly

clog the entire micro-irrigation system.

4.1.4 Monitoring of TWW quality (see 4.2) can provide users with efficient real-time information.

4.1.5 Changes in TWW quality should be responded to by the adaptation of irrigation parameters, such

as flow reduction, filters insertion and chemical treatments.

4.1.6 The quality of TWW should be monitored using the devices listed in 4.2, and according to the

procedure described in 4.3.

4.2 TWW quality monitoring devices

4.2.1 Flushing counter for automated filters

A flushing counter for automated filters monitors changes that occur between one period of flushing

and the next period of flushing.

A change in flushing frequency should indicate changes in water quality.

4.2.2 pH level sensor

A pH level sensor indicates calcium and calcium carbonate levels, as well as the expected efficiency of

any injected chlorine (see Annex C).

4.2.3 Clogging capacity meter

A clogging capacity meter provides immediate information about changes in TWW and identifies the

main material causing the clogging.

4 © ISO 2018 – All rights reserved

The clogging capacity meter allows a thorough examination of water quality changes and clogging

causes throughout the water supply — from the pump to the dripperlines.

4.2.4 Chlorine demand sensor

A chlorine demand sensor informs TWW users about changes in the concentration of slime or organic

matter in the water.

4.3 TWW quality monitoring procedure

4.3.1 The quality of TWW should be monitored in accordance with the requirements of the irrigation

system, the plantation and the crop.

4.3.2 The monitoring procedure should depend on water quality.

4.3.3 The monitoring procedure should start at the TWW reservoir and continue through the main

head system, while checking the filters, all the way through to the last emitter.

5 TWW reservoirs

5.1 General

Reservoirs for TWW systems balance any disproportions between the TWW routine production

and the TWW irrigation consumption throughout the year. Such reservoirs are normally open to the

atmosphere.

5.2 TWW reservoir safety

The design of reservoir systems should include safety measures (fence construction surrounding the

reservoir, signing and pipeline painting).

5.3 TWW reservoir design

In TWW reservoir design, the following parameters should be considered:

a) the type of TWW stored in the reservoir (see 5.4);

b) TWW quality (see 5.5);

c) reservoir processes affecting TWW quality and derived reservoir operation (see 5.6);

d) engineering data and design (see 5.7);

e) pumping station (see Clause 7);

f) TWW quality monitoring (see Clause 4);

g) reservoir biological and chemical treatment (see 5.8, Annex H);

h) safety measures (see 5.2).

5.4 Type of TWW stored in the reservoir

A reservoir should store TWW.

Surface runoff may also be discharged into the reservoir.

5.5 Quality of TWW stored in the reservoir

The quality of the TWW stored in the reservoir should be in accordance with Annex A of this document,

and ISO 16075-1 to −4.

5.6 Reservoir processes affecting TWW quality and derived reservoir operation

The residence of TWW in an open reservoir can affect its quality, due to the following factors and

processes, which can become more intensive as the TWW quality decreases.

a) growth of living organisms (bacteria, algae, algae predators, zooplankton, etc.) and organic

material transformation;

b) external pollution (dust, birds, insects, fumigation);

c) climate influences;

d) surface runoff flow and rainfall over the reservoir causing a salt concentration decrease in the TWW;

e) evaporation from the reservoir causing a salt concentration increase in the TWW;

f) winds contributing to the formation of waves resulting in TWW layers inversion;

g) layers development in the reservoir;

h) chemical processes that characterize TWW open reservoir storage, e.g. rising pH levels, changes in

the relative concentration of nitrogen components.

5.7 Reservoir engineering data and design

In a TWW reservoir design for irrigation, the following should be complied:

a) Engineering data should be collected;

1) TWW data: TWW sources and discharge distribution throughout the year;

2) soil data: type of soil, soil compatibility to reservoir construction, soil hydraulic conductivity;

3) groundwater data: type, depth and flow direction;

b) A minimum residual TWW volume should be maintained in the reservoir while using a bottom

pumping chamber, to avoid mud penetration to the irrigation system;

c) TWW level control systems should be installed to prevent overflow and control the operative

storage;

d) Environmental and human health damage resulting from TWW excess overflow should be

prevented;

e) The reservoir's maintenance should be tested. See an example of maintenance control guidelines in

Annex G.

5.8 Biological treatment in reservoirs

5.8.1 Where oxygen levels in open reservoirs are between 0,5 mg/l to 1,0 mg/l, different types of fish can

be introduced to clean the reservoir from surface and subsurface algae, and reduce filter flushing events.

An oxygen level of 1,0 mg/l or more does not require a more extensive use of oxygen fountains and/or

expenses.

6 © ISO 2018 – All rights reserved

5.8.2 The introduction of fish can help to remove clogging causes such as algae, zooplankton in the

upper part of the TWW column and algae at the bottom and walls of the reservoir.

5.8.3 The following species are generally recommended for stocking open reservoirs in warm climates.

In other climates or geographical regions, the fish species selected for stocking the reservoir should

reflect local species and climate conditions.

a) big-head carp,

b) grass carp to treat plants and huge algae,

c) silver carp to feed on plankton and zooplankton, and

d) black carp to feed on snails and slugs.

5.8.4 The fish population introduced into the reservoir should consist of either male fish or female

fish, to avoid reproduction.

5.8.5 Death of fish in TWW reservoir should be controlled. One or more of the following methods may

be used:

a) monitoring TWW quality conditions to anticipate, detect or predict distress during critical season,

b) installing aeration units where conditions of low oxygen levels are likely or known to occur, or

c) introducing freshwater.

5.8.6 To prevent conditions of distress for fish, the oxygen level should not be lower than 1 mg/l.

NOTE Oxygen levels lower than 1 mg/l can occur during early morning hours.

5.8.7 Un-ionized ammonia concentration should not be higher than 0,5 mg/l.

5.8.8 Oxygen fountains of at least 1,5 pH each should be introduced, in accordance with the size of the

reservoir.

5.8.9 Oxygen fountains as well as electricity cables should be prepared in advance to allow spreading

50 metres from shoreline.

6 Filtration systems

6.1 General

6.1.1 The design of the filtration system should take into account the worst case scenario due to

seasonal changes in TWW quality in a reservoir (see Annex I). Unpredicted occurring events should also

be considered.

6.1.2 Where TWW is used, biofilm is often formed and developed in laterals and emitters. Filtration, a

physical water treatment, removes suspended material from the water entering the system to avoid its

deposition in pipes and emitters. The filtration system is a primary, multistep means that facilitates the

separation and disposal of suspended materials.

6.1.3 With few exceptions such as high flow sprinklers or irrigation gun, irrigation systems should be

filtered.

6.1.4 The degree of filtration (mesh/micron) should be defined by the system requirements and

should be sized according to the emitter manufacturer’s specifications.

6.1.5 As filtration alone cannot provide a complete solution for the factors affecting the performance

of emitters applying TWW, chemical and physical treatments should be used (see Clause 10 for physical

treatment and Clause 11 for chemical treatment).

6.1.6 Depending on the circumstances, as many as three or more filtration locations, with a different

filtration degree, should be installed along the system.

6.1.7 A filtration system should be designed to consider the reservoir, TWW intake quality and distance

between the reservoir and the irrigated field.

6.1.8 Filtration should be carried through the following stages:

a) pre-filtration unit — in the reservoir outlet;

b) primary filtration unit — with filtration requirements per emitter manufacture recommendations;

c) check filter — following the primary filtration, which should not be finer than the primary filtration.

6.1.9 With TWW quality (see Table A.1, column “Poor Quality”), if the distance between two filter

locations is more than 500 metre–700 metre, an additional filter station should be installed.

6.1.10 Pre-filter and primary filters [6.1.8 a) and 6.1.8 b)] in the multistep filtration should be self-

cleaning filters.

If a signal is not received after a certain time period has passed, the flushing process should start.

6.1.11 In automatic filter batteries, a flushing controller should detect excessively frequent self-cleaning

or flushing cycles shorter than time pre-set. Excessive flushing cycles or short run cycles should indicate

adverse change in TWW quality such as increased dirt load requiring the operator’s immediate attention.

6.1.12 Suspended material content in the TWW should be measured by a clogging capacity meter

(see Annex D).

6.2 Filtration battery manifold structure

6.2.1 Due to TWW quality variation, a filtration battery manifold should include extra fittings that

should be ready for a fast connection of supplementary filter units, in case they are needed. See examples

of filter batteries in Figure 1.

8 © ISO 2018 – All rights reserved

6.2.2 To balance the load on the battery's filters, the battery should be installed in a way that allows for

each filtration unit to have the same hydraulic loss.

a) Gravel filtration batter

b) Screen filtration battery

10 © ISO 2018 – All rights reserved

c) Disc filtration battery

Key

1 inlet

2 drain

3 outlet

Figure 1 — Examples of filter batteries

6.3 Filtration technology — Filtration media

A filtration media should be used for TWW.

The type of filtration media (e.g. screen, disc, gravel) should be selected according to its resistance to

corrosive water and the chemicals utilized (see Clause 11).

6.4 Flow/filter area ratio

Depending on the TWW quality at the reservoir, harsh TWW conditions should be considered. Filtration

systems should be designed allowing 50 %–70 % of the nominal flow rate of filtration in order to

overcome high backwash frequencies.

6.5 Filtration stations location in accordance with flow direction

6.5.1 A self-cleaning strainer filtration unit with a 250 and coarser micron pore size for the removal

of coarse dirt should be installed at the outlet of a low quality TWW source or at pump suction inlet,

see Figure 2 and Figure 3.

Figure 2 — Self-cleaning strainer in water

Figure 3 — Self-cleaning strainer

6.5.2 The main filtration TWW passage should comply with dripper/micro-sprinkler requirements

(see 6.6)

The battery or the filter should have an automatic flushing mechanism.

The main filtration should be in proximity to the irrigated plots.

The filtration system should consist of a battery of filters in order to prevent irrigation interruption.

The check filter should be a manually flushed disc and screen filter of 130 micron, to enable examination

of the materials accumulated on the filtration mediator.

12 © ISO 2018 – All rights reserved

6.5.3 When the battery is located near the operational reservoir, backflush TWW should be returned

to the reservoir, at a location distant from the pumping point. Wind regime in site should be considered.

6.5.4 When a battery is located at an area where flushing TWW cannot be discharged, a special pipe

installation should be considered, to return flushing TWW back to the reservoir.

Such a piping system should include hydraulic considerations in the design.

Resistance along the return stream should be minimized, to optimize the backflush efficiency.

An alternative way to return backflush TWW from the filter to the reservoir can be employed by filling

up a water tank which is occasionally emptied into the reservoir, at a location which is distanced from

the pumping point.

6.5.5 For a distant or isolated irrigation plot inlet, to prevent flushing TWW nuisances, backflush TWW

should be captured and removed in a way that does not contaminate the soil and underground water

resources.

6.6 Filtration grade

The size of filtration required (e.g. media discs or screen) should correspond with the requirements

of the emitters as prescribed by the manufacturer. In filtration, water passages ratio should be 1:10 in

drip irrigation, and 1:7 in micro-irrigation.

6.7 Manual filter cleaning

If flushing cannot remove all particles, to avoid accumulation of scale or sticky substances on the body

of the filter, the filtration mediator should be cleaned periodically and thoroughly.

The periodical cleaning of the disc filter should be executed by dismantling the filter interior out of the

filter housing and immersing it in chemicals, i.e. acid and hydrogen peroxide.

7 Pumping stations

7.1 General

In a reservoir, TWW quality can vary with water depth, which can cause an increase in risks of irrigation

systems clogging.

Due to biofilm development in the piping or distribution systems, the reservoir design should include a

disinfection port in the pumping station, in accordance with maintenance protocol (see Annex G).

To improve the quality of TWW delivered to the field, the location of pumping stations should be

considered. See possible pumping station locations in 7.1.1 and 7.1.2.

7.1.1 Bottom pumping chamber

The installation of a bottom pumping chamber should prevent the invasion of accumulated sediments

and bottom materials into the pumps.

7.1.2 Floating suction head

The installation of a floating suction head should allow suction depth adaptation, in order to reach an

optimal pumping level.

See Figure 4 for an example of a floating pumping station location.

Figure 4 — Floating pumping station location

7.2 Reservoir stratification prevention

When using a floating suction head in a reservoir, the reservoir stratification should be considered.

In warm and/or hot seasons while no wind condition exist stratification can be formed in reservoirs

during daytime and remain at night time.

In winter season when temperatures change between day and night and wind condition exist there is

no stratification.

Electrical conductivity at the bottom strata of the reservoir is much higher than that on the water

surface. The amount of energy required to prevent stratification in reservoirs under warm weather

conditions is relatively small.

The use of size of mixer should be examined in accordance with local conditions and size of reservoirs.

Stratification prevention has the following benefits:

a) improved oxygen balance: water mixing that spreads oxygen throughout the depth of the reservoir;

b) prevention of algae growth: in non-stratified reservoirs there is less algae;

c) improved removal of pathogenic bacteria: bacteria mortality is much higher on the surface due to

sun radiation.

For more information on thermal stratification, see Figure 5 and Annex F.

Figure 5 — Thermal stratification

14 © ISO 2018 – All rights reserved

8 Adaptation of emitters to TWW

8.1 General

Pipelines of secondary and tertiary TWW should be continuously and systematically monitored and

maintained in order to detect clogging potential and preserve the system's functionality for long term

durability.

8.2 Emitters classification

Drippers’ classification is specified in ISO 9261.

Other emitters such as rotating sprinklers’ classification is specified in ISO 15886-1 to -4.

8.3 Drippers

8.3.1 General

Drippers can be used for TWW application, as they can minimize the physical contact between the

irrigation TWW and crops and the operators. Drip irrigation can also prevent aerosol dispersion and

limit odours, which are typical in emitters dispersing water in the air.

Source: Israel Ministry of Health, Public Health Services, Department of Environmental Health,

Standards and guidelines for irrigation with effluents in Israel, 1999, Clauses 4.2, 4.3, Jerusalem.

8.3.2 On-surface dripper and sub-surface dripper

The selection of the best compatible dripper and its installation should comply with the

recommendations provided by the manufacturer.

Following are drippers' features that are compatible for sub-surface systems:

a) unregulated dripper,

b) regulated dripper,

c) in-line emitter, and

d) on-line emitter.

8.4 Durability and longevity of dripper

The system's operation and maintenance should comply with the manufacturer's recommendations, to

improve durability and longevity (see Clause 10 and Clause 11).

8.5 Functional features of the dripper

8.5.1 General

The structure of the dripper can affect its functionality and performance when used with TWW.

The functional features of the dripper should be as described in 8.5.2.1 to 8.5.2.4.

8.5.2 Functional features

8.5.2.1 Water inlet of the dripper

The dripper's water inlet into the flow path should go through a filter, which should be adapted to

TWW use.

The net filtration area should be as large as possible.

16 © ISO 2018 – All rights reserved

See examples of water inlets in Figure 6.

Figure 6 — Examples of water inlets into the dripper

8.5.2.2 Labyrinth flow path

Flow path dimensions should be as following:

a) The overall length of the water flow path in regulated drippers should include a regulation area.

This area, combined with the flow path, is critical for the performance of the dripper.

b) The flow path’s cross-sectional area should be as large as possible with more effective self-cleaning

mechanism. Flow path length should be as short as possible and irrigation water flow regime

should be more turbule

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...